Understanding the Parts Diagram for John Deere 7200

Understanding the intricacies of agricultural machinery is essential for effective maintenance and operation. This section delves into the essential elements that comprise a specific model of farm equipment, highlighting the interconnections and functionalities of various components. A detailed examination of these parts allows operators to optimize their machinery’s performance and longevity.

With a focus on a particular series of agricultural tools, this guide provides a visual representation of the component layout. Each element plays a vital role in the overall efficiency of the equipment, and familiarizing oneself with these parts can significantly enhance operational knowledge. By gaining insights into the configuration and function of each piece, users can ensure that their machinery operates at its best.

Ultimately, this resource aims to empower operators with the knowledge necessary to tackle maintenance tasks confidently. Whether it’s routine checks or addressing specific issues, understanding the assembly of the equipment will facilitate more informed decisions and improve the user experience.

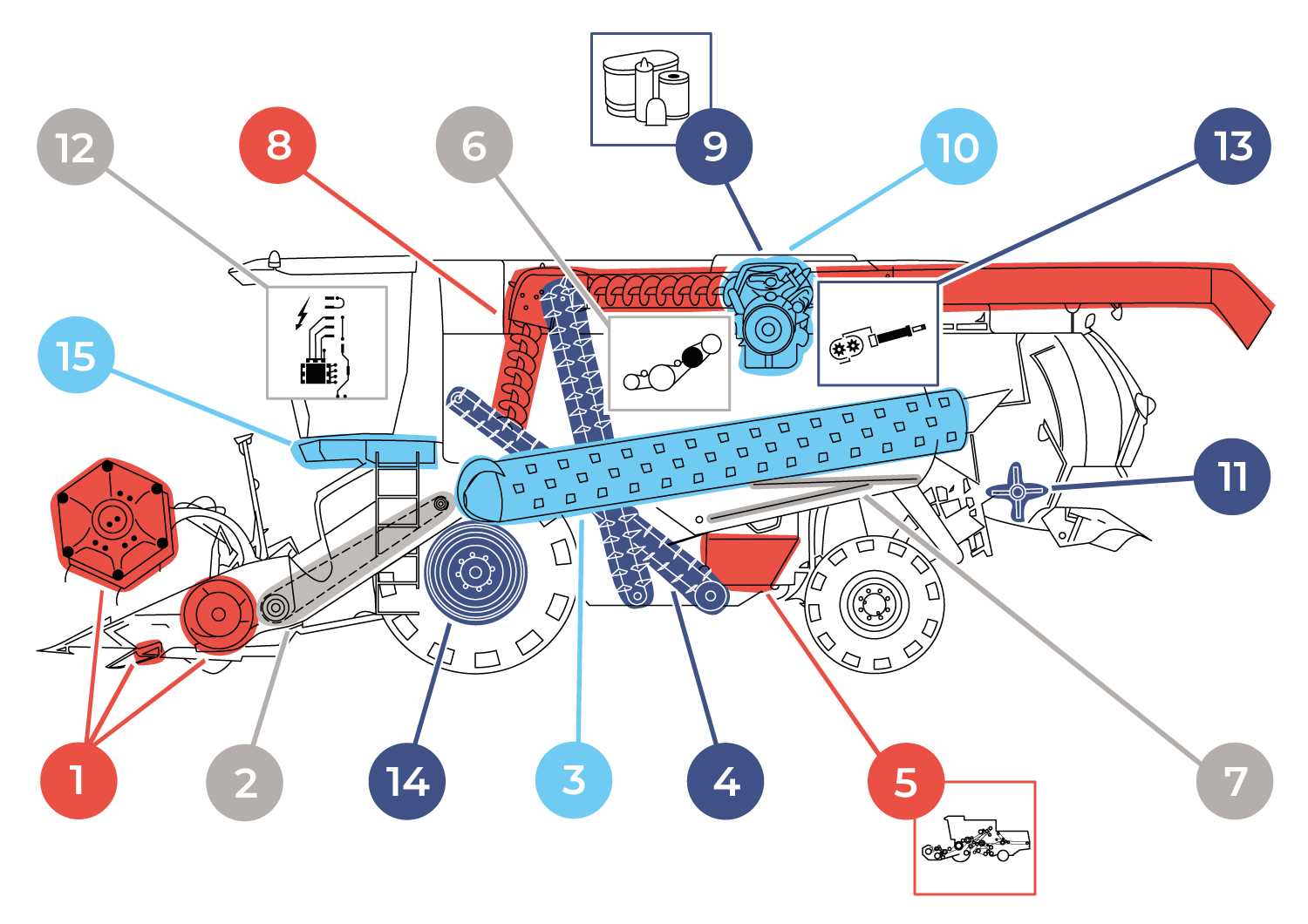

John Deere 7200 Overview

This section provides an insightful look into a specific agricultural implement known for its efficiency and durability. Designed for modern farming practices, this equipment integrates advanced technology to enhance crop production. Its robust construction and innovative features make it a valuable asset for farmers seeking reliability and performance.

Key Features

- Enhanced operational efficiency

- Durable materials for longevity

- Advanced technology integration

- User-friendly controls for ease of operation

Applications

- Planting various crop types

- Soil preparation for optimal growth

- Supporting precision agriculture techniques

- Enhancing productivity through innovative designs

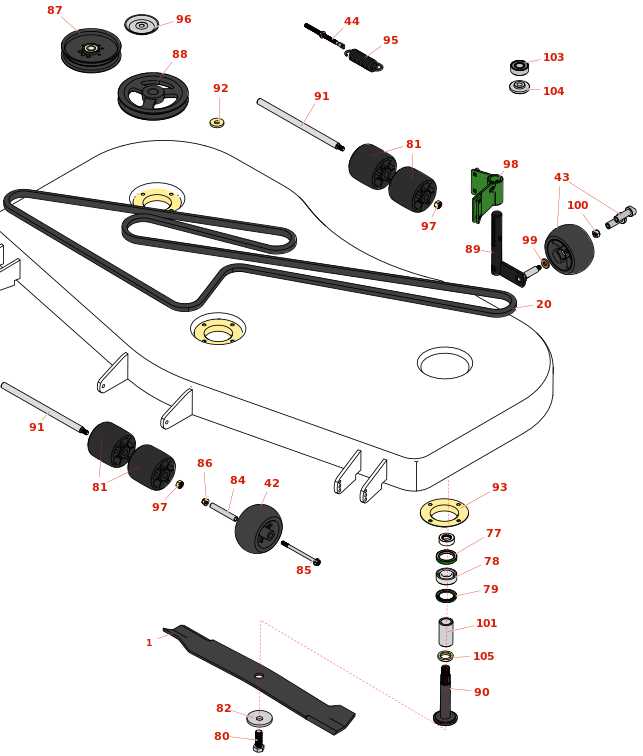

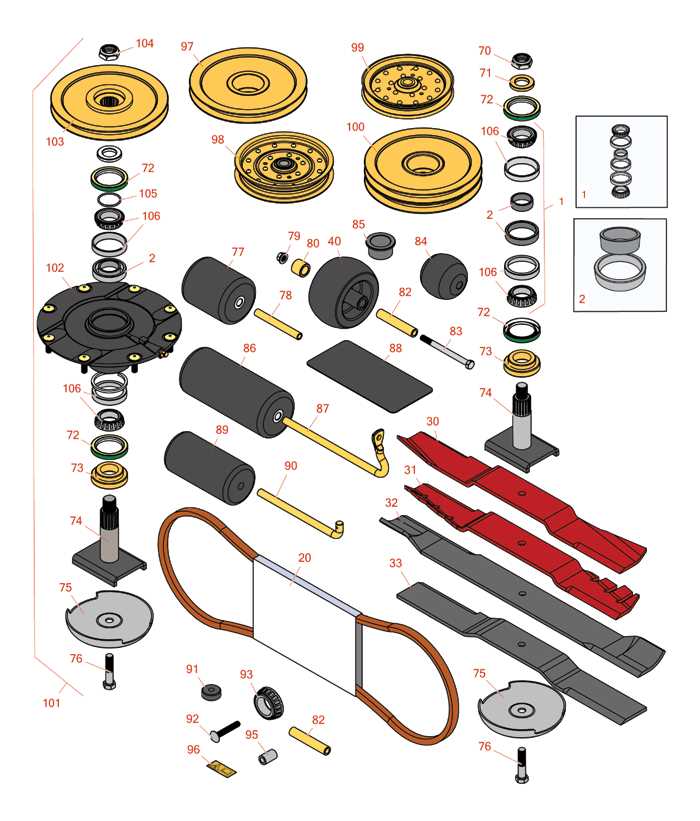

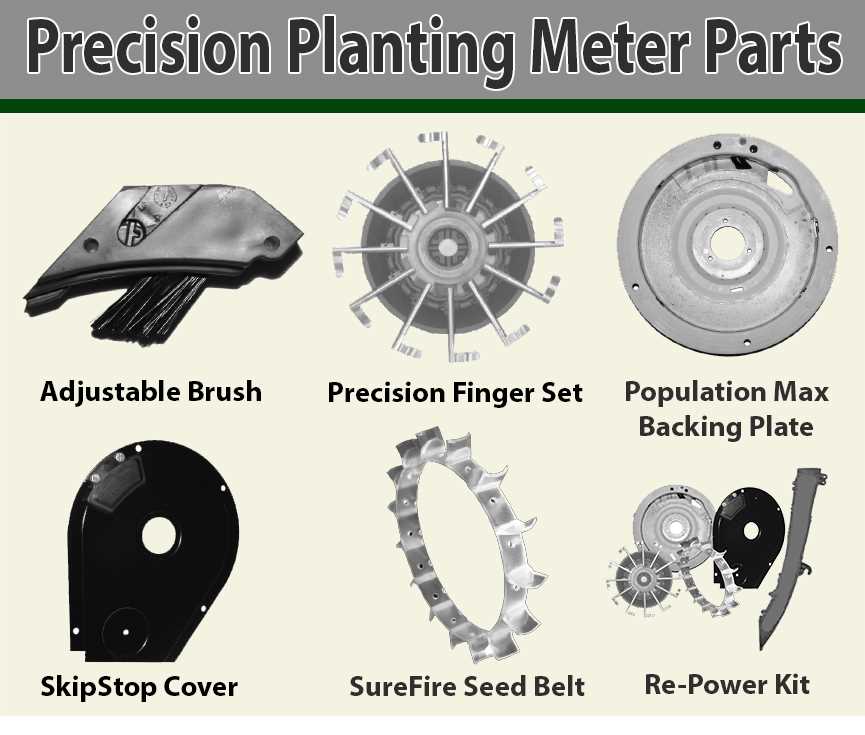

Understanding the Parts List

The components list serves as a crucial resource for anyone looking to maintain or repair machinery. It outlines essential elements, providing clarity on each item’s function and placement within the system. A comprehensive overview helps in identifying necessary replacements and ensuring optimal performance.

Each entry in this compilation typically includes detailed descriptions, specifications, and part numbers. Familiarizing oneself with this information can greatly enhance the efficiency of maintenance tasks. Furthermore, understanding the relationship between different components can lead to more informed decisions when addressing issues.

Utilizing this guide effectively ensures that all necessary components are accounted for, facilitating a smoother repair process. By leveraging this knowledge, operators can contribute to the longevity and reliability of their equipment.

Key Components Explained

This section aims to provide an overview of essential elements that contribute to the efficient operation of agricultural machinery. Understanding these components is crucial for maintenance and optimal performance.

- Engine: The powerhouse that drives the entire system, ensuring effective energy conversion.

- Transmission: A vital mechanism that transmits power from the engine to the wheels, allowing for varied speeds and torque.

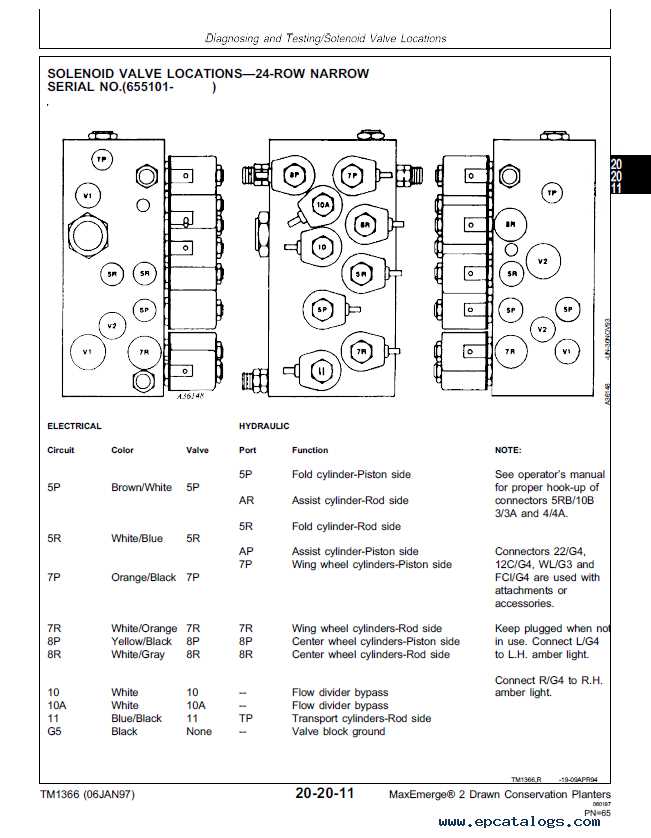

- Hydraulic System: This system plays a key role in facilitating movement and control of various implements and attachments.

- Chassis: The structural framework that supports all components, providing stability and durability.

- Electrical System: Essential for starting the engine and powering various electronic devices and safety features.

Familiarity with these crucial parts enhances the ability to troubleshoot issues and perform necessary repairs effectively.

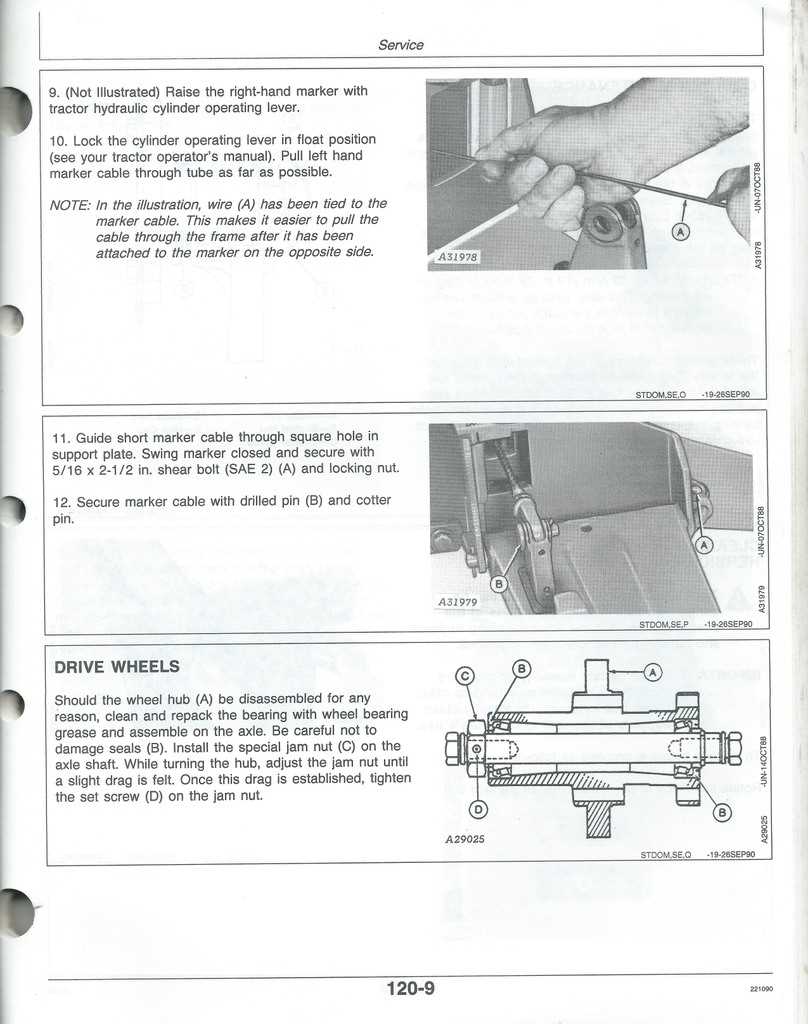

Maintenance Recommendations for Longevity

Ensuring the durability of agricultural machinery requires a systematic approach to upkeep and care. Regular attention to maintenance tasks not only enhances performance but also extends the lifespan of equipment. By following specific guidelines, operators can significantly reduce the likelihood of unexpected breakdowns.

Routine Inspections: Schedule frequent checks to identify wear and tear before they escalate into major issues. Look for signs of damage or fatigue in components and address them promptly.

Lubrication: Keep moving parts well-lubricated to minimize friction and prevent premature wear. Use high-quality lubricants appropriate for the machinery’s requirements.

Cleaning: Regularly clean the equipment to remove dirt and debris that can cause blockages or damage. Pay special attention to filters and air intakes to ensure optimal airflow.

Storage: When not in use, store machinery in a dry, sheltered location to protect it from environmental elements. Covering equipment can further shield it from dust and moisture.

By adhering to these practices, operators can maintain their machinery in optimal condition, ensuring efficiency and longevity.

Common Issues and Solutions

This section addresses frequent challenges encountered by users of agricultural machinery and offers practical solutions. Understanding these common problems can help maintain optimal performance and extend the lifespan of equipment.

One typical issue is engine overheating, which may arise from insufficient coolant levels or a malfunctioning radiator. Regular checks and timely maintenance can prevent this complication.

Another common problem involves electrical failures, often caused by worn-out wiring or corroded connections. Inspecting and replacing damaged components can restore functionality and ensure reliable operation.

Hydraulic system malfunctions may also occur, frequently linked to leaks or low fluid levels. Regular inspections and immediate repairs can mitigate these risks, enhancing overall efficiency.

Lastly, wear and tear on belts and hoses is an inevitable issue. Regular replacements and routine checks can prevent breakdowns and ensure smooth operation.

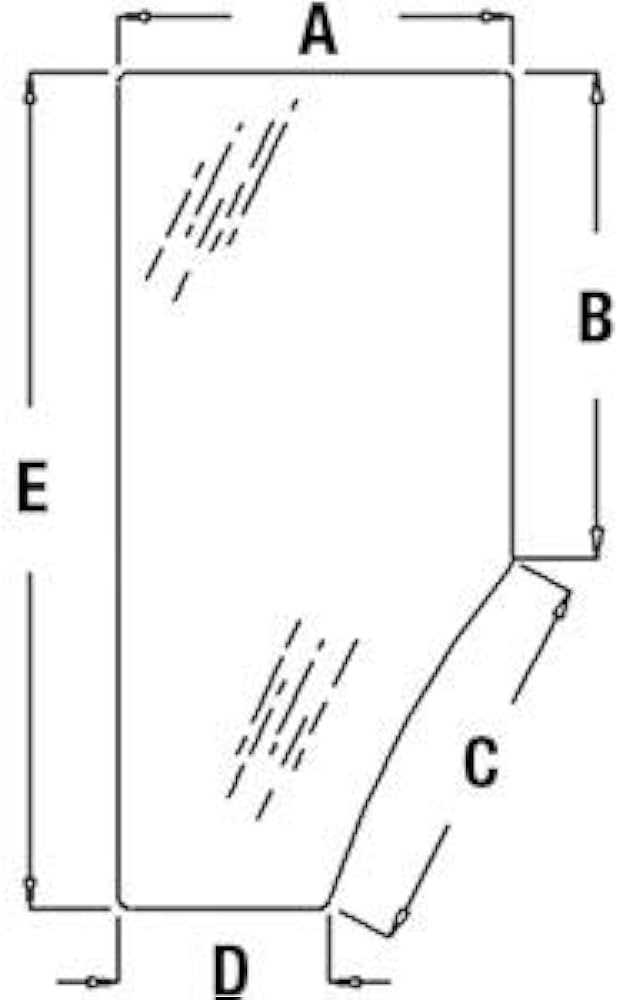

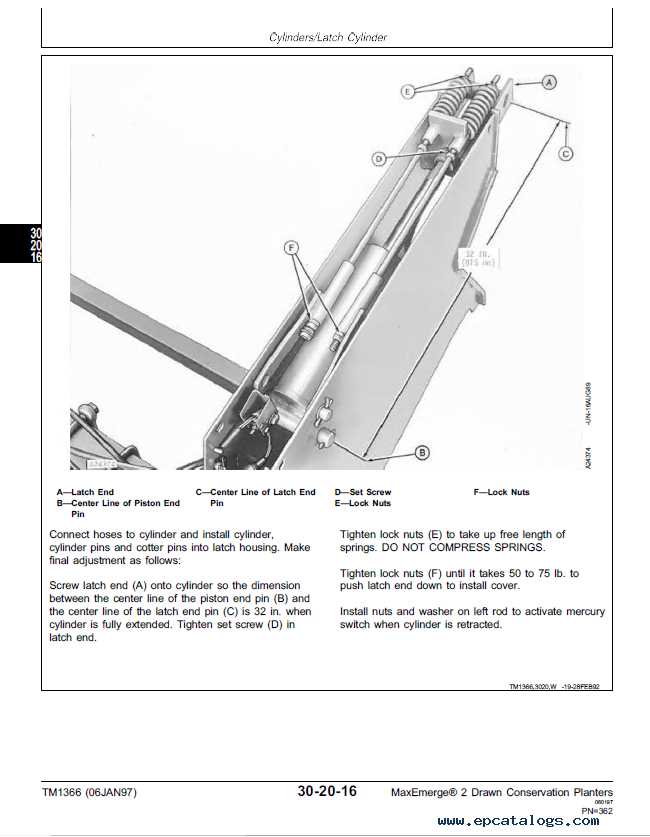

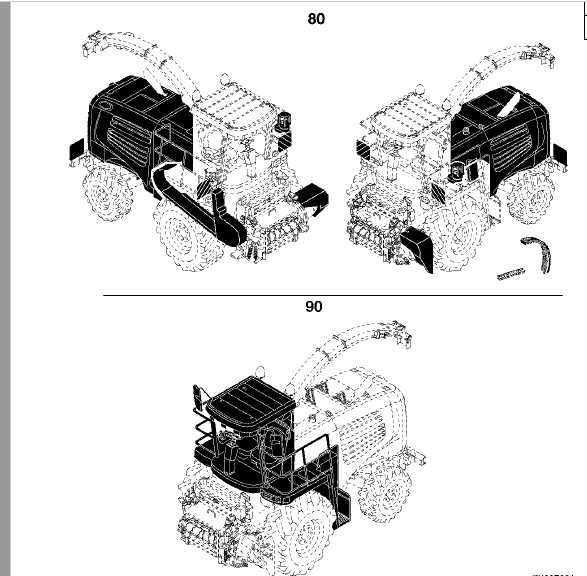

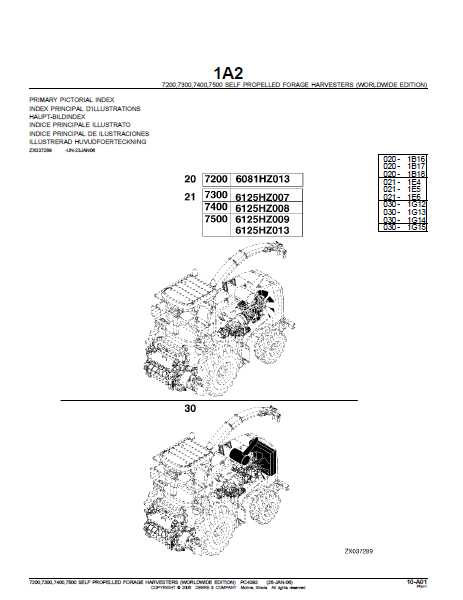

Visual Guide to the Diagram

This section provides a comprehensive overview of the visual representation related to agricultural machinery components. It aims to enhance understanding of the various elements and their interconnections, facilitating easier identification and maintenance. The illustrations serve as an effective tool for users to familiarize themselves with the equipment’s structure.

Utilizing this guide, operators can quickly locate and comprehend the function of each element, ensuring efficient operation. By examining the visuals closely, one can gain insights into the assembly and layout, which are crucial for troubleshooting and repairs. This resource not only simplifies the learning process but also empowers users to manage their equipment with confidence.

Ordering Replacement Parts Online

In today’s digital age, acquiring essential components for machinery has become a straightforward process. Online platforms offer a vast selection of items, enabling users to quickly locate and order what they need without the hassle of traditional shopping methods.

Finding Reliable Suppliers

It is crucial to identify trustworthy vendors when seeking replacements. Look for websites with positive customer reviews, clear return policies, and comprehensive product descriptions. Established suppliers often provide detailed information, ensuring you make informed decisions.

Ensuring Compatibility

Before finalizing your purchase, verify that the selected items are suitable for your equipment. Check specifications and compare them with your current components. This step helps prevent issues that may arise from incompatible products.

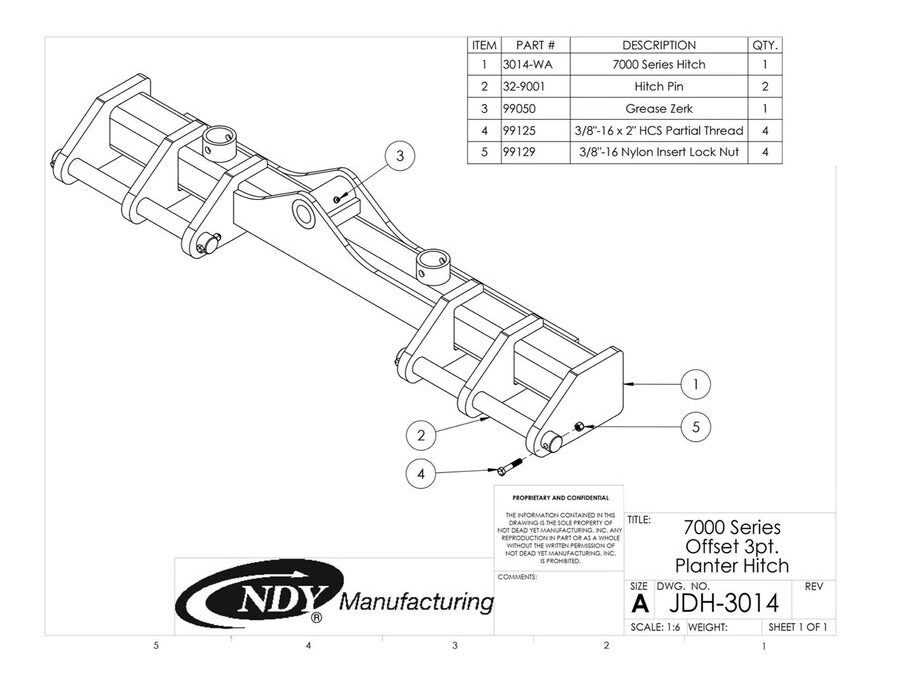

Compatibility with Other Models

This section explores the adaptability of components designed for a specific model to be utilized with various other machinery. Understanding the interchangeability of parts can enhance maintenance efficiency and reduce costs for operators.

Interchangeable Components

Many elements from this particular model can be effectively employed in different machines within the same category. This compatibility is often due to similar engineering standards and design principles, allowing for seamless integration.

Considerations for Compatibility

When assessing compatibility, it is essential to verify specific measurements and specifications. Utilizing a compatible component can significantly enhance performance while ensuring longevity. Always consult detailed references before making substitutions.

Assembly Instructions for Efficiency

Effective assembly is crucial for optimal performance and longevity of agricultural machinery. Following a systematic approach can enhance functionality and minimize downtime. This section outlines key steps to ensure a smooth assembly process.

- Preparation:

- Gather all necessary components and tools.

- Review the assembly guide thoroughly.

- Organize parts in a logical order to streamline the process.

- Step-by-Step Assembly:

- Begin with the main frame, ensuring all connections are secure.

- Install secondary components, verifying alignment as you proceed.

- Attach any additional features or accessories as specified in the guide.

- Final Checks:

- Inspect all connections for tightness and stability.

- Test functionality before full operation.

- Make necessary adjustments to enhance efficiency.

By adhering to these guidelines, you can ensure a reliable assembly that supports peak performance in the field.

Tools Required for Repairs

When undertaking maintenance or restoration of machinery, having the right tools is essential for ensuring efficiency and effectiveness. A well-equipped toolbox not only facilitates smooth repairs but also enhances safety during the process.

Essential Hand Tools

Basic hand tools such as wrenches, pliers, and screwdrivers are fundamental for any repair task. These instruments allow for the tightening and loosening of components, making them indispensable for routine upkeep.

Power Equipment

In addition to hand tools, power equipment like drills and impact wrenches can significantly speed up the repair process. Utilizing these devices reduces manual effort and can improve precision when working on intricate parts.

FAQs About John Deere 7200

This section addresses common inquiries related to a specific agricultural machine, focusing on its components, functionality, and maintenance practices. Understanding these aspects is crucial for users seeking to enhance performance and longevity.

Here are some frequently asked questions:

| Question | Answer |

|---|---|

| What are the main components of the machine? | The primary elements include the frame, drive system, and various attachments designed for specific tasks. |

| How do I maintain my equipment? | Regular inspections, lubrication, and timely replacements of worn parts are essential for optimal performance. |

| Where can I find replacement components? | Replacement elements can be sourced from authorized dealers, online retailers, or agricultural supply stores. |

| What troubleshooting steps should I follow? | Start with a visual inspection, check fluid levels, and refer to the manual for specific issues. |

Expert Tips for Troubleshooting

When encountering issues with your agricultural machinery, a systematic approach can make all the difference. Understanding common challenges and knowing how to address them can enhance performance and extend the lifespan of your equipment.

Identify Common Symptoms

Start by observing the equipment closely. Note any unusual sounds, vibrations, or performance drops. Common symptoms often point to specific issues that can be addressed without extensive repairs.

Consult Technical Resources

Utilize available manuals and guides for troubleshooting. These resources often provide valuable insights into common problems and recommended solutions.

| Issue | Potential Cause | Solution |

|---|---|---|

| Unusual Noise | Worn bearings | Inspect and replace bearings |

| Inconsistent Performance | Fuel quality | Use recommended fuel type |

| Frequent Stalling | Clogged filters | Clean or replace filters |

Resources for Further Learning

Exploring advanced machinery requires access to diverse educational materials and reference guides. Whether you are a novice or an experienced operator, various resources can enhance your understanding and proficiency. These materials often include manuals, online courses, and community forums, providing valuable insights into the intricacies of mechanical systems.

Online Platforms

Numerous websites offer comprehensive tutorials and instructional videos tailored to enhance your knowledge about agricultural machinery. Engaging with these platforms can provide practical insights and troubleshooting techniques that are beneficial for both maintenance and operation.

Community Forums

Participating in discussion groups and forums dedicated to agricultural equipment can be invaluable. Here, users share experiences, tips, and solutions to common challenges, creating a collaborative learning environment that fosters expertise among peers.