Understanding the John Deere Z425 Parts Diagram for Maintenance

For anyone maintaining a high-performance lawn machine, understanding how various mechanical elements work together is crucial. This section will guide you through the key systems and essential assemblies that ensure the smooth operation of a zero-turn riding mower. Whether you’re troubleshooting or simply enhancing your knowledge, having a clear breakdown of these components will help keep your equipment running efficiently.

From the engine to the cutting deck, each part of this machine plays a pivotal role in delivering precise, clean cuts across your lawn. We’ll delve into the layout of these mechanisms, ensuring that you grasp how they contribute to the mower’s superior maneuverability and performance. By familiarizing yourself with these elements, you can improve maintenance practices and address potential issues before they become major problems.

In the following sections, we will look closely at individual units like the powertrain, steering controls, and the chassis framework. By the end, you’ll have a thorough understanding of what makes your mower function effectively, providing the durability and reliability that it’s known for.

Mechanical System Overview for the Z-Series Mower

The Z-Series lawn equipment features a robust mechanical structure designed for efficient grass cutting. This system is built with several key components that ensure smooth operation and durability over time. Each of these elements plays a crucial role in maintaining performance and ease of maintenance.

- Engine Assembly – The central power source, driving the entire operation.

- Transmission – Transfers energy from the power unit to the wheels, enabling precise movement and control.

- Blades and Cutting Deck – Ensures sharp, even cutting for a clean finish on various terrains.

- Hydraulic System – Assists in controlling the movement of the machine, providing smooth transitions and stability.

- Fuel System – Powers the engine with reliable energy flow, ensuring consistent performance during long operations.

Each component is crafted with precision, allowing easy access for maintenance and replacement. Understanding the role of each part is essential for keeping the machine in optimal condition.

Engine Components Breakdown

The engine is made up of various crucial elements that work together to ensure efficient power generation and smooth operation. Understanding the structure and function of these individual components is essential for maintenance and repair.

- Cylinder Head: This part covers the cylinder and is responsible for housing several important systems like the valve train and spark plugs.

- Pistons: These move inside the cylinder, converting the force of expanding gas into mechanical motion.

- Crankshaft: This component transforms the linear motion of the pistons into rotational energy, which powers the rest of the machine.

- Camshaft: Working in sync with the crankshaft, the camshaft manages the timing of the opening and closing of the valves.

- Fuel Injector: It ensures that the right amount of fuel is delivered into the engine at the correct time for combustion.

- Air Filter: This keeps debris from entering the engine, maintaining clean airflow, which is essential for efficient combustion.

Each of these components plays a pivotal role in maintaining the performance and longevity of the engine. Proper understanding can aid in troubleshooting issues and ensuring the system runs optimally.

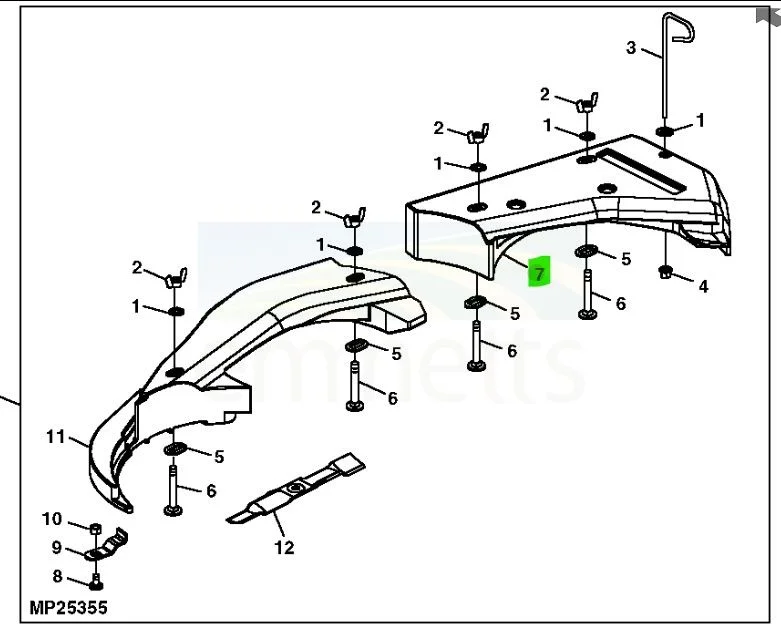

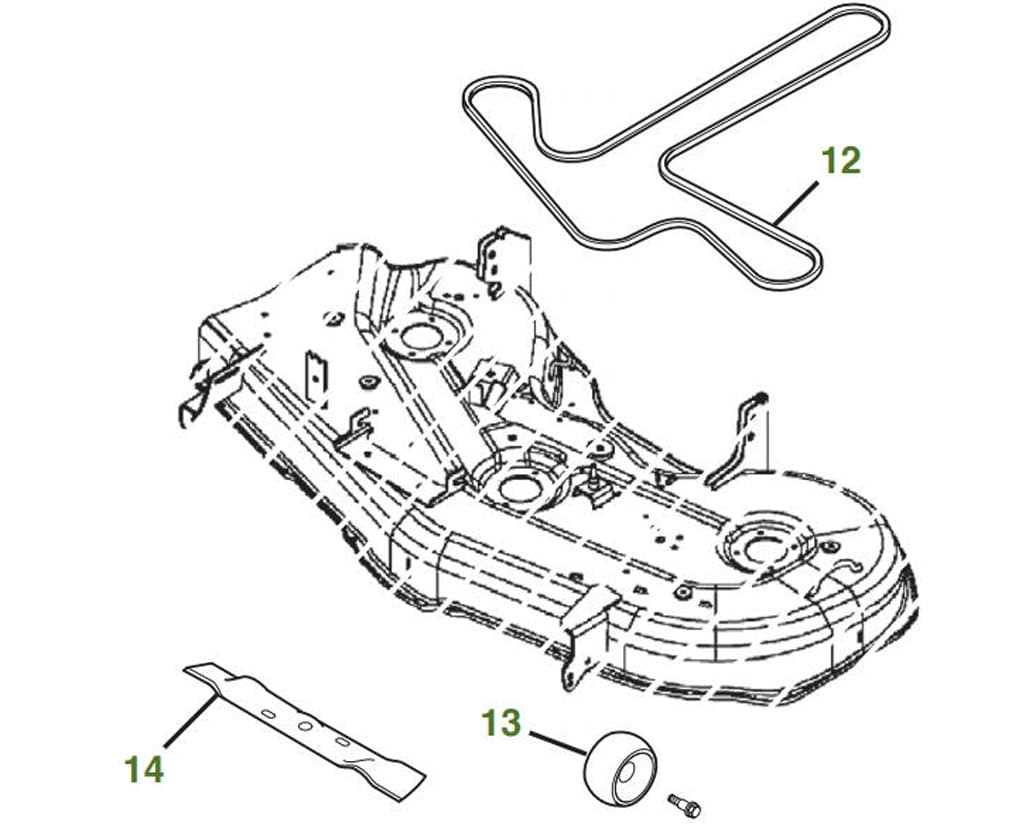

Mower Deck Structure and Details

The mower deck is a crucial component designed to ensure efficient grass cutting. Its overall layout is engineered for durability and performance, allowing for smooth operation in varying conditions. Understanding its structure helps to maintain optimal functioning, especially when it comes to achieving an even cut and reducing the strain on the machine.

The deck consists of multiple elements working together, including the blades, spindles, and discharge chute. These parts are aligned to enhance precision and efficiency, ensuring the lawn is cut to a desired height. Each section of the deck plays a role in the overall performance, from the height adjustments to the mechanism that powers the blades.

It’s essential to regularly inspect and maintain the deck to prolong its life and maintain cutting quality. Routine checks for wear and tear, proper blade sharpening, and cleaning debris are key steps to ensuring your equipment runs smoothly for an extended period of time.

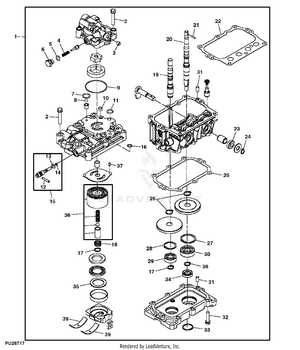

Transmission System Components

The transmission system plays a crucial role in transferring power from the engine to the wheels, ensuring smooth and efficient movement. It consists of various interconnected elements that work together to regulate speed, torque, and overall vehicle control. Understanding these components is essential for maintaining optimal performance and addressing any potential issues.

Drive Belt: The drive belt is responsible for transmitting power from the engine to the transmission. A well-functioning belt ensures smooth operation and reduces strain on other mechanical parts.

Pulleys: Pulleys help control the movement and tension of the drive belt. Proper pulley alignment and tension adjustment are critical for the system to operate smoothly without excessive wear.

Hydraulic System: The hydraulic system within the transmission manages fluid pressure, allowing the vehicle to smoothly adjust speed and handle different terrains. Regular fluid checks and maintenance are essential to avoid overheating and ensure consistent performance.

Axles: Axles distribute power to the wheels, allowing the vehicle to move efficiently. These components must be well-lubricated and checked for wear to prevent performance issues and ensure long-lasting durability.

Electrical System Diagram

The electrical system of a riding mower is a complex network that controls various essential functions. This section explores how electrical components work together to ensure efficient operation. Understanding the connections between the power source, switches, and wiring is key to troubleshooting and maintaining the system’s performance.

| Component | Function |

|---|---|

| Battery | Supplies power to the entire electrical system. |

| Ignition Switch | Activates the starter and other key systems. |

| Solenoid | Acts as a relay, connecting the battery to the starter motor. |

| Starter Motor | Turns over the engine to initiate combustion. |

| Safety Switches | Ensure safe operation by controlling power flow based on specific conditions. |

Steering and Control Mechanisms

The steering and control systems are vital components of any mower, providing the necessary guidance and maneuverability for effective operation. These systems are designed to offer precise handling, allowing the operator to navigate through various terrains and obstacles with ease.

At the core of the steering mechanism is the steering wheel, which translates the operator’s movements into directional changes. This connection is facilitated through a series of linkages and gears that enhance responsiveness and control. Additionally, the integration of hydraulic cylinders plays a crucial role in providing smooth steering action, especially during tight turns or when navigating challenging landscapes.

Moreover, the control mechanisms incorporate throttle levers and brake pedals, which enable the operator to adjust speed and stop the machine as needed. The design of these controls is ergonomic, ensuring comfort and accessibility while maintaining safety standards. Overall, understanding the layout and function of these mechanisms is essential for proper maintenance and optimal performance.

Blades and Cutting System

The cutting mechanism plays a crucial role in ensuring efficient grass trimming and lawn maintenance. This system is designed to deliver precise results, making it essential for achieving a well-manicured landscape. Understanding its components can enhance performance and durability, allowing for better upkeep of green spaces.

Central to this system are the blades, which are crafted to provide optimal cutting efficiency. Their design influences the quality of the cut and the overall health of the grass. Regular inspection and maintenance of these components are vital for sustained performance.

| Component | Description | Function |

|---|---|---|

| Cutting Blades | Sharp, durable pieces designed to slice through grass. | Provide a clean cut for a healthier lawn. |

| Deck | The housing that supports the blades. | Ensures stability and protection during operation. |

| Spindle Assembly | Holds the blades and allows them to rotate. | Facilitates blade movement for effective cutting. |

| Height Adjustment | Mechanism to modify the cutting height. | Enables customization for different grass types and conditions. |

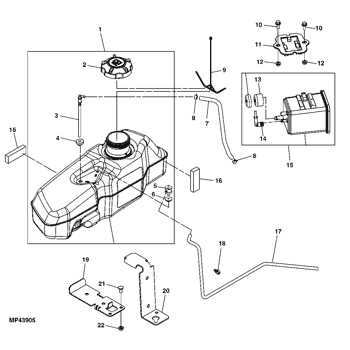

Fuel System Components

The fuel system plays a crucial role in the overall performance of small engines, ensuring efficient combustion and optimal power output. Understanding the various elements involved in this system is essential for maintaining and troubleshooting any issues that may arise.

Key Elements of the Fuel System

- Fuel Tank: Stores the fuel required for engine operation.

- Fuel Pump: Delivers fuel from the tank to the engine at the necessary pressure.

- Fuel Filter: Cleans the fuel by removing impurities before it reaches the engine.

- Carburetor or Fuel Injector: Mixtures air and fuel for combustion.

- Fuel Lines: Connect various components and transport fuel throughout the system.

Maintaining the Fuel System

Regular maintenance of the fuel system is essential to ensure efficient operation. Here are some tips:

- Inspect and clean the fuel filter periodically.

- Check for leaks in fuel lines and connections.

- Replace any worn or damaged components promptly.

- Ensure the fuel tank is free from contaminants.

Seat and Comfort Features

The seating and comfort elements in a riding mower are essential for enhancing the user experience during prolonged operation. These features are designed to provide support, stability, and relaxation, ensuring that the operator can focus on the task without discomfort.

Key aspects of seating and comfort include:

- Ergonomic Design: The seat is crafted to support the natural curves of the body, reducing fatigue during long hours of use.

- Adjustable Options: Many models offer adjustable seats to accommodate different user heights and preferences, ensuring an optimal driving position.

- Soft Cushioning: High-quality padding helps absorb shocks and vibrations, enhancing overall comfort on uneven terrain.

- Armrests: Integrated armrests provide additional support, allowing for relaxed posture and reducing strain on the arms and shoulders.

- Easy Entry and Exit: The design facilitates simple access to the seat, making it easy for users to get on and off the machine.

Incorporating these features enhances the overall experience, making mowing more enjoyable and less physically taxing.

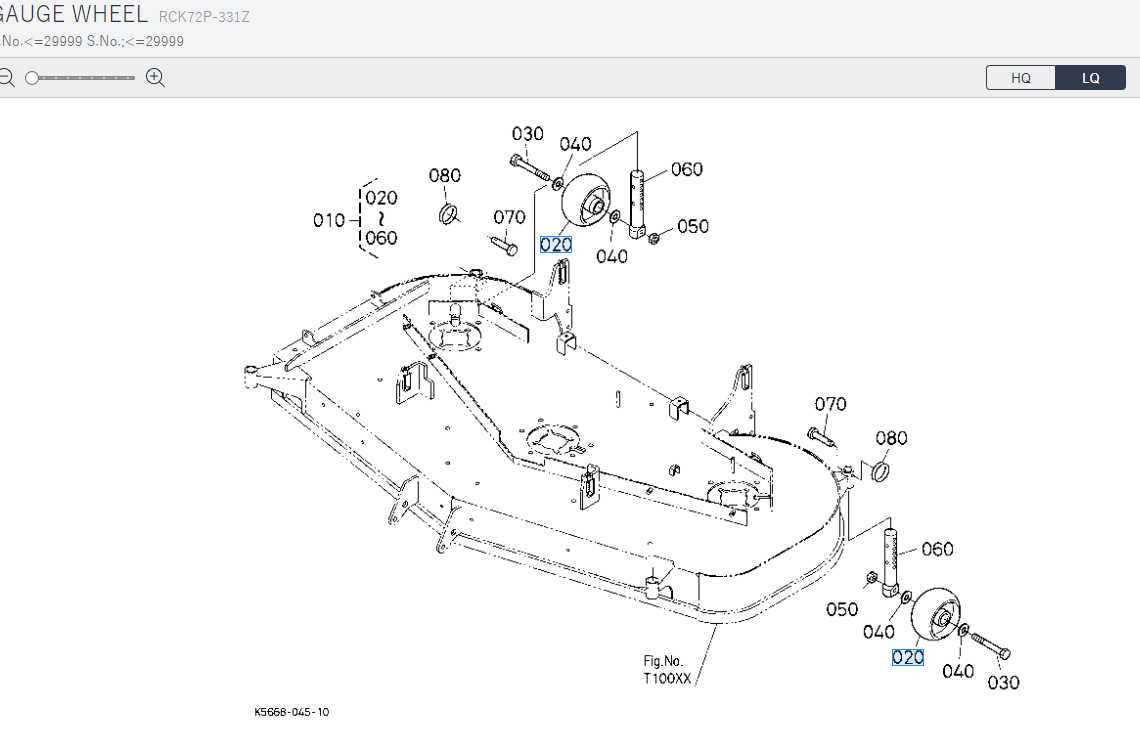

Wheels and Tires Assembly

The assembly of wheels and tires is crucial for ensuring optimal performance and stability in various machinery. A well-designed system not only supports the weight of the equipment but also enhances maneuverability and traction on different terrains. Understanding the components and their arrangement can significantly aid in maintenance and troubleshooting processes.

Key Components

In the wheels and tires assembly, several essential elements come into play. These include the rim, tire, axle, and various fasteners. Each component serves a specific function that contributes to the overall efficacy of the system. Rims provide a sturdy foundation for the tires, while the axle connects the wheels to the machinery, allowing for rotation and movement.

Maintenance Tips

Regular inspection and maintenance of the wheels and tires assembly can prevent premature wear and ensure a smooth operation. It is advisable to check the air pressure of the tires regularly, as improper inflation can lead to reduced performance and increased fuel consumption. Additionally, keeping the rims free from debris and inspecting for any signs of damage will prolong the life of the assembly and enhance overall efficiency. Proper care will result in improved functionality and safety of the equipment.

Safety Features and Components

Ensuring operator protection is a critical aspect of modern machinery. Various mechanisms are integrated to enhance safety and prevent accidents during operation. These components work together to create a secure environment for users, minimizing risks associated with equipment use.

One essential feature is the presence of emergency shut-off systems, which allow operators to quickly halt machine function in case of danger. Additionally, protective guards and shields are installed to prevent contact with moving parts, reducing the likelihood of injuries. Stability features are also vital, designed to maintain balance and prevent rollovers, particularly on uneven terrain.

Moreover, visual and auditory alerts are implemented to signal potential hazards, ensuring that users remain aware of their surroundings. Regular maintenance and inspections of these safety features are crucial to guarantee their effectiveness, ultimately contributing to a safer working environment.

Maintenance and Replacement Guidelines

Regular upkeep and timely substitutions are essential for ensuring the longevity and optimal performance of your outdoor equipment. This section outlines the fundamental practices that should be followed to maintain functionality and efficiency, along with the recommendations for replacing components when necessary.

Routine Maintenance Practices

Implementing consistent maintenance tasks can prevent significant issues and extend the lifespan of your machinery. These practices include cleaning filters, checking fluid levels, inspecting belts and blades, and ensuring that all connections are secure. A proactive approach helps identify wear and tear early, allowing for prompt action to avoid costly repairs.

Replacement Recommendations

When components show signs of damage or reduced performance, timely replacement is crucial. Refer to the manufacturer’s guidelines for specific replacement intervals and recommendations for each part. Utilizing genuine replacement items ensures compatibility and maintains the efficiency of your equipment. Always prioritize safety by disconnecting power before attempting any replacements.