Understanding the Parts Diagram for Polaris Glacier 2 Plow

Maintaining efficiency during winter operations relies heavily on a comprehensive understanding of the machinery involved in snow removal. Proper knowledge about the components and their functionalities is essential for optimal performance and longevity of your equipment. This exploration aims to provide valuable insights into the intricacies of your snow-clearing tool, helping you navigate its essential elements.

Recognizing the individual components is crucial for troubleshooting and maintenance. By familiarizing yourself with the various sections and mechanisms, you can ensure that your device operates smoothly, reducing downtime during critical snow events. Furthermore, having a clear understanding of the assembly will aid in identifying wear and tear, facilitating timely repairs or replacements.

Equipped with a detailed visual representation of the various elements, you will be better prepared to address issues as they arise. This knowledge empowers you to enhance your equipment’s performance and ensure a reliable and efficient snow removal process throughout the season. An informed operator is the key to effective management and care of essential winter gear.

Understanding Polaris Glacier 2 Plow Components

Grasping the essential elements of a snow-clearing apparatus is crucial for efficient operation and maintenance. Each component plays a vital role in the overall functionality, ensuring that the equipment performs effectively in harsh conditions. This section delves into the various segments that comprise this type of system, shedding light on their significance and interconnections.

Main Components

- Frame: The backbone of the equipment, providing stability and support.

- Blade: The primary element responsible for moving snow, designed for durability and effectiveness.

- Lift Mechanism: Enables the operator to raise and lower the blade for optimal performance.

- Mounting System: Facilitates secure attachment to the vehicle, ensuring reliability during operation.

- Controls: The interface that allows the operator to manage the equipment efficiently.

Additional Features

- Wear Shoes: These protect the blade’s edge and enhance longevity.

- Hydraulic System: Powers the lift and tilt functions, offering precision in operation.

- Lighting: Improves visibility during nighttime or low-light conditions.

- Stabilizers: Ensure steady performance on uneven surfaces.

Understanding these components is essential for proper handling and maintenance, ultimately leading to improved performance and longevity of the snow management tool.

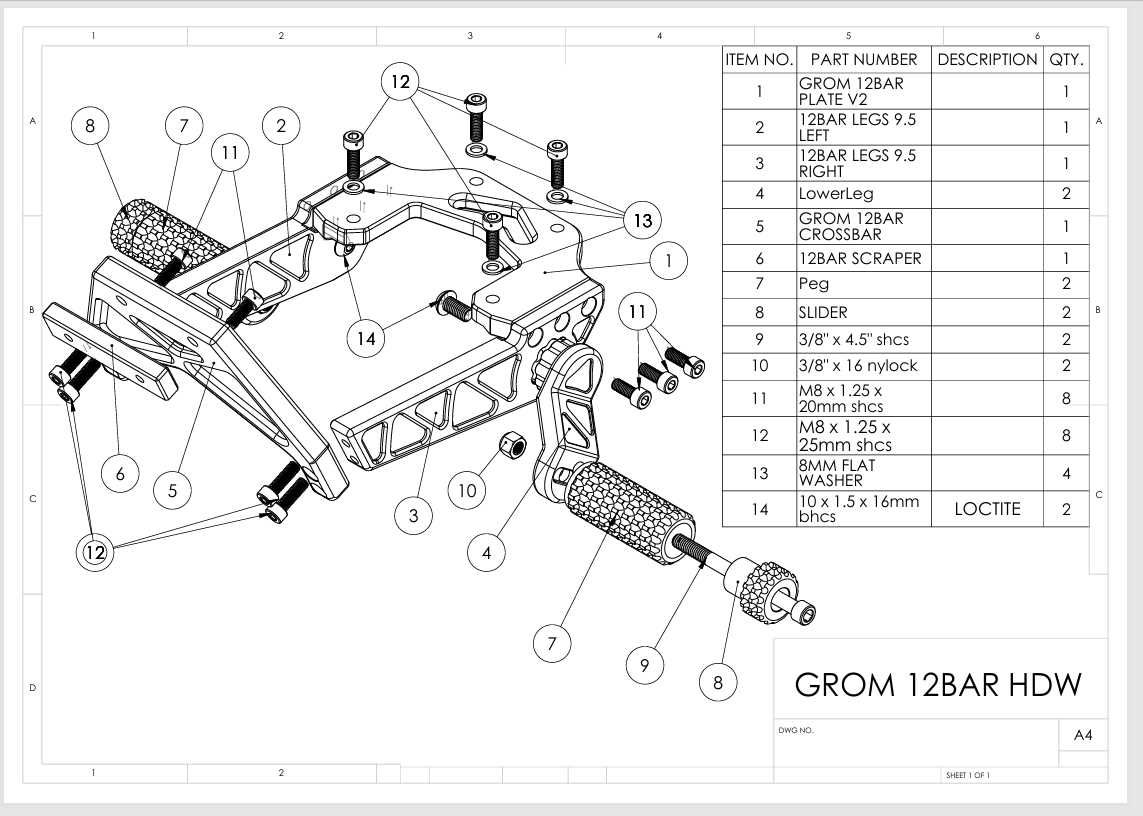

How to Read a Parts Diagram

Understanding a schematic representation of components can greatly enhance your ability to identify and source necessary items for repairs or maintenance. These illustrations provide a visual guide, mapping out the relationship between different elements and their functions. Mastering the interpretation of these visuals can save time and reduce confusion during projects.

1. Familiarize Yourself with Symbols: Each illustration typically employs specific icons to denote various elements. Spend some time studying these symbols to grasp their meanings, as they are essential for effective navigation through the image.

2. Follow the Numbering System: Components are often labeled with numbers or letters, which correspond to a list of items or descriptions. By referring to this list, you can gain a clearer understanding of each part’s purpose and characteristics.

3. Observe the Layout: The arrangement of the components within the illustration can indicate their order of assembly or their functional relationship. Pay attention to how parts are grouped or connected, as this can provide insights into their interactions.

4. Utilize Additional Resources: Accompanying documentation may provide further context, including specifications or installation tips. Don’t hesitate to consult these resources to enhance your understanding of the schematic.

5. Take Notes: While studying the visual representation, jot down any observations or questions you might have. This practice can help reinforce your learning and clarify any uncertainties as you proceed with your project.

Key Features of Glacier 2 Plow

This section highlights the essential attributes that make this snow-clearing tool stand out in its category. Its design and functionality cater to various needs, ensuring efficiency and ease of use in challenging winter conditions.

- Durability: Constructed from high-strength materials, this equipment is built to withstand harsh environments and heavy usage.

- Adjustable Angles: Features multiple angle settings, allowing for customizable snow management and effective clearing strategies.

- Quick Attachment System: Designed for easy installation and removal, facilitating quick transitions between different tasks.

- Enhanced Stability: Equipped with reinforced supports to maintain stability during operation, ensuring safe and effective performance.

- Optimal Width: The ideal width provides a balance between efficiency and maneuverability, making it suitable for both open areas and tight spaces.

- Versatile Compatibility: Compatible with a range of vehicles, enhancing its utility across different platforms.

These characteristics contribute to the overall performance, making it a reliable choice for managing snow accumulation and ensuring safe surfaces throughout the winter season.

Common Replacement Parts for Maintenance

Regular upkeep of outdoor equipment is essential for optimal performance and longevity. Identifying and replacing worn or damaged components is a key part of this process. Various elements may require attention over time, ensuring that the machinery operates smoothly and efficiently.

Wear Strips: These components protect the main body of the device from abrasion and damage. They often experience significant wear, necessitating frequent replacements to maintain functionality.

Hydraulic Hoses: Over time, hoses can develop leaks or become brittle due to exposure to harsh conditions. Regular checks and timely replacements can prevent hydraulic failure and ensure reliable operation.

Belts: These are crucial for the transmission of power within the system. A frayed or broken belt can lead to operational inefficiencies, making regular inspection and replacement vital.

Cutting Edges: Essential for effective performance, these edges can become dull or damaged, impacting the ability to perform tasks efficiently. Routine monitoring and replacement keep the equipment in prime working condition.

Fasteners: Nuts, bolts, and screws can loosen or corrode over time. Ensuring that all fasteners are secure and in good condition is critical for the overall integrity of the machinery.

Maintaining a proactive approach to these components can significantly enhance the reliability and effectiveness of your equipment, minimizing downtime and costly repairs.

Assembly Process of Polaris Plow System

The assembly process of the snow removal system is a crucial step in ensuring optimal performance and durability. This section outlines the key phases involved in bringing together various components to form a cohesive unit. Attention to detail during this process not only guarantees functionality but also enhances the longevity of the equipment.

Initially, it is essential to gather all necessary components and tools before starting the assembly. This preparation phase helps prevent delays and ensures a smooth workflow. Each item should be inspected for any signs of damage or defects, as quality is paramount for effective operation.

Once all components are ready, the next step involves aligning and securing the main structural elements. Proper alignment is vital to ensure that all pieces fit seamlessly together. Fastening mechanisms, such as bolts and screws, should be tightened to the manufacturer’s specifications to avoid any operational issues later on.

After securing the primary structure, the installation of auxiliary components follows. This includes attaching any necessary hydraulic systems or electronic controls that enhance functionality. Each connection should be checked for reliability to prevent leaks or malfunctions during use.

Finally, a comprehensive inspection of the assembled unit is necessary. This final check should include testing the mobility and stability of the system to ensure it meets performance standards. Addressing any discrepancies at this stage is crucial for achieving a fully operational and efficient setup.

Troubleshooting Common Plow Issues

When dealing with winter equipment, various challenges may arise that affect functionality and performance. Identifying and addressing these issues promptly can enhance efficiency and ensure safe operation. Below are some typical problems and their possible solutions.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Inadequate Lifting | Hydraulic fluid levels low, blockages in the system, worn-out components | Check fluid levels, inspect hoses for obstructions, and replace worn parts. |

| Uneven Surface Contact | Improper alignment, damaged blade, or frame | Adjust alignment, examine blade for damage, and repair or replace if necessary. |

| Noise During Operation | Loose fittings, lack of lubrication, or damaged components | Tighten loose fittings, apply lubricant to moving parts, and inspect for damage. |

| Electrical Issues | Faulty wiring, blown fuses, or weak battery | Inspect wiring for breaks, replace any blown fuses, and ensure the battery is fully charged. |

| Difficulty Steering | Improper weight distribution, mechanical failure | Reassess weight balance, check for mechanical issues, and make necessary adjustments. |

By recognizing these common challenges and applying the suggested remedies, operators can maintain optimal performance and extend the lifespan of their equipment.

Tools Needed for Repairing the Plow

When it comes to maintaining and fixing your snow removal equipment, having the right tools is essential for effective repairs. A well-equipped toolkit not only speeds up the process but also ensures that tasks are completed accurately and safely. Below is a list of necessary implements that will aid you in your repair endeavors.

- Wrenches: Various sizes for loosening and tightening bolts.

- Sockets: Socket sets can make it easier to reach difficult spots.

- Ratchet: For quick adjustments and securing fasteners.

- Screwdrivers: Both flathead and Phillips for various screws.

- Pliers: Useful for gripping, twisting, and cutting wires.

- Jack: To elevate the equipment for better access.

- Torque wrench: To ensure that fasteners are tightened to the correct specifications.

- Utility knife: Handy for cutting materials such as rope or tape.

Having these tools on hand will prepare you for most maintenance tasks, allowing you to efficiently address any issues that arise. Regular upkeep not only extends the life of your equipment but also enhances its performance during operation.

Differences Between Plow Models

When it comes to snow-clearing equipment, various models exhibit distinct features that cater to different needs and preferences. Understanding these variations can greatly influence efficiency and performance during winter tasks.

- Design and Structure: Models can differ significantly in their build and overall design. Some are crafted for heavy-duty operations, while others are more suited for lighter tasks.

- Blade Width: The width of the clearing edge plays a crucial role in determining how much snow can be handled at once. Wider blades are ideal for expansive areas, whereas narrower options offer better maneuverability in tight spaces.

- Material Composition: The materials used in construction affect durability and weight. Some models utilize robust steel, while others may incorporate lighter alloys or composites.

- Attachment Mechanism: The way a unit connects to the vehicle can vary. Quick-release systems provide ease of use, while more traditional methods may offer enhanced stability.

- Height Adjustment: Certain designs allow for adjustable height settings, enabling operators to adapt to varying snow depths and surface conditions.

By familiarizing oneself with these distinctions, users can select the right equipment that aligns with their specific requirements and operating environments.

Where to Find Authentic Parts

When it comes to maintaining your equipment, sourcing genuine components is crucial for ensuring optimal performance and longevity. Authentic pieces not only guarantee compatibility but also enhance reliability during usage. Identifying the right vendors and resources can make all the difference in keeping your machinery in top condition.

Official Dealers are often the best starting point. These establishments provide verified components directly from the manufacturer, ensuring that you receive high-quality items designed specifically for your model. Look for authorized dealerships in your area or check their websites for online ordering options.

Reputable Online Retailers also offer a wide selection of genuine items. Many of these platforms have user reviews and ratings that can help you assess the credibility of the products being sold. Be sure to verify that the seller is recognized and has a good track record in the industry.

Community Forums and Groups can be invaluable resources for locating authentic components. Engaging with fellow enthusiasts and professionals can lead to recommendations for trustworthy sources and insights into the best practices for sourcing quality items.

Finally, Local Repair Shops often have connections with suppliers of authentic components. They can not only assist you in finding what you need but also provide expertise in installation and maintenance, ensuring that your equipment remains reliable and efficient.

Safety Tips for Plowing Operations

Effective snow management requires careful consideration of safety protocols to ensure the well-being of operators and bystanders. Proper precautions and awareness can prevent accidents and enhance overall efficiency during winter maintenance tasks.

1. Conduct a Pre-Operation Inspection: Always inspect your equipment before starting. Check for any signs of wear or damage, ensuring all components are functioning correctly. This includes examining fluid levels, brakes, and safety features.

2. Wear Appropriate Personal Protective Equipment (PPE): Equip yourself with the right gear. This includes gloves, boots, and reflective clothing to enhance visibility and protect against harsh weather conditions.

3. Stay Aware of Surroundings: Be vigilant of your environment. Look out for obstacles, pedestrians, and other vehicles. Maintain a safe distance from these elements to avoid collisions.

4. Use Proper Techniques: Familiarize yourself with safe operational methods. Adjust your speed according to conditions, and avoid sudden movements that could lead to loss of control.

5. Communicate Effectively: When working in a team, clear communication is crucial. Use hand signals or radios to coordinate movements and ensure everyone is aware of each other’s actions.

6. Take Breaks: Fatigue can lead to mistakes. Schedule regular breaks to maintain alertness and focus throughout the operation.

Implementing these guidelines can significantly reduce risks associated with snow removal tasks, creating a safer environment for everyone involved.

Owner Reviews and Experiences with Glacier 2

This section delves into the insights and feedback from users regarding their experiences with the equipment. Owners share their thoughts on performance, durability, and overall satisfaction, providing a well-rounded perspective for potential buyers.

Performance Insights

- Many users appreciate the efficiency and effectiveness of the device in handling various conditions.

- Some have noted that it excels in heavy snowfall, making winter maintenance tasks more manageable.

- However, a few reports indicate occasional struggles with particularly icy surfaces.

Durability and Maintenance

- Users frequently highlight the robust build quality, stating it withstands rigorous use over multiple seasons.

- Regular maintenance is essential, with most owners recommending routine checks to ensure longevity.

- Complaints about wear and tear are minimal, but some have encountered issues that required prompt attention.

Overall, the shared experiences provide valuable insights for anyone considering this equipment, emphasizing its strengths while also acknowledging areas for improvement.