Ryobi RY3716 Chainsaw Parts Diagram Overview

For anyone working in outdoor maintenance, having a reliable cutting tool is essential. Whether you are trimming branches or cutting through wood, knowing how each element of the device functions can help ensure efficient operation and longer lifespan. By understanding the various mechanisms, you can perform repairs or replacements when necessary, avoiding costly downtime.

This guide will provide a detailed breakdown of the key elements that make up this tool, explaining how they contribute to its overall performance. From the power source to the cutting mechanism, we will explore every aspect to help you maintain and service the equipment with confidence. Proper knowledge of these components allows for smoother, safer operation, ensuring your device stays in top shape.

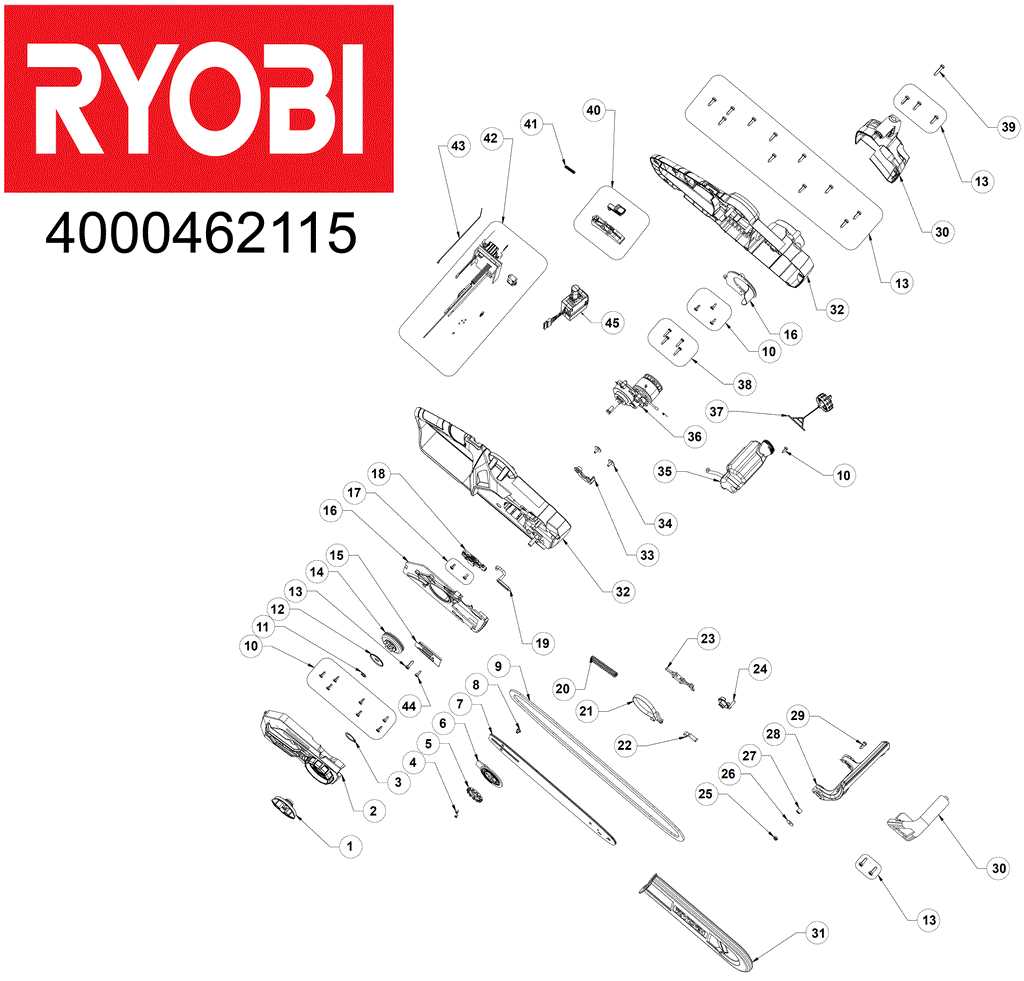

Ryobi ry3716 Chainsaw Parts Diagram

Understanding the layout and structure of mechanical tools is essential for proper maintenance and repair. A detailed visual representation allows users to easily identify individual components and ensure accurate assembly or replacement when needed. This section explores the key features of a commonly used tool, providing clarity on how its various elements interact to function smoothly.

Component Overview

Each element in the tool’s design plays a specific role in ensuring efficiency and performance. From the engine to the cutting mechanism, every part is meticulously placed to guarantee reliability. Familiarizing oneself with these components can aid in troubleshooting and extending the tool’s lifespan.

Table of Key Elements

| Component | Function |

|---|---|

| Engine Assembly | Provides power for cutting operations |

| Handle | Ensures stability and control during use |

| Bar and Chain | Responsible for cutting through material |

| Fuel System | Supplies the engine with necessary fuel |

Overview of Ryobi ry3716 Components

Understanding the key elements that make up this machine is essential for proper maintenance and operation. Each section of the tool plays a vital role in ensuring its performance, from the mechanism that drives the engine to the components that provide safety and control. Below is a detailed look at the most important elements of this device.

Engine Assembly

The power unit serves as the heart of the machine. It transforms fuel into mechanical energy, driving the cutting mechanism. This assembly includes critical elements like the cylinder, carburetor, and crankshaft, all working together to maintain efficient power output.

- Cylinder – Houses the piston and manages the combustion process.

- Crankshaft – Converts the piston’s motion into rotational energy.

- Carburetor – Mixes air and fuel for optimal combustion.

Safety and Control Features

For effective and safe operation, the machine is equipped with several control systems. These elements not only enhance the user’s control but also ensure that the tool operates safely under different conditions.

- Cylinder: The heart of the engine, where combustion takes place, converting fuel into mechanical energy.

- Piston: Moves inside the cylinder, driven by expanding gases, transmitting energy to other components.

- Crankshaft: Converts the reciprocating motion of the piston into rotational energy, driving the system.

- Carburetor: Mixes air and fuel in the correct ratio for combustion, ensuring efficient power generation.

- Ignition Coil: Generates the electrical spark necessary for igniting the fuel mixture in the cylinder.

- Flywheel: Helps maintain consistent engine speed and enhances the cooling system by directing air over the engine.

- Guide Frame: The supporting structure that directs the cutting edge along its path, ensuring stability and precision.

- Cutting Edge: The sharp, rotating element responsible for cutting through material, which is powered by the drive system.

- Ignition Coil: Converts low battery voltage to a high voltage required to create a spark.

- Spark Plug: Produces the spark that ignites the fuel-air mixture within the combustion chamber.

- Magneto: Generates electrical energy to power the ignition system and recharge the battery.

- Kill Switch: Disconnects the ignition coil from the power source to stop the engine safely.

- Wiring Harness: Connects various electrical parts, ensuring seamless communication between them.

- Battery: Supplies power to the ignition system and other electrical components.

- Switches: Control the flow of electricity within the system, allowing the user to start or stop the engine.

- Fuel Tank: Stores the fuel necessary for operation.

- Fuel Line: Transports the fuel from the tank to the carburetor.

- Carburetor: Mixes air and fuel in the correct ratio for combustion.

- Air Filter: Prevents debris from entering the carburetor.

- Primer Bulb: Helps to start the fuel flow into the carburetor.

Key Engine Parts of the Chainsaw

The internal components responsible for the proper functioning of the engine are crucial for optimal performance. Each element plays a significant role in ensuring the machine operates smoothly, delivering the power necessary for demanding tasks.

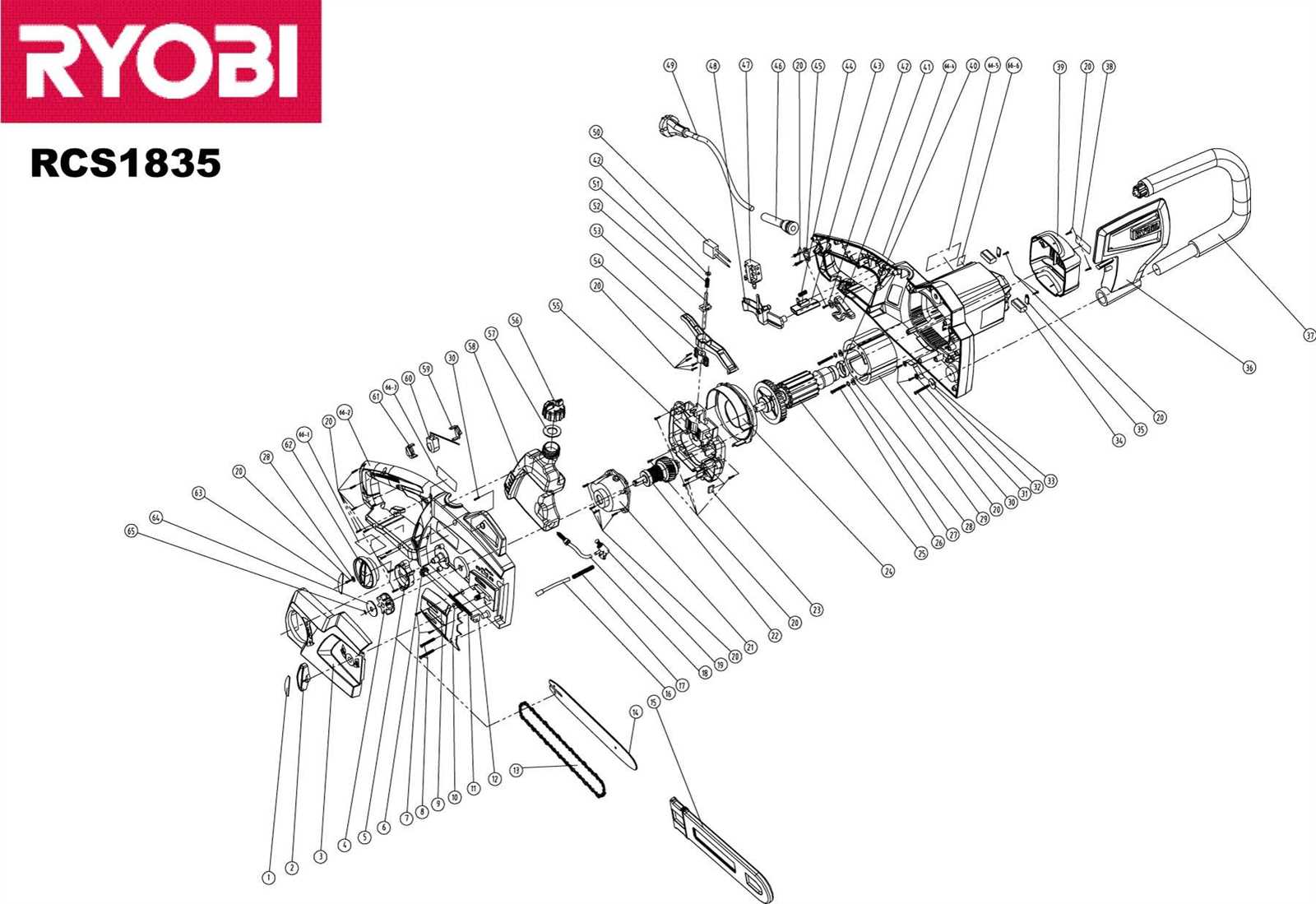

Guide Bar and Chain Mechanism Explained

The cutting system relies on a combination of components working together to ensure smooth and efficient operation. Central to this is the interaction between the primary cutting element and the supporting structure, which guides and stabilizes the motion. Understanding how these elements function together can help maintain performance and prolong the life of the machine.

Main Components

The core elements consist of the guiding frame and the moving cutting edge. These parts need to be properly aligned and tensioned for optimal operation. The guiding frame serves as a track for the cutting edge, ensuring a consistent path during operation.

How the Mechanism Works

The guiding frame holds the cutting edge in place, allowing it to rotate freely while staying on a defined track. Tension is crucial here, as too much or too little tension can lead to poor

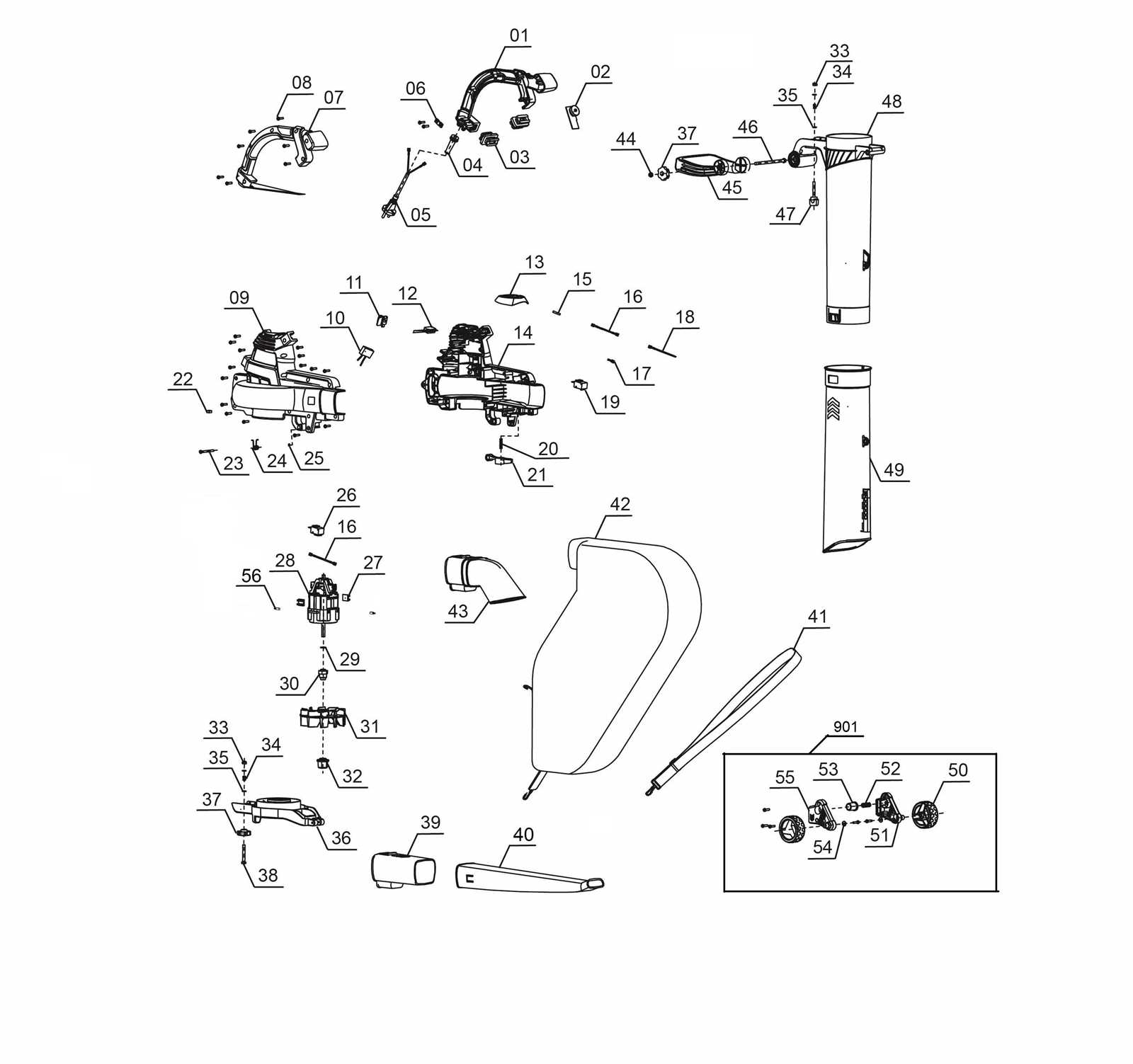

Chainsaw Starter Assembly and Function

The starter mechanism plays a critical role in initiating engine operation. It converts manual effort into the energy needed to ignite the internal combustion process. Understanding how this component functions is essential for proper maintenance and troubleshooting.

Main Components of the Starter Mechanism

The starter system typically consists of several key parts working together to create a seamless start. These include a recoil spring, a pull cord, and a pulley system. Each part has its specific role in ensuring smooth functionality.

| Component | Function |

|---|---|

| Recoil Spring | Stores energy when the cord is pulled and releases it to turn the engine over. |

| Pull Cord | Manually operated to engage the engine by winding and unwinding the spring. |

| Pulley System | Houses the cord and controls its movement during the starting process. |

How the Starter Mechanism Works

When the cord is pulled, it tightens the spring and rotates the flywheel, which causes the engine to initiate its first cycles. The stored energy in the spring is then released, helping the engine achieve ignition speed. This process is designed for reliability, allowing quick restarts when necessary.

Ignition System and Electrical Components

The ignition system plays a crucial role in the functionality of small engine equipment, ensuring efficient combustion and reliable operation. This system is responsible for igniting the fuel-air mixture, enabling the engine to generate power. Understanding the electrical components involved is essential for maintenance and troubleshooting.

Key components of the ignition system include:

Electrical components also contribute to the overall functionality, including:

Regular inspection and maintenance of these components are vital to ensure optimal performance and longevity of the equipment. Proper functioning of the ignition system leads to enhanced efficiency and reduces the risk of operational failures.

Fuel System and Carburetor Breakdown

The fuel delivery mechanism is essential for optimal engine performance in outdoor power equipment. This system ensures that the right mixture of fuel and air reaches the combustion chamber, facilitating efficient operation. Understanding the components involved can help diagnose issues and maintain smooth functionality.

Key Components

Carburetor Functionality

The carburetor plays a crucial role in regulating the air-fuel mixture. It operates based on the principle of airflow. As air enters the carburetor, it creates a vacuum that draws fuel from the tank. This mixture is then delivered to the engine, where combustion occurs. Proper adjustment and maintenance of the carburetor are vital to ensure efficient performance and reduce emissions.

Common issues with the fuel system include clogs in the fuel line, a malfunctioning primer bulb, or a dirty air filter. Regular inspection and maintenance of these components can prevent operational failures and enhance longevity.

Oil Pump and Lubrication System

The oil pump and lubrication system play a crucial role in ensuring the smooth operation of power tools that require cutting mechanisms. This system is designed to deliver the necessary lubricant to vital components, reducing friction and wear, ultimately enhancing the tool’s performance and longevity.

Functionality of the Oil Pump

The oil pump is responsible for circulating lubricant throughout the engine and cutting apparatus. By maintaining a consistent flow of oil, it helps create a protective barrier between moving parts, minimizing damage caused by heat and friction. A well-functioning pump ensures that the lubricant reaches all critical areas, allowing for optimal operation during extended use.

Importance of Proper Lubrication

Effective lubrication is essential for the efficiency and durability of any mechanical device. Insufficient oil flow can lead to overheating, increased wear, and even catastrophic failure. Therefore, regular maintenance of the lubrication system, including checking oil levels and replacing worn components, is vital for sustaining performance and preventing costly repairs.

Handle and Safety Features Overview

The ergonomic design of a cutting tool significantly enhances user comfort and control, allowing for safer operation during tasks. This section explores the essential components that contribute to safety and usability, ensuring a more secure experience while handling powerful machinery.

Handle Design

The handle is crafted to provide an optimal grip, reducing fatigue during prolonged use. Its shape and material composition ensure that users can maintain a firm hold, even in challenging conditions. Key features include anti-slip surfaces and strategically positioned controls for ease of access.

Safety Mechanisms

Various safety mechanisms are integrated into the tool to minimize the risk of accidents. These include features such as a chain brake, which halts the chain’s movement in case of sudden jerks or contact with obstacles. Additionally, throttle lock systems prevent accidental activation, further enhancing user protection.

| Feature | Description |

|---|---|

| Ergonomic Handle | Designed for comfort and reducing fatigue. |

| Anti-Slip Grip | Ensures a secure hold under various conditions. |

| Chain Brake | Stops the chain quickly during emergencies. |

| Throttle Lock | Prevents accidental activation of the cutting tool. |

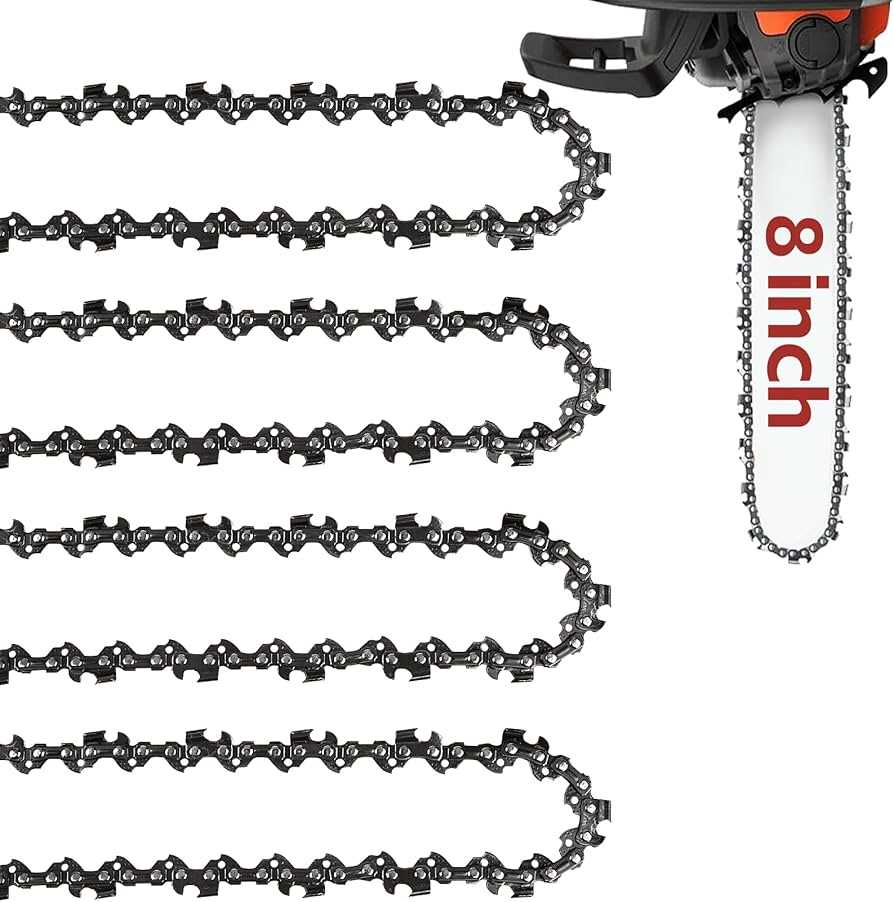

Chain Tensioner and Adjustment Parts

The mechanism responsible for maintaining optimal tension on the cutting component is crucial for efficient operation and longevity. Proper adjustment ensures that the tool performs at its best, providing effective cutting while minimizing wear and tear.

Within this system, various elements play significant roles. The tensioning mechanism typically includes a adjusting screw, which allows the user to modify the tightness of the chain easily. This screw is often paired with a tensioning nut, securing the chain in place once the desired tension is achieved.

In addition, a guide bar plays a pivotal role in alignment and stability, ensuring that the chain remains properly seated during operation. Regular checks and adjustments of these components contribute to maintaining safety and performance, making it essential for users to familiarize themselves with these crucial aspects.

Air Filter and Muffler Configuration

The arrangement of the air filtration system and exhaust silencer is crucial for the optimal performance of outdoor power equipment. These components work together to ensure that the engine receives clean air for combustion while effectively reducing noise and emissions.

The air filter plays a vital role in trapping dirt and debris, preventing them from entering the engine. A well-maintained filter contributes to improved airflow and efficiency. Regular inspection and replacement of the filter are essential to maintain engine performance and longevity.

In tandem with the air filter, the exhaust silencer is designed to minimize noise output and redirect harmful gases away from the operator. The configuration of the muffler affects both the sound levels produced and the overall efficiency of the engine. Ensuring proper alignment and integrity of these components is necessary for safe and effective operation.

Common Replacement Parts and Maintenance Tips

Understanding the essential components and upkeep practices for your cutting tool can significantly enhance its longevity and performance. Regularly checking and replacing worn or damaged elements ensures that the equipment operates efficiently and safely. This section covers key components that often require attention and provides valuable maintenance advice to keep your machine in optimal condition.

| Component | Description | Maintenance Tips |

|---|---|---|

| Bar | The elongated metal piece that supports the cutting chain. | Inspect for wear and damage; rotate periodically to promote even wear. |

| Chain | The loop of sharp links that cuts through wood. | Sharpen regularly and replace if links are broken or excessively worn. |

| Air Filter | Prevents debris from entering the engine. | Clean or replace as needed to ensure proper airflow and performance. |

| Oil Pump | Delivers lubrication to the chain and bar. | Check oil levels frequently and ensure the pump is functioning correctly. |

| Spark Plug | Ignites the fuel-air mixture in the engine. | Inspect and replace if necessary to maintain reliable starting and operation. |

By staying attentive to these components and implementing regular maintenance practices, you can ensure that your equipment remains reliable and efficient for years to come.