Dewalt Shop Vac Parts Diagram Overview

Effective maintenance of your cleaning apparatus is essential for optimal performance and longevity. Familiarizing yourself with the various components can significantly enhance your ability to troubleshoot and repair any issues that may arise. This guide aims to provide a clear and detailed overview of the internal structures and functionalities of your device.

Identifying each element within your equipment can streamline repairs and ensure that you are using the correct replacement components when necessary. By visualizing the assembly and understanding the role of each part, you can tackle maintenance tasks with confidence. This resource is designed to help you navigate through the intricacies of your machinery.

In addition to offering insight into the different elements, this guide emphasizes the importance of regular inspections and preventive measures. Knowing when and how to address wear and tear can save you time and money in the long run. Dive into the specifics, and empower yourself with the knowledge needed to keep your equipment in peak condition.

Dewalt Shop Vac Overview

This section provides a comprehensive look at a powerful cleaning solution designed for various environments. These versatile machines are engineered to tackle both dry and wet debris, making them essential for both home improvement projects and professional applications.

Featuring robust construction and user-friendly design, these units ensure efficient operation and ease of maintenance. Their portability allows for seamless transport, enabling users to address messes wherever they occur. Additionally, the innovative filtration systems enhance performance by trapping dust and particles effectively.

With a variety of models available, each equipped with distinct features, users can select the perfect option tailored to their specific needs. Whether for light-duty household tasks or heavy-duty commercial use, these reliable machines deliver consistent results, underscoring their status as indispensable tools in any toolkit.

Understanding Shop Vac Components

When it comes to powerful cleaning solutions, familiarity with the essential elements can greatly enhance performance and maintenance. Each component plays a vital role in the overall functionality, contributing to efficiency and effectiveness during use. Recognizing how these parts interact allows for better troubleshooting and optimization.

Key Elements: The primary sections include the motor, collection tank, filtration system, and various attachments. Each part serves a specific purpose, from generating suction to collecting debris, ensuring a thorough clean-up experience.

Maintenance Insights: Regular inspection and care of these components are crucial for longevity. Understanding the importance of filters and the motor can prevent common issues and enhance the device’s operational life.

In summary, a comprehensive grasp of these integral components not only facilitates effective usage but also empowers users to make informed decisions regarding upkeep and potential upgrades.

Importance of Parts Diagrams

Understanding the layout and components of any mechanical device is crucial for maintenance and repair. Visual representations serve as essential guides, allowing users to identify each element and its function efficiently. This knowledge not only simplifies the troubleshooting process but also enhances overall operational efficiency.

Benefits of Visual Guides

- Streamlined Repairs: Quickly locate and replace damaged or worn components.

- Enhanced Understanding: Gain insights into the assembly and functionality of various parts.

- Time Savings: Reduce downtime by having clear references during maintenance tasks.

Facilitating Communication

- Standardization: Provides a common language for technicians and users.

- Training Aid: Serves as a helpful resource for new team members learning the equipment.

- Collaboration: Encourages teamwork by ensuring everyone is on the same page regarding repairs and maintenance.

In summary, visual aids are indispensable tools that enhance both the efficiency and effectiveness of repair processes, fostering a deeper understanding of the machinery involved.

Common Dewalt Shop Vac Models

When it comes to powerful cleaning tools, various models stand out for their efficiency and versatility. These units are designed to tackle a range of tasks, from heavy-duty debris collection to fine particle filtration, making them essential for both professionals and DIY enthusiasts.

Popular Models

- Model A: Known for its robust construction and portability, perfect for both indoor and outdoor use.

- Model B: Features advanced filtration technology, ideal for fine dust and allergens.

- Model C: Offers a large capacity, suitable for extensive clean-up projects.

- Model D: Compact and lightweight, perfect for quick jobs and easy storage.

Key Features

- Powerful motor for effective suction.

- Multiple attachment options for various cleaning tasks.

- Durable design for long-lasting use.

- Easy-to-empty collection system for convenience.

Identifying Key Components

Understanding the essential elements of a cleaning apparatus is crucial for effective maintenance and repair. Each component plays a significant role in the overall functionality, ensuring optimal performance. By familiarizing oneself with these parts, users can troubleshoot issues more efficiently and extend the lifespan of the device.

The following table outlines some of the critical elements typically found in a cleaning machine, along with their respective functions:

| Component | Description |

|---|---|

| Motor | Powers the device, creating suction to gather debris and liquids. |

| Filter | Traps dust and allergens, ensuring clean air is expelled. |

| Hose | Connects the main unit to the cleaning tools, allowing for versatile usage. |

| Collection Tank | Holds the collected materials until it is emptied. |

| Wheels | Facilitate mobility, allowing for easy transport across different surfaces. |

By understanding these components, users can ensure their equipment remains functional and effective for all cleaning tasks.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of any equipment. By following a few key practices, users can significantly extend the lifespan of their tools, preventing unnecessary breakdowns and costly repairs.

Regular Cleaning

Keeping your equipment clean is crucial. Accumulated debris can lead to malfunctions and reduced performance. Regularly inspect and remove any dust, dirt, or particles that may obstruct airflow or mechanical parts.

Periodic Inspection

Routine checks for wear and tear can help identify potential issues before they escalate. Look for signs of damage or deterioration in components and replace any parts that show significant wear.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Clean Filters | Monthly | Remove and clean or replace filters to ensure optimal airflow. |

| Inspect Hoses | Every 3 Months | Check hoses for cracks or blockages that may hinder performance. |

| Lubricate Moving Parts | Biannually | Apply appropriate lubricant to moving components to reduce friction. |

| Check Electrical Components | Annually | Inspect cords and plugs for damage to prevent electrical hazards. |

Where to Find Replacement Parts

Finding components for your equipment can be straightforward if you know where to look. Various resources are available, ranging from online marketplaces to specialized retailers, ensuring you can get the right items to keep your machinery running smoothly.

Online Retailers

The internet is a treasure trove for sourcing components. Websites dedicated to tools and machinery often have extensive catalogs, allowing you to search by model or category. Utilizing filters can help narrow down options, making it easier to find what you need. Don’t forget to check user reviews to gauge the reliability of the components.

Local Supply Stores

Visiting a physical store can provide immediate access to necessary components. Local hardware and tool supply shops often carry a range of items, and staff can assist in locating the specific parts you require. Establishing a relationship with your local supplier may also yield valuable insights into maintenance and product recommendations.

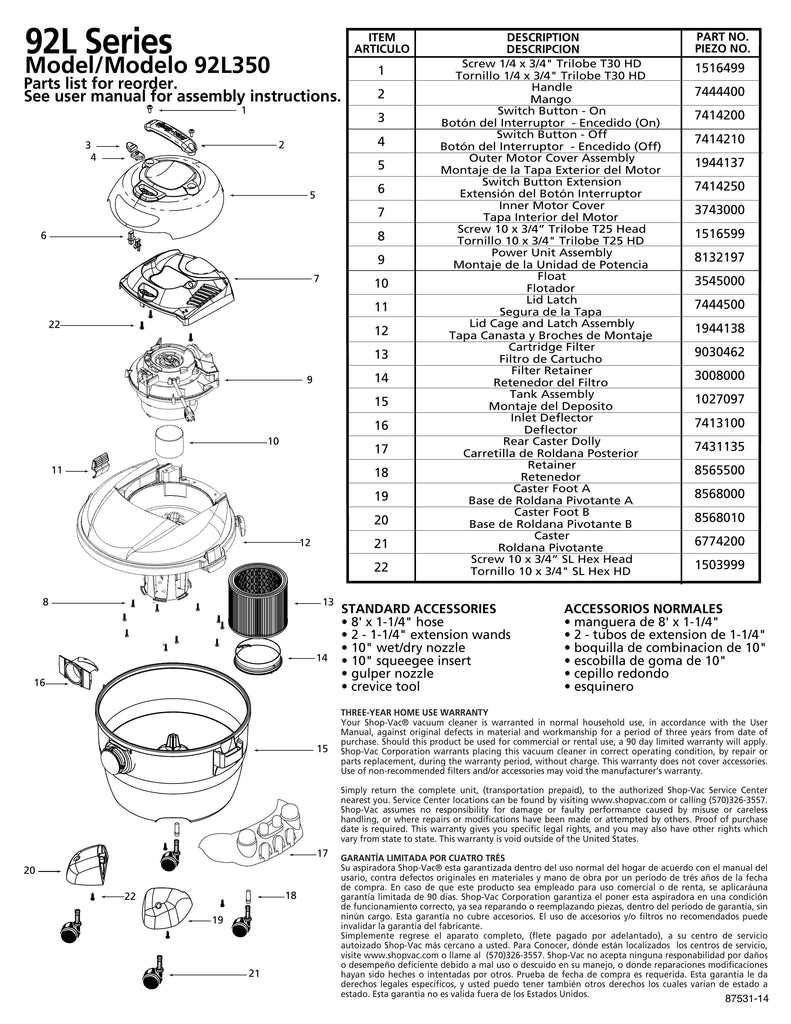

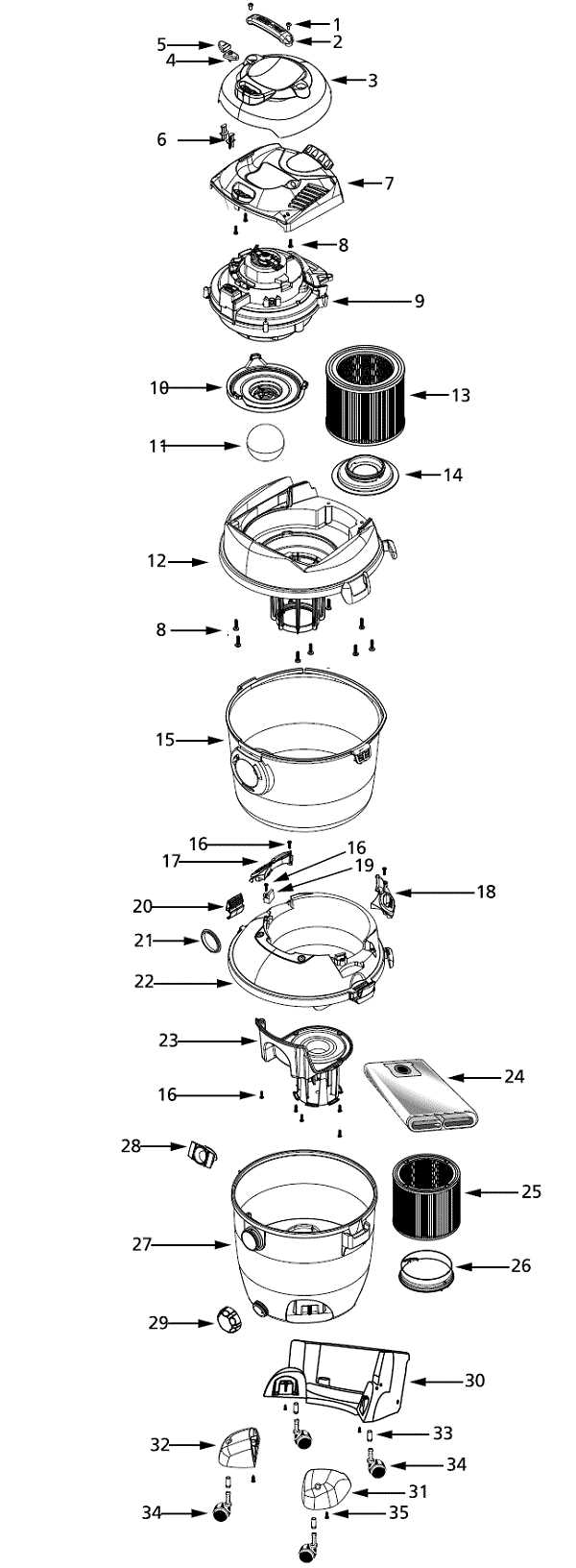

How to Read a Parts Diagram

Understanding a component illustration is essential for effective maintenance and repairs. These visual guides simplify the identification of various elements within a device, allowing users to locate and replace specific components with ease.

First, familiarize yourself with the layout of the illustration. Each section typically highlights different parts, often organized in a logical manner. Pay attention to labels and numbers that correspond to a parts list, which can provide further details about each item.

Next, identify the key symbols used in the illustration. Common symbols may represent various types of components, such as fasteners, connectors, or housings. Knowing these symbols helps in quickly deciphering the visual representation.

Additionally, review the scale of the illustration. Some diagrams may not be to scale, so understanding this aspect is crucial for accurately visualizing the size and fit of the components. Ensure that you have the correct specifications before proceeding with any repairs.

Finally, refer to the accompanying documentation. Manuals often contain important information regarding assembly and disassembly, safety precautions, and maintenance tips. Combining this knowledge with the visual representation will greatly enhance your repair skills.

Assembly Instructions for Beginners

Building a device from various components can seem daunting, especially for those new to this task. However, with clear guidance and a systematic approach, anyone can successfully assemble their equipment. This section aims to provide straightforward instructions that will help you navigate through the assembly process with confidence.

Before you start, ensure you have all necessary tools and components ready. Familiarizing yourself with each part will make the assembly smoother.

- Gather Your Tools:

- Screwdriver (appropriate size)

- Wrench or pliers

- Safety goggles

- Review the Components:

Identify each item included in your kit. A quick glance at the list will help you recognize the function of each part.

- Prepare Your Workspace:

Find a clean, well-lit area where you can lay out your components. This will make it easier to access everything during assembly.

- Follow Step-by-Step Instructions:

Start with the first step of the assembly. It’s crucial to follow the instructions in the correct order to avoid complications later on.

- Connect the base to the main unit.

- Secure any joints with screws or fasteners.

- Attach the hose or any other accessories as indicated.

- Double-Check Your Work:

Once assembled, review your work to ensure everything is secure and properly aligned. This can help prevent issues during use.

By adhering to these guidelines, you can efficiently assemble your device, transforming individual components into a fully functional tool. Happy building!

Troubleshooting Common Issues

When utilizing a powerful suction device, various challenges may arise that can hinder performance. Identifying and resolving these common problems can significantly enhance functionality and prolong the lifespan of the equipment.

Power-Related Issues

- No Power: Ensure the unit is plugged in and check for any blown fuses or tripped circuit breakers.

- Intermittent Operation: Inspect the power cord for damage and verify connections are secure.

- Overheating: Allow the machine to cool down and check for blockages that may impede airflow.

Suction Problems

- Reduced Suction: Clean or replace the filter, and check for clogs in the hose or attachments.

- Unusual Noises: Investigate for foreign objects lodged in the hose or motor that may disrupt normal operation.

- Leaks: Examine connections and seals for wear and replace any damaged components.

Upgrading Your Shop Vac Efficiency

Enhancing the performance of your cleaning apparatus can significantly improve your workflow and save time on maintenance tasks. By focusing on specific upgrades and adjustments, you can ensure optimal functionality and longevity of your equipment. This section explores effective strategies to boost efficiency and productivity.

1. Optimize Filtration System

Upgrading to a high-quality filtration mechanism can trap smaller particles and allergens, resulting in cleaner air and a more thorough cleaning process. Consider investing in HEPA filters, which provide superior filtration and are essential for environments requiring high standards of cleanliness.

2. Assess and Improve Suction Power

Enhancing suction power can make a significant difference in performance. Regularly check for clogs in hoses and connectors, and replace any worn-out components. Additionally, using a larger diameter hose can facilitate better airflow, thus increasing overall efficiency.

3. Implement Proper Maintenance Practices

Routine maintenance is key to preserving the effectiveness of your equipment. Ensure regular cleaning of filters and replace them as necessary. Inspect all connections and seals to prevent air leaks, which can diminish performance.

4. Accessorize for Versatility

Utilizing specialized attachments can enhance your device’s capability to handle various tasks. From crevice tools for tight spaces to larger nozzles for extensive surfaces, having the right accessories can make cleaning more efficient and effective.

5. Invest in a Reliable Power Source

Ensuring a consistent power supply is crucial for maintaining optimal operation. If using an electric model, consider dedicated circuits or using extension cords that can handle the load without causing performance issues.

By implementing these strategies, you can significantly enhance the efficiency and effectiveness of your cleaning equipment, ensuring a cleaner environment and a more productive experience.

Frequently Asked Questions About Parts

This section aims to address common inquiries related to components and their functionalities. Understanding these elements is crucial for maintaining and optimizing performance, ensuring longevity and efficiency in your equipment.

What should I do if I can’t find the specific component I need? Consider checking with authorized retailers or online platforms that specialize in these items. It may also be beneficial to consult the manufacturer’s website for more information.

How often should I replace components to ensure optimal performance? Regular inspections are recommended. Typically, replacing elements every few months or as wear becomes apparent will help maintain efficiency.

Are there universal components that can fit multiple models? Yes, many components are designed to be compatible across different models. However, it’s essential to verify compatibility before purchasing.

What is the best way to clean and maintain these elements? Routine cleaning and proper storage are key. Ensure that all components are free from debris and moisture to prevent deterioration.

Can I install components myself, or should I seek professional help? Many individuals choose to install components themselves, provided they follow guidelines. However, consulting a professional can ensure proper installation and function.