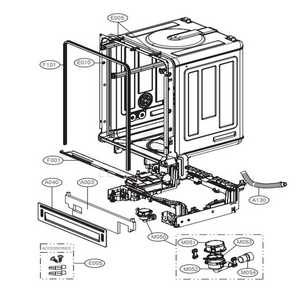

Components Layout for Ldf7774st

When dealing with home devices, it’s essential to understand how various elements come together to ensure proper functionality. The different sections of a household machine play a vital role in its operation, and knowing their arrangement can help with both maintenance and troubleshooting.

Understanding the layout of these components provides a clearer picture of how everything is interconnected. This knowledge is crucial for anyone looking to perform repairs or optimize performance, as it enables them to identify specific areas that may need attention.

Whether you are aiming to replace certain elements or simply improve the efficiency of your device, having a visual reference of its structure makes the task much easier. With a thorough grasp of these details, you can keep your appliance in top working condition for longer periods.

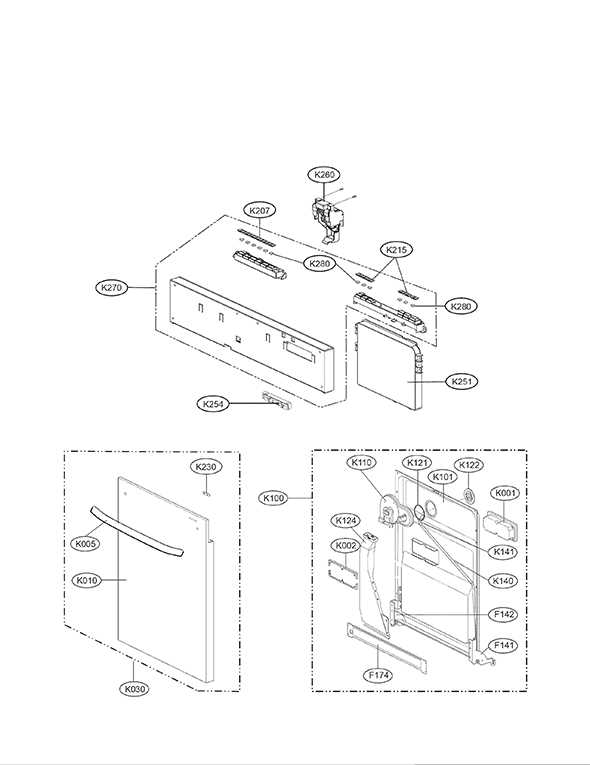

Detailed Breakdown of Component Categories

This section offers a comprehensive overview of the main groups of elements that make up the structure and functionality of the device. Each category plays a significant role in ensuring optimal performance and reliability, contributing to the overall efficiency of the system. By understanding the various types of components, users can gain deeper insight into the device’s operation and maintenance.

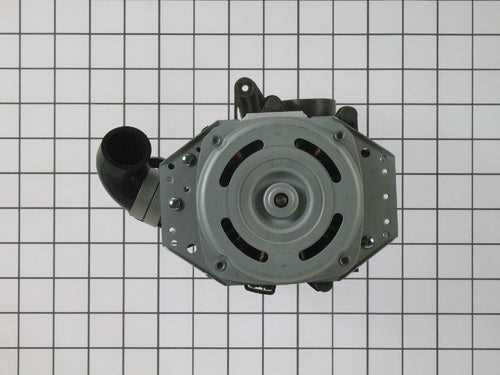

Core Functional Units

The primary units are responsible for the essential functions of the device. These include various mechanical and electronic elements that work together to deliver consistent performance. Each part within this category has a distinct purpose, contributing to the overall operation and longevity of the machine.

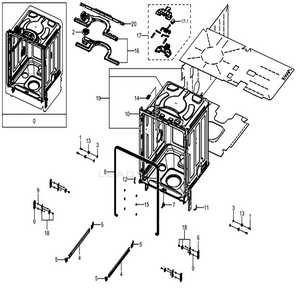

Supporting Structures

In addition to the core units, several supportive structures ensure stability and protection. These include external casings, internal supports, and connectors, all of which are crucial for maintaining the integrity and smooth operation of the device. Proper attention to these elements can enhance durability and reduce the likelihood of failures.

Understanding the Internal Structure

The inner layout of this model is a carefully organized system designed to ensure smooth operation and functionality. Every element within the construction plays a key role in contributing to the overall performance. By gaining insight into how these components interact and are positioned, users can better maintain and troubleshoot the device when necessary.

Examining the core features reveals a balance between efficiency and durability. These elements work in harmony to create a cohesive and reliable mechanism. Understanding the configuration helps in recognizing how the different sections complement each other, leading to optimal performance.

Proper upkeep of these internal elements is essential for long-term use. Knowing how the system is arranged allows for more effective maintenance, ensuring each piece functions as intended and the whole device remains in excellent condition.

Key Elements in the Assembly Process

Understanding the primary components involved in the assembly process is essential for achieving a smooth and efficient build. This section focuses on the core aspects that must be handled with precision to ensure optimal functionality and durability of the product.

Main Structural Components

The main structural elements form the backbone of the entire assembly. These include the foundational pieces that hold various mechanisms together, requiring careful alignment and secure fastening during the process.

Supportive Mechanisms

Supportive mechanisms are crucial for enhancing the stability and operation of the assembled unit. These components aid in balancing loads and facilitating the movement of interconnected parts, contributing to the overall performance.

| Component | Function |

|---|---|

| Primary Fasteners | Ensure firm connections between key sections. |

| Guide Rails | Help in the smooth movement of adjustable parts. |

| Reinforcement Frames | Provide extra support to critical areas. |

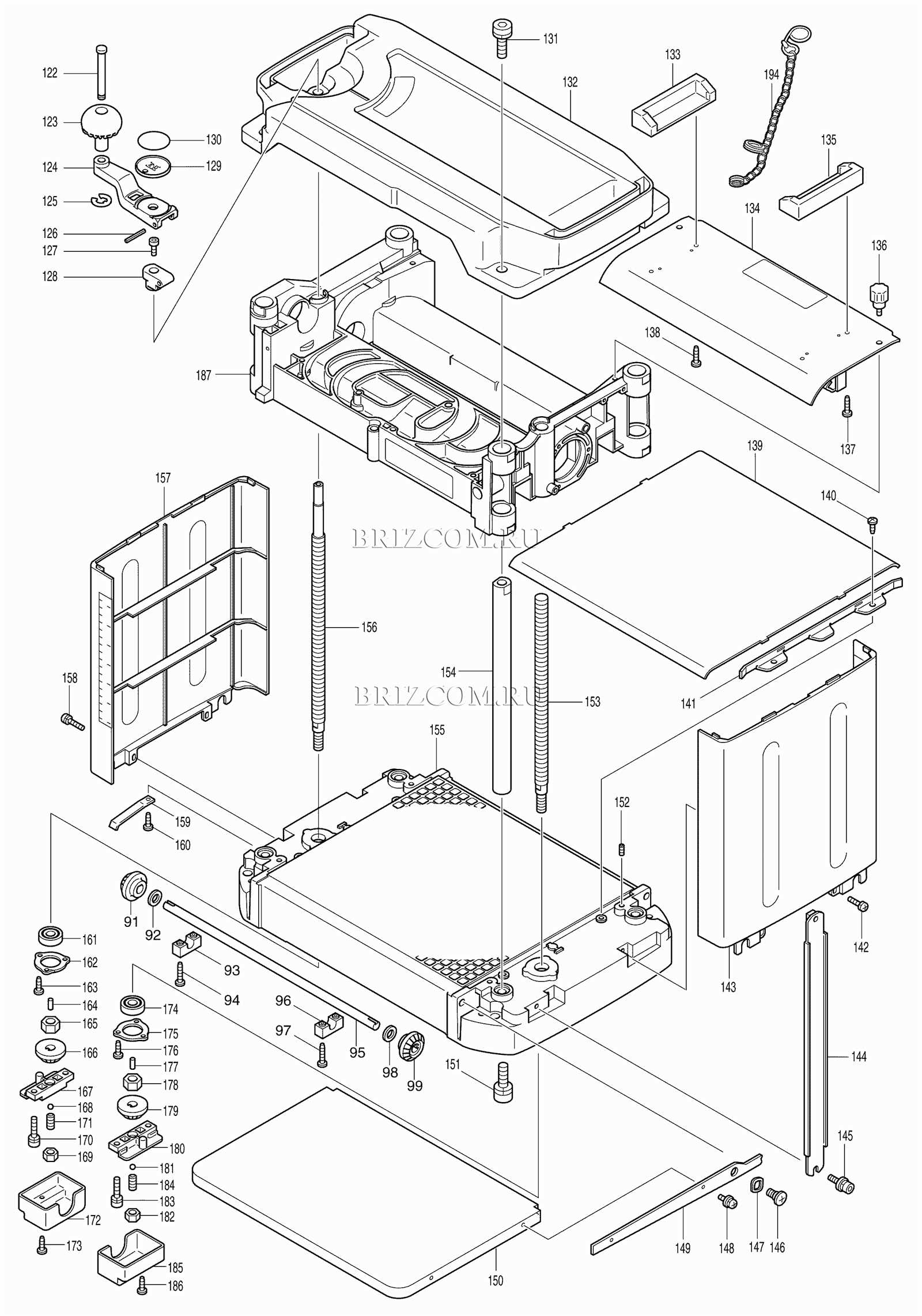

Primary Mechanisms and Their Functions

The key systems within this appliance work together to ensure efficient operation. Each component plays a crucial role in maintaining performance, from the control systems to the physical elements that contribute to functionality. Understanding how these parts interact offers insight into the overall structure and effectiveness of the unit.

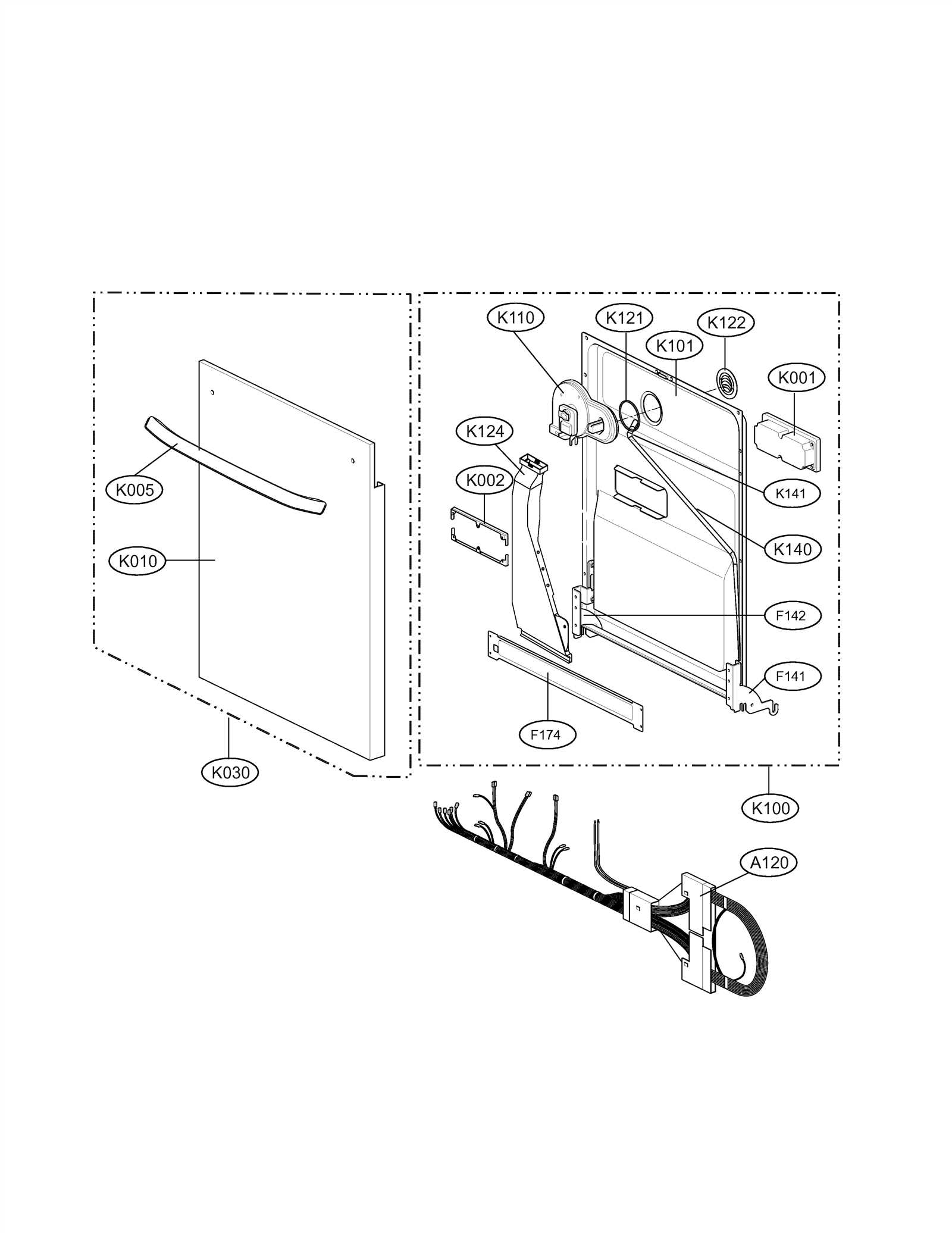

Control System

The control system manages the settings and operation of the device, allowing users to select options that best suit their needs. This mechanism regulates everything from energy consumption to specific task execution, ensuring optimal performance and user convenience.

Water Distribution System

This mechanism is responsible for ensuring that water flows through the unit as required. It distributes water evenly, ensuring thorough cleaning or operation, while also controlling the pressure and direction of flow. Proper water distribution is essential for the device to perform effectively.

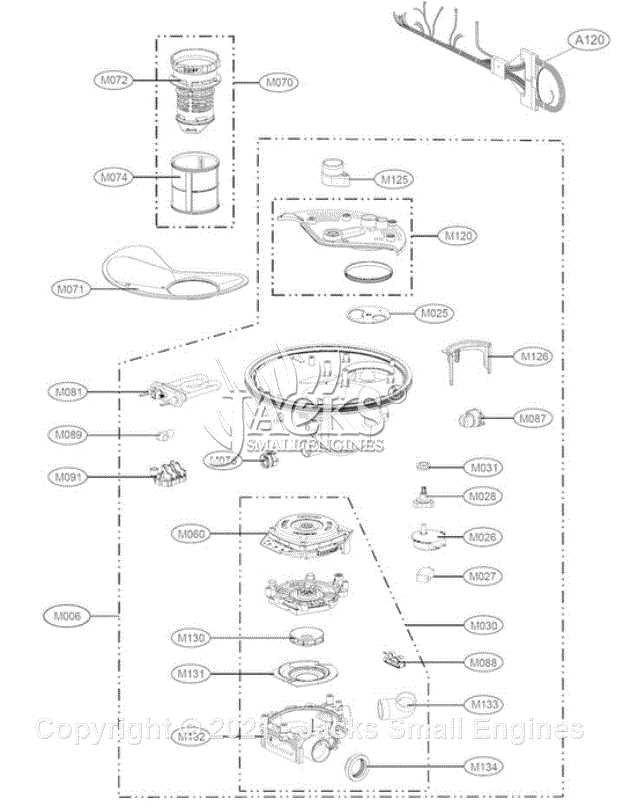

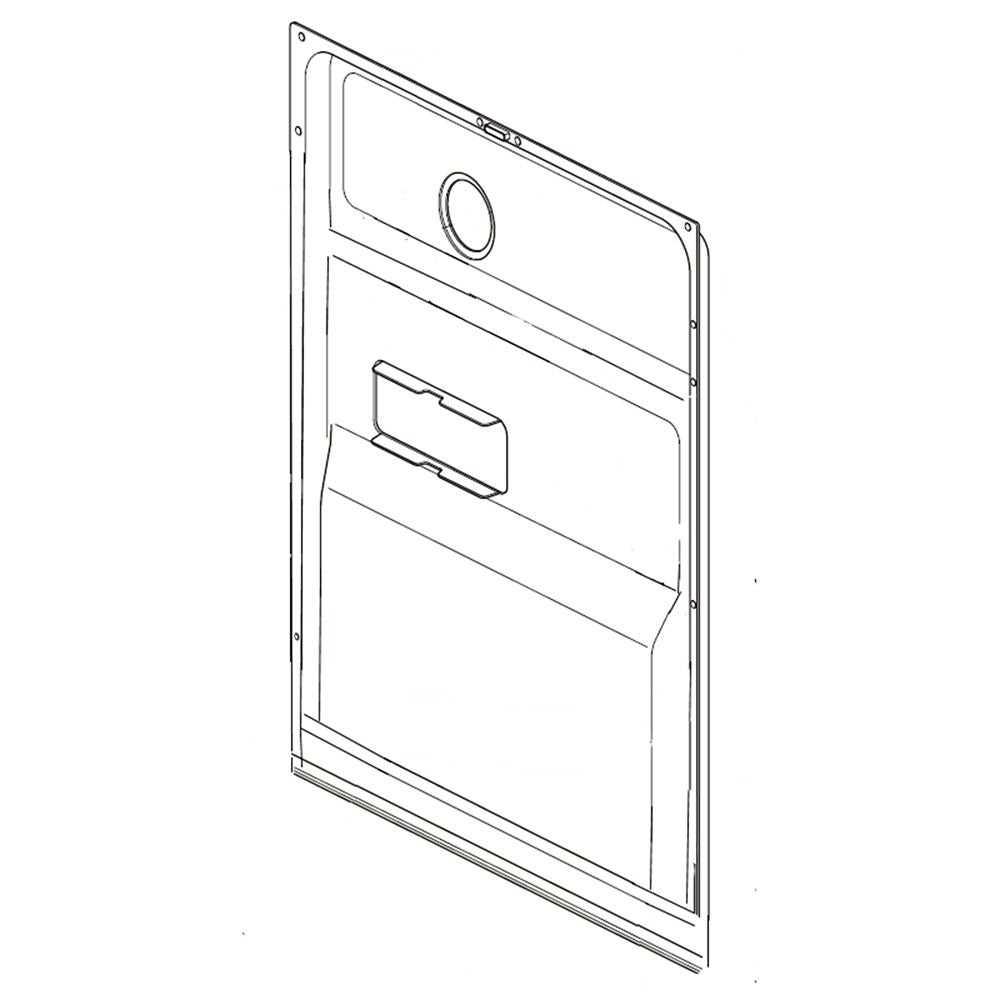

Visual Guide to Part Placement

Understanding how each component is organized and positioned is crucial for proper assembly and functionality. This section offers a clear and straightforward overview, helping you to identify where each element fits within the overall structure. By following this guide, you will be able to streamline the setup process and ensure everything is aligned correctly for optimal performance.

Key areas of the system are broken down step by step to assist in locating specific sections and ensuring compatibility between all elements. Precise placement is essential for smooth operation and avoiding potential issues, making it important to follow the outlined arrangement carefully.

Analyzing the Critical Connections

Understanding the essential linkages within any complex system is crucial for effective maintenance and troubleshooting. These connections serve as the backbone of functionality, ensuring that various components work harmoniously. By examining these relationships, one can identify potential points of failure and areas requiring attention.

Importance of Structural Relationships

The structural relationships among different elements play a significant role in the overall performance of the device. Each connection contributes to the system’s efficiency, affecting how energy flows and how signals are transmitted. Recognizing these interdependencies allows for better planning in repairs and upgrades.

Identifying Weak Points

Through careful analysis, weak points can be identified within the network of connections. Monitoring these vulnerable areas can prevent larger issues from arising, ultimately enhancing the longevity of the equipment. Utilizing a systematic approach to assess these connections will enable users to maintain optimal functionality.

Overview of Main and Auxiliary Systems

This section provides an insight into the primary and secondary systems that contribute to the overall functionality of the equipment. Understanding these components is essential for ensuring optimal performance and maintenance.

Main Systems

The primary systems are fundamental for the core operations of the device. These systems work in unison to achieve the desired outcomes. Key aspects include:

- Power Supply: The source that energizes the device, ensuring reliable operation.

- Control Mechanisms: These regulate the functions and operations, allowing for user inputs and automated processes.

- Heating or Cooling Elements: Vital for temperature regulation, affecting overall efficiency and performance.

Auxiliary Systems

Secondary systems play a supportive role, enhancing the functionality of the main components. Their contributions include:

- Safety Features: These ensure the safe operation of the equipment, preventing potential hazards.

- Monitoring Systems: These track performance and alert users to any irregularities, enabling timely interventions.

- Maintenance Tools: Essential for regular upkeep, these tools assist in prolonging the lifespan of the device.

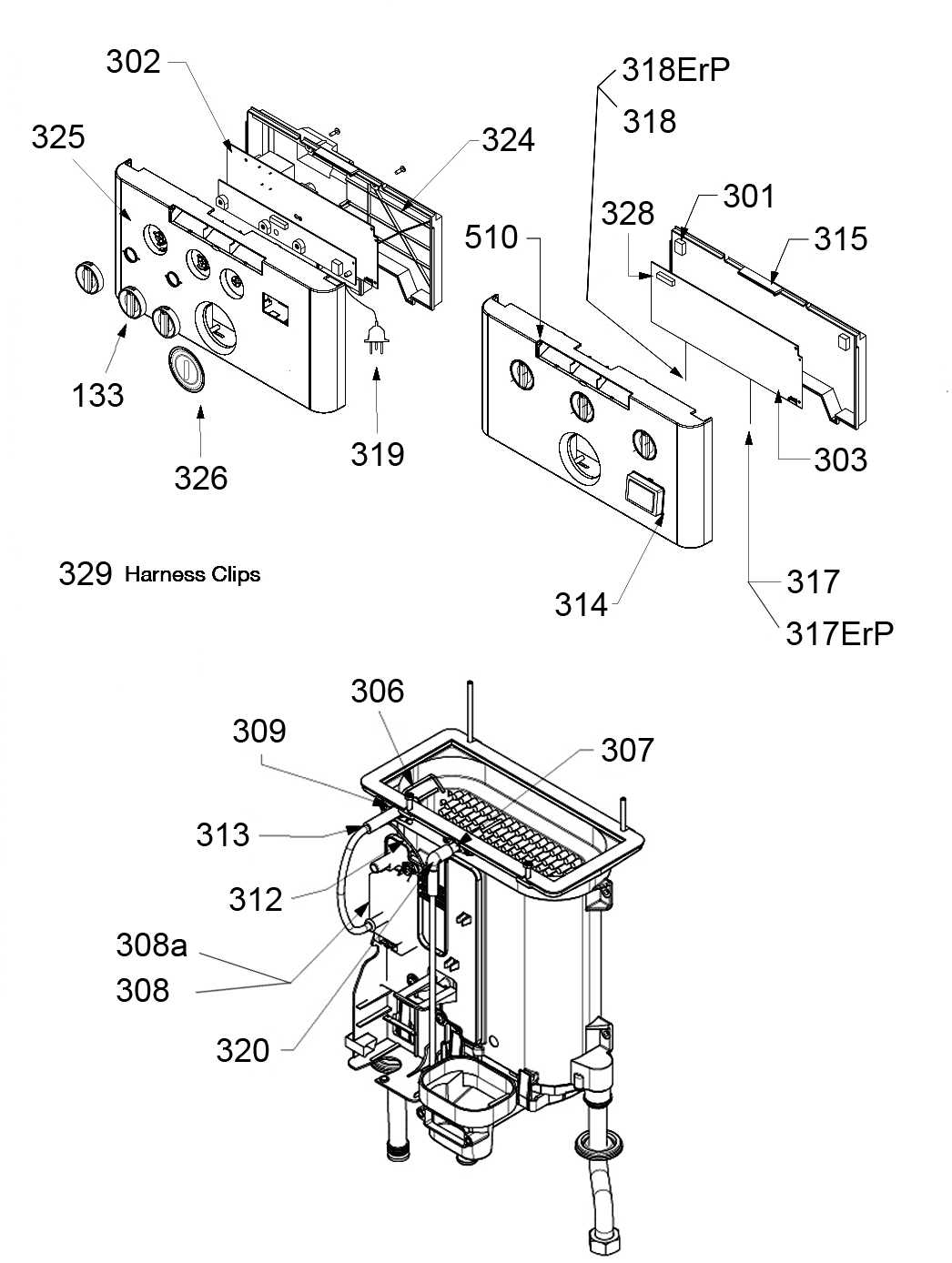

Identifying Replaceable Components

Understanding which elements of a device can be swapped out is essential for maintenance and repair. By recognizing the various replaceable units, users can ensure optimal functionality and longevity of their equipment. This section outlines the critical components that may require replacement over time.

Commonly Replaceable Units

Several key elements are often designed to be interchangeable. These include:

| Component Name | Description | Replacement Frequency |

|---|---|---|

| Filter | Captures impurities to maintain system efficiency. | Every 6 months |

| Seals | Prevents leaks and ensures proper functioning of moving parts. | Annually |

| Fan | Regulates temperature and prevents overheating. | As needed |

Importance of Regular Assessment

Regular evaluation of these components is crucial for maintaining performance. Proactive replacement not only enhances efficiency but also extends the overall lifespan of the device.

Common Issues Related to Specific Parts

Understanding the common challenges associated with individual components is crucial for maintaining optimal functionality. These issues often arise from wear and tear, improper installation, or external factors that can affect performance. By recognizing these problems, users can implement effective solutions and ensure longevity.

Frequent Malfunctions

One of the most prevalent issues involves malfunctions that can stem from a variety of sources. For example, components may become damaged due to overheating or exposure to moisture, leading to inefficient operation. Regular inspection can help identify these malfunctions early, allowing for timely repairs.

Maintenance Tips

To prevent common issues, it’s essential to adhere to recommended maintenance practices. Regular cleaning and lubrication of moving parts can significantly enhance performance. Additionally, consulting the user manual for specific guidelines will provide insights into how to care for these components effectively.

Maintaining the Integrity of the System

Ensuring the robustness of a system is crucial for its longevity and efficient operation. Regular attention to its components and functionalities contributes significantly to preventing potential issues that could compromise overall performance.

Routine inspections are essential for identifying any wear or damage that may occur over time. By proactively checking the various elements, one can address minor problems before they escalate into major failures. This approach not only safeguards the equipment but also enhances reliability during usage.

Moreover, it is vital to follow maintenance guidelines provided by the manufacturer. These guidelines offer valuable insights into the recommended practices for upkeep, including cleaning, adjustments, and necessary replacements. Adhering to these instructions helps maintain optimal operation and extends the life of the system.

Additionally, utilizing quality materials and components during any repairs or replacements plays a significant role in preserving system integrity. Investing in high-quality items ensures compatibility and durability, reducing the likelihood of future complications. Ultimately, a well-maintained system leads to improved performance and user satisfaction.