Understanding the Husqvarna 460 Parts Diagram for Efficient Repairs

In the realm of outdoor machinery, having a comprehensive grasp of the individual elements that make up your tools is essential for optimal performance. Each component plays a vital role, influencing both functionality and longevity. A clear visual representation can aid in recognizing these parts, allowing for more effective maintenance and repairs.

Utilizing an illustrative guide not only simplifies the identification process but also enhances your ability to address potential issues. When you can pinpoint the specific elements that may require attention, you empower yourself to make informed decisions about servicing your equipment.

By delving into the intricacies of these components, users can ultimately ensure that their machines operate at peak efficiency. Understanding how each piece interacts fosters a deeper connection to your tools, leading to improved care and longevity.

Understanding the Husqvarna 460 Model

This section aims to explore the intricacies of a popular power tool model known for its reliability and performance. Understanding its components and functionality is essential for effective operation and maintenance. By delving into its design and mechanisms, users can enhance their experience and longevity of the equipment.

Key Features: The model showcases a robust construction, making it suitable for various tasks. Its ergonomic design ensures comfort during extended use, while advanced technology enhances efficiency.

Maintenance Tips: Regular upkeep is crucial to ensure optimal performance. Familiarity with the internal mechanisms aids in troubleshooting and repairs, allowing for a seamless user experience.

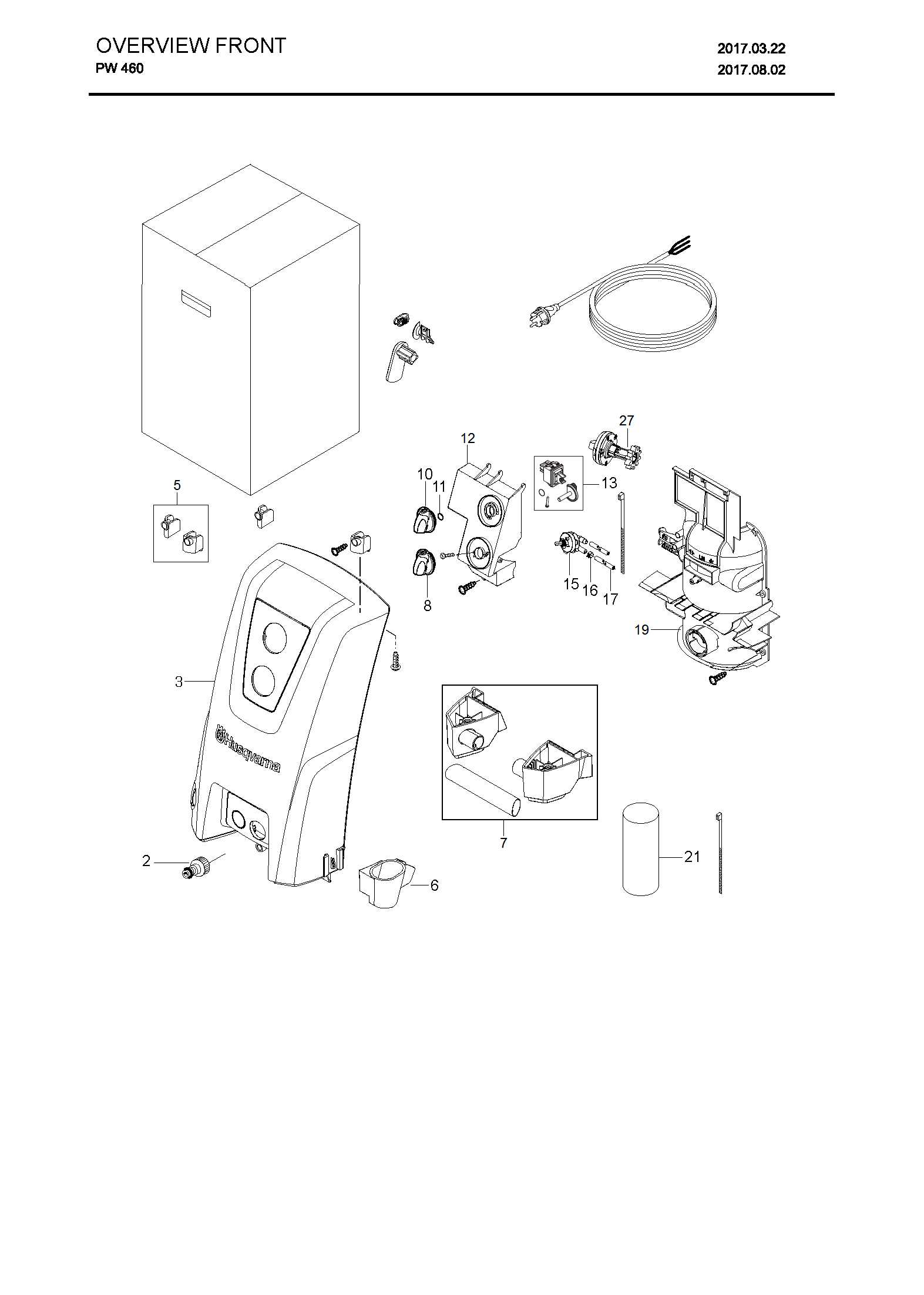

Importance of Parts Diagrams

Visual representations of components are crucial for understanding the assembly and functionality of various machinery. These illustrations serve as essential tools for maintenance, repair, and troubleshooting, enabling users to identify each element and its relationship within the whole system.

Benefits of Visual Representations

- Enhanced understanding of the machinery

- Streamlined maintenance processes

- Facilitated troubleshooting and repairs

- Reduced risk of errors during reassembly

Conclusion

Utilizing such visual aids not only simplifies complex procedures but also ensures that users can effectively manage their equipment, leading to better performance and longevity.

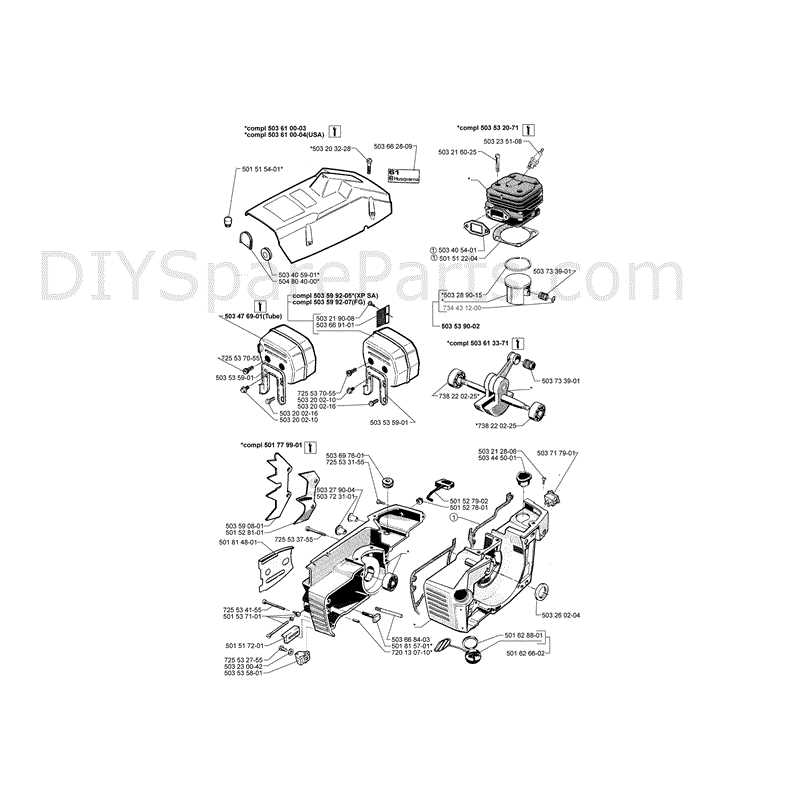

Common Components of the Chainsaw

Understanding the essential elements of a cutting tool is crucial for its effective operation and maintenance. Each component plays a vital role in ensuring the machine performs optimally, making it important for users to familiarize themselves with these parts. From the power source to the cutting mechanism, each piece contributes to the overall functionality and efficiency of the device.

Engine: The heart of the tool, the engine generates the necessary power for operation. Typically found in two-stroke or four-stroke designs, the engine’s efficiency directly affects performance.

Bar: This long, flat piece serves as the guide for the chain, allowing for precision cutting. The length and design of the bar can vary based on the intended use and type of material being cut.

Chain: The cutting element that wraps around the bar, the chain consists of sharp teeth that rotate at high speeds to slice through wood. Maintenance of the chain, including sharpening and tension adjustments, is essential for safety and effectiveness.

Fuel System: This system includes the fuel tank and carburetor, working together to ensure the engine receives the right mixture of fuel and air. Proper maintenance of this system is critical for optimal engine performance.

Safety Features: Modern cutting tools are equipped with various safety components, such as chain brakes and anti-vibration systems, to protect the user during operation. Understanding these features enhances safe handling and reduces the risk of accidents.

By gaining knowledge about these fundamental components, users can ensure better maintenance and a more efficient cutting experience.

How to Read the Diagram

Understanding a technical illustration can significantly enhance your ability to service or repair machinery effectively. These visuals serve as a roadmap, guiding you through the components and their relationships. By familiarizing yourself with the symbols, notations, and layout, you can streamline your repair process and ensure that you have all necessary elements at hand.

Identifying Components

Each element in the illustration is usually labeled clearly, allowing you to easily identify specific parts. Look for alphanumeric codes that correspond to parts lists, providing crucial information about sizes, shapes, and functions. Familiarizing yourself with these identifiers is essential for accurate replacement or maintenance.

Understanding Connections

Beyond identifying individual components, pay attention to how they connect with one another. Lines and arrows typically indicate the relationships and pathways between parts, highlighting how they work together within the system. Understanding these connections is vital for troubleshooting and ensuring that everything functions smoothly.

Essential Tools for Repair

When tackling maintenance or fixing machinery, having the right instruments is crucial for achieving optimal results. This section will explore the must-have tools that facilitate effective repairs, ensuring both efficiency and safety in the process.

Basic Hand Tools

Start with a solid set of hand tools. Screwdrivers, wrenches, and pliers are indispensable for various tasks. A well-organized toolkit allows for quick access to the instruments needed for disassembly and assembly, making the repair process smoother and more efficient.

Specialized Equipment

In addition to basic tools, having specialized equipment can make a significant difference. Torque wrenches ensure that fasteners are tightened to the manufacturer’s specifications, while calipers and measuring tapes help in accurate assessments of components. Investing in these tools enhances precision and prolongs the lifespan of the equipment being serviced.

Identifying Wear and Tear

Recognizing the signs of deterioration in equipment is crucial for maintaining optimal performance and longevity. Various components can exhibit wear due to regular usage, environmental factors, and the nature of tasks performed. Early detection can prevent costly repairs and enhance safety during operation.

Common Indicators

Look for visible signs such as cracks, discoloration, or unusual wear patterns. Additionally, listen for strange noises during operation, as these can signal underlying issues. Regular inspections are essential for identifying these problems before they escalate.

Importance of Timely Intervention

Addressing wear promptly not only extends the life of the machinery but also ensures optimal efficiency. Neglecting these signs can lead to more significant failures, resulting in downtime and increased costs. Prioritize routine checks to safeguard your equipment.

Replacement Parts Availability

When it comes to maintaining outdoor power equipment, accessibility to components is crucial for ensuring optimal performance and longevity. A well-stocked inventory of replacement elements can significantly enhance the efficiency of repairs and upgrades. Understanding where to find these essential items is vital for users aiming to keep their machinery in peak condition.

Local Retailers often serve as the first point of contact for those in need of specific components. These establishments typically carry a selection of frequently used items, making it convenient for immediate repairs. However, availability may vary based on location and demand.

Online Platforms have transformed the way users procure essential items. Numerous websites specialize in offering a wide range of components, often providing detailed descriptions and compatibility information. This allows users to easily compare prices and find the exact items they require without leaving their homes.

Manufacturer Networks play a pivotal role in ensuring that high-quality replacements are available. Many brands maintain official channels through which users can order specific components directly. This not only guarantees authenticity but also provides access to the latest innovations and improvements.

In summary, having reliable access to necessary components is essential for effective maintenance and repair of outdoor equipment. By exploring local shops, online resources, and official manufacturer channels, users can ensure their machinery remains in top working order.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the lifespan of your outdoor equipment. By following a consistent maintenance routine, you can enhance performance, reduce wear, and ensure reliable operation over time.

Routine Checks

- Inspect the air filter regularly for clogs and clean or replace as necessary.

- Check spark plugs for wear; replace them if they show signs of damage.

- Examine fuel lines for leaks and ensure connections are secure.

Cleaning and Lubrication

- Clean the exterior of the machine to prevent dirt buildup.

- Lubricate moving parts according to the manufacturer’s guidelines.

- Ensure that the cutting equipment is sharp and properly aligned for optimal performance.

Upgrading Your Husqvarna 460

Enhancing your outdoor power tool can significantly improve its performance and longevity. By focusing on specific upgrades, you can achieve greater efficiency and reliability for your tasks.

Consider the following upgrades to elevate your equipment:

- Engine Performance: Installing a high-performance air filter can enhance airflow, leading to better combustion.

- Chain Options: Upgrading to a premium chain can provide smoother cuts and extend blade life.

- Handle Grip: A rubberized grip improves control and comfort during extended use.

- Anti-Vibration Technology: Adding vibration dampeners can reduce fatigue and improve handling.

Each of these enhancements can help you delve deeper into the capabilities of your tool, allowing for an ultimate user experience.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a safe working environment is paramount. Proper precautions can prevent accidents and injuries, allowing for a more efficient repair process. Always be aware of potential hazards and prepare accordingly to protect yourself and others.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. This includes safety goggles to shield your eyes, gloves to protect your hands, and sturdy footwear to safeguard your feet. Investing in quality gear can significantly reduce the risk of injury during repairs.

Work Environment Safety

Maintaining a clean and organized workspace is crucial. Ensure tools are easily accessible, and eliminate clutter to prevent tripping hazards. Additionally, work in a well-ventilated area to avoid inhaling harmful fumes. By prioritizing safety, you can delve into repairs with confidence and focus on achieving ultimate results.

Frequently Asked Questions

This section addresses common inquiries related to the components and maintenance of outdoor equipment. Here, you will find answers to some of the most frequently posed questions that users encounter while dealing with their machinery.

| Question | Answer |

|---|---|

| What are the essential components of my equipment? | The primary parts typically include the engine, fuel system, air filter, and ignition system, among others. |

| How can I identify a faulty component? | Signs of malfunction may include unusual noises, poor performance, or visible damage to any part. |

| Where can I find replacement parts? | Replacement components can be sourced from authorized dealers, online retailers, or specialty shops. |

| How often should I perform maintenance? | Regular maintenance is recommended after a specific number of operating hours, typically outlined in the user manual. |

| What tools do I need for basic repairs? | A standard toolkit with wrenches, screwdrivers, and pliers is usually sufficient for most minor repairs. |

Where to Find Official Resources

Accessing reliable information and components for your equipment is essential for maintenance and repair. Official resources provide the most accurate and up-to-date details, ensuring you can effectively manage your tools. Utilizing these sources can greatly enhance your understanding and performance.

Start by visiting the manufacturer’s official website, where you can often find comprehensive guides and manuals. Many brands also offer customer support sections, allowing for direct inquiries. Additionally, authorized dealers and service centers can provide specific information and genuine items, ensuring quality and compatibility.