Understanding the Ryobi BC30 Parts Diagram for Efficient Repairs

Every mechanical device consists of numerous individual elements that work in unison to deliver optimal performance. Understanding the layout and function of these components is essential for effective maintenance and troubleshooting. By familiarizing yourself with these intricate details, you can ensure that your machine operates smoothly and efficiently.

In this section, we will explore the essential features and individual parts of a specific model. We will provide a clear representation that highlights the relationships between various components, making it easier for users to identify and understand each section of their equipment. A comprehensive overview can significantly enhance your ability to care for and repair your machinery.

By delving into the specifics of your device, you’ll gain valuable insights that can help you make informed decisions about repairs, replacements, and upgrades. This knowledge not only prolongs the lifespan of your equipment but also enhances its overall functionality, ensuring you get the most out of your investment.

Understanding Ryobi BC30 Components

This section delves into the essential elements that make up a specific model of outdoor equipment, providing a comprehensive overview of its structure and functionality. By familiarizing oneself with these components, users can enhance their operational efficiency and maintenance practices.

Key Elements and Their Functions

Every piece of equipment comprises various critical elements, each serving a unique purpose. Understanding these parts not only aids in troubleshooting but also contributes to better performance and longevity of the device.

| Component | Description |

|---|---|

| Engine | Powers the machine, converting fuel into mechanical energy. |

| Trimmer Head | Holds the cutting line and allows for efficient trimming of vegetation. |

| Shaft | Connects the engine to the trimmer head, transmitting power effectively. |

| Handle | Provides stability and control, allowing for comfortable operation. |

| Guard | Protects the user from debris and ensures safe operation. |

Maintenance Tips

Regular inspection and maintenance of each component are crucial for optimal performance. Users should be attentive to wear and tear, replacing or repairing parts as needed to ensure efficiency and safety during use.

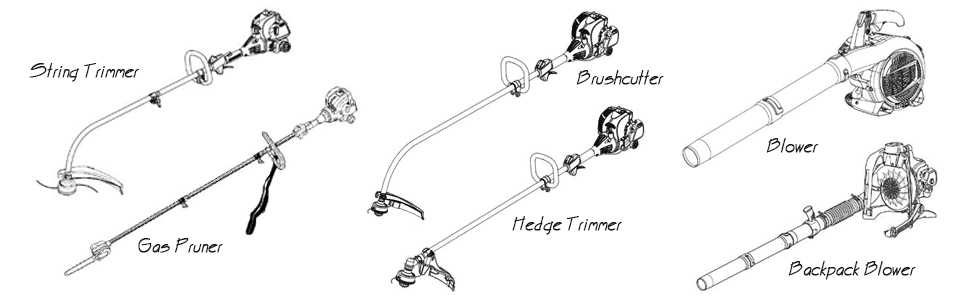

Overview of the BC30 Model

This model is designed for users who seek efficiency and reliability in their outdoor tasks. It combines robust engineering with user-friendly features, making it suitable for both casual users and professionals. Its versatile applications range from trimming to clearing, enhancing its appeal across various gardening and landscaping needs.

Key Features

- Powerful engine for optimal performance

- Lightweight design for ease of handling

- Durable materials ensuring long-lasting use

- Adjustable components for user comfort

- Easy maintenance for hassle-free operation

Applications

- Trimming overgrown grass and weeds

- Clearing brush and small shrubs

- Maintaining pathways and gardens

- Performing light landscaping tasks

This model stands out for its blend of power and convenience, making it a reliable choice for various outdoor activities.

Key Features of Ryobi Trimmers

When it comes to maintaining a pristine outdoor space, a reliable cutting tool is essential. These versatile devices stand out due to their innovative design and user-friendly functionality, making them ideal for both casual users and gardening enthusiasts. Understanding their key attributes can help users select the right model for their needs.

Versatile Performance

These cutting machines offer an array of performance features that enhance their usability:

- Adjustable Cutting Width: Many models provide options for customizing the cutting width, allowing for efficiency in various gardening tasks.

- Multiple Power Sources: Users can choose between electric and battery-powered options, catering to different preferences and requirements.

- Lightweight Design: Most units are designed for easy handling, reducing fatigue during prolonged use.

User-Friendly Features

Convenience and ease of use are also significant aspects:

- Easy String Replacement: Quick-load spool systems simplify the process of replacing cutting lines, saving time and effort.

- Adjustable Handles: Ergonomically designed handles can be adjusted for comfort, providing better control during operation.

- Safety Features: Built-in safety mechanisms ensure user protection, making these tools suitable for a wide range of users.

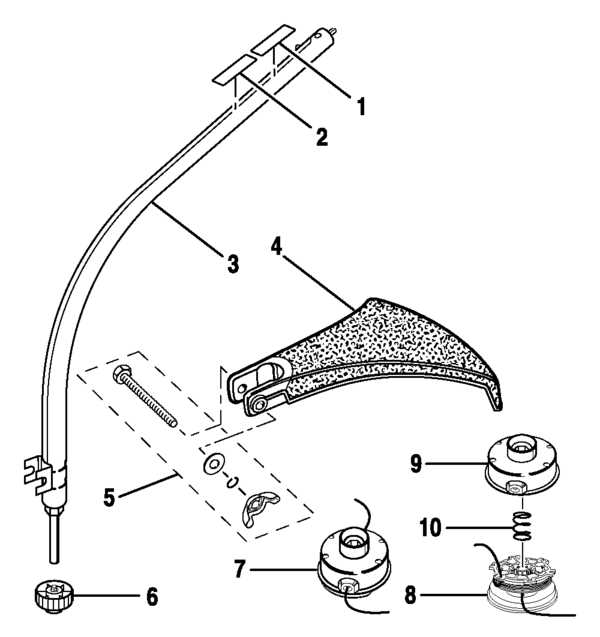

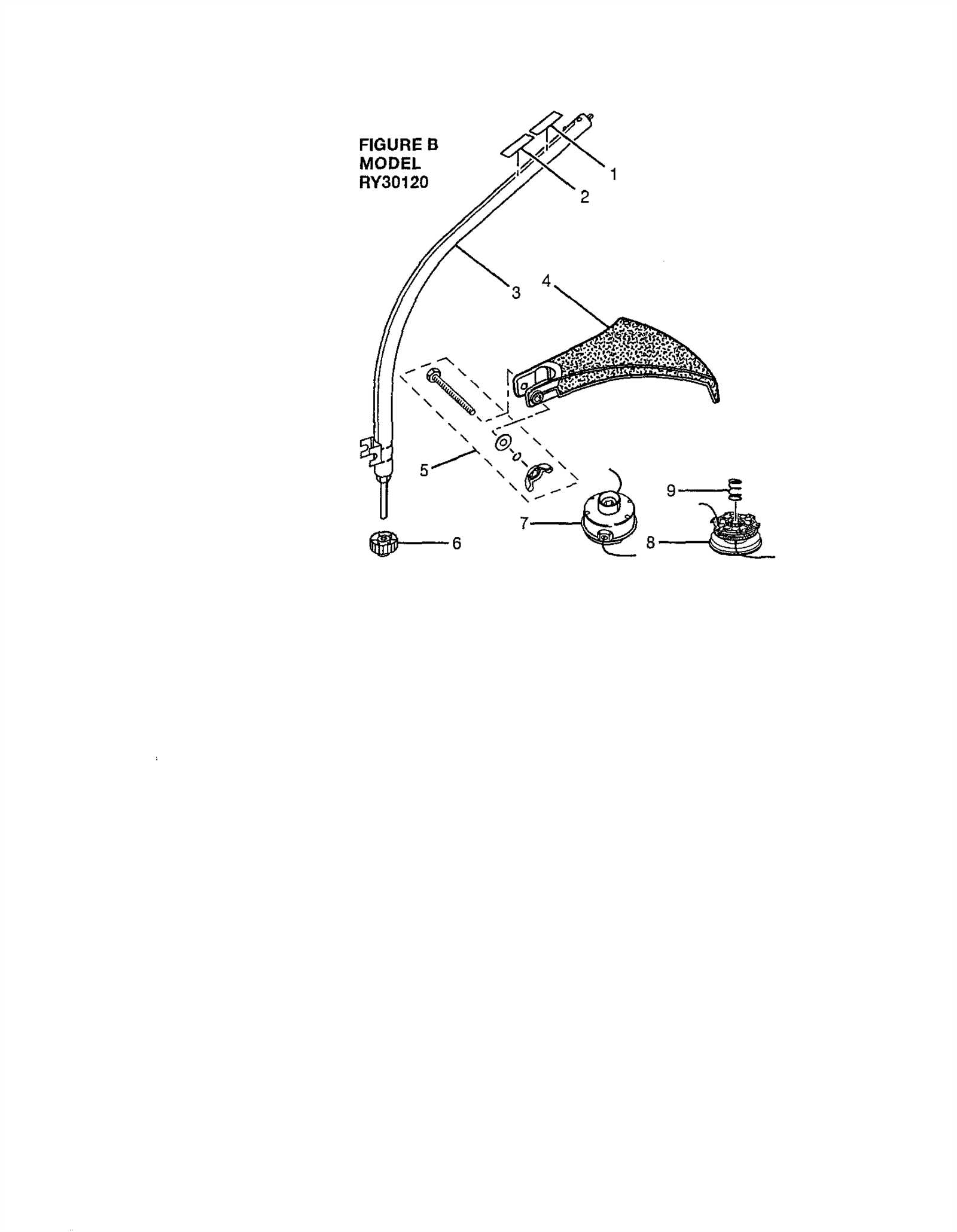

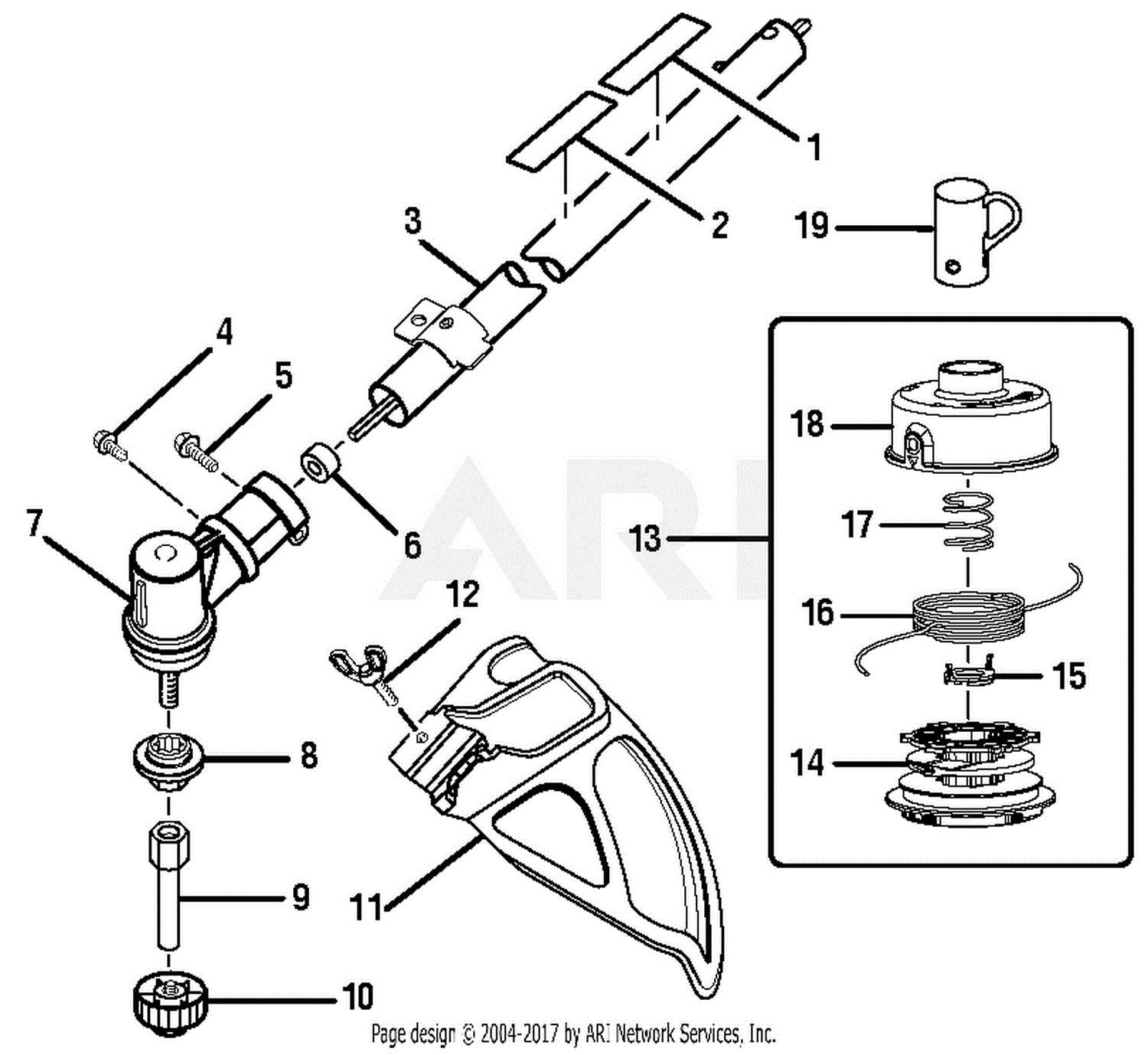

Importance of Parts Diagrams

Understanding the various components of machinery is crucial for effective maintenance and repair. Visual representations play a significant role in illustrating how each element fits together, enabling users to identify and locate specific parts with ease. This knowledge is essential not only for troubleshooting but also for optimizing performance and longevity.

Enhancing Maintenance Efficiency

Utilizing schematic visuals can greatly improve the efficiency of maintenance tasks. Here are some key benefits:

- Clear identification of components, reducing time spent searching.

- Facilitates understanding of assembly and disassembly processes.

- Helps in recognizing wear and tear on individual pieces.

Supporting Replacement and Repair Decisions

When it comes to replacing or repairing parts, detailed visuals are invaluable. They provide:

- A reference for selecting the correct replacement items.

- Guidance on the proper tools needed for repairs.

- A visual checklist to ensure all necessary components are addressed during maintenance.

In summary, these visual aids are essential tools that enhance both the understanding and execution of maintenance tasks, ensuring equipment operates smoothly and efficiently.

Common Issues with BC30 Parts

When working with small engine equipment, users often encounter various challenges related to components and their functionality. Understanding these common problems can significantly improve maintenance and enhance performance.

Wear and Tear: Over time, essential components may degrade due to frequent use. This deterioration can lead to reduced efficiency and potential failure. Regular inspections can help identify these issues early.

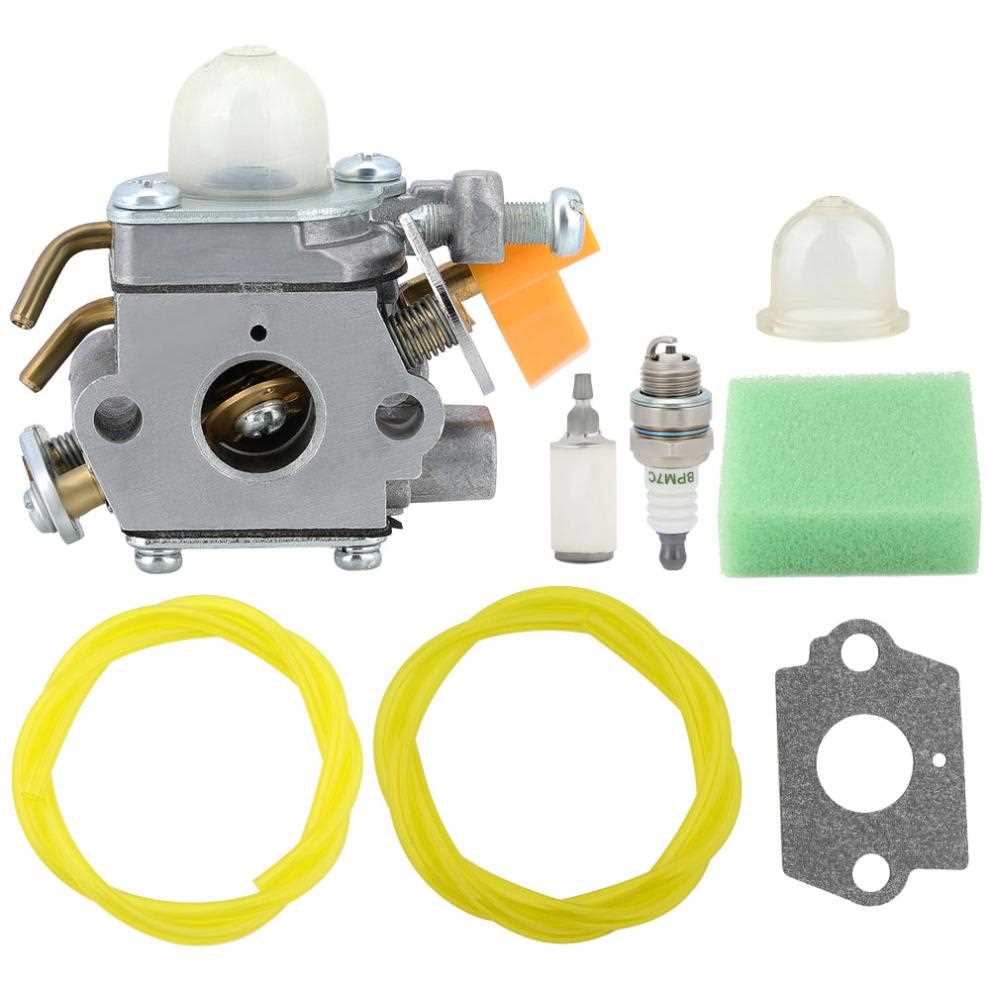

Fuel System Problems: Clogs in the fuel delivery system can hinder performance. Blocked filters or damaged lines may prevent the engine from receiving adequate fuel, causing stalling or poor acceleration. Cleaning and replacing these parts as needed is crucial.

Ignition Failures: Issues with the ignition system can lead to starting difficulties. Worn-out spark plugs or faulty ignition coils are common culprits. Regular checks can ensure reliable ignition and smooth operation.

Vibration and Noise: Excessive vibration or noise may indicate loose or damaged components. This can not only affect the machine’s operation but also lead to further damage if not addressed. Tightening bolts and inspecting parts can mitigate these concerns.

Corrosion: Exposure to moisture can lead to rust and corrosion, particularly on metal components. This deterioration can compromise the integrity of the machine. Keeping equipment clean and dry can help prevent these issues.

By recognizing these typical challenges and implementing preventative measures, users can maintain their equipment more effectively and prolong its lifespan.

How to Access the Diagram

To effectively locate the schematic for your equipment, you need to follow a series of straightforward steps. Understanding where to find reliable sources is crucial for maintaining and repairing your tools efficiently. This guide outlines the best methods to access detailed illustrations that will aid in identifying components and their configurations.

Online Resources

One of the most convenient ways to obtain the necessary illustrations is through various online platforms. Manufacturer websites often provide comprehensive resources for users. Additionally, specialized forums and community groups can serve as valuable repositories of information.

| Source | Description |

|---|---|

| Official Website | Check the manufacturer’s site for official manuals and resources. |

| Online Retailers | Some retailers offer downloadable manuals along with product listings. |

| Forums | Participate in discussions where users share insights and documents. |

Physical Manuals

In addition to online sources, consider consulting physical manuals that may have accompanied your equipment. These documents often contain detailed images and explanations of each part. If you cannot find your original manual, check local libraries or bookstores for replacement copies.

Identifying Each Component

Understanding the various elements of a machine is essential for effective maintenance and repair. Each part plays a specific role in ensuring the device functions smoothly. By recognizing these components, users can troubleshoot issues more efficiently and enhance the longevity of their equipment.

| Component Name | Description |

|---|---|

| Engine | The heart of the device, responsible for power generation. |

| Handle | Provides a grip for maneuvering the equipment comfortably. |

| Fuel Tank | Holds the fuel necessary for operation, ensuring a steady supply. |

| Throttle Control | Regulates engine speed and power output based on user input. |

| Cutting Head | The component that houses the cutting mechanism, crucial for performance. |

| Safety Guard | Protects the user from debris and enhances operational safety. |

| Starter Mechanism | Facilitates the initial ignition of the engine for operation. |

Replacement Parts Availability

Access to essential components is crucial for maintaining and repairing outdoor equipment. Whether you’re looking to replace worn-out items or upgrade specific features, knowing where to find high-quality alternatives can significantly enhance your experience. Various sources offer a wide range of options, ensuring that users can keep their tools in optimal condition for longer periods.

Sources for Components

Numerous retailers specialize in outdoor equipment and often carry a comprehensive selection of individual items. Online marketplaces provide convenient access to numerous suppliers, allowing users to compare prices and availability easily. Additionally, local hardware stores might stock essential components, making it simple for individuals to acquire what they need without long wait times.

Considerations for Quality

When searching for replacements, it’s vital to assess the quality of the items. Opting for reputable brands and trusted suppliers ensures durability and performance. Reading reviews and seeking recommendations can also guide users toward reliable sources, helping to avoid potential issues associated with inferior products.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular care and attention. By implementing a few straightforward maintenance practices, you can enhance performance and avoid premature wear and tear. This section outlines essential strategies to keep your tools in optimal condition.

Regular Cleaning

One of the simplest yet most effective ways to prolong the life of your machinery is through consistent cleaning. After each use, remove dirt, debris, and any residue that may accumulate. This helps prevent corrosion and maintains the functionality of moving parts. Utilize a soft brush or cloth to gently clean surfaces, paying special attention to hard-to-reach areas.

Lubrication and Inspections

Routine lubrication is vital for smooth operation. Use the recommended lubricants to minimize friction and protect internal components. Additionally, conduct regular inspections to identify any signs of wear, such as cracks or loose fittings. Addressing minor issues promptly can prevent them from escalating into significant problems.

Incorporating these maintenance tips into your regular routine will not only enhance performance but also ensure that your equipment remains reliable for years to come.

Tools Required for Repairs

When undertaking maintenance or restoration of outdoor equipment, having the right instruments is essential for a successful outcome. Proper tools not only facilitate the repair process but also ensure safety and efficiency, making the task manageable and less time-consuming.

Firstly, a screwdriver set is crucial for loosening and tightening various screws. Both flat-head and Phillips screwdrivers should be included to accommodate different fasteners. Additionally, a wrench set will be necessary for working with nuts and bolts, providing the leverage needed for effective manipulation.

Another important tool is a socket set, which offers versatility for tasks requiring more precise torque application. For adjustments that involve small components, a precision tool kit may be useful, including tweezers and small pliers to handle delicate pieces safely.

Moreover, keeping a work light handy can greatly improve visibility, particularly in poorly lit areas, helping to avoid mistakes during repairs. Finally, don’t overlook the significance of a repair manual or guide, which can provide valuable insights and instructions specific to the equipment you are working on.

Step-by-Step Repair Process

This section outlines a comprehensive guide to efficiently resolving issues with your equipment. By following a systematic approach, you can identify the problem, gather the necessary tools, and execute repairs with confidence.

1. Identify the Issue: Begin by closely examining the device to pinpoint the source of the malfunction. Look for unusual sounds, leaks, or performance drops, and note any symptoms that may provide insight into the underlying problem.

2. Gather Necessary Tools: Ensure you have all required instruments and replacement components on hand. Common tools may include screwdrivers, wrenches, pliers, and safety gear to protect yourself during the repair.

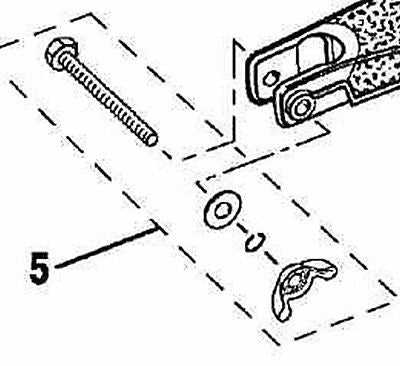

3. Disassemble the Unit: Carefully take apart the device, making sure to keep track of each component. Organizing parts as you remove them will facilitate easier reassembly later.

4. Inspect Individual Components: Examine each part for signs of wear or damage. Look for cracks, corrosion, or any other anomalies that could contribute to the malfunction.

5. Replace Defective Parts: If you find any faulty components, replace them with new or refurbished ones. Ensure that the new parts are compatible with your specific model to avoid further issues.

6. Reassemble the Equipment: Once all necessary replacements have been made, carefully reassemble the device. Follow your initial organization strategy to ensure all parts are returned to their correct positions.

7. Test the Device: After reassembly, perform a thorough test to confirm that the repair was successful. Observe the equipment in action to verify that it operates as intended.

8. Maintain Regular Checks: To prevent future issues, establish a routine maintenance schedule. Regular inspections can help catch potential problems early, ensuring longevity and performance of your equipment.

Safety Precautions During Repair

When engaging in maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also ensure that the equipment remains in good working condition.

Firstly, always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. This gear acts as a barrier against potential hazards, including sharp edges and flying debris.

Secondly, ensure that the equipment is powered down and disconnected from any power source before starting any work. This step minimizes the risk of accidental activation, which could lead to severe injuries.

Additionally, keep your workspace organized and free from clutter. A tidy environment reduces the chances of slips and falls, making it easier to locate tools and parts when needed.

Finally, if you are unfamiliar with certain components or procedures, consult the manufacturer’s guidelines or seek professional assistance. Understanding the equipment is crucial to performing repairs safely and effectively.