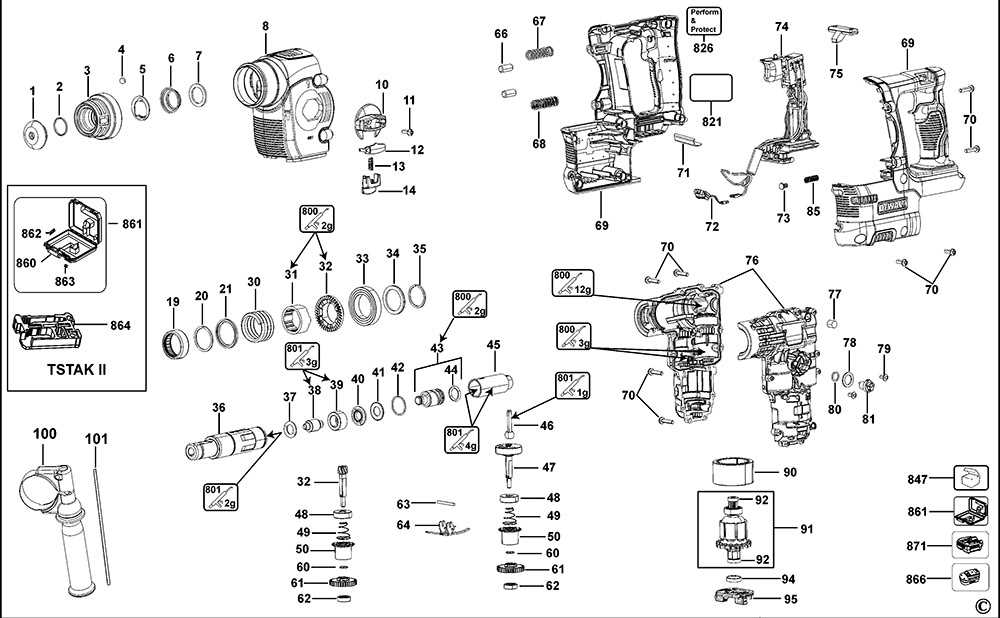

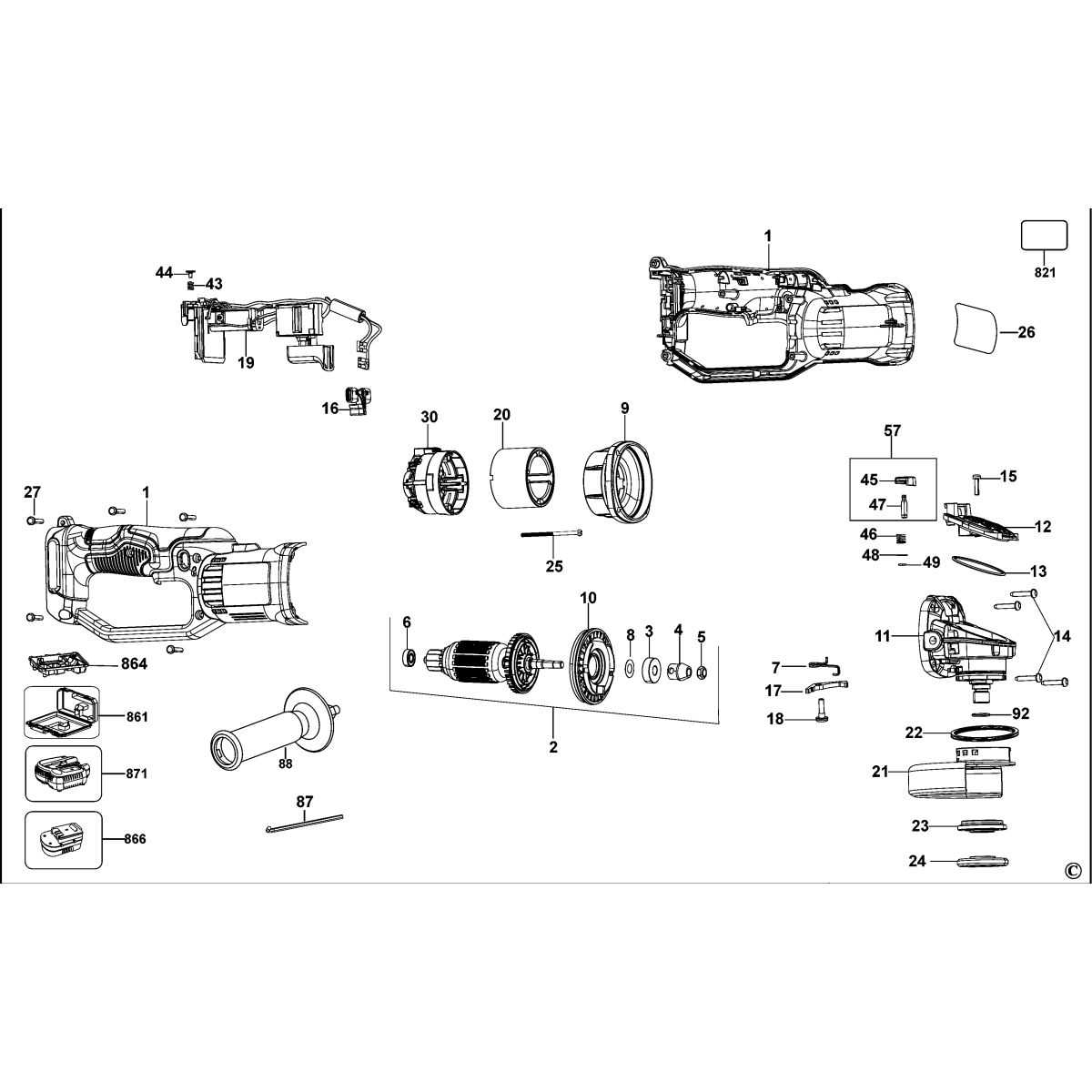

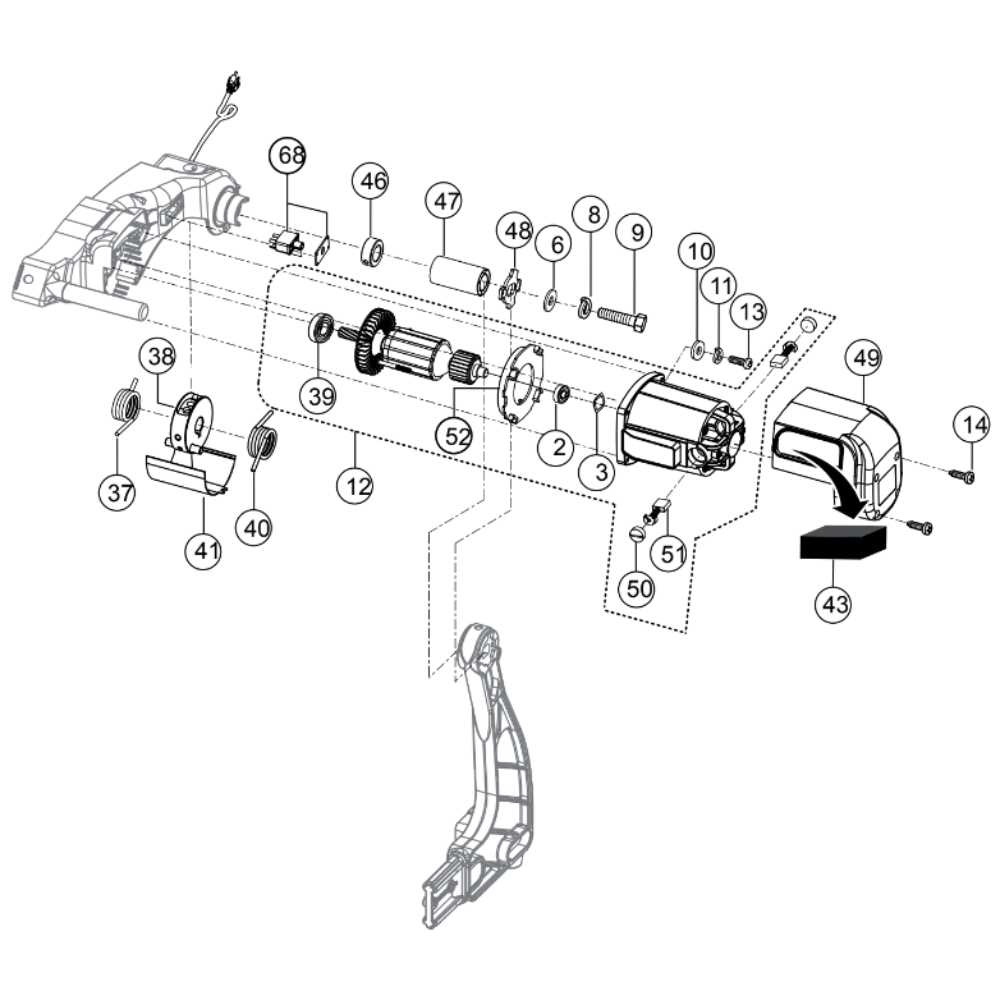

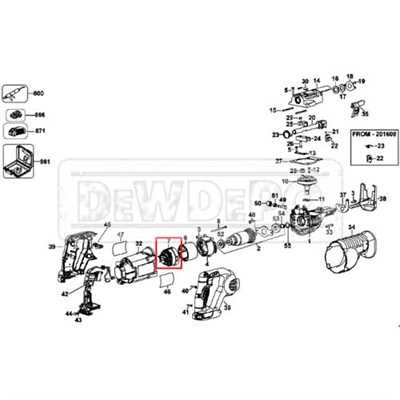

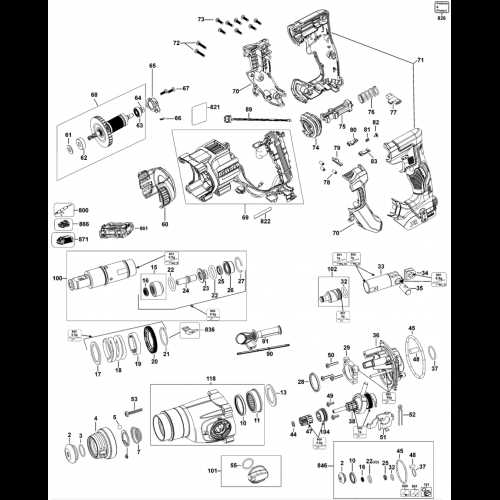

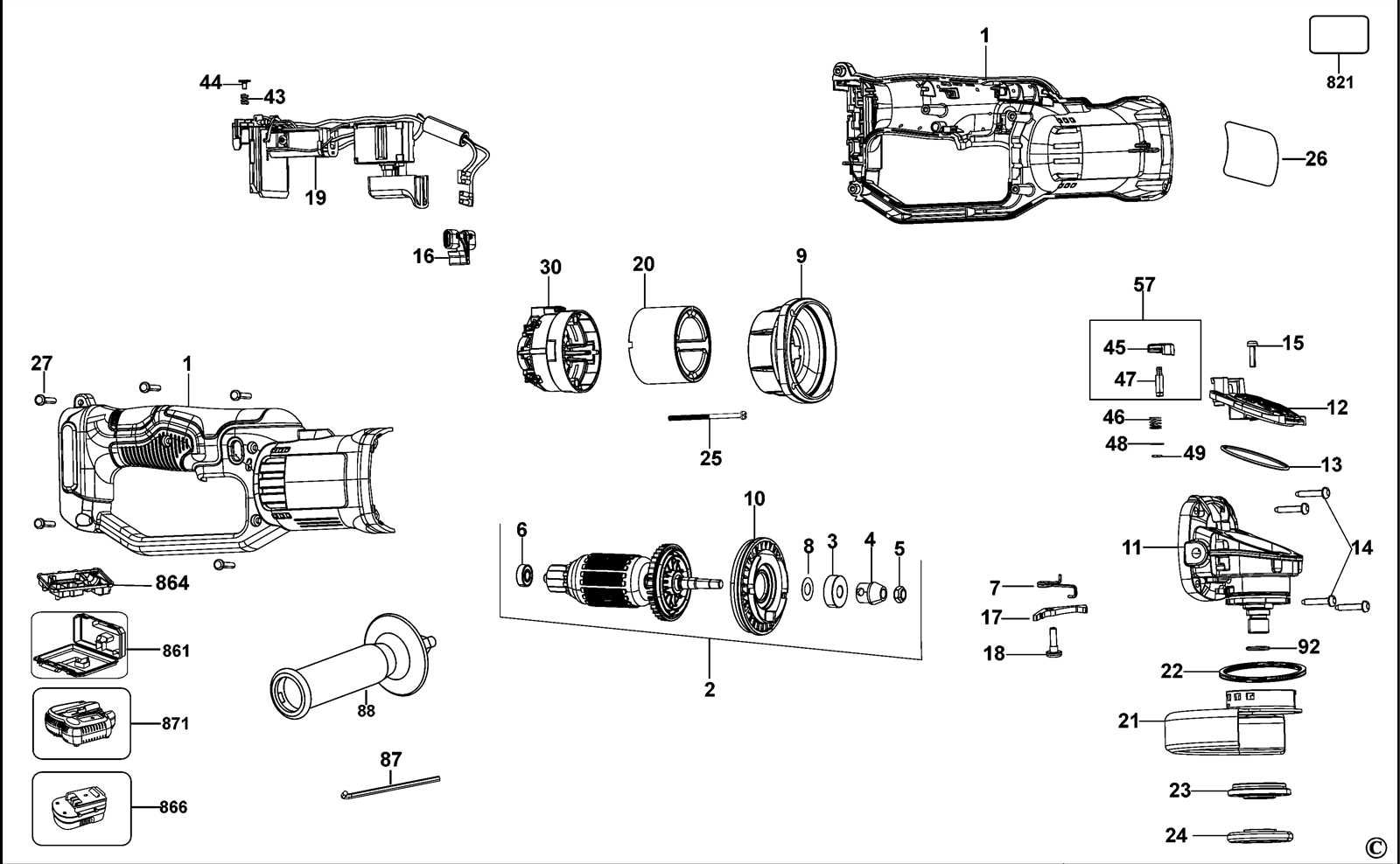

Dewalt DCS380 Parts Diagram Overview

In the realm of power equipment, familiarity with the individual elements that comprise a tool is essential for both maintenance and effective usage. A comprehensive understanding of these components not only enhances the longevity of the equipment but also empowers users to troubleshoot issues and perform repairs with confidence.

Visual representations of assembly structures serve as valuable resources, illustrating how various parts interconnect and function together. This knowledge is crucial for anyone looking to optimize their experience with these tools, whether for professional purposes or home projects.

By exploring detailed schematics, users can gain insights into the configuration and role of each segment, facilitating easier identification of worn or malfunctioning components. With such resources at hand, maintaining peak performance becomes a manageable task, ultimately leading to improved results in any undertaking.

Dewalt DCS380 Overview

This section provides a comprehensive look at a specific power tool, focusing on its key features, capabilities, and advantages for users. Understanding its components and how they function together is essential for optimal performance and maintenance.

Key Features

- High-performance motor for efficient cutting.

- Lightweight design for easy maneuverability.

- Variable speed settings for versatility in various applications.

- Durable construction for long-lasting use.

Benefits

- Enhanced productivity with quick and precise cuts.

- Improved safety features to protect the user during operation.

- Compatibility with a range of blades for diverse materials.

- Easy maintenance, allowing for straightforward repairs and upgrades.

Key Features of DCS380

This powerful tool is designed to enhance performance and efficiency, making it an essential addition to any professional or DIY enthusiast’s arsenal. Its innovative design and advanced functionality cater to a variety of cutting tasks, ensuring precision and ease of use across different materials.

Robust Construction

Engineered with durability in mind, this model boasts a sturdy frame that withstands demanding work conditions. Its ergonomic design provides comfort during prolonged use, minimizing fatigue and allowing for better control.

Versatile Cutting Capabilities

Equipped with a high-performance motor, this tool offers impressive cutting speeds and the ability to tackle a wide range of materials. Whether it’s wood, metal, or plastic, users can expect clean and accurate cuts, making it suitable for various projects.

Understanding the Parts Diagram

Comprehending the assembly layout of a tool is essential for effective maintenance and troubleshooting. This visual representation serves as a guide to identify individual components and their interrelations, enabling users to understand how each part contributes to the overall functionality of the equipment.

Importance of Visual Representation

A clear illustration allows for quick recognition of parts, making it easier to pinpoint any issues or necessary replacements. This can save both time and resources, ensuring that repairs or upgrades are carried out efficiently. Furthermore, a comprehensive visual guide fosters better familiarity with the equipment, enhancing user confidence during operation.

Navigating the Layout

When examining the schematic, it’s crucial to familiarize yourself with the various sections and labels. Each component is typically marked with a unique identifier, which correlates with detailed descriptions elsewhere. This organized approach aids in understanding the role of each element, from the motor to smaller attachments, facilitating a more informed and efficient repair process.

Importance of Accurate Diagrams

Precision in visual representations is essential for effective understanding and maintenance of complex machinery. Such illustrations serve as invaluable resources for technicians and users, guiding them through assembly, repair, and troubleshooting processes. When these visuals are accurate, they significantly reduce the likelihood of errors, ensuring that each component is properly identified and handled.

Enhancing Efficiency

When users rely on well-crafted illustrations, they can execute tasks more swiftly and confidently. Clear visuals minimize the time spent searching for information, allowing individuals to focus on the job at hand. This efficiency not only benefits personal productivity but also contributes to overall project timelines.

Ensuring Safety

Inaccurate or unclear visuals can lead to serious safety hazards. Properly detailed representations help users recognize potential risks associated with specific components and their functions. By adhering to accurate schematics, individuals can better protect themselves and others during maintenance and repair activities.

Common Issues with DCS380 Parts

When dealing with power tools, various components can experience wear and tear, leading to performance issues. Understanding the most frequent problems can help users troubleshoot effectively and maintain their equipment in optimal condition.

Wear and Tear on Components

Frequent use can result in degradation of essential parts. Factors like friction and heat buildup can cause these components to lose efficiency or fail entirely. Regular inspections are vital to identify any signs of wear, ensuring timely replacements and preventing more significant malfunctions.

Electrical Problems

Issues with wiring and connections are common in power tools. Loose connections or damaged wires can lead to inconsistent operation or complete failure to start. It’s important to check the electrical system periodically, ensuring all connections are secure and that no visible damage is present.

How to Read Parts Diagrams

Understanding technical illustrations can significantly enhance your ability to identify components and perform maintenance effectively. These visual guides provide a detailed view of an assembly, making it easier to locate and understand the function of each element within the system.

Key Elements of Visual Guides

- Labels: Each component is typically marked with a unique identifier, often corresponding to a list that provides further details.

- Groupings: Parts are often grouped according to their function or location within the assembly, which aids in comprehension.

- Connections: Arrows or lines may indicate how different pieces connect, which is crucial for understanding assembly or disassembly processes.

Steps to Interpret the Visual Representation

- Familiarize Yourself: Take a moment to look over the entire illustration to get a sense of the layout and major components.

- Identify Labels: Refer to the accompanying list to match the labeled components with their descriptions or specifications.

- Follow Connections: Trace lines or arrows to understand how parts interact and where they fit within the larger assembly.

- Cross-Reference: If available, consult the service manual for additional context or instructions related to the components.

By mastering these techniques, you can improve your maintenance skills and ensure efficient repairs and assembly. This knowledge is invaluable for both professionals and DIY enthusiasts alike.

Replacement Parts Availability

Access to quality components is essential for maintaining the functionality and longevity of any power tool. Users often seek reliable sources to obtain these necessary elements, ensuring that their equipment remains in peak condition. Understanding where to find these items can greatly enhance the performance and reliability of your tools.

Where to Find Quality Components

There are several avenues to explore when looking for replacement items. Authorized retailers often provide the most reliable options, ensuring that users receive authentic merchandise. Online marketplaces also present a variety of choices, allowing for easy comparisons and competitive pricing. Additionally, local hardware stores may stock some commonly needed components, providing immediate solutions for urgent repairs.

Benefits of Using Genuine Components

Opting for original replacements can significantly impact the overall performance of your equipment. Authenticity ensures compatibility and durability, minimizing the risk of future breakdowns. Furthermore, using legitimate components often comes with warranties, offering peace of mind to the user. Prioritizing quality over cost can ultimately save time and resources in the long run.

Maintenance Tips for DCS380

Proper upkeep is essential for ensuring the longevity and optimal performance of your tool. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some crucial tips to keep your equipment in top condition.

Routine Cleaning

Maintaining a clean work environment is vital. Dust and debris can accumulate and affect functionality. Follow these steps for effective cleaning:

- Disconnect the power source before cleaning.

- Use a soft brush or cloth to remove dust from the exterior.

- Inspect and clean air vents to prevent overheating.

- Wipe down moving parts with a damp cloth and mild soap.

Regular Inspections

Conducting frequent checks on your tool can help identify issues before they escalate. Focus on these areas:

- Inspect the battery for signs of wear or damage.

- Check the blade for sharpness and replace it if necessary.

- Examine all connections for secure fittings.

- Ensure that all safety features are functioning correctly.

By adhering to these maintenance guidelines, you can ensure that your equipment remains reliable and efficient throughout its lifespan.

Comparison with Similar Models

When selecting a power tool, it’s essential to consider various options available on the market. Understanding the differences between models can help users identify which tool best suits their needs. This section explores how a particular reciprocating saw stacks up against its closest competitors, focusing on features, performance, and user experience.

Performance Metrics

In terms of cutting power and speed, several comparable models exhibit similar capabilities. However, some standout features may enhance user experience, such as stroke length and variable speed settings. While one model may offer a slightly higher RPM, another might excel in delivering smoother cuts, making it crucial to evaluate these specifications based on specific tasks.

Ergonomics and Design

Comfort during use is a vital aspect of any tool. Comparing grip design, weight distribution, and overall build quality can reveal which model provides a more pleasant user experience. Some options feature lightweight construction that reduces fatigue, while others incorporate advanced grip technology to enhance control and precision during operation.

Ultimately, the right choice will depend on individual preferences and project requirements. Careful consideration of these factors can lead to a more satisfying and efficient tool selection process.

Tools Required for Repairs

When undertaking maintenance or repair tasks on power tools, having the right equipment is essential. Proper tools not only streamline the process but also ensure safety and efficiency. This section outlines the necessary implements that can aid in effectively managing any repair job.

Essential Tools

For successful repairs, it’s crucial to have a selection of standard tools readily available. These typically include hand tools, power tools, and safety gear. Below is a summary of the key tools you might need:

| Tool Type | Purpose |

|---|---|

| Adjustable Wrench | To loosen or tighten nuts and bolts. |

| Screwdriver Set | For fastening and unfastening screws. |

| Socket Set | For working with various sizes of fasteners. |

| Pliers | For gripping, twisting, and cutting wire. |

| Power Drill | To make holes and drive screws quickly. |

| Safety Goggles | To protect eyes from debris during repairs. |

Optional Tools

In addition to the basic tools, having a few optional implements can enhance your repair capabilities. These tools may not be essential for every job but can be invaluable in specific situations:

| Tool Type | Purpose |

|---|---|

| Multimeter | For measuring voltage, current, and resistance. |

| Wire Stripper | To remove insulation from electrical wires. |

| Heat Gun | For applying heat to shrink materials or remove paint. |

| Level | To ensure surfaces are even and aligned. |

Safety Precautions During Repair

When undertaking maintenance or repairs on power tools, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also ensure the longevity of the equipment. Adhering to safety guidelines creates a secure environment conducive to effective troubleshooting and repair.

First and foremost, always disconnect the tool from its power source before starting any maintenance tasks. This simple action significantly reduces the risk of accidental activation. Additionally, wear appropriate personal protective equipment, such as safety goggles and gloves, to shield yourself from debris and sharp components during disassembly.

It is also crucial to work in a well-lit area that provides adequate visibility of the tool’s parts and components. Maintain a clean workspace to minimize the chances of losing small pieces and to prevent tripping hazards. Furthermore, familiarize yourself with the tool’s manual to understand specific repair procedures and potential hazards associated with each task.

Lastly, avoid rushing through repairs. Take your time to ensure that each step is completed correctly, which will ultimately enhance safety and performance. By following these essential safety measures, you can effectively minimize risks and ensure a successful repair process.

User Experiences and Reviews

This section highlights the feedback and insights shared by users regarding their experiences with the tool. Understanding real-life applications and performance can provide valuable information for potential buyers, helping them make informed decisions. Users often discuss various aspects such as usability, durability, and overall satisfaction.

Overall Satisfaction

Many users express high levels of satisfaction, praising the effectiveness and reliability of the device. A common sentiment is that it delivers consistent performance across various tasks, making it a go-to option for both professionals and DIY enthusiasts. The balance between power and ease of use is frequently noted, which enhances the overall user experience.

Durability and Maintenance

Feedback regarding the longevity of the tool is generally positive. Users appreciate its robust construction, which withstands frequent use and challenging conditions. However, some reviews mention the importance of regular maintenance to ensure optimal performance. A few users highlight the ease of access to components for repairs, emphasizing the tool’s design that facilitates upkeep.

Where to Find Technical Support

Accessing reliable assistance for your tools can greatly enhance their performance and longevity. Whether you need troubleshooting guidance or replacement components, knowing where to seek support is essential. There are several avenues you can explore to obtain the help you need.

Official Manufacturer Resources

- Visit the official website for access to manuals, FAQs, and product information.

- Contact customer service via phone or email for direct support.

- Check for online chat options for immediate assistance.

Community Forums and Online Groups

- Join dedicated forums to connect with other users for advice and tips.

- Participate in social media groups to share experiences and solutions.

- Utilize platforms like Reddit or specialized discussion boards for broader discussions.

By leveraging these resources, you can ensure you have the support necessary to maintain and optimize your tools effectively.