Kohler K321 Engine Parts Diagram Overview

The intricate world of small machinery reveals a fascinating array of components that work in harmony to deliver optimal performance. Each element plays a crucial role, and understanding their functions can greatly enhance maintenance and troubleshooting efforts. This exploration delves into the essential parts that comprise these powerful machines, shedding light on their interconnections and overall significance.

Every unit operates through a carefully engineered system where precision and efficiency are paramount. By familiarizing oneself with the various sections and their specific roles, users can not only improve the longevity of their equipment but also maximize its capabilities. From the ignition system to the fuel delivery mechanisms, each component contributes to the overall functionality.

Whether you’re a seasoned mechanic or a novice enthusiast, gaining insight into these intricate mechanisms empowers you to tackle repairs and upgrades with confidence. Visual representations of these assemblies can serve as invaluable references, enabling a clearer understanding of how each piece fits into the larger puzzle. Embracing this knowledge opens the door to enhanced performance and reliability.

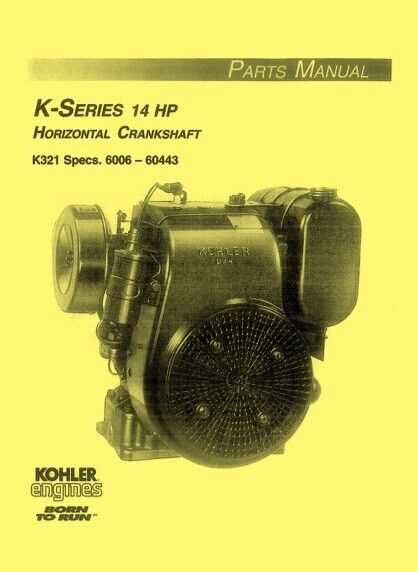

Kohler K321 Engine Overview

This section delves into a specific model known for its robust design and reliability in various applications. With a focus on performance, this unit has been widely utilized in outdoor machinery and equipment. Its reputation is built on durability and efficiency, making it a preferred choice for many users.

Key Features

- Air-cooled design ensures optimal performance in diverse conditions.

- Powerful output suitable for a range of tasks.

- Compact size allows for easy installation in various setups.

- Simple maintenance procedures contribute to longevity.

Applications

- Lawn and garden machinery

- Tractors and agricultural equipment

- Construction tools

- Generators and auxiliary power units

Understanding the characteristics and applications of this unit helps users maximize its potential and ensure effective operation in their specific tasks.

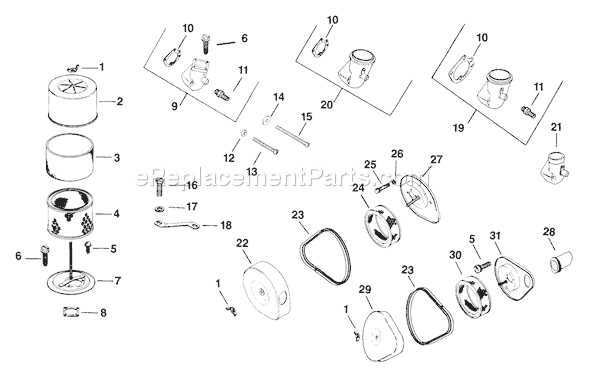

Key Components of Kohler K321

This section focuses on the essential elements that constitute a specific model of small combustion machinery. Understanding these crucial components can enhance maintenance practices and improve overall functionality. Each element plays a vital role in ensuring optimal performance and longevity.

| Component | Description |

|---|---|

| Crankshaft | A fundamental rotating element that converts linear motion into rotational force, essential for powering the system. |

| Cylinder Block | The core structure that houses the combustion chamber, providing stability and support to other components. |

| Piston | This movable part compresses the air-fuel mixture and transfers energy to the crankshaft. |

| Flywheel | Serves to stabilize the rotational motion and maintain momentum, allowing for smoother operation. |

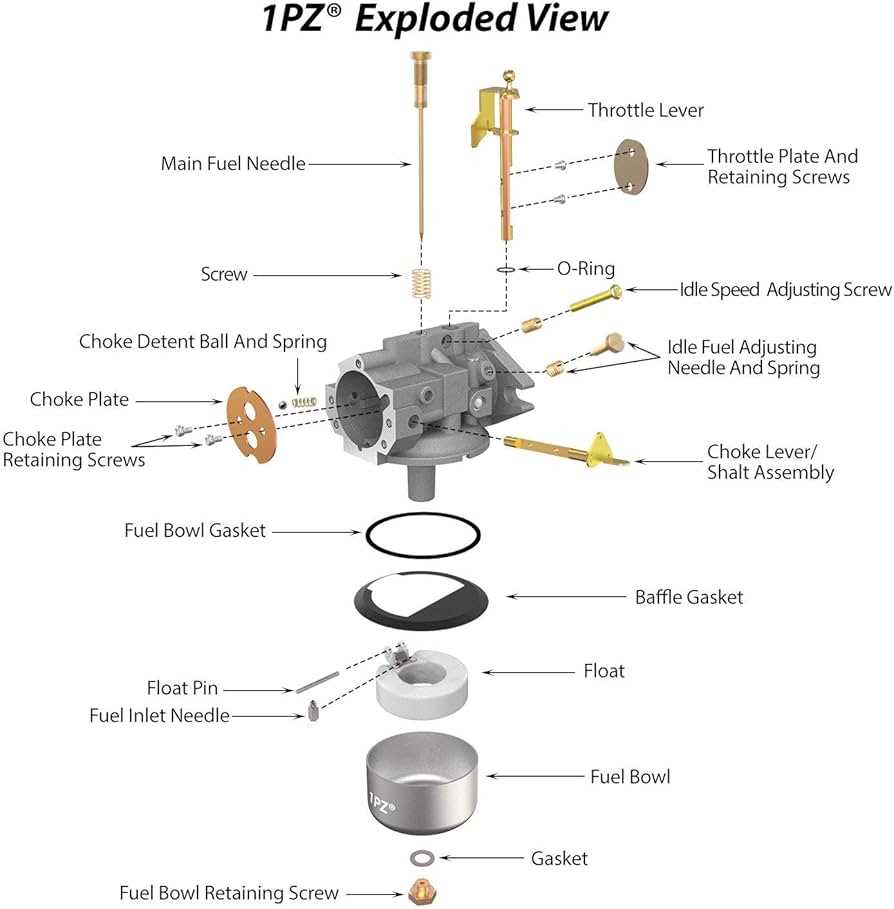

| Fuel System | A crucial assembly that delivers the necessary fuel to the combustion chamber, ensuring efficient operation. |

| Ignition System | This component is responsible for generating the spark that ignites the air-fuel mixture, initiating the combustion process. |

Understanding Engine Diagrams

Visual representations of mechanical systems play a crucial role in comprehending their structures and functions. These illustrations provide an organized view of components and their interrelations, facilitating easier maintenance, troubleshooting, and assembly. A clear understanding of these schematics is essential for anyone working with machinery.

The Importance of Visual Guides

Visual aids serve multiple purposes, from enhancing learning to simplifying complex concepts. By breaking down intricate designs into manageable sections, individuals can grasp how each element contributes to the overall functionality. This clarity can significantly reduce the time spent on repairs and improvements.

Components of Mechanical Schematics

Typically, these visual aids include symbols and notations that represent various elements and their connections. Understanding these symbols is vital for interpreting the guides correctly. Below is a simplified table of common symbols used in such illustrations:

| Symbol | Description |

|---|---|

| ⚙️ | Gear or rotating component |

| Tool or adjustment point | |

| Electrical connection | |

| ️ | Assembly point |

By familiarizing oneself with these symbols and their meanings, one can effectively navigate and utilize mechanical illustrations, leading to improved understanding and efficiency in handling machinery.

Importance of Accurate Parts Identification

Identifying components with precision is crucial for maintaining the efficiency and longevity of any mechanical system. When each element is recognized correctly, it ensures seamless functionality and reduces the likelihood of malfunctions. Proper identification also aids in sourcing the right replacements, minimizing downtime and enhancing overall performance.

Enhancing Operational Efficiency

When every component is accurately distinguished, the assembly and repair processes become streamlined. This efficiency not only saves time but also reduces the risk of errors during maintenance. Operators can swiftly locate the necessary items, ensuring that tasks are completed promptly and effectively, ultimately contributing to smoother operations.

Cost-Effectiveness and Resource Management

Correct identification helps in avoiding unnecessary expenses associated with incorrect purchases or compatibility issues. By ensuring that the right components are selected, businesses can manage their resources better, preventing waste and optimizing their investment in equipment. This approach fosters a more sustainable operational model, where resources are allocated judiciously.

Common Issues with Kohler K321

This section discusses frequent problems encountered with a specific type of small power unit commonly used in various applications. Understanding these issues can help users maintain optimal performance and prolong the lifespan of the machinery.

Frequent Symptoms

Operators often report a variety of symptoms that indicate underlying troubles. Recognizing these signs early can facilitate timely intervention, preventing more significant damage.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Hard starting | Weak battery or faulty ignition system | Check battery charge and replace spark plug |

| Overheating | Blocked cooling fins or low coolant level | Clean cooling fins and check coolant |

| Excessive vibration | Worn mounts or unbalanced components | Inspect mounts and balance all moving parts |

Preventive Measures

Regular maintenance is key to minimizing issues. Routine checks can help identify potential problems before they escalate, ensuring the longevity of the unit.

Replacement Parts Availability

Access to high-quality components is essential for maintaining optimal performance and longevity of machinery. With a wide range of suppliers and distributors, finding suitable alternatives for worn or damaged items can be streamlined. Ensuring that the necessary replacements are readily available minimizes downtime and enhances overall efficiency.

Sources for Components

There are several avenues to explore when seeking out replacement items. Local retailers often stock common components, while online marketplaces provide a vast selection, sometimes at competitive prices. Additionally, specialized vendors can offer hard-to-find items that might not be available through standard outlets.

Quality Assurance

When procuring replacements, it’s crucial to consider the quality of the components. Opting for reputable brands or certified alternatives can ensure reliability and compatibility. Furthermore, many suppliers provide warranties or guarantees, offering peace of mind with each purchase.

| Source | Type | Notes |

|---|---|---|

| Local Retailers | Common Components | Quick access, limited selection |

| Online Marketplaces | Wide Variety | Competitive pricing, shipping times vary |

| Specialized Vendors | Hard-to-Find Items | Higher reliability, often knowledgeable staff |

Maintenance Tips for Longevity

Regular upkeep is essential for extending the lifespan of any mechanical unit. By implementing a systematic approach to care, you can ensure optimal performance and minimize the risk of breakdowns. This section outlines key practices that contribute to durability and reliability.

Routine Inspections

Conducting frequent checks can help identify potential issues before they escalate. Look for signs of wear or damage, and ensure all components are securely attached. Regular cleaning is also vital, as debris accumulation can lead to overheating and inefficiency.

Fluid Management

Maintaining the correct levels of lubricants and coolants is crucial for smooth operation. Change fluids as recommended, and monitor their condition to prevent sludge buildup. Additionally, consider using high-quality products to enhance protection and performance.

By following these guidelines, you can significantly enhance the operational life of your machinery, ensuring it remains a reliable asset for years to come.

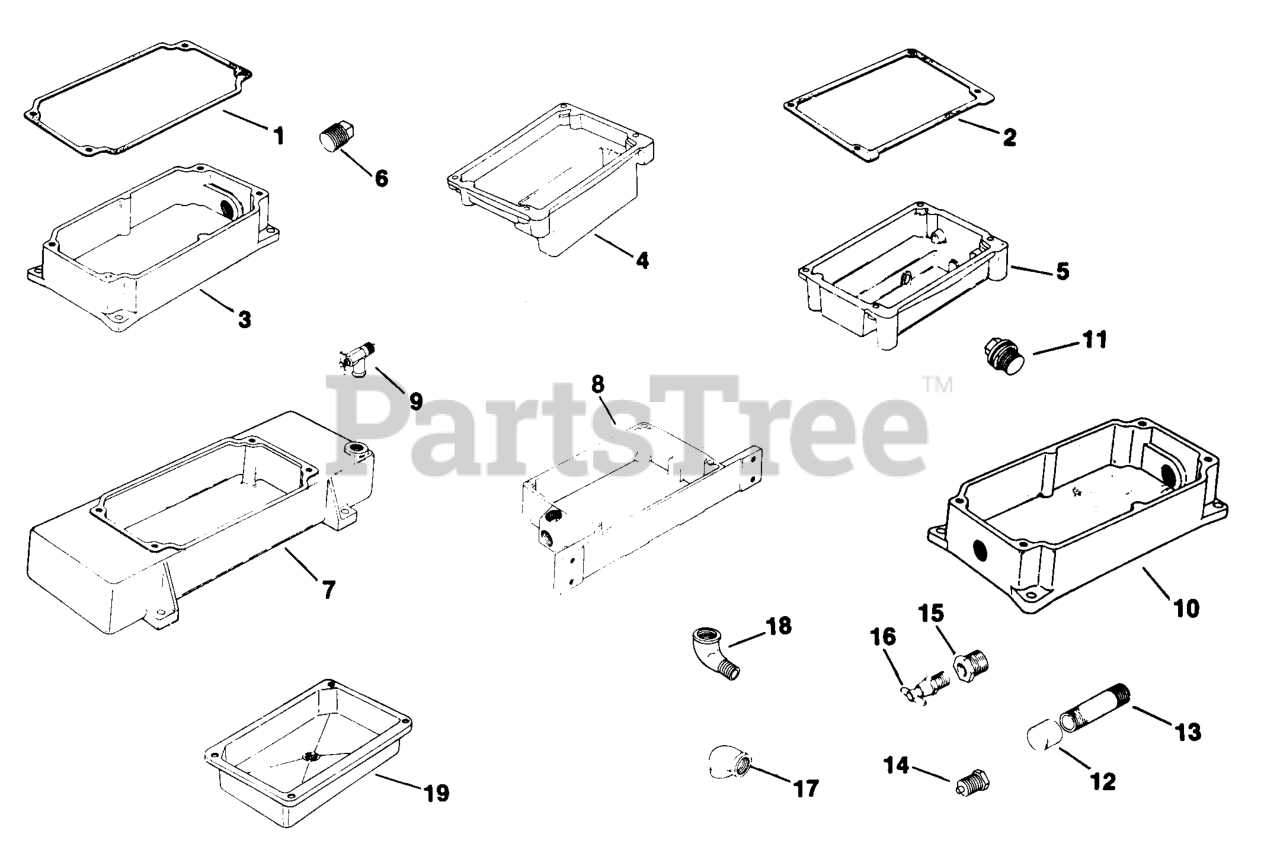

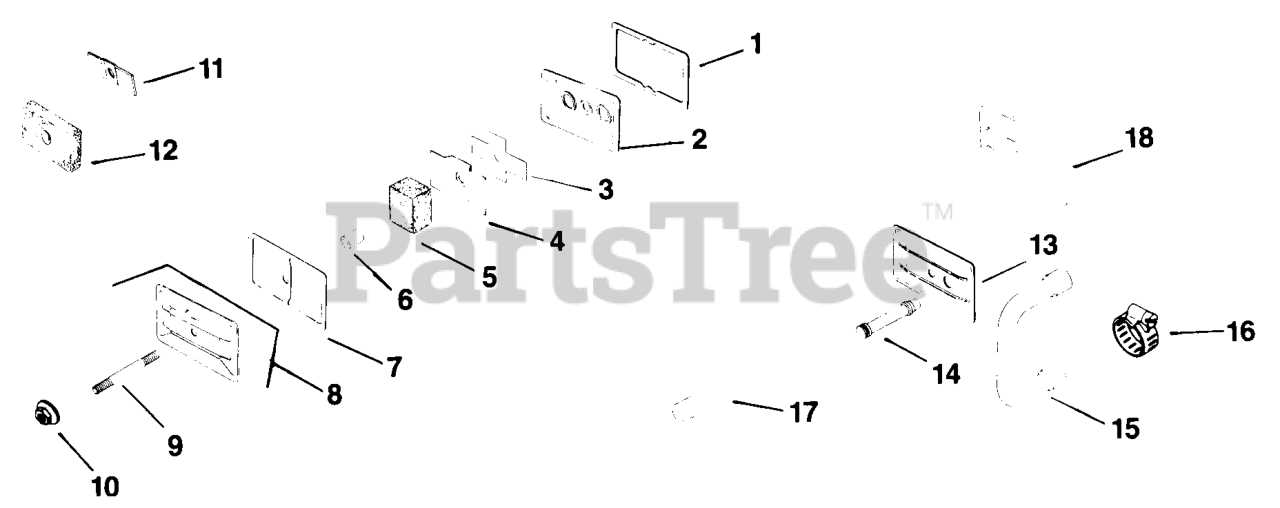

Visualizing the K321 Parts Layout

This section aims to enhance understanding of the assembly by providing a clear representation of its components and their arrangements. A well-structured overview allows for easier identification and comprehension of each element’s role within the system.

When examining the layout, it’s important to focus on several key areas:

- Component arrangement: How different elements are positioned in relation to one another.

- Functionality: Understanding the purpose of each item within the assembly.

- Interconnectivity: Identifying how various components interact to create a cohesive unit.

To gain a deeper insight, consider the following aspects:

- Top View: An aerial perspective can help visualize the overall structure and organization.

- Side Profiles: Lateral views reveal depth and spatial relationships between parts.

- Exploded View: This method highlights individual elements, showcasing their connections and positioning.

Utilizing these visual approaches provides a comprehensive understanding of the system’s configuration, facilitating better maintenance and troubleshooting practices.

Comparing K321 with Other Models

When evaluating various power units, it’s essential to understand how one model stacks up against others in terms of performance, reliability, and efficiency. Each variant in the lineup serves specific applications and possesses unique features that cater to different needs.

Performance metrics are a crucial factor in this comparison. While some models may excel in torque delivery, others might prioritize speed or fuel efficiency. For instance, certain alternatives provide a more robust output, making them suitable for heavy-duty tasks, whereas others are designed for lighter applications, ensuring smooth operation without compromising on economy.

Another significant aspect is durability and maintenance. Different designs may vary in build quality, affecting their longevity and ease of service. Some units are engineered for straightforward upkeep, allowing users to perform routine maintenance with minimal hassle, while others might require specialized tools or expertise.

Technology and innovation also play a role in distinguishing between these models. Advanced features, such as electronic ignition systems or improved cooling mechanisms, can significantly enhance performance and reliability. Users should consider these elements when selecting the most appropriate unit for their specific requirements.

Ultimately, understanding the distinctions among these various models helps consumers make informed choices, ensuring they select the most suitable option tailored to their operational needs.

Resources for Further Research

When delving into the specifics of mechanical components and their functionalities, having access to a variety of informative resources is essential. This section aims to provide valuable references that can enhance understanding and facilitate maintenance or restoration projects.

| Resource Type | Description | Link |

|---|---|---|

| Technical Manuals | Comprehensive guides that offer detailed information on assembly, disassembly, and troubleshooting. | View Manuals |

| Forums and Online Communities | Platforms where enthusiasts and experts share experiences, tips, and advice. | Join Forums |

| Video Tutorials | Visual aids that demonstrate various repair techniques and best practices. | Watch Tutorials |

| Parts Suppliers | Websites that specialize in selling components, often with schematics for reference. | Explore Suppliers |

FAQs About Kohler K321 Engine

This section aims to address common inquiries regarding a specific model known for its durability and efficiency. Understanding various aspects of this mechanism can help users maintain optimal performance and troubleshoot issues effectively.

What are the common issues associated with this model?

Users frequently report challenges such as overheating, starting difficulties, and fuel inefficiencies. Regular maintenance and timely inspections can mitigate these problems, ensuring smooth operation.

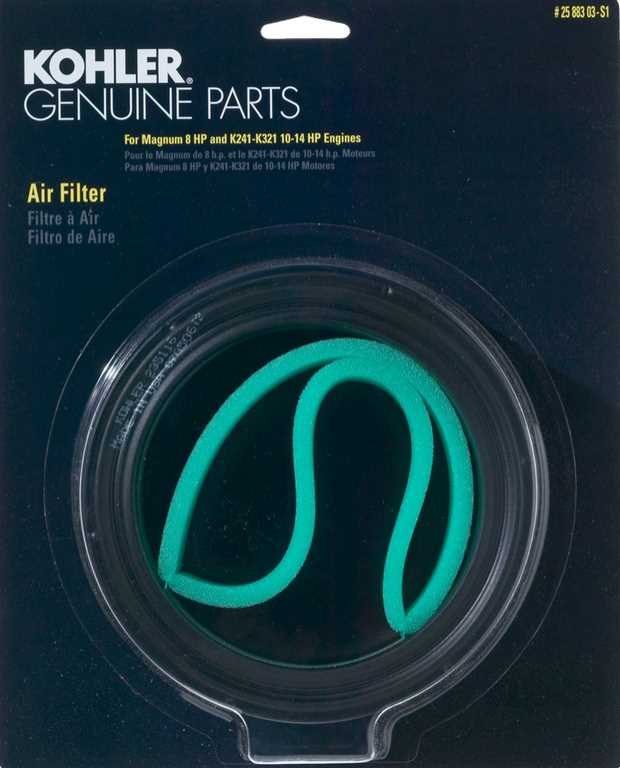

How can I improve the performance of my machine?

To enhance functionality, consider routine servicing, such as changing the oil and air filters. Using high-quality fuel and ensuring proper alignment of components also contribute significantly to overall performance.

Is there a specific maintenance schedule I should follow? Yes, adhering to a recommended schedule helps prolong lifespan and efficiency. Regular check-ups every 50 hours of use, along with seasonal maintenance, are advisable.

What replacement components are typically needed? Over time, parts such as spark plugs, filters, and gaskets may require replacement. Keeping an inventory of essential items can minimize downtime.