Understanding the Echo PB-200 Parts Diagram for Efficient Repairs

In the realm of outdoor machinery, comprehending the intricate elements that contribute to their functionality is crucial for optimal performance and longevity. Each device is composed of numerous specific parts, each playing a vital role in the overall operation. Gaining insight into these components not only enhances maintenance efforts but also empowers users to troubleshoot issues effectively.

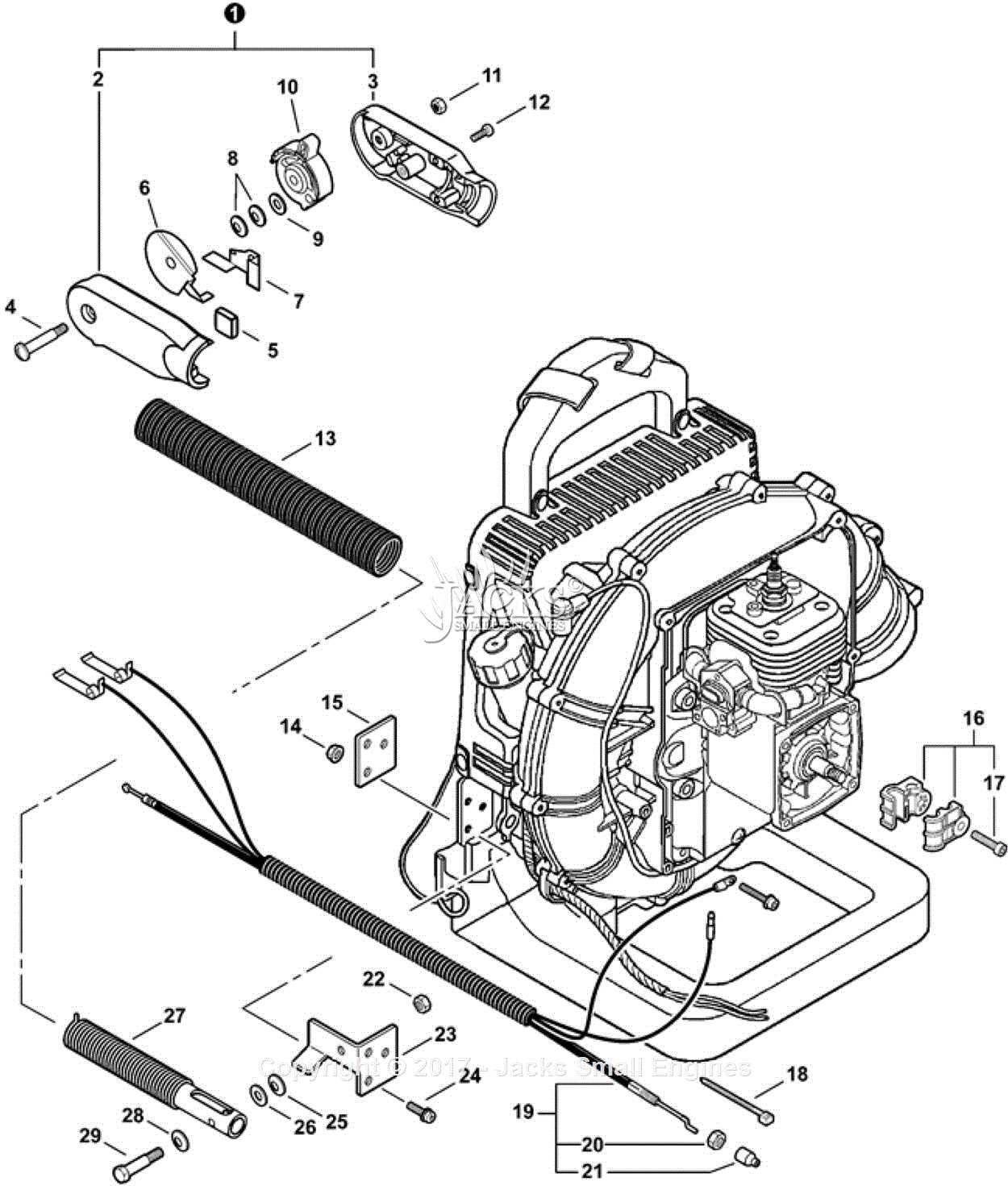

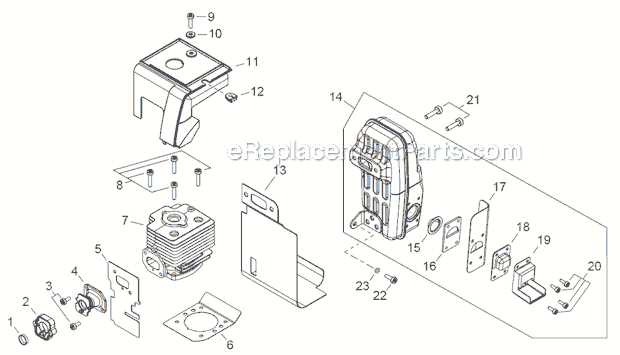

For enthusiasts and professionals alike, visual representations of these elements serve as invaluable resources. Such illustrations clarify the relationships between various components, making it easier to identify and address potential problems. By familiarizing oneself with these layouts, users can approach repairs and maintenance with increased confidence and efficiency.

Moreover, understanding the structure of equipment aids in the selection of appropriate replacements when the need arises. Knowing which components are critical and how they interact ensures that any modifications or repairs are performed with precision. This knowledge not only preserves the functionality of the machine but also extends its operational lifespan.

Understanding Echo PB-200 Components

In any mechanical system, comprehending the individual elements is crucial for effective maintenance and troubleshooting. Each component plays a significant role, contributing to the overall functionality and efficiency of the machinery. A clear understanding of these elements not only enhances operational knowledge but also aids in identifying potential issues before they escalate.

Key Elements and Their Functions

Various parts work together harmoniously, each fulfilling a unique function. For instance, the engine serves as the powerhouse, converting fuel into motion. Coupled with this, the fuel system ensures that the energy source is delivered efficiently, maintaining optimal performance. Additionally, the ignition system initiates the combustion process, critical for starting the device.

Importance of Regular Maintenance

To ensure longevity and peak performance, regular inspection and maintenance of each component are essential. By identifying wear and tear early, users can avoid costly repairs and enhance the operational lifespan of the equipment. Routine checks of filters, spark plugs, and other essential elements contribute to the overall health of the system, promoting reliability and efficiency.

Importance of Parts Diagrams

Understanding the assembly and components of any machinery is crucial for effective maintenance and repair. Visual representations that outline each element and its relationship to others serve as invaluable tools for technicians and hobbyists alike. These illustrations simplify complex information, making it accessible to users with varying levels of expertise.

Utilizing these visual aids can significantly enhance the troubleshooting process. When issues arise, having a clear view of each component allows for quicker identification of potential problems. Furthermore, these resources can help ensure that replacements are accurately sourced and fitted, thereby extending the lifespan of the equipment.

| Benefits | Description |

|---|---|

| Clarity | Offers a clear view of the relationships between different components. |

| Efficiency | Speeds up the diagnosis of issues and the repair process. |

| Accuracy | Facilitates correct identification of replacement items. |

| Education | Helps users learn about the machinery and its functioning. |

Overview of Echo PB-200 Model

This model is a powerful tool designed for efficient performance and durability, making it a favorite among users. It integrates advanced technology with a user-friendly interface, ensuring that both novice and experienced operators can utilize its features effectively.

Key characteristics include a robust engine and ergonomic design, which provide optimal handling and reduced fatigue during prolonged use. Additionally, maintenance and accessibility are prioritized, enabling straightforward upkeep to extend the lifespan of the equipment.

Overall, this machine exemplifies a commitment to quality and reliability, catering to various needs in outdoor tasks and landscape management.

Common Issues and Solutions

When dealing with outdoor power equipment, users may encounter a variety of challenges that can affect performance and reliability. Understanding these frequent problems and their corresponding solutions can greatly enhance the user experience and prolong the lifespan of the machinery.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Engine won’t start | Fuel blockage, spark plug issues, or air filter contamination | Check fuel lines for clogs, replace spark plug, clean or replace air filter |

| Reduced power output | Dirty air filter, clogged fuel filter, or improper fuel mixture | Clean or replace air filter, check fuel filter, ensure correct fuel mixture |

| Excessive vibration | Loose components, unbalanced blade, or worn-out parts | Tighten loose screws, balance the blade, inspect and replace worn parts |

| Overheating | Blocked cooling vents, low oil levels, or faulty ignition | Clear cooling vents, check and refill oil, inspect ignition system |

By addressing these common issues with the suggested remedies, users can ensure their equipment operates efficiently and effectively. Regular maintenance and timely interventions can prevent minor problems from escalating into more significant concerns.

Finding Replacement Parts

Locating the necessary components for equipment maintenance can often feel daunting. However, understanding where to seek out these vital elements can simplify the process significantly. Whether you’re dealing with wear and tear or a sudden malfunction, having access to reliable sources is crucial for effective repairs.

One of the best places to start is by consulting the manufacturer’s official resources. They often provide comprehensive catalogs and listings of available items, ensuring you find exactly what you need. Additionally, exploring online marketplaces and specialized retailers can yield a wealth of options, often at competitive prices.

Another strategy involves engaging with user communities and forums dedicated to similar equipment. Fellow enthusiasts and experts can offer insights, recommendations, and even direct links to vendors. This collaborative approach not only aids in finding specific components but also fosters a sense of camaraderie among users.

Lastly, don’t overlook local repair shops or authorized service centers. These establishments may have stock on hand or the ability to order specific items, streamlining your search while providing professional guidance throughout the process. With the right resources and strategies, acquiring replacements becomes a more manageable task.

Assembly Process Explained

The assembly process is a crucial phase in bringing components together to form a complete unit. This intricate procedure requires careful attention to detail and systematic execution to ensure that all elements function harmoniously. Understanding each step is essential for achieving optimal performance and longevity of the final product.

Steps Involved

Initially, it is important to gather all necessary components and tools. This preparation phase sets the foundation for a smooth assembly. Each part must be inspected for quality and compatibility, as even minor discrepancies can lead to operational issues.

Final Checks

After the assembly is complete, conducting thorough testing is vital. This step verifies that every element operates as intended, highlighting any adjustments needed. Proper documentation of this phase can assist in future maintenance and troubleshooting.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires regular upkeep and attention. By adopting a consistent maintenance routine, you can significantly extend the life of your tools and minimize the risk of unexpected breakdowns. This section outlines essential practices that will help you keep your machinery in optimal condition.

Regular Cleaning

One of the simplest yet most effective maintenance tasks is regular cleaning. After each use, remove dirt, debris, and any residues that may accumulate on the surface and in the operational areas. Using a soft brush or a cloth can prevent buildup that could hinder performance. Additionally, inspect and clean filters or vents to ensure proper airflow and function.

Periodic Inspections

Conducting routine inspections is crucial for identifying potential issues before they escalate. Check for signs of wear or damage, such as cracks or loose components. Pay special attention to moving parts, as they are often subject to more stress. Replace worn-out components promptly to avoid further complications. Keeping a maintenance log can also help track performance and highlight any recurring issues.

Tools Needed for Repairs

Having the right equipment is essential for effective maintenance and restoration tasks. Proper tools not only simplify the process but also ensure that repairs are performed safely and efficiently. Investing in quality instruments can save time and enhance the overall outcome of any repair endeavor.

Essential Equipment

First and foremost, a comprehensive set of hand tools, including screwdrivers, wrenches, and pliers, is vital. Additionally, a reliable set of power tools, such as drills and saws, can expedite various tasks. Don’t forget to include measuring tools like calipers or tape measures to ensure accuracy in your work.

Safety Gear

Equipping yourself with proper safety gear is crucial. Items like gloves, goggles, and ear protection help minimize risks during repairs. Always prioritize your safety to maintain focus and efficiency throughout the process.

Safety Precautions During Repairs

When undertaking maintenance on machinery, it is crucial to prioritize safety to prevent accidents and ensure efficient operation. Proper precautions help safeguard both the technician and the equipment from potential hazards.

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. This minimizes the risk of injury from sharp components or debris. Additionally, ensure the workspace is well-ventilated and free of clutter to promote a safe working environment.

Before starting any repair work, disconnect the power source to eliminate the chance of accidental activation. Familiarize yourself with the equipment’s manual and safety guidelines, and utilize tools designed for the specific tasks to avoid unnecessary risks.

Lastly, consider having a second person present during repairs for assistance in case of emergencies. Regularly inspect your tools and equipment for wear and tear, ensuring they are in good condition for safe use.

Comparing Echo PB-200 to Competitors

In the realm of portable leaf blowers, evaluating one model against its peers reveals essential differences in performance, design, and functionality. Understanding these variances is crucial for making an informed decision about which device best suits your needs.

Power and Efficiency: When analyzing power output and efficiency, various models demonstrate distinct capabilities. Some competitors may offer more robust engines, providing higher airspeed, while others emphasize fuel efficiency, appealing to environmentally conscious users.

Weight and Ergonomics: The weight of a blower significantly impacts usability. Lighter options can enhance maneuverability, making prolonged use more comfortable. Ergonomic designs are also critical, as they can reduce fatigue during extensive tasks.

Noise Levels: Noise pollution is an often-overlooked factor. Some alternatives boast quieter operations, which is advantageous for residential areas or early morning use. This consideration can enhance user experience and neighborhood relations.

Durability and Maintenance: The longevity of a device is a key aspect of its value. Comparing materials and construction quality can highlight which brands require less frequent maintenance and offer better warranties, ensuring peace of mind for the user.

Features and Accessories: Additional features, such as variable speed controls and different nozzle attachments, can greatly enhance functionality. Evaluating these options helps determine which blower provides the ultimate versatility for diverse tasks.

User Experiences and Reviews

This section aims to capture the voices of individuals who have interacted with the product, highlighting their insights and feedback. Understanding user opinions can significantly influence potential buyers and enhance overall satisfaction with their purchase.

Common Themes in Feedback

- Durability: Many users praised the robustness and long-lasting nature of the equipment.

- Performance: A significant number of reviews highlighted effective functionality, making tasks easier and quicker.

- Ease of Use: Several users noted the straightforward operation, even for beginners.

Suggestions for Improvement

- Some users recommended clearer instructions for assembly and maintenance.

- A few mentioned the need for more readily available replacement components.

- Enhanced customer support services were also suggested for quicker issue resolution.

Resources for Further Learning

Expanding your knowledge in equipment maintenance and repair can be greatly beneficial. Various resources are available that cater to different learning styles, from visual guides to detailed manuals. Exploring these can enhance your understanding and skills in handling machinery effectively.

- Online Forums: Join communities where enthusiasts share experiences and solutions.

- Video Tutorials: Platforms like YouTube offer step-by-step guides that are easy to follow.

- User Manuals: Always check for official documentation that provides in-depth information.

- Workshops: Look for local classes or online webinars that offer hands-on training.

- Books and Guides: Explore literature focusing on repair techniques and best practices.

Utilizing these resources will help you delve deeper into the subject and achieve ultimate proficiency in maintenance tasks.