Comprehensive Guide to John Deere 2305 Parts Diagram

In the realm of agricultural machinery, a comprehensive grasp of the individual elements that make up a specific model is essential for effective maintenance and repair. Whether you are a seasoned mechanic or a farmer looking to enhance your knowledge, familiarizing yourself with the intricacies of each component can greatly improve the overall performance of your equipment.

Every machine comprises numerous interconnected pieces, each serving a vital role in its operation. Recognizing these elements not only aids in troubleshooting but also empowers users to optimize functionality and longevity. This exploration delves into the various sections and assemblies of a well-known tractor model, offering insights into how each part contributes to its effectiveness.

By examining the relationships and arrangements of these components, users can gain valuable information that assists in identifying potential issues and planning for necessary repairs. Understanding the layout of this machinery is crucial for anyone involved in agricultural practices, ensuring that operations run smoothly and efficiently.

Understanding John Deere 2305 Model

The compact utility tractor is a remarkable machine known for its versatility and efficiency. Designed to tackle a variety of tasks, this model serves both agricultural and landscaping needs, making it a popular choice among enthusiasts and professionals alike.

When exploring this machine, several key features contribute to its performance:

- Engine Power: The robust engine provides ample power for various attachments and implements.

- Size and Maneuverability: Its compact design allows for easy navigation in tight spaces, perfect for smaller properties.

- Attachment Compatibility: A wide range of accessories enhances functionality, from mowing to tilling.

Understanding the components and their arrangement is crucial for optimal operation. Familiarity with the layout ensures effective maintenance and troubleshooting. Below are some common elements to consider:

- Transmission system

- Hydraulic components

- Electrical system

- Chassis structure

By comprehensively understanding this machine, operators can maximize its potential, ensuring that it meets their specific needs efficiently and effectively.

Key Features of the 2305 Tractor

This compact machine is designed to deliver exceptional performance for a variety of tasks. With its efficient engine and robust construction, it stands out in the realm of agricultural and landscaping equipment. Users benefit from a range of features that enhance both functionality and comfort, making it an ideal choice for homeowners and professionals alike.

Power and Efficiency

Equipped with a powerful engine, this model provides reliable torque and speed, enabling it to tackle challenging jobs with ease. The fuel efficiency is a significant advantage, allowing operators to complete tasks without frequent refueling. Moreover, the intuitive controls ensure a smooth operation, even for those who are less experienced.

Versatility and Attachments

The versatility of this tractor is enhanced by its compatibility with numerous attachments. Whether it’s mowing, tilling, or snow removal, the machine adapts to various applications effortlessly. The ease of switching between implements is a key feature, saving time and increasing productivity. This adaptability makes it a valuable asset for a wide range of users.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations of these elements serve as essential guides, enabling users to identify, locate, and comprehend each part’s function within the overall system. This clarity not only facilitates quicker troubleshooting but also enhances the user’s confidence when addressing mechanical issues.

Enhancing Efficiency

Having a clear visual reference significantly boosts operational efficiency. It allows technicians and operators to quickly pinpoint areas needing attention, reducing downtime and minimizing the likelihood of errors during assembly or disassembly. This efficiency is vital in maintaining productivity, especially in environments where time is a critical factor.

Facilitating Learning and Knowledge Sharing

Visual aids play a key role in education and training. Newcomers can familiarize themselves with machinery through detailed illustrations, promoting a better understanding of complex systems. Furthermore, these resources can enhance communication among team members, as they provide a common language for discussing specific components and their roles.

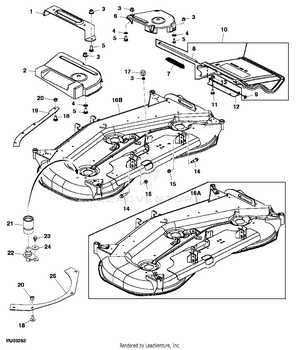

How to Read Parts Diagrams

Understanding visual representations of components is essential for anyone looking to maintain or repair machinery. These illustrations serve as guides, providing a clear view of how different elements are arranged and connected within a system. Familiarizing yourself with these visuals can enhance your ability to identify necessary replacements and perform effective troubleshooting.

To effectively interpret these visuals, start by examining the overall layout. Note the arrangement and grouping of various elements, which can indicate their function and relationship to one another. Look for labels or reference numbers that correspond to descriptions in accompanying documentation. This can help clarify the role of each part and how they contribute to the machinery’s operation.

Next, pay attention to the symbols and lines used in the illustration. Solid lines often represent physical connections, while dashed lines may indicate relationships that are less direct. Understanding these symbols is crucial for deciphering the intended design and function of each component.

Additionally, consider the scale of the representation. Some visuals may be simplified for clarity, while others provide detailed views of complex assemblies. Always cross-reference with manufacturer specifications to ensure accuracy in identification and selection of components.

Lastly, practice is key. The more you engage with these representations, the more intuitive your understanding will become. Over time, you will be able to quickly identify essential elements and navigate through the information with confidence.

Common Issues with 2305 Parts

When working with a compact utility tractor, several challenges may arise regarding its components. Understanding these common concerns can help owners maintain their equipment more effectively and avoid unnecessary downtime.

Wear and Tear

Over time, components can experience significant wear, leading to decreased performance and potential failure. Regular inspection of moving parts, belts, and hoses is crucial to identify signs of deterioration early. Ignoring these issues can result in more extensive repairs and increased costs.

Compatibility Problems

Using incorrect or incompatible components can lead to malfunction or inefficiency. It’s essential to ensure that any replacements match the specifications of the equipment. Owners should always refer to the manufacturer’s guidelines to confirm compatibility before making any purchases.

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process if you know where to look. Various resources offer a wide selection of items that ensure your equipment remains operational and efficient. Whether you prefer online shopping or visiting local retailers, understanding your options will save time and effort.

Online Retailers

The internet hosts numerous platforms dedicated to selling machinery components. Major websites provide user-friendly interfaces, allowing you to search for specific items with ease. Additionally, many sites offer customer reviews and ratings to assist in making informed decisions.

Local Dealerships

Visiting nearby dealerships can also yield valuable results. These establishments often stock a range of items tailored for specific machinery. Speaking with knowledgeable staff can provide insights into compatibility and alternative solutions that might suit your needs.

| Resource Type | Advantages |

|---|---|

| Online Retailers | Wide selection, customer reviews, convenience |

| Local Dealerships | Personalized service, immediate access, expert advice |

| Used Parts Suppliers | Cost-effective options, unique finds |

| Manufacturer Websites | Genuine components, warranty options |

Maintenance Tips for John Deere 2305

Proper upkeep is essential for the longevity and performance of your machinery. Regular maintenance ensures that all components function optimally, reducing the risk of unexpected failures and enhancing efficiency. Following a structured maintenance routine can save time and costs in the long run.

Here are some vital maintenance tips to consider:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace engine oil to ensure smooth operation and prevent wear. |

| Filter Replacement | Every 100 hours | Change air and fuel filters to maintain optimal airflow and fuel efficiency. |

| Tire Inspection | Monthly | Check tire pressure and tread for safety and performance. |

| Battery Maintenance | Monthly | Inspect terminals and connections; clean corrosion if necessary. |

| Greasing | Every 25 hours | Lubricate moving parts to reduce friction and extend service life. |

Implementing these practices will ensure your equipment remains in peak condition, ready to tackle any tasks effectively. Always refer to the manufacturer’s guidelines for specific recommendations and additional care tips.

Upgrading Components for Better Performance

Enhancing the functionality of machinery is crucial for achieving optimal results in various tasks. By upgrading specific elements, users can significantly improve efficiency, durability, and overall performance. This section explores essential upgrades that can lead to substantial improvements.

Consider focusing on the following components:

- Engine Upgrades: Increasing horsepower and torque can lead to better handling of demanding tasks.

- Transmission Enhancements: Improving shifting mechanisms allows for smoother transitions and better power delivery.

- Hydraulic System Modifications: Upgrading pumps and valves can enhance lifting capacity and speed.

- Electrical System Improvements: Incorporating advanced wiring and battery systems can boost reliability and performance.

In addition to these components, consider the benefits of regular maintenance and compatibility checks when selecting upgrades. Ensuring that new parts work harmoniously with existing systems is key to maximizing performance gains.

Ultimately, investing in high-quality upgrades not only enhances functionality but also extends the lifespan of the equipment, making it a worthwhile endeavor for any operator.

Original vs. Aftermarket Parts

When it comes to machinery maintenance, choosing between factory-made components and those produced by independent manufacturers can significantly impact performance and longevity. Each option presents distinct advantages and considerations that can influence decision-making for owners and operators alike.

Factory-manufactured components often guarantee compatibility and reliability, as they are specifically designed to fit the machinery’s specifications. They typically undergo rigorous testing to ensure they meet industry standards, providing peace of mind to users who prioritize quality and performance.

On the other hand, components from third-party suppliers may offer cost savings and a wider variety of choices. While some aftermarket options can match or even exceed the performance of original offerings, it’s crucial to research the reputation and quality of the manufacturer to avoid potential pitfalls associated with inferior products.

Ultimately, the choice between these two types of components hinges on factors such as budget, performance requirements, and individual preferences. Making an informed decision can lead to improved efficiency and a more satisfying ownership experience.

Safety Precautions During Repairs

When undertaking maintenance or repair tasks on machinery, ensuring safety is paramount. Proper precautions help mitigate risks associated with mechanical work, creating a secure environment for both the technician and the equipment. This section outlines essential measures to prioritize during any repair process.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and steel-toed boots. These items provide essential protection against potential hazards such as sharp edges, flying debris, or heavy objects.

Additionally, it is crucial to work in a well-ventilated area. Many repairs involve the use of chemicals or create dust, which can be harmful if inhaled. Ensuring adequate airflow minimizes exposure to these substances, promoting a healthier workspace.

Before starting any work, ensure the machinery is turned off and properly secured. Disengaging power sources and using lockout/tagout procedures prevents accidental starts, reducing the risk of injury. Always verify that all moving parts are at a complete stop.

Furthermore, familiarize yourself with the specific equipment being serviced. Understanding its components and functionality helps in recognizing potential dangers. Consulting the manufacturer’s guidelines or technical manuals can provide valuable insights into safe handling practices.

Lastly, maintain a clean and organized workspace. Clutter can lead to accidents, making it difficult to move safely around the area. Keeping tools and materials neatly stored minimizes distractions and enhances overall efficiency during the repair process.