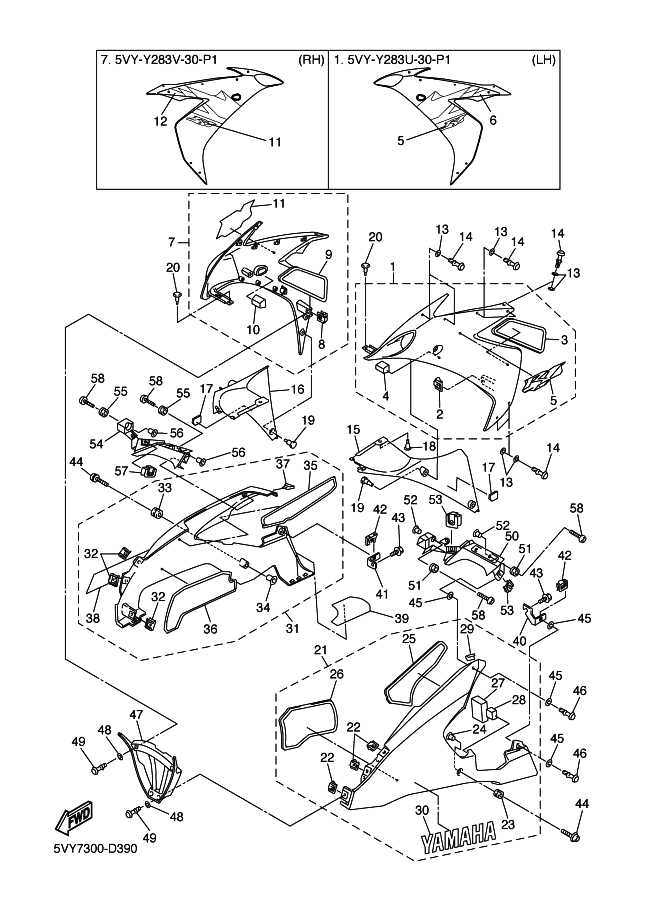

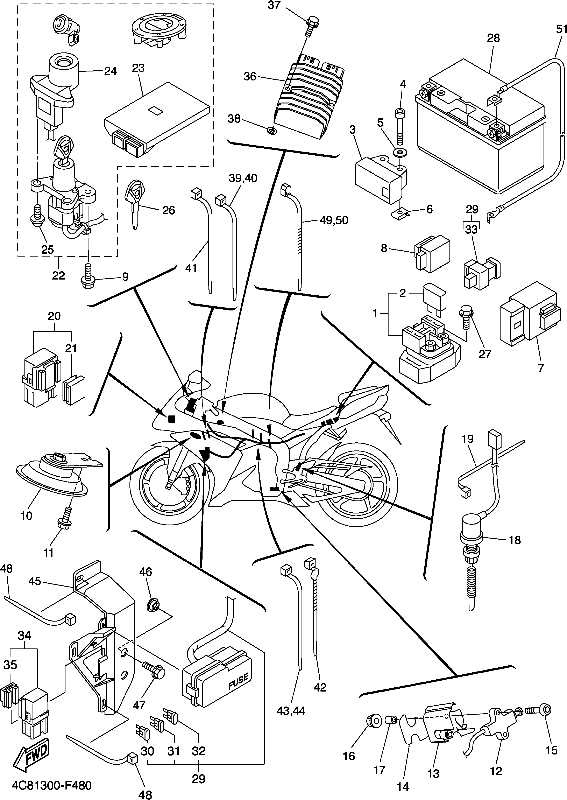

Complete Parts Diagram for the 2007 Yamaha R1

In the realm of high-performance motorcycles, comprehending the intricate layout of various components is essential for both enthusiasts and mechanics. Each model boasts a unique arrangement that plays a crucial role in its overall functionality and performance. By delving into these schematics, one can gain invaluable insights into the mechanics of the machine, enhancing both maintenance practices and customization efforts.

Detailed illustrations serve as a roadmap for those looking to understand how each element interconnects. Such visual guides not only simplify complex assemblies but also empower users to identify potential areas for improvement or repair. This knowledge can be particularly beneficial for those embarking on restoration projects or seeking to upgrade their ride.

Moreover, familiarizing oneself with the layout can lead to a greater appreciation of engineering excellence in motorcycle design. Each part, from the engine to the frame, is meticulously crafted to deliver an exhilarating experience on the road. By exploring these layouts, riders can better appreciate the craftsmanship that goes into creating a high-performance machine.

Understanding the 2007 Yamaha R1

This section delves into the intricacies of a high-performance motorcycle model, emphasizing its engineering excellence and design philosophy. A blend of speed, agility, and aesthetics, this machine captures the essence of modern motorcycling, appealing to enthusiasts and professionals alike. Understanding its components can enhance the riding experience and maintenance knowledge.

Design and Performance

The aesthetic appeal of this model is matched by its powerful engine and cutting-edge technology. Every curve and contour serves a purpose, contributing to aerodynamics and stability. Riders can appreciate the balance between form and function, which ensures optimal performance on various terrains.

Maintenance Insights

Maintaining such a sophisticated vehicle requires knowledge of its inner workings. Familiarity with essential elements not only prolongs the lifespan but also ensures safety and reliability. Regular inspections and understanding how each component interacts will empower riders to make informed decisions regarding upkeep and modifications.

Key Features of the 2007 Model

This model is renowned for its remarkable blend of performance, design, and advanced technology. It reflects the pinnacle of engineering in its category, offering a riding experience that is both exhilarating and precise. Here are some of the standout attributes that contribute to its legendary status.

Performance Enhancements

- Powerful engine with enhanced torque delivery.

- Lightweight chassis for improved handling and agility.

- Advanced suspension system providing superior stability.

- State-of-the-art braking technology for optimal safety.

Design Features

- Sleek, aerodynamic profile reducing drag.

- High-quality materials ensuring durability and style.

- Ergonomic seating position for comfort during long rides.

- Vibrant color options that enhance visual appeal.

These characteristics not only elevate the riding experience but also solidify the model’s reputation in the competitive landscape of high-performance motorcycles.

Importance of Parts Diagrams

Understanding the intricate layout of components within any machine is crucial for maintenance and repair. Visual representations that illustrate how various elements fit together not only enhance comprehension but also facilitate efficient troubleshooting. These resources serve as essential tools for both professionals and enthusiasts, enabling a clearer grasp of complex systems.

Additionally, these illustrations play a vital role in ensuring that the correct replacements are identified, reducing the risk of errors during repairs. With accurate depictions, users can locate specific pieces with ease, leading to quicker assembly and disassembly processes. Furthermore, they help in planning upgrades or modifications by showcasing compatibility between different components.

Ultimately, having access to detailed visual guides enhances the overall experience of ownership and maintenance, allowing users to engage more deeply with their machinery. This level of insight not only fosters a greater appreciation for engineering but also empowers individuals to take control of their maintenance tasks with confidence.

How to Read Parts Diagrams

Understanding the layout of technical illustrations can significantly enhance your ability to identify and source components for maintenance or repair. These visual guides serve as a reference to show the arrangement and relationship between various elements, facilitating a smoother workflow when tackling any project.

Breaking Down the Visuals

The first step in interpreting these illustrations is to familiarize yourself with the symbols and notations used. Each representation corresponds to a specific item, often accompanied by a reference number that links it to a detailed list. This list typically includes descriptions and part numbers, enabling efficient ordering.

Utilizing the Key Information

| Reference Number | Description | Part Number |

|---|---|---|

| 1 | Handlebar Grip | GRP1234 |

| 2 | Foot Peg | PEG5678 |

| 3 | Brake Lever | LEV9101 |

By cross-referencing the visual with the accompanying list, you can easily locate and order the items you need, ensuring your project remains on track and well-organized. Mastering this skill not only saves time but also reduces frustration, making your repair or maintenance efforts more effective.

Common Replacement Parts for R1

Maintaining optimal performance and safety is crucial for any motorcycle enthusiast. Over time, certain components may wear out or require replacement to ensure the vehicle operates smoothly. Identifying these key elements can greatly enhance the longevity and reliability of your ride.

One of the most frequently replaced items is the brake pads, which are essential for effective stopping power. Regular inspections are necessary to determine their condition and replace them as needed. Additionally, the chain and sprockets are vital for power transmission, and periodic replacement can improve acceleration and handling.

Another common component that may need attention is the air filter. Keeping it clean ensures proper airflow to the engine, which can positively impact performance and fuel efficiency. Furthermore, batteries are essential for starting the motorcycle and powering electrical systems. A faulty battery can lead to starting issues and should be tested regularly.

Lastly, tires are critical for traction and stability. Replacing worn tires is necessary to maintain safety and handling characteristics. Staying proactive about these components will help ensure a smooth and enjoyable riding experience.

Maintenance Tips for 2007 Yamaha R1

Proper upkeep is essential for ensuring optimal performance and longevity of your motorcycle. Regular maintenance not only enhances reliability but also contributes to a safer riding experience. Following a systematic approach to care can prevent common issues and keep your machine in top condition.

Start by checking the fluid levels regularly, including engine oil, coolant, and brake fluid. Maintaining appropriate levels is crucial for smooth operation and can help avoid serious damage. It’s advisable to replace the engine oil and filter at recommended intervals to keep the engine running smoothly.

Inspect the tires frequently for wear and proper inflation. Proper tire pressure ensures better handling and stability, especially during high-speed rides. Additionally, ensure that the tread depth is adequate to provide necessary grip on the road.

Pay attention to the braking system, as it is vital for safety. Regularly check the brake pads for wear and replace them if they appear worn down. Also, inspect the brake fluid for contamination and replace it if necessary to ensure optimal braking performance.

Don’t forget about the chain maintenance. Keep it clean and lubricated to ensure smooth power transfer. Adjust the tension as needed to prevent excessive wear and prolong its lifespan.

Finally, keep an eye on the electrical system. Regularly inspect the battery and connections for corrosion. Cleaning these components can help maintain electrical efficiency and prevent starting issues.

Where to Find Authentic Parts

Locating genuine components for your motorcycle is essential for ensuring optimal performance and longevity. When seeking out these items, it’s crucial to focus on trusted sources that prioritize quality and reliability. By doing so, you can avoid potential pitfalls associated with counterfeit or substandard replacements.

One of the best approaches is to visit authorized dealers who specialize in your specific brand. These establishments often carry a comprehensive selection of genuine components and provide expert advice. Additionally, they frequently have access to the latest inventory and can assist with any specific needs you might have.

Online marketplaces can also serve as valuable resources. Look for reputable websites that are known for their commitment to authenticity. Always check customer reviews and ratings to gauge the reliability of the seller before making a purchase.

Another option is to connect with local motorcycle clubs or forums. Enthusiasts often share insights about where to find authentic components and may even sell items they no longer need. Engaging with a community of riders can lead to excellent recommendations and potential discounts.

Lastly, consider attending motorcycle shows or swap meets. These events often feature vendors specializing in genuine components and can provide unique opportunities to find exactly what you need while networking with other enthusiasts.

Popular Upgrades for Performance

Enhancing the performance of a high-performance motorcycle can significantly improve riding experience and overall capabilities. Riders often seek modifications that boost speed, handling, and acceleration, allowing them to fully exploit the machine’s potential. Below are some of the most sought-after enhancements to elevate your riding performance.

Engine Modifications

- High-Performance Exhaust System: Upgrading to a more efficient exhaust system can increase horsepower by reducing back pressure and improving engine breathability.

- Fuel Management System: A programmable fuel management system optimizes fuel delivery, ensuring the engine runs smoothly and efficiently under various conditions.

- Air Intake Kit: A high-flow air intake allows more air into the engine, promoting better combustion and improved throttle response.

Suspension Enhancements

- Adjustable Shock Absorbers: Installing adjustable shocks can provide personalized suspension tuning, enhancing comfort and handling.

- Upgraded Forks: Replacing the stock forks with high-quality aftermarket options can significantly improve front-end stability and cornering performance.

- Stiffer Springs: Upgrading to stiffer springs can help maintain ride height and prevent bottoming out during aggressive maneuvers.

DIY Repair Techniques Explained

When it comes to maintaining and fixing your vehicle, understanding fundamental repair methods can save both time and money. Mastering these skills empowers you to tackle various issues independently, ensuring your machine runs smoothly and efficiently. This section delves into essential repair techniques that every enthusiast should know, enabling you to perform effective repairs with confidence.

From diagnosing common problems to executing simple fixes, grasping these techniques will enhance your mechanical knowledge and proficiency. Below, you will find a table summarizing key repair methods along with brief explanations.

| Repair Technique | Description |

|---|---|

| Visual Inspection | A thorough examination of components for wear, damage, or leaks to identify issues before they escalate. |

| Basic Tools Usage | Employing standard tools like wrenches and screwdrivers to perform minor repairs and adjustments. |

| Fluid Changes | Regularly replacing oils and other fluids to maintain optimal performance and prolong component life. |

| Electrical Diagnostics | Utilizing multimeters and testers to troubleshoot electrical systems and ensure proper functionality. |

| Part Replacement | Swapping out faulty components with new or refurbished ones to restore operational integrity. |

Choosing the Right Tools

When working on any vehicle, selecting the appropriate tools is essential for effective maintenance and repair. Having the right equipment not only enhances efficiency but also ensures that tasks are completed safely and accurately.

Begin by assessing the specific requirements of the task at hand. Different jobs may necessitate various instruments, from basic hand tools to specialized equipment. For instance, a quality set of wrenches and sockets is vital for most assembly and disassembly tasks, while precision tools like torque wrenches are crucial for ensuring that components are secured to the manufacturer’s specifications.

Quality matters. Investing in durable and reliable tools can save time and money in the long run. Tools that are built to last will provide better performance and reduce the risk of damage to your vehicle. Additionally, consider the ergonomics of the tools you choose; comfortable handles and designs can significantly improve your overall experience while working.

Don’t forget about organization. Keeping your tools neatly arranged and accessible can streamline your workflow. Toolboxes or organizers not only protect your equipment but also make it easier to find what you need quickly, minimizing downtime during repairs.

Identifying OEM vs. Aftermarket Parts

Understanding the distinction between original equipment and alternative components is essential for any enthusiast. Original equipment components are produced by the manufacturer and are typically designed to meet specific quality and performance standards. In contrast, alternative components are made by third-party companies, often aiming to provide similar functionality at a potentially lower cost.

When evaluating these options, consider factors such as compatibility, performance, and warranty coverage. Original components generally ensure a perfect fit and reliable operation, while alternative options may offer varied quality. Researching the reputation of alternative manufacturers can help in making informed decisions.

Ultimately, the choice between original and alternative components depends on personal preferences and the intended use of the vehicle. Whether seeking authenticity or value, understanding these differences is key to making the right choice.

Online Resources for R1 Owners

For enthusiasts and operators of high-performance motorcycles, accessing reliable information is crucial. A variety of online platforms cater to the needs of riders, offering a wealth of resources such as manuals, repair guides, and community forums. These tools not only enhance the ownership experience but also provide vital support for maintenance and upgrades.

Essential Websites

Several dedicated websites focus on delivering comprehensive information for motorcycle owners. Here are a few noteworthy platforms:

| Website | Description |

|---|---|

| Motorcycle Forums | A vibrant community where riders share experiences, tips, and troubleshooting advice. |

| Service Manuals | Access to downloadable manuals that cover a range of maintenance procedures and specifications. |

| Parts Retailers | Online shops that provide a wide selection of aftermarket and OEM components. |

Social Media Groups

Social platforms have become valuable tools for connecting with fellow enthusiasts. Joining specific groups can lead to discovering new tips, event notifications, and collaborative projects.

Benefits of Using Parts Diagrams

Utilizing visual schematics for components can significantly enhance the understanding and maintenance of mechanical systems. These illustrations provide a clear representation of individual elements and their relationships, aiding both novice and experienced individuals in grasping complex assemblies.

Improved Clarity and Understanding

Visual representations simplify the intricacies of machinery. By presenting components in an organized manner, users can easily identify specific elements and their functions within the overall structure. This clarity fosters a deeper comprehension of how various elements interact, ultimately leading to more effective repairs and modifications.

Enhanced Efficiency in Repairs

Using schematics streamlines the repair process by allowing quick identification of necessary items for replacement or adjustment. This efficiency minimizes downtime and reduces the likelihood of errors during maintenance tasks. Consequently, individuals can complete repairs swiftly and accurately, ensuring optimal performance of their mechanical systems.