Woodmaster 5500 Parts Breakdown and Diagram

Outdoor heating units play a vital role in ensuring comfort during cold seasons, but like any mechanical system, they require regular upkeep to function at their best. Understanding how each component fits into the overall structure of the heating setup is key to maintaining its performance. Keeping the system in top condition minimizes the risk of unexpected breakdowns and extends its lifespan.

Familiarizing yourself with the various elements that make up the heating unit helps in identifying issues quickly and implementing solutions effectively. Whether it’s ensuring the fluid circulation is uninterrupted or making sure the airflow is optimal, knowing the ins and outs of these systems empowers you to take timely action and avoid costly repairs.

For anyone tasked with the upkeep of such systems, having a clear and detailed visual guide to the individual components is indispensable. This allows for an accurate understanding of what needs attention and ensures smooth and consistent operation.

Understanding the Woodmaster 5500 Components

Exploring the key elements of this heating system helps users understand its functionality and efficiency. Familiarity with the major sections and their roles can significantly enhance performance and maintenance practices.

Core Structure and Functionality

The core sections are responsible for the heating process and ensuring proper circulation. The primary heating chamber, heat exchangers, and connecting pipes work together to distribute warmth efficiently. These parts create a seamless flow, optimizing energy use and minimizing heat loss.

- Heating chamber: Maintains optimal temperatures for fuel combustion.

- Exchangers: Transfer heat to water for even distribution.

- Pipes: Direct the heated water to connected systems for space warming.

Control and Monitoring Elements

Proper monitoring is essential to keep the system running smoothly. The control panel, sensors, and safety valves work in harmony to ensure stability and provide real-time updates on performance.

- Control panel: Allows users to adjust settings and view system status.

- Sensors: Detect temperature changes and trigger necessary actions.

- Safety valves: Prevent overheating by regulating pressure levels.

Burning Chamber: Core Functionality

The burning chamber is the heart of the heating system, where fuel is converted into energy through controlled combustion. It plays a vital role in maintaining consistent heat output, ensuring the efficient transformation of fuel into usable heat. The chamber’s design allows for optimal air circulation, promoting a cleaner burn and maximizing energy production.

Key Elements of the Burning Process

- Airflow management: Ensures sufficient oxygen reaches the fire, allowing for consistent combustion.

- Temperature regulation: Maintains a balanced internal temperature, critical for maximizing fuel efficiency.

- Ash collection: Helps remove byproducts of combustion, preventing buildup that could affect performance.

Maintenance for Longevity

Regular upkeep of the burning chamber is essential for maintaining its efficiency and prolonging the system’s life. Cleaning out ash and inspecting components can prevent potential issues and ensure that the chamber continues to function at its best.

Water Circulation System Overview

The water circulation system plays a crucial role in maintaining consistent thermal regulation by transporting heated liquid through the system. This process ensures that heat is evenly distributed, supporting efficient energy use and stable temperature management. By facilitating a continuous flow, the system prevents overheating and helps maintain a balanced environment.

Flow of Heated Liquid

At the heart of the circulation process is the movement of warmed liquid through insulated pathways. This flow ensures the transfer of thermal energy, directing the warmth to where it’s needed. By circulating in a closed-loop, the system minimizes heat loss and enhances overall performance.

Maintaining Balance and Efficiency

Efficient circulation helps regulate the temperature across all zones. By ensuring smooth flow, the system reduces the chances of uneven heating, promoting energy conservation and preventing stress on the components.

Heat Exchanger Components Explained

A heat exchanger operates by transferring heat from one medium to another, ensuring an efficient energy exchange. The components within this system are carefully designed to facilitate this process while maintaining temperature control. Each element plays a role in optimizing the flow and distribution of heat.

Core Tubing is where the actual heat exchange happens, allowing thermal energy to pass between two environments without direct contact. The material of the tubing is selected for its ability to withstand high temperatures and corrosion.

The fins attached to the tubing increase the surface area for heat transfer, enhancing the efficiency of the entire unit. These fins ensure that more heat is absorbed or released during the process.

Headers at both ends of the system guide the flow of the mediums through the exchanger. These components ensure the fluid or gas is distributed evenly throughout the tubes, maximizing the system’s performance.

In conclusion, the seamless interaction of these parts guarantees efficient heat exchange, contributing to the overall energy efficiency of the system.

Maintenance of the Ash Removal System

The efficiency of any heating system largely depends on the proper upkeep of its ash removal mechanism. Regular cleaning and inspection ensure smooth functioning, reduce wear and tear, and enhance the longevity of the system. Neglecting this can lead to blockages and inefficient operation, making maintenance essential for optimal performance.

Regular Cleaning

- Empty the ash tray frequently to prevent overflow and excessive buildup.

- Inspect the tray for any signs of rust or damage and replace it if necessary.

- Clear any debris from the surrounding area to avoid interference with system components.

System Check

- Ensure the ash auger, if present, operates smoothly and without obstruction.

- Lubricate moving parts periodically to reduce friction and prevent wear.

- Check the seals around the ash door to maintain a proper seal and avoid heat loss.

Insulation Panels: Purpose and Benefits

Insulation panels serve a crucial role in enhancing energy efficiency and maintaining optimal temperatures in various environments. These components are designed to minimize heat transfer, thereby contributing to a more comfortable atmosphere while reducing energy costs. Their application spans across multiple sectors, including residential, commercial, and industrial settings.

Key Functions of Insulation Panels

- Energy Conservation: By reducing heat loss in winter and keeping spaces cooler in summer, insulation panels help lower energy consumption.

- Noise Reduction: These panels can effectively dampen sound, making environments quieter and more conducive to work or relaxation.

- Moisture Control: They can prevent condensation and moisture buildup, protecting structures from potential damage.

Advantages of Using Insulation Panels

- Cost Savings: Lower energy bills due to improved efficiency lead to long-term savings.

- Comfort: Enhanced thermal performance creates a more pleasant living or working environment.

- Environmental Impact: Reduced energy use contributes to lower carbon emissions and supports sustainability efforts.

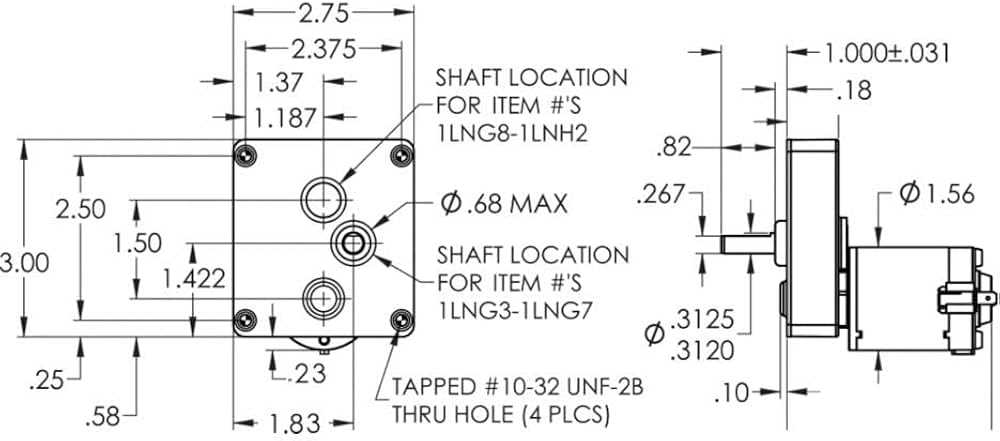

Blower Fan: Importance in Operation

The blower fan plays a crucial role in the functionality of various machinery, contributing significantly to overall performance. It facilitates air circulation, ensuring that components remain cool and operate efficiently. Proper airflow is essential for maintaining optimal temperatures, which can directly affect the longevity and effectiveness of the equipment.

Key Functions of the Blower Fan

- Cooling: The primary function of the blower fan is to dissipate heat generated by internal components, preventing overheating.

- Airflow Management: It helps regulate air movement within the system, promoting consistent performance and reliability.

- Dust and Debris Removal: The fan aids in removing particles and contaminants that can accumulate, ensuring clean operation.

Impact on Performance

A well-functioning blower fan not only enhances efficiency but also reduces energy consumption. If the fan is malfunctioning, it can lead to decreased performance and potential damage to other parts. Regular maintenance and timely replacement are vital for sustaining optimal operations.

Understanding the Temperature Control System

The temperature regulation mechanism is essential for ensuring optimal operation in various appliances. This system maintains the desired thermal conditions by continuously adjusting the heat output based on user settings and environmental changes. A comprehensive grasp of how this control system functions can significantly enhance the efficiency and effectiveness of the equipment.

Key Components of the Temperature Regulation Mechanism

Several crucial elements work in unison to facilitate accurate temperature management. Sensors play a vital role by detecting the current temperature and relaying this information to the control unit. This unit processes the data and sends signals to heating elements to either increase or decrease their activity, thereby achieving the target temperature.

Importance of Calibration and Maintenance

Regular calibration and maintenance of the temperature control system are vital for its longevity and reliability. Ensuring that sensors are clean and functioning properly helps prevent inaccurate readings that could lead to undesired temperature fluctuations. Moreover, periodic checks on the control unit and heating elements can help identify potential issues before they escalate, ensuring consistent performance.

Accessing and Replacing Door Seals

Maintaining the integrity of the door seals is essential for optimal performance and efficiency. Properly functioning seals prevent air and moisture from entering, ensuring a stable environment inside. This section outlines the steps to access and replace these components effectively.

Steps to Access the Seals

To begin the replacement process, follow these instructions:

- Gather the necessary tools, including a screwdriver, replacement seals, and cleaning materials.

- Ensure the equipment is powered off and disconnected from any power source.

- Carefully remove any screws or fasteners securing the door to expose the seals.

- Inspect the existing seals for signs of wear or damage.

Replacing the Seals

Once the seals are accessible, proceed with the replacement:

- Clean the sealing surface to remove any debris or old adhesive.

- Align the new seals with the designated grooves, ensuring a snug fit.

- Secure the seals in place, applying adhesive if necessary.

- Reattach the door, ensuring all screws and fasteners are tightened properly.

Regularly inspecting and replacing seals will enhance the longevity and functionality of your equipment.

Electrical Wiring: Safety and Layout

Ensuring proper electrical wiring is essential for the functionality and safety of machinery. A well-planned layout can help prevent hazards and improve operational efficiency. Understanding the fundamental principles of wiring can assist users in maintaining a safe working environment.

When dealing with electrical systems, it is crucial to adhere to safety protocols. Consider the following guidelines:

- Use Protective Gear: Always wear appropriate safety equipment, such as gloves and goggles, to minimize risks.

- Turn Off Power: Before starting any work, ensure that the power supply is disconnected to prevent electric shock.

- Check Connections: Regularly inspect all connections for signs of wear or damage, which could lead to malfunctions.

- Follow Wiring Codes: Adhere to local electrical codes and standards to ensure compliance and safety.

Layout planning is equally important. A clear and organized wiring scheme can enhance maintenance and troubleshooting. Here are some tips for effective wiring layout:

- Plan Pathways: Designate specific pathways for wiring to avoid interference with moving parts.

- Label Wires: Clearly label all wires to simplify identification during repairs or modifications.

- Group Similar Circuits: Keep similar electrical circuits together to streamline troubleshooting efforts.

- Utilize Cable Management: Employ cable ties or channels to keep wires neat and reduce clutter.

By following these safety measures and layout strategies, users can create a secure and efficient electrical environment, ultimately enhancing the overall performance of the equipment.

Optional Accessories and Enhancements

Enhancements and supplementary components can significantly improve the functionality and versatility of your equipment. These additional features offer users the ability to customize their setup, allowing for more efficient operation and greater adaptability to various tasks.

Common enhancements include upgraded blades, specialized attachments, and advanced control systems that facilitate more precise adjustments. These accessories not only enhance performance but also contribute to a more user-friendly experience.

| Accessory Type | Description | Benefits |

|---|---|---|

| Upgraded Blades | High-quality blades designed for specific materials | Increased cutting efficiency and durability |

| Specialized Attachments | Additional tools that extend functionality | Versatility for various tasks and projects |

| Control Systems | Advanced settings for precision and ease of use | Enhanced control over operation parameters |

Investing in these accessories can lead to improved outcomes, making it easier to achieve your desired results while enhancing the overall user experience.