Understanding the New Holland 499 Haybine Parts Diagram

In the world of modern agriculture, efficient machinery plays a crucial role in maximizing productivity. One such implement is designed for cutting and conditioning forage, ensuring that farmers can maintain high-quality feed for their livestock. Grasping the intricacies of this machine’s structure is essential for both operation and maintenance, enabling users to achieve optimal performance.

Farmers and technicians alike benefit from a comprehensive understanding of the various elements that comprise this essential tool. By familiarizing themselves with the configuration and function of each segment, they can ensure smoother operation and quicker repairs. This knowledge not only enhances the lifespan of the implement but also contributes to a more productive farming experience.

This article will delve into the specifics of the machine’s components, offering a detailed visual representation to aid in understanding. Whether you are a seasoned professional or a newcomer to agricultural practices, this information will equip you with the insights needed to work efficiently with this vital equipment.

Understanding New Holland 499 Haybine

This section delves into the essential components and mechanisms of a well-known agricultural implement designed for cutting and conditioning forage. By grasping its functionality, users can optimize performance and ensure effective maintenance for prolonged use.

Key Features and Benefits

The implement boasts a robust construction, which is vital for handling various field conditions. Its ability to efficiently cut grass and legumes significantly enhances productivity on the farm. The unique design facilitates seamless operation, minimizing downtime during busy seasons.

Maintenance Tips

Regular upkeep is crucial to prolong the life of this machinery. It is advisable to conduct routine inspections and address any wear promptly. Keeping blades sharp and ensuring proper lubrication are essential practices that contribute to overall efficiency and reliability.

Overview of Haybine Equipment

In the world of agricultural machinery, certain implements play a crucial role in enhancing efficiency and productivity during the harvesting process. These versatile tools are designed to cut and condition forage, ensuring optimal preparation for drying and storage. Understanding the functionality and components of such equipment is essential for maximizing its benefits on the farm.

Typically, these machines feature a combination of cutting blades and conditioning rolls that work in tandem to provide a clean cut while also breaking down plant material. This dual-action not only accelerates the drying process but also improves the quality of the final product. With various models available, farmers can select equipment tailored to their specific needs, balancing size, power requirements, and additional features.

Maintenance is a critical aspect of using these implements effectively. Regular checks on the blades, conditioning systems, and overall mechanics ensure smooth operation and longevity. By understanding the main components and their functions, operators can troubleshoot issues quickly, minimizing downtime during peak seasons.

Overall, these specialized agricultural tools represent a significant investment in productivity. By integrating modern technologies and innovative designs, they provide essential support to farmers striving for efficiency in forage management.

Key Features of the 499 Model

This model stands out due to its exceptional design and functionality, making it an ideal choice for efficient agricultural operations. Users appreciate its reliability and advanced technology that enhances productivity in the field.

- Durability: Constructed with high-quality materials for long-lasting performance.

- Efficiency: Optimized for quick and effective cutting, saving time during harvest.

- Versatility: Capable of handling various crop types, ensuring adaptability across different farming needs.

- User-Friendly Controls: Intuitive operation system simplifies the handling for operators.

- Maintenance Accessibility: Designed for easy access to components, facilitating quick servicing.

These features collectively contribute to the ultimate performance, making it a valuable asset for modern farming practices.

Importance of Replacement Parts

Ensuring the optimal performance and longevity of agricultural machinery hinges on the availability and quality of essential components. Timely replacement of worn or damaged elements is crucial for maintaining efficiency, enhancing productivity, and minimizing downtime. Understanding the significance of these components can greatly impact operational success.

Benefits of Timely Replacements

- Enhanced Performance: Fresh components ensure machinery operates at peak efficiency, reducing the risk of breakdowns.

- Increased Safety: Replacing faulty parts minimizes the risk of accidents, protecting both the operator and the equipment.

- Cost-Effectiveness: Regular updates prevent more severe damage, which can lead to costly repairs and replacements in the future.

- Improved Reliability: Trustworthy components enhance the overall reliability of machinery, providing peace of mind during operations.

Choosing the Right Components

- Evaluate compatibility with existing machinery.

- Consider the quality and reputation of the manufacturer.

- Assess the warranty and support options available.

- Review user feedback and testimonials for insights.

By prioritizing the maintenance and replacement of critical components, operators can ensure their machinery remains functional and efficient for years to come.

Common Issues with Haybines

In the world of agricultural machinery, certain challenges frequently arise that can impede the efficiency and effectiveness of cutting and conditioning crops. Understanding these common problems can help operators maintain their equipment and ensure smooth operation during critical harvesting periods.

| Issue | Description | Possible Solutions |

|---|---|---|

| Worn Blades | Over time, the cutting edges can become dull, leading to inefficient crop cutting. | Regularly sharpen or replace blades to ensure optimal performance. |

| Clogging | Debris and wet materials can accumulate, blocking the flow of cut crops. | Inspect and clean the machine frequently to prevent build-up. |

| Alignment Issues | Improper alignment can lead to uneven cutting and additional strain on components. | Regularly check and adjust the alignment of the cutting assembly. |

| Hydraulic Failures | Leaks or malfunctions in hydraulic systems can impede operation. | Conduct regular inspections and maintenance of hydraulic components. |

| Mechanical Wear | Parts may wear out over time, affecting overall efficiency. | Perform routine maintenance and replace worn components promptly. |

Finding the Right Parts Online

Locating the appropriate components for agricultural machinery can be a straightforward task with the right approach. The vast selection available online allows users to efficiently find what they need without the hassle of traditional shopping.

Here are some effective strategies to ensure a successful search:

- Utilize Specific Keywords: Include model numbers or unique identifiers to narrow down your search results.

- Check Manufacturer Websites: Often, official sites provide accurate and comprehensive catalogs.

- Explore Online Marketplaces: Platforms like eBay or Amazon can have a variety of sellers offering competitive prices.

- Read Customer Reviews: Insights from other buyers can help assess the quality and reliability of the components.

- Join Online Forums: Engaging with communities focused on agricultural equipment can provide valuable recommendations and sources.

By applying these strategies, you can enhance your chances of finding the exact components you require efficiently and effectively.

Maintenance Tips for Longevity

Ensuring the durability of agricultural machinery requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of the equipment. By following a few essential guidelines, operators can avoid costly repairs and downtime.

Regular Inspections

Conduct frequent examinations of your machinery to identify any signs of wear and tear. Check for loose components, leaks, and unusual noises. Addressing small issues promptly can prevent them from escalating into major problems.

Proper Lubrication

Utilize the recommended lubricants for all moving parts. Adequate lubrication minimizes friction, reducing wear and enhancing efficiency. Refer to the manufacturer’s guidelines for specific intervals and types of lubricant to use.

Emphasizing routine maintenance is vital for optimal functionality. A proactive approach not only safeguards your investment but also ensures reliable operation during critical harvesting periods.

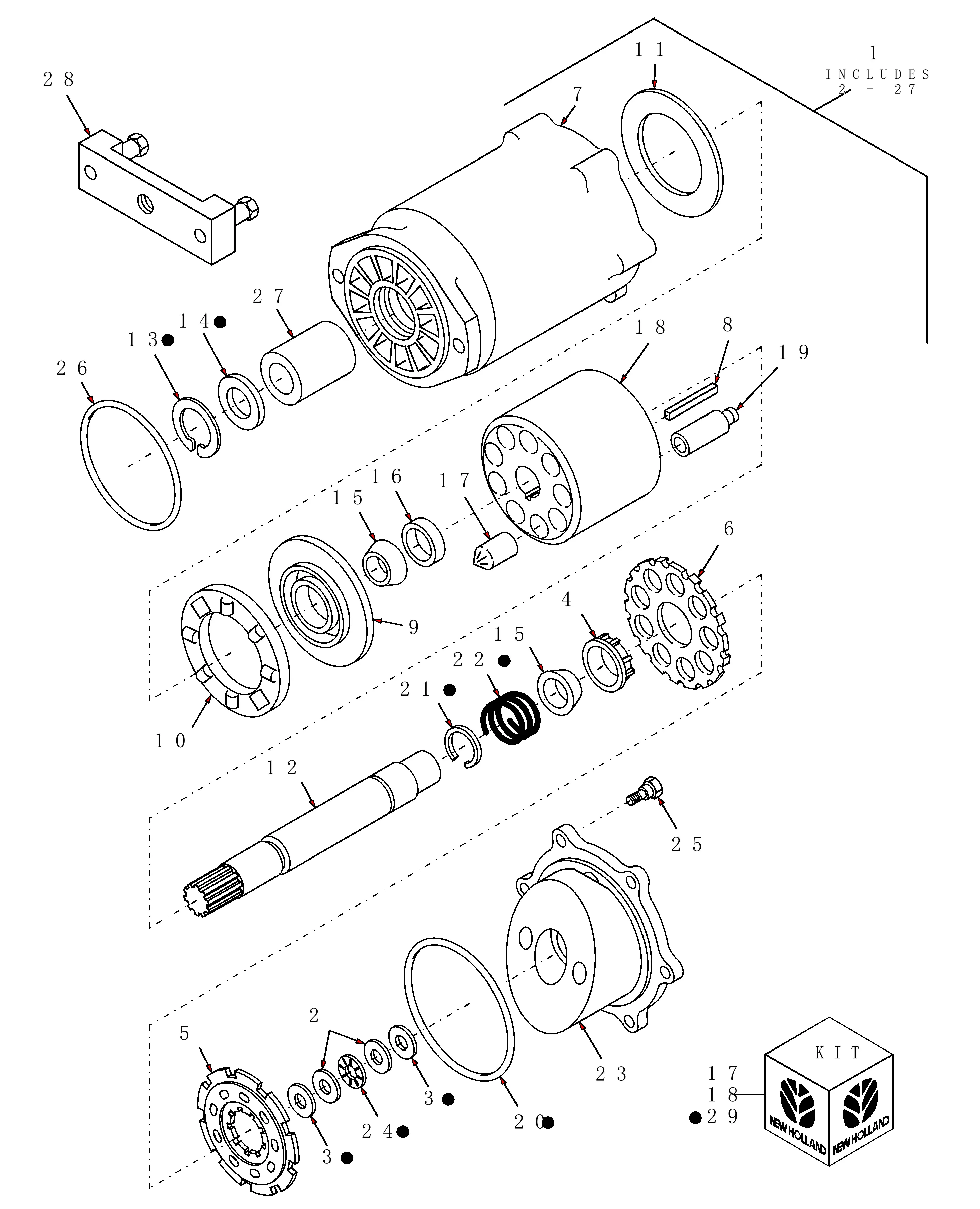

Parts Diagram Explained

The visual representation of components serves as a crucial tool for understanding the assembly and functionality of agricultural machinery. By illustrating the various elements, it enables users to identify specific pieces and comprehend how they interact within the larger system. This understanding is essential for effective maintenance and repair tasks.

Benefits of Understanding Component Layouts

Grasping the arrangement of different elements can significantly enhance operational efficiency. Users can quickly pinpoint which components require attention, leading to timely repairs and reduced downtime. Furthermore, familiarity with the layout promotes better troubleshooting, allowing operators to address issues before they escalate.

How to Use Visual Representations Effectively

To maximize the utility of these illustrations, users should familiarize themselves with the symbols and notations used within the visuals. Cross-referencing these images with manuals or service guides can provide deeper insights into each element’s function. Engaging with the diagram regularly reinforces knowledge, making it easier to recall information when needed.

How to Read Parts Diagrams

Understanding visual representations of machinery components is crucial for effective maintenance and repairs. These illustrations serve as a guide, helping users identify individual elements and their relationships within a system. By familiarizing yourself with these visuals, you can streamline your approach to troubleshooting and parts replacement.

Familiarize Yourself with the Legend

Most schematics come with a legend or key that explains symbols and lines used throughout the illustration. Take time to review this section as it will clarify what each symbol represents, including specific features or assembly points. This knowledge is essential for accurately interpreting the layout.

Break Down the Sections

Diagrams are often divided into sections that correspond to different components or assemblies. Focus on one area at a time to avoid feeling overwhelmed. Start with major assemblies and gradually work your way down to individual parts. This methodical approach ensures you grasp the overall structure before delving into details.

Identifying Essential Components

Understanding the key elements of agricultural machinery is crucial for effective maintenance and operation. Recognizing these vital parts helps in ensuring optimal performance and longevity of the equipment. This section aims to provide insights into the fundamental components that play a significant role in the functionality of these machines.

Key Mechanisms and Their Functions

Among the primary mechanisms are the cutting systems, which are responsible for harvesting crops efficiently. These elements must be sharp and well-aligned to achieve a clean cut. Additionally, the drive assembly provides the necessary power to the entire system, ensuring that all operations run smoothly. Regular inspection of these components is essential to prevent potential breakdowns and enhance productivity.

Maintenance and Upkeep

Routine care of the essential parts is vital for sustaining performance. Lubrication and cleaning of moving components help reduce wear and tear, while timely replacement of worn-out elements can prevent larger issues down the line. By focusing on these critical areas, operators can maximize the efficiency and reliability of their machinery.

Resources for Parts Procurement

When it comes to sourcing components for agricultural machinery, having access to reliable resources is essential. This section outlines various avenues that can be explored to find high-quality items, ensuring optimal performance and longevity of your equipment. Utilizing a mix of online platforms, local suppliers, and community networks can streamline the process of obtaining the necessary elements for maintenance and repair.

Online Marketplaces

Numerous online marketplaces cater specifically to the agricultural sector. Websites dedicated to equipment sales often feature a wide array of components, allowing users to compare prices and options conveniently. Additionally, forums and classified ads can provide leads on both new and used items, helping buyers find exactly what they need without excessive expenditure.

Local Suppliers and Dealers

Visiting local suppliers or authorized dealers can be advantageous. These establishments typically carry a comprehensive selection of components and offer expertise in compatibility and installation. Building relationships with local vendors can also lead to exclusive deals and timely access to necessary materials, enhancing the efficiency of any maintenance task.

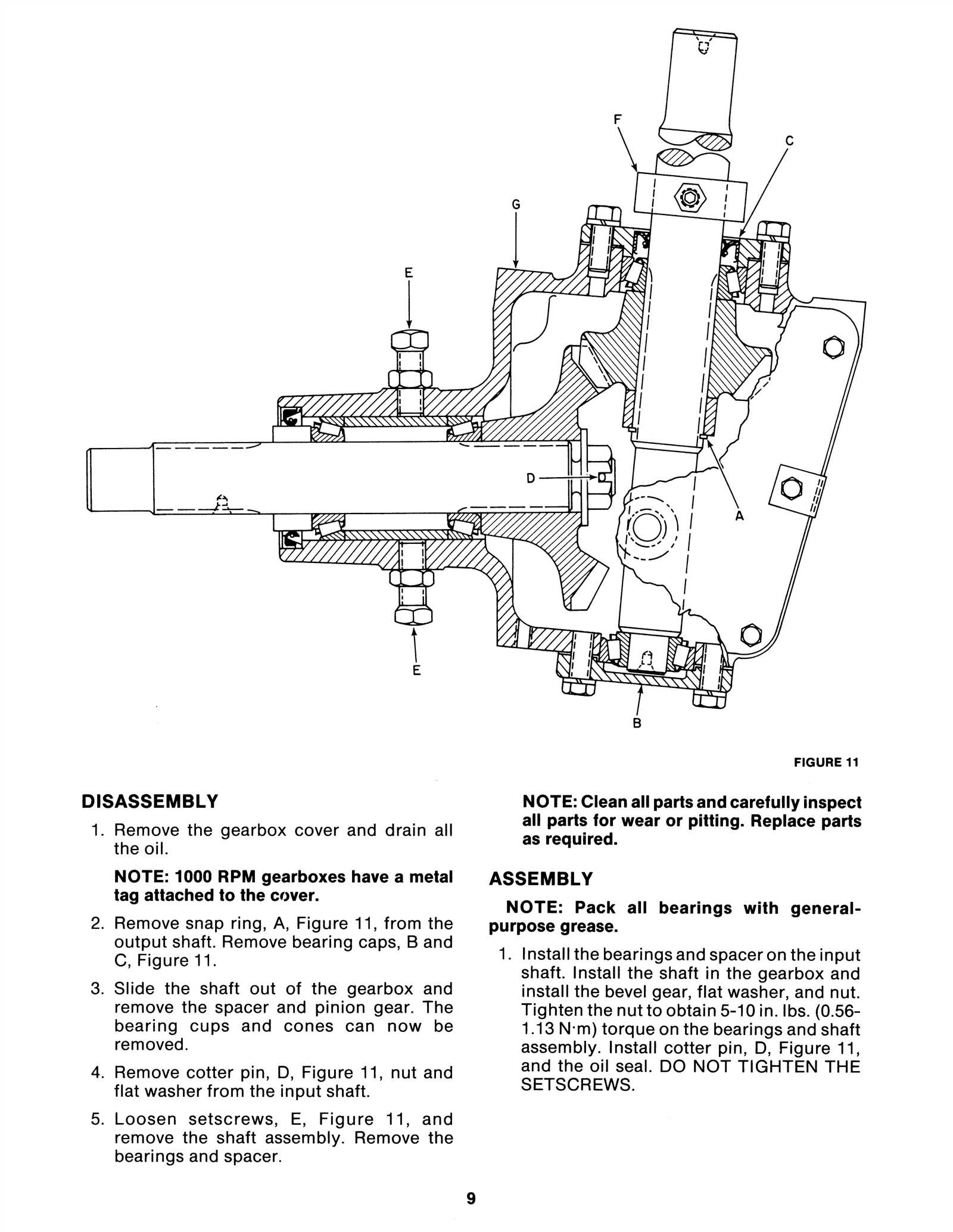

Assembly and Disassembly Guide

This section provides essential instructions for assembling and disassembling the equipment efficiently. Understanding the correct procedures not only ensures optimal performance but also extends the lifespan of the machinery. Adhering to these guidelines will help prevent damage and promote safe handling during maintenance tasks.

Preparation Steps

Before beginning the assembly or disassembly process, gather all necessary tools and materials. Ensure the working area is clean and free of obstructions. It is important to review the manual for any specific safety precautions related to the equipment.

Assembly Procedure

Follow these steps to properly assemble the machinery:

| Step | Description |

|---|---|

| 1 | Identify and organize all components required for assembly. |

| 2 | Align the main frame and secure it with appropriate fasteners. |

| 3 | Install any auxiliary parts, ensuring they fit snugly without forcing. |

| 4 | Connect hydraulic lines and electrical connections as per the schematic. |

| 5 | Conduct a thorough inspection to confirm that all parts are securely fastened. |

By following these guidelines, users can achieve a successful assembly that guarantees reliable operation.

Disassembly Procedure

When it becomes necessary to disassemble the equipment, use the following steps:

| Step | Description |

|---|---|

| 1 | Disconnect power sources and hydraulic connections for safety. |

| 2 | Carefully remove any fasteners and set them aside in a designated area. |

| 3 | Detach components methodically, avoiding unnecessary force. |

| 4 | Inspect parts for wear and damage as they are removed. |

| 5 | Store disassembled components in a clean and organized manner. |

Adhering to these disassembly instructions will facilitate smooth repairs and maintenance, ensuring all components can be effectively reused or replaced as needed.

Cost Factors for Replacement Parts

When considering the expenses associated with obtaining components for agricultural machinery, several elements come into play. Understanding these factors can aid in making informed decisions, ultimately affecting the overall budget for maintenance and repairs. Various aspects, including material quality, brand reputation, and market demand, influence the pricing of these essential items.

Quality and Material

The durability and performance of components are often linked to the materials used in their production. Higher-quality materials tend to be more expensive but can provide better longevity and efficiency. Conversely, lower-cost alternatives may save money upfront but could lead to higher replacement costs over time due to wear and tear.

Market Demand and Availability

The availability of specific items can fluctuate based on market demand. When certain components are in high demand or become scarce, prices may rise significantly. Additionally, seasonal trends in agriculture can also affect pricing, making it crucial to purchase items proactively when they are readily available.

| Factor | Description | Impact on Cost |

|---|---|---|

| Material Quality | Higher-quality materials enhance durability. | Increases initial cost but reduces long-term expenses. |

| Brand Reputation | Established brands often charge a premium. | May lead to higher costs but ensures reliability. |

| Market Demand | Supply and demand can drive prices up. | Fluctuates based on seasonal and economic factors. |

| Location | Shipping and distribution can affect prices. | Costs may vary based on proximity to suppliers. |