Comprehensive Guide to Paasche Talon Parts Diagram

The intricate design of airbrush equipment plays a crucial role in achieving precision and creativity in various artistic endeavors. Whether for illustration, model painting, or cosmetic applications, comprehending the elements involved can greatly enhance user experience and output quality. A thorough grasp of each component’s functionality allows artists and enthusiasts to troubleshoot issues effectively and optimize their tools.

In the realm of airbrush technology, various elements work in harmony to create the perfect spray pattern. Familiarity with these pieces not only aids in maintenance but also empowers users to customize their setup according to specific project needs. Knowledge of how these components interconnect enhances both the efficiency and effectiveness of the airbrush system.

To fully appreciate the capabilities of an airbrush, one must delve into the specifics of its construction. By examining each essential part, users can develop a deeper understanding of their tool’s performance and potential. This exploration is vital for anyone looking to elevate their artistic skills and achieve desired results in their craft.

Understanding Paasche Talon Components

Gaining insight into the various elements of a specialized mechanical system is crucial for effective operation and maintenance. Each component plays a significant role, contributing to the overall functionality and efficiency of the device. A clear comprehension of these individual segments allows users to troubleshoot issues, optimize performance, and ensure longevity.

Core Elements include essential mechanisms that facilitate movement and interaction within the system. Understanding how these interact with one another is vital for achieving seamless operation. For example, the primary structures often dictate the speed and responsiveness of the entire assembly, making them key to overall performance.

In addition to core elements, supportive features enhance the system’s stability and reliability. These components, while sometimes overlooked, provide necessary balance and assist in load distribution, ensuring that the device operates smoothly under various conditions. Familiarity with their function can prevent common issues related to wear and tear.

Finally, control mechanisms are integral to user interaction, allowing for adjustments and settings to be modified according to specific needs. Understanding how to effectively utilize these controls can significantly enhance the user experience and adaptability of the system.

Importance of Talon Parts in Operation

The functionality of any precision instrument relies heavily on its individual components. Each element plays a crucial role in ensuring smooth performance, facilitating optimal operation and enhancing overall efficiency. Understanding how these pieces interconnect can significantly influence the effectiveness of the device.

Role of Each Component

Every segment within the assembly contributes to the seamless execution of tasks. For instance, elements responsible for airflow regulation must operate flawlessly to achieve the desired results. When these sections are well-designed and maintained, they enable users to perform intricate tasks with ease and accuracy.

Impact on Performance and Longevity

The quality and integrity of the individual components directly affect both the performance and durability of the system. Regular inspection and timely replacement of worn-out elements can prevent malfunctions, thus prolonging the lifespan of the entire apparatus. This proactive approach not only enhances user satisfaction but also ensures consistent results over time.

Common Issues with Talon Parts

When dealing with precision equipment, various complications can arise that may hinder performance and usability. Understanding these common challenges can help users maintain optimal functionality and extend the lifespan of their devices.

Frequent Problems

- Wear and Tear: Continuous use can lead to gradual deterioration of components, affecting overall efficiency.

- Misalignment: Improper assembly or external factors can result in misalignment, leading to operational difficulties.

- Blockages: Accumulation of debris or residue can obstruct moving parts, causing malfunctions.

- Corrosion: Exposure to moisture can lead to rusting, which compromises the integrity of metallic elements.

Prevention Strategies

- Regular Maintenance: Implementing a routine check-up can identify issues early.

- Proper Storage: Keep equipment in a dry and safe environment to reduce the risk of damage.

- Quality Supplies: Use high-quality materials and tools to minimize wear.

- Training: Ensure users are well-trained in the proper operation to prevent accidental misuse.

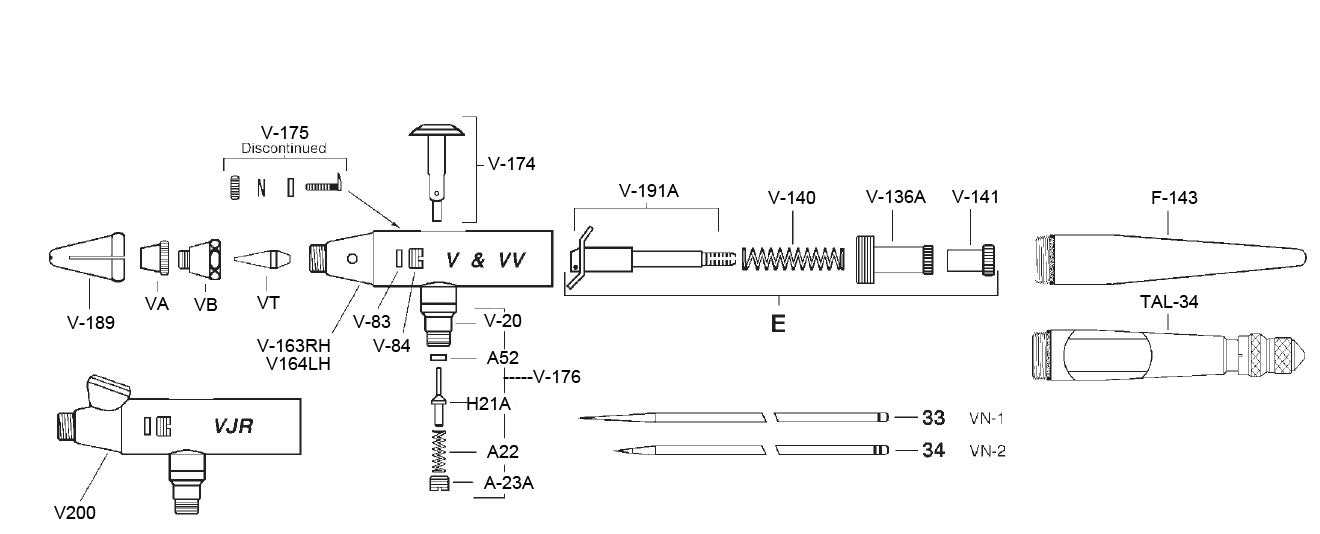

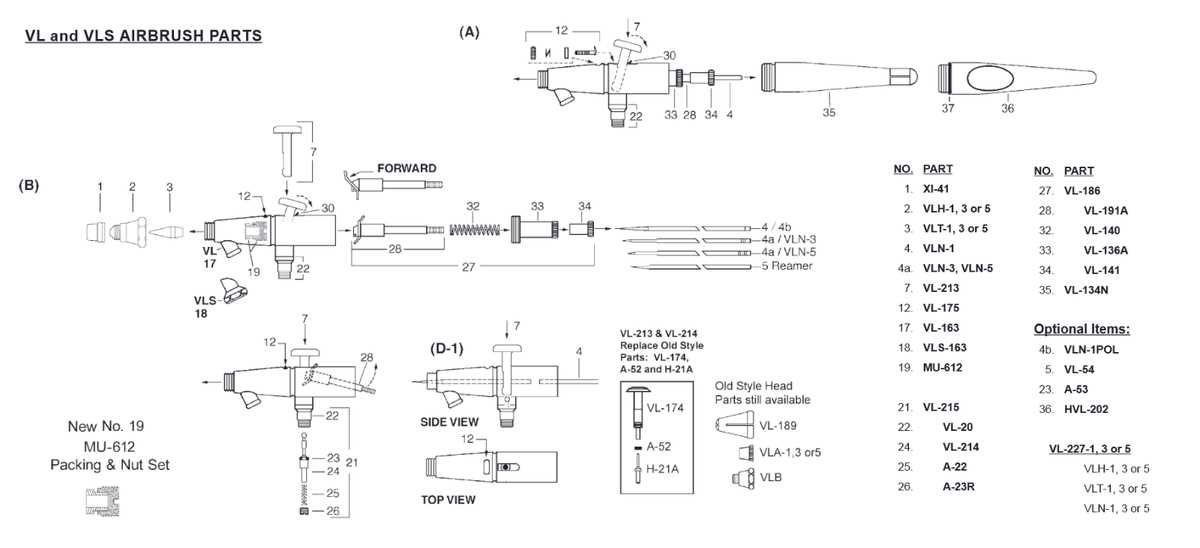

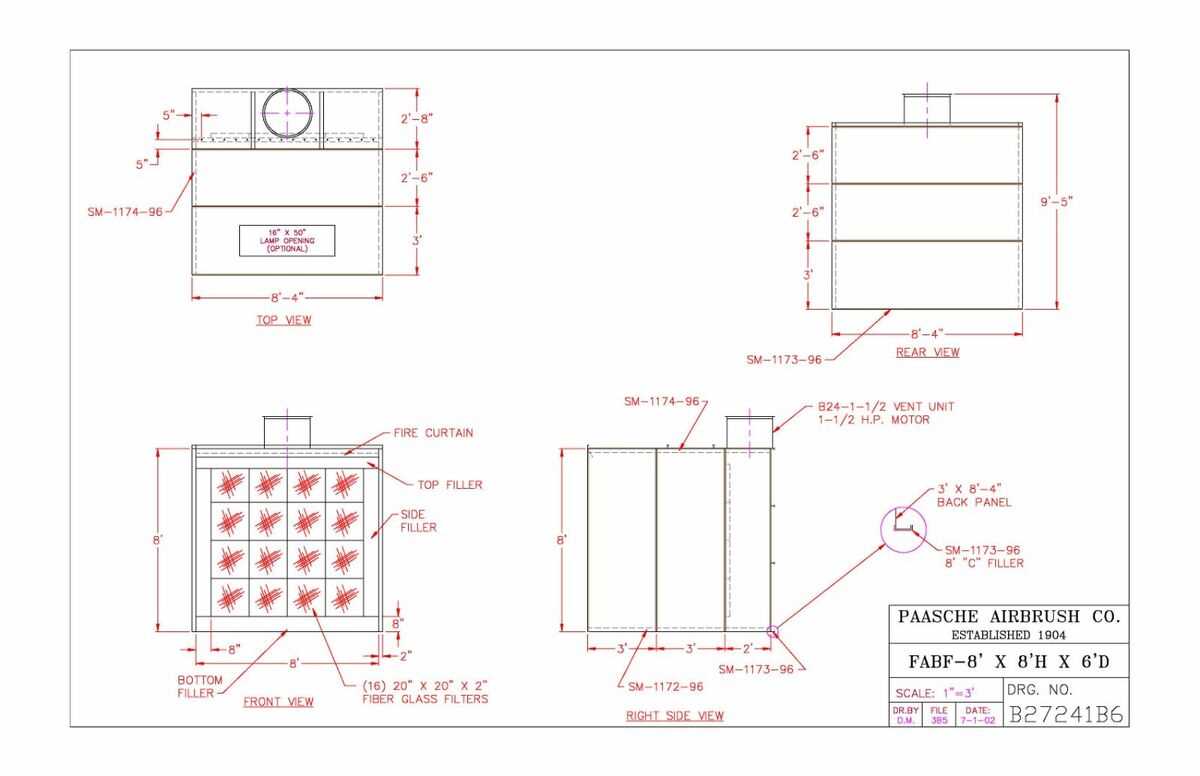

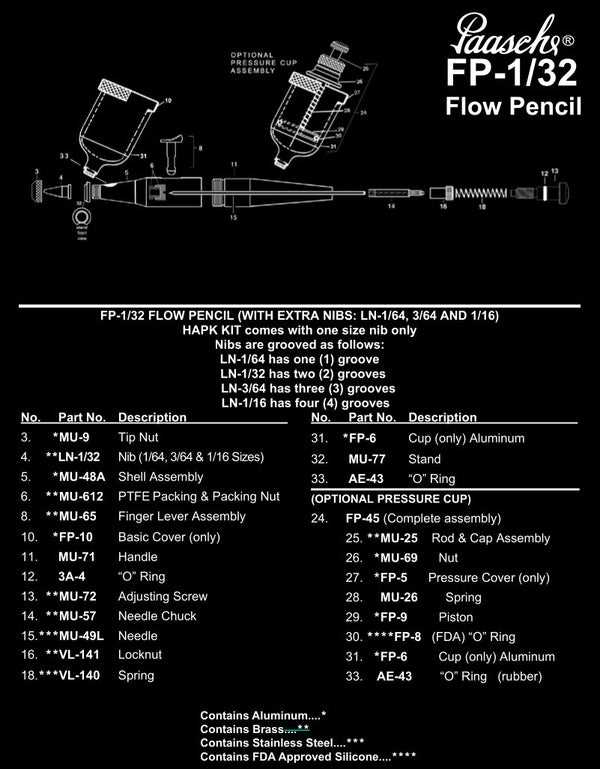

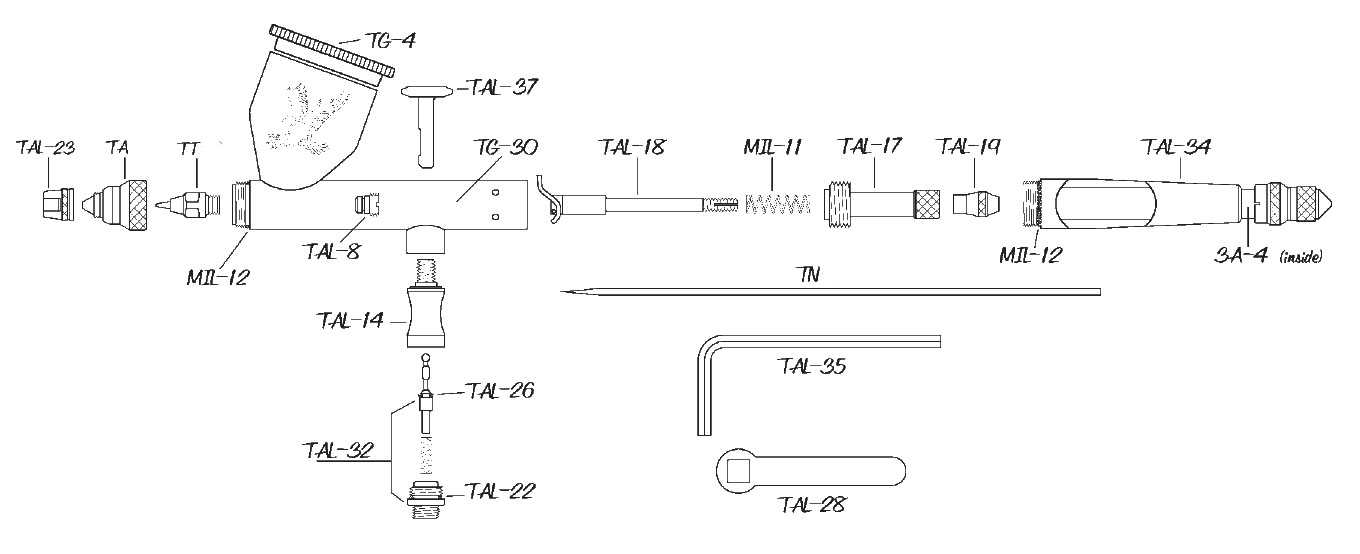

Detailed Breakdown of Talon Diagram

This section aims to provide a comprehensive analysis of the intricate design elements involved in a specific mechanical assembly. Understanding the structure and functionality of each component is essential for effective usage and maintenance.

To facilitate clarity, we will explore various segments of the assembly, detailing their roles and interconnections:

- Component A: Serves as the foundational element, providing stability and support to the overall structure.

- Component B: Functions as a connector, ensuring seamless interaction between adjacent sections.

- Component C: Plays a crucial role in the operational efficiency, optimizing performance through precise mechanics.

- Component D: Acts as a safety feature, preventing potential failures during operation.

Each of these segments contributes uniquely to the functionality and reliability of the complete system. Understanding their interactions is vital for troubleshooting and enhancing performance.

For a more in-depth examination, consider the following aspects:

- Material Quality: The choice of materials impacts durability and efficiency.

- Assembly Process: Proper assembly techniques are crucial for ensuring optimal performance.

- Maintenance Protocol: Regular checks can significantly extend the lifespan of the components.

By analyzing these factors, one can gain valuable insights into the mechanics at play, leading to improved operational knowledge and expertise.

Tools Needed for Talon Maintenance

Proper upkeep of your equipment requires having the right tools on hand to ensure smooth performance and long-term durability. This section will guide you through the essential instruments needed for efficient care, focusing on preserving functionality and maintaining high precision. Whether you’re conducting minor clean-ups or more thorough inspections, the right set of items is crucial for achieving the best results.

Cleaning Essentials

To maintain cleanliness, it’s important to have a selection of cleaning materials. A small set of brushes, cotton swabs, and microfiber cloths will help remove any debris without causing damage. For stubborn areas, a soft cleaning solution can be applied to dissolve residue, ensuring that all internal and external parts stay free from contaminants.

Lubrication and Tightening Tools

Lubrication is key for reducing friction in moving components. A precision oil dropper or a silicone-based lubricant will be ideal for ensuring smooth operation. Additionally, having small screwdrivers and wrenches available is essential for tightening connections and securing joints. This will help in preventing unnecessary wear and tear, keeping everything in working order.

Step-by-Step Assembly Guide

This guide provides detailed instructions for assembling the airbrush system, ensuring that each component fits together seamlessly for optimal performance. Following the steps carefully will help maintain the equipment’s efficiency and longevity.

Preparation

Before starting, make sure all necessary tools and components are laid out in an organized manner. It’s important to verify that each item is clean and free from any debris to prevent clogging or malfunction during use.

Assembly Process

| Step | Action |

|---|---|

| 1 | Start by attaching the nozzle securely to the main body. Ensure a tight fit to avoid air leakage. |

| 2 | Next, connect the trigger mechanism by sliding it into place and aligning it with the control lever. |

| 3 | Install the air hose by screwing it onto the inlet valve. Check that it is firmly attached to avoid interruptions in airflow. |

| 4 | Finally, mount the fluid cup on top, making sure it is secure and ready to hold the paint. |

Once all parts are properly assembled, perform a quick test to confirm everything is functioning as expected. If any issues arise, review the steps and ensure each connection is secure

How to Identify Worn Components

Regular use of any tool or device inevitably leads to wear and tear on its internal and external elements. Identifying these worn components early can help ensure consistent performance and prevent further damage. Recognizing the signs of aging, such as decreased efficiency or minor structural changes, allows for timely replacements and smoother operation over time.

Visual inspections are one of the simplest ways to check for deterioration. Look for signs like discoloration, surface cracks, or deformation, as these often indicate a need for replacement. Additionally, listen for any unusual sounds, as these could point to internal strain or misalignment in moving parts.

Functional tests can also reveal worn components. If you notice a drop in precision, increased effort during operation, or inconsistencies in performance, it’s likely that certain elements are experiencing wear. Regularly performing these checks can help catch issues before they escalate.

Upgrading Your Airbrush Components

Enhancing the performance and functionality of your airbrushing tool can significantly improve your overall experience, offering greater precision and control. By focusing on specific areas, you can tailor the device to meet your artistic or technical needs. Whether you’re seeking finer lines or smoother coverage, there are various methods to improve the efficiency of your setup without overhauling the entire system.

Choosing the Right Enhancements

When selecting improvements, it’s essential to consider what aspects of your equipment need the most attention. You might opt for a finer needle or nozzle to achieve more detailed work, or perhaps a larger cup to accommodate extended sessions. Evaluate each part to ensure it complements your airbrushing style and provides the desired results.

Maintaining Consistent Performance

Upgrading certain components can also enhance durability and maintain a consistent level of performance over time. Opt for parts made from higher-quality materials to ensure longevity. Regularly inspecting and replacing worn-out elements will not only maintain precision but also prevent potential damage to other areas of your tool.

Comparing Talon Models and Diagrams

When looking at different models from this series, it’s important to understand the variations and unique characteristics they offer. Each design comes with subtle changes that affect its functionality and performance. By comparing these models, users can identify the key differences that set each apart.

- Some designs focus on precision control, offering enhanced accuracy for detailed work.

- Others may prioritize versatility, providing adjustable settings for various applications.

- Certain models are designed with durability in mind, incorporating reinforced materials for extended use.

Analyzing the layout and structure of each version reveals how certain components are arranged to meet specific needs. By studying these variations, users can make informed decisions on which model suits their requirements best.

- Consider the level of detail required for your projects.

- Evaluate the range of adjustability and control in different designs.

- Compare the materials and build quality for long-term usage.

Tips for Effective Talon Repairs

When working on the restoration or maintenance of intricate airbrush systems, understanding the fundamentals of efficient repair methods is essential. Whether it’s addressing airflow issues or restoring precision, following proper techniques will enhance the overall performance and longevity of the equipment.

- Clean thoroughly: Before starting any repair, ensure that all components are meticulously cleaned. Residue build-up can often cause malfunctions, so regular maintenance is key to preventing future issues.

- Use the right tools: Always utilize the appropriate instruments for each task. Using incorrect or makeshift tools may cause damage to delicate parts or lead to ineffective repairs.

- Inspect frequently: Regular inspection of nozzles, needles, and seals is crucial. Early detection of wear or damage can save time and prevent larger problems from arising.

- Apply lubrication sparingly: While lubrication can help certain components function smoothly, overuse can lead to clogging or inconsistent performance. Apply only where necessary.

- Reassemble with care: After completing repairs, carefully reassemble the device, ensuring all parts fit correctly. Misalignment can cause operational issues or reduce the tool’s efficiency.

By adhering to these practices, you can maintain peak performance and ensure long-lasting operation with minimal disruptions.

Safety Precautions During Maintenance

Regular upkeep of your equipment is essential for optimal performance, but safety should always be your priority. Before starting any work, it’s important to ensure that the surrounding area is well-organized and free from distractions. Proper lighting and ventilation are also critical to avoid any unexpected accidents.

When handling tools or sensitive components, make sure to wear appropriate protective gear such as gloves and safety glasses. This helps prevent injuries from sharp edges or accidental splashes of chemicals. Additionally, always follow manufacturer guidelines regarding the use of cleaning agents and lubricants to avoid damage to internal mechanisms.

Before disassembling any sections, disconnect all power sources and depressurize systems if applicable. It is crucial to document each step of the process, ensuring that all parts are reassembled correctly. By adhering to these safety measures, you can maintain your equipment efficiently while minimizing the risk of harm.

Frequently Asked Questions About Talon Parts

In this section, we’ll address the most common inquiries regarding the functionality, maintenance, and replacement of components in a widely used airbrushing tool. This guide will provide clear and concise answers to help both beginners and experienced users better understand how to keep their equipment performing at its best.

How Can I Maintain My Airbrush for Optimal Performance?

Regular cleaning is essential to ensure smooth operation. After each use, make sure to thoroughly rinse and clean the internal parts to prevent clogging. For deeper cleaning, disassemble the airbrush, paying attention to the condition of seals and valves, and lubricate moving sections as needed. A clean tool significantly extends the life of each component and improves precision.

When Should I Replace Components?

Key parts such as needles, nozzles, and seals may wear out over time, especially with frequent use. If you notice issues like inconsistent spray patterns or leakage, it’s a sign that some elements may need replacement. Always keep spare parts on hand to avoid interruptions in your work. Replacement schedules vary, but regular checks will help you identify when maintenance or new parts are necessary.