Ford Fiesta Engine Parts Layout Guide

When diving into the mechanics of a compact car, it’s essential to gain an understanding of how various essential components work together under the hood. Each element, from critical mechanisms to supporting systems, plays a distinct role, contributing to the performance and reliability that drivers rely on daily. For those looking to maintain or repair their vehicle, knowing the purpose and layout of these components can make a significant difference.

Many of these components work in harmony to create a smooth and efficient experience, each responsible for specific tasks that range from power generation to optimizing fuel use. This knowledge helps in identifying any potential issues early and allows for more efficient servicing and replacement of parts, which can extend the vehicle’s lifespan.

This section provides a structured look at the main components and their interconnected functions, offering valuable insights for anyone from the everyday driver to the seasoned mechanic. With a clear understanding of each section, it’s easier to make informed choices about maintenance and performance improvements, ensuring the vehicle continues to meet expectations on the road.

Ford Fiesta Engine Components Overview

This section provides a comprehensive look into the key elements that contribute to the efficient operation of this compact vehicle’s power system. The layout and structure of the system reflect careful engineering, aimed at delivering a balance of performance, reliability, and fuel economy.

Main Structural Elements

The primary construction includes essential modules responsible for combustion, cooling, and energy transfer. Each component works in harmony to ensure smooth function, supporting overall durability and adaptability for various driving conditions.

- Combustion Chamber: This section manages fuel and air mixing, critical for energy release and propulsion.

- Cooling System: Components here help regulate temperature, preserving optimal performance and preventing overheating.

- Power Distribution: The power generated is effectively channeled to enable both motion and accessory support within the vehicle.

Supportive Systems

Additional structures supplement the main modules, working to enhance efficiency, reduce wear, and maintain emissions standards. These systems are interconnected to streamline performance while upholding environmental considerations.

- Fuel Injection: Regulates fuel entry, balancing power output and fuel economy.

- Exhaust Handling: Channels emissions safely, ensuring adherence to environmental norms.

- Lubrication Network: Reduces friction and wear, extending the lifespan of critical parts.

Together, these systems form an intricate network, designed to maximize the balance between performance and sustainability for a reliable and responsive driving experience.

Detailed Look at Engine Block Structure

This section explores the intricate construction of the central component responsible for housing the essential working elements within a vehicle’s power system. By understanding the architecture of this core structure, one gains insights into how various connected elements operate together efficiently, providing stability, support, and fluidity to the overall mechanical system.

Main Structural Elements

The core block is composed of multiple interconnected areas that work in harmony to support and protect vital moving elements. Key parts of the central structure include:

- Cylinder Spaces: These sections house the primary movement channels and provide enclosed spaces for essential processes.

- Connecting Channels: These allow fluids to circulate throughout, assisting in cooling and maintaining optimal operational conditions.

- Support Sections: Reinforcements located at key points to add durability and stability to the entire structure.

Cooling and Fluid Flow Channels

Another important aspect of this core design is its ability to efficiently manage temperature and maintain fluid circulation. It incorporates a network of internal passages that facilitate the transfer and regulation of heat. This network includes:

- Primary Flow Channels: Designed to circulate cooling fluids, they work to maintain a consistent temperature within the structure.

- Vent Passageways: Small, strategically placed openings that help in releasing heat, preventing overheating during intense operation.

- Sealing Points: Positioned at connection points to prevent leakage and ensure smooth fluid movement throughout the entire layout.

By examining these structural elements, one can better appreciate the thought put into each aspect of this block’s design, ultimately contributing to the efficiency and reliability of the larger system.

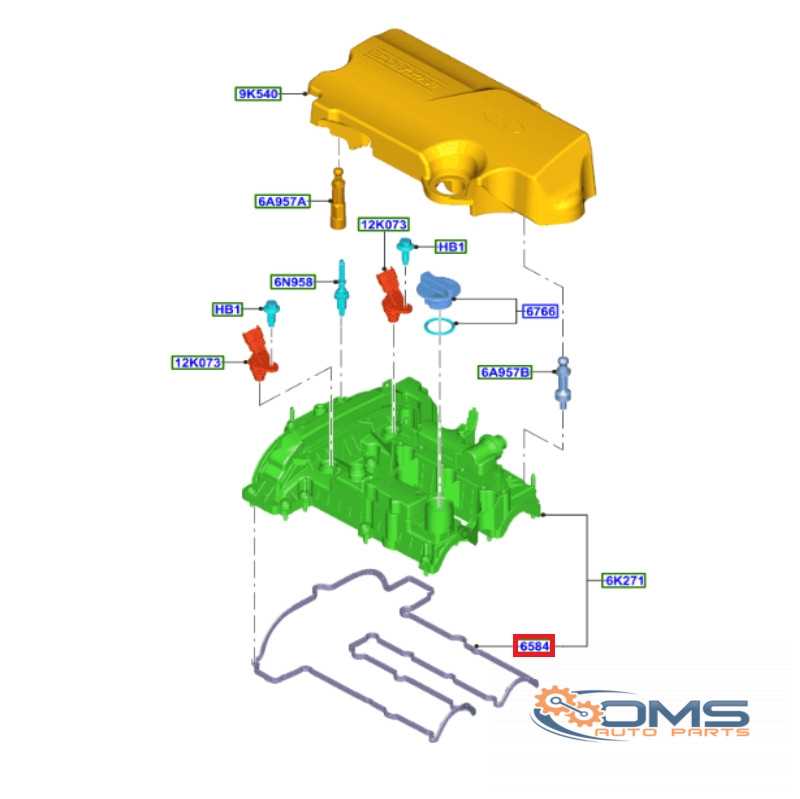

Understanding Cylinder Head Assembly

The cylinder head assembly is a critical component within a vehicle’s power system, influencing overall functionality and performance. This part combines several integral sections that enable the process of air intake, fuel injection, and exhaust release, working together to ensure smooth and efficient operation.

Key Components of the Assembly

The assembly includes several main elements, such as the valves, camshaft, and springs. Valves control the flow of air and fuel mixture, while the camshaft synchronizes their movement, ensuring precise timing for optimal performance. Springs provide the necessary tension to keep the valves securely in position, avoiding any disruption in airflow or energy release.

Assembly Functionality and Maintenance

The synchronized operation of these parts contributes to efficient energy production. Proper maintenance of this assembly is crucial, as wear on individual parts can lead to a decrease in overall power output. Regular checks help to identify early signs of wear, ensuring that each component functions reliably over time.

Camshaft and Timing Mechanism Insights

The camshaft and timing components play a crucial role in synchronizing movement within the motor system, ensuring that internal operations align for efficient performance. This system influences the motion of critical elements, helping achieve smooth, regulated cycles that enhance overall operation.

| Component | Function | Effect on Performance |

|---|---|---|

| Camshaft | Controls the sequence of opening and closing of certain internal channels, contributing to precise timing for optimal power output. | Improves synchronization, enhancing power and efficiency. |

| Tensioner | Maintains consistent tension within the timing system, preventing slack that could disrupt alignment. | Reduces vibration, supporting stability in operation. |

| Timing Belt | Transfers rotation from one component to another, allowing harmonious movement between interconnected parts. | Ensures balanced movement, reducing mechanical strain and wear. |

Essential Features of the Crankshaft

The crankshaft plays a crucial role in converting linear energy into rotational power, helping drive various mechanisms. Its design is pivotal for efficient motion transfer, providing durability under intense forces. Understanding the components and functionality of this part offers insights into its importance within the broader mechanical system.

Key Components of the Crankshaft

This mechanical component features several vital sections, each contributing to its stability and effectiveness. Balancing weights, journals, and webs collectively ensure smooth operation. The balanced weight placement prevents excessive vibration, while journals enable secure connections to other moving parts, maintaining precise alignment.

Material and Design Considerations

Constructed from durable materials, this component withstands high-pressure cycles. Forged steel or cast iron variations are commonly used, chosen for their resilience. The design often includes carefully calculated dimensions to maximize power efficiency, minimizing material stress while maintaining operational reliability.

| Feature | Description |

|---|---|

| Counterweights | Help balance the motion, reducing vibration for smoother operation. |

| Main Journals | Provide stable mounting points, connecting the component to other systems. |

| Throws | Offset sections that allow conversion of linear forces into rotation. |

| Webs | Link various sections together, adding structural support. |

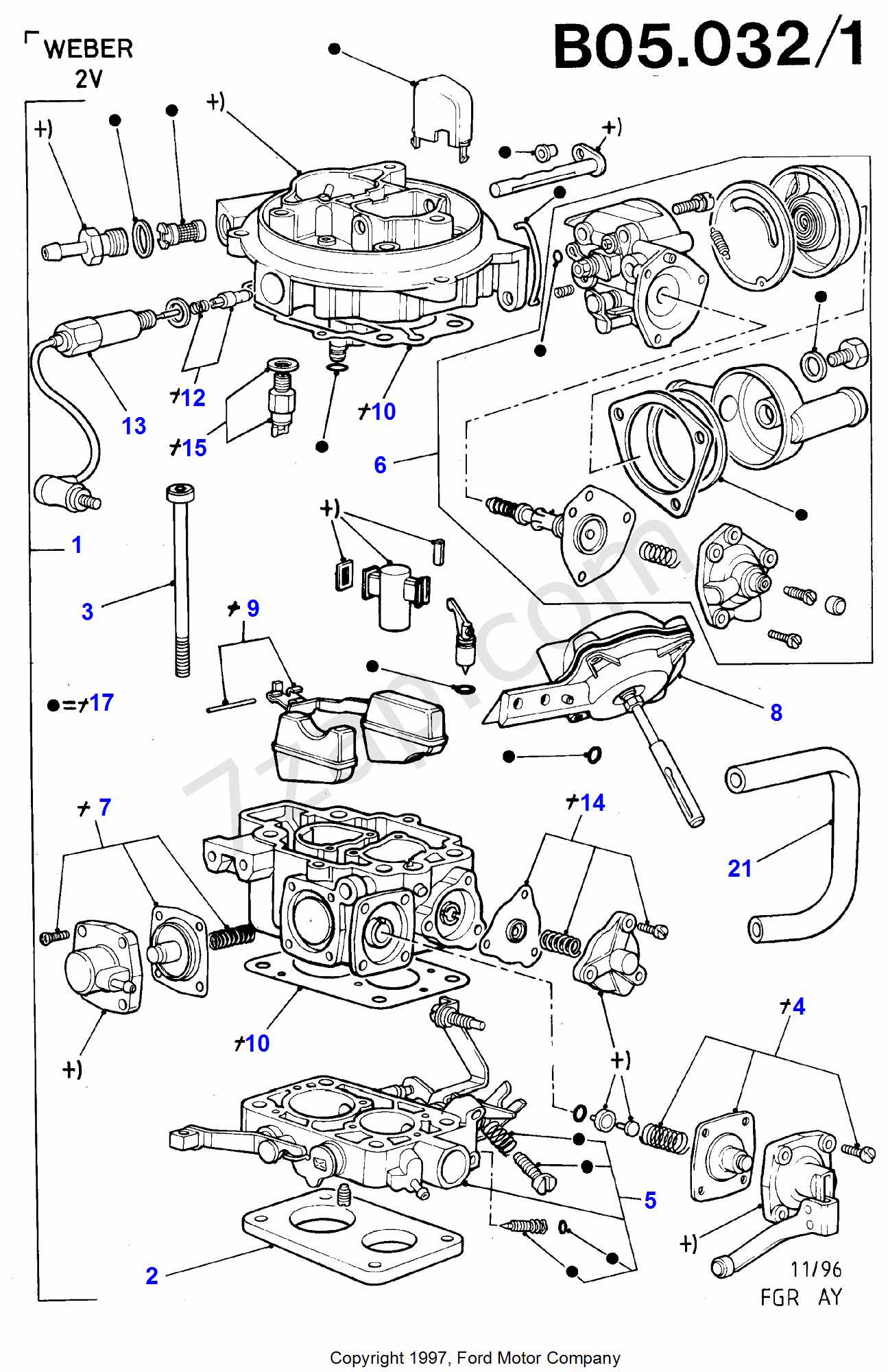

Fuel Injection System and Its Role

The fuel injection mechanism is crucial for optimizing the combustion process within a vehicle’s propulsion unit. By delivering precise amounts of fuel into the combustion chamber, this system enhances performance, efficiency, and emissions control. Understanding its components and functions reveals its significance in modern automotive technology.

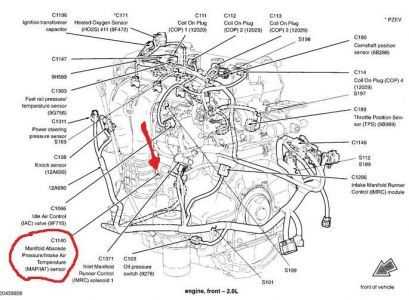

Components of the Fuel Injection Mechanism

This mechanism comprises several essential components, including the injector, fuel pump, and control unit. The injector’s role is to atomize fuel, creating a fine mist that mixes with air for optimal combustion. The fuel pump ensures a consistent supply of fuel at the required pressure, while the control unit regulates the timing and duration of the injection, adapting to varying operational conditions.

Importance in Vehicle Performance

A well-functioning fuel injection mechanism significantly impacts overall vehicle performance. It contributes to better acceleration, smoother operation, and improved fuel efficiency. Additionally, by reducing harmful emissions, it plays a vital role in meeting environmental standards, making it an indispensable part of modern vehicles.

Cooling System Components and Functions

The effective management of temperature within a vehicle is crucial for optimal performance and longevity. The components responsible for this task work in harmony to maintain the right thermal conditions, ensuring that the machinery operates smoothly. Each element plays a specific role, contributing to the overall efficiency and reliability of the system.

Key Elements of the Cooling Mechanism

The primary components include a radiator, which dissipates heat from the coolant; a water pump, responsible for circulating the coolant throughout the system; and thermostats, which regulate the temperature by controlling the flow of coolant. Together, these elements work seamlessly to transfer heat away from critical areas and maintain operational efficiency.

Importance of Proper Functioning

Ensuring that each component functions effectively is vital for preventing overheating and potential damage. Regular maintenance and inspection of these components help to identify issues early, preserving the overall integrity and performance of the machinery. Neglecting the cooling system can lead to severe consequences, emphasizing the need for vigilance in monitoring its health.

Lubrication System for Engine Longevity

A well-functioning lubrication mechanism is crucial for the durability and efficiency of any motor. It minimizes friction between moving components, thereby reducing wear and tear. This section explores the significance of a properly maintained lubrication system and its impact on the lifespan of a power unit.

Key Components of the Lubrication Mechanism

- Oil Pump: Responsible for circulating lubricant throughout the system, ensuring all vital areas receive adequate protection.

- Oil Filter: Removes impurities and contaminants from the lubricant, maintaining its quality and performance.

- Oil Cooler: Regulates the temperature of the lubricant, preventing overheating and degradation.

Maintenance Tips for Optimal Functioning

- Regularly check and replace the lubricant according to manufacturer recommendations.

- Inspect the oil filter for blockages and replace it when necessary.

- Monitor the levels and condition of the lubricant to ensure it remains clean and effective.

By prioritizing the upkeep of the lubrication system, you can enhance the performance and lifespan of the entire assembly. A proactive approach to maintenance leads to a smoother operation and helps avoid costly repairs down the line.

Understanding the Intake and Exhaust Valves

The components responsible for regulating airflow within a combustion chamber play a critical role in the performance and efficiency of a vehicle. These mechanisms open and close at precise moments, allowing the necessary mixture of air and fuel to enter while expelling exhaust gases effectively. Understanding their functionality is essential for optimizing overall operation.

Functionality of Intake Valves

Intake valves are designed to control the entry of the air-fuel mixture into the chamber. They open during specific phases of the cycle, enabling the mixture to flow freely into the combustion area. The timing and precision of these actions significantly impact the power output and efficiency of the vehicle. Proper maintenance and adjustments of these components ensure that optimal performance is achieved.

Role of Exhaust Valves

Exhaust valves serve a crucial function by allowing the expulsion of combustion byproducts after the power stroke. Their timely closure and opening are essential for preventing backpressure, which can hinder performance. By facilitating the efficient removal of exhaust gases, these components contribute to the overall effectiveness of the vehicle’s operation and compliance with emission standards.

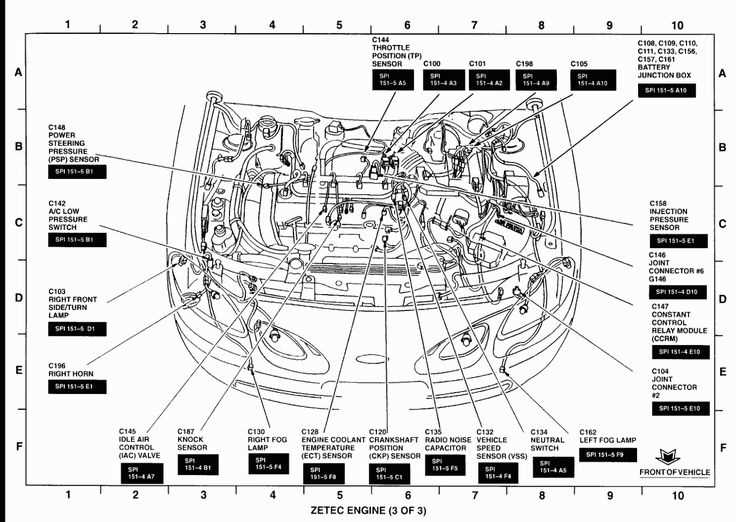

Battery Placement and Electrical Integration

The positioning of the power source within a vehicle is crucial for both performance and maintenance. Proper placement ensures efficient operation and accessibility for servicing, while also influencing the overall electrical architecture. Understanding the intricacies of how the power source connects with other components is essential for optimal functionality.

When considering the integration of the power source, several factors come into play:

- Accessibility: The location should allow easy access for routine checks and replacements.

- Protection: Placement must safeguard the power source from environmental elements and physical damage.

- Connection Efficiency: Proximity to essential systems can minimize power loss and improve response times.

- Weight Distribution: Strategic positioning contributes to balanced weight distribution, enhancing stability.

To ensure seamless electrical integration, the following considerations should be taken into account:

- Wiring Layout: A well-organized wiring scheme helps prevent interference and facilitates troubleshooting.

- Grounding: Effective grounding practices reduce electrical noise and improve overall reliability.

- Connector Quality: Utilizing high-quality connectors minimizes resistance and enhances connection integrity.

- Fusing Systems: Implementing appropriate fuses protects against overloads and potential damage.

In conclusion, thoughtful planning of the power source’s placement and its electrical connections significantly influences the operational efficiency and reliability of the entire system.

Alternator and Charging System Essentials

The alternator and charging system play a crucial role in ensuring the electrical components of a vehicle operate efficiently. This system is responsible for converting mechanical energy into electrical energy, which powers various devices and recharges the battery while the vehicle is in motion.

The alternator is a key component within this setup, generating electricity through electromagnetic induction. As the engine runs, the alternator spins, producing alternating current (AC) that is converted into direct current (DC) for use by the vehicle’s electrical systems.

In addition to the alternator, the charging system includes various elements such as the battery, voltage regulator, and wiring harnesses. The battery stores energy and provides power during start-up, while the voltage regulator ensures that the output voltage remains within a safe range, protecting sensitive electronic components from damage.

Understanding the functions and interactions of these components is vital for maintaining the overall health of the vehicle’s electrical system. Regular inspections can help identify potential issues, ensuring reliable performance and longevity.

Air Filter Housing and Pathway

The air filter housing and its associated pathway play a crucial role in maintaining optimal airflow within the vehicle’s intake system. This assembly ensures that clean air is delivered to the combustion chamber, enhancing performance and efficiency. Understanding the layout and function of these components is essential for proper maintenance and troubleshooting.

The air filter housing serves as a protective enclosure for the filter, preventing contaminants from entering the system. It is typically designed to facilitate easy access for replacement or inspection. The pathway, on the other hand, directs the filtered air towards the intake manifold, ensuring a steady flow necessary for combustion.

| Component | Function |

|---|---|

| Air Filter Housing | Encloses and protects the air filter from debris. |

| Air Filter | Removes impurities from incoming air. |

| Intake Duct | Guides air from the housing to the engine. |

| Seals | Ensures a tight fit to prevent unfiltered air entry. |

Regular maintenance of the air filter housing and pathway is vital for optimal vehicle performance. Neglecting these components can lead to restricted airflow, decreased fuel efficiency, and potential damage to internal systems.

Radiator and Cooling Efficiency in Fiesta

The effectiveness of the cooling system plays a crucial role in maintaining optimal performance and longevity of any vehicle. This section delves into the essential components that contribute to heat management, ensuring that the machinery operates within safe temperature limits. An efficient cooling mechanism prevents overheating, which can lead to severe mechanical issues and reduced functionality.

The radiator serves as a vital element in this system, facilitating the transfer of heat away from the liquid coolant as it circulates through the machinery. By dissipating excess heat into the atmosphere, it helps maintain a stable operating temperature. Furthermore, the arrangement of the cooling fins and the flow of air through the radiator significantly impact its efficiency. Ensuring that these components are free of obstructions and well-maintained can enhance heat dissipation.