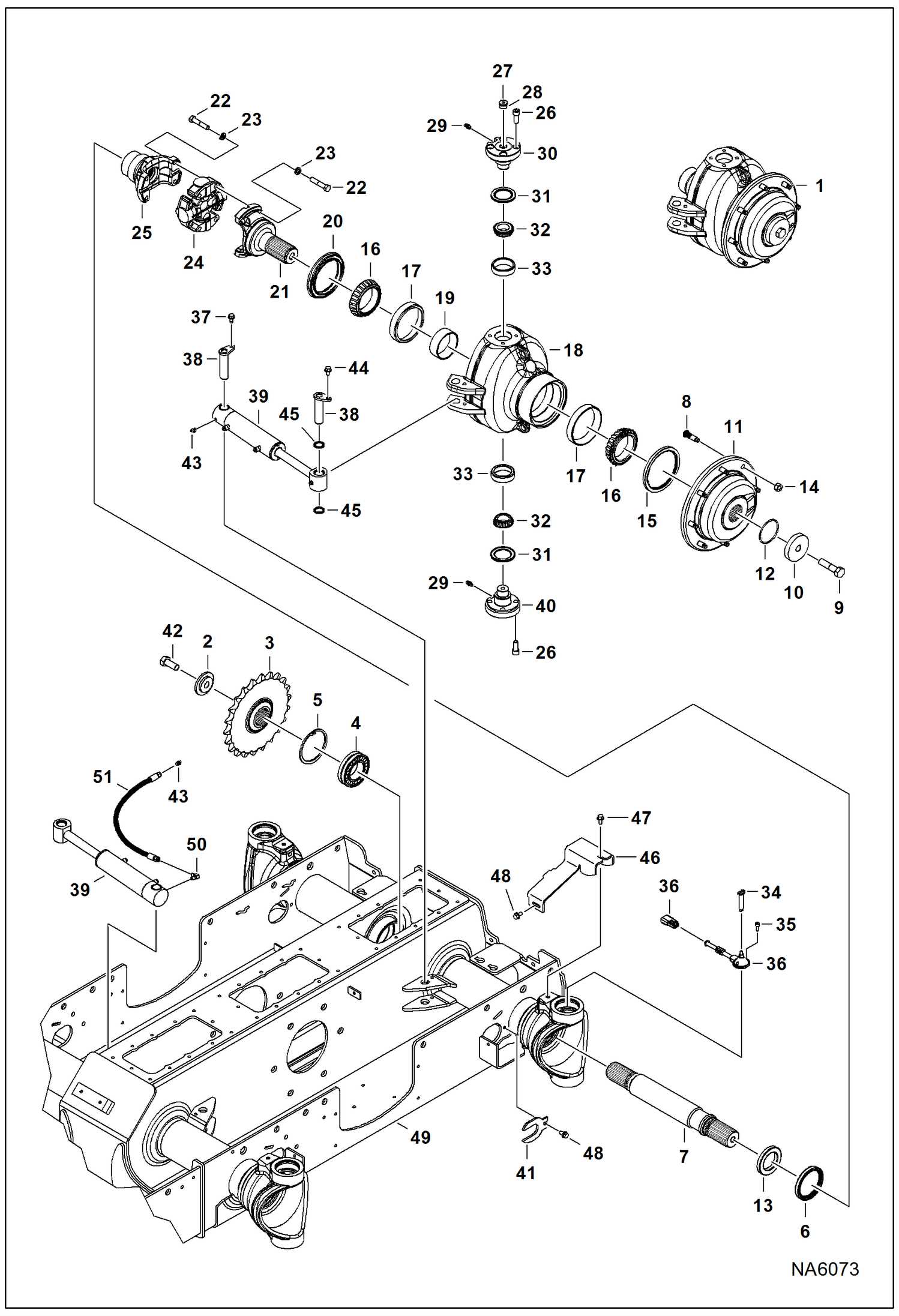

Understanding the Peerless 700 Transmission Parts Diagram

The intricate world of mechanical assemblies plays a crucial role in various applications, providing essential functionality and efficiency. Within these systems, specific elements work in harmony to facilitate the transfer of power and motion. A thorough grasp of these components is vital for anyone engaged in maintenance or repair tasks, ensuring optimal performance and longevity.

Delving into the layout of these mechanisms reveals a complex arrangement of individual pieces, each serving a distinct purpose. By analyzing their organization, one can better appreciate how they interact to achieve smooth operation. Familiarity with these structures enhances the ability to diagnose issues and implement effective solutions.

Equipped with knowledge of these configurations, users can navigate the challenges of mechanical work with confidence. Understanding how each segment fits into the larger assembly not only simplifies repairs but also empowers enthusiasts to innovate and optimize their systems. The following exploration offers insights into these vital components and their arrangement within the machinery.

Understanding Peerless 700 Transmission

This section explores the mechanics and components of a specific gear system designed for various applications, focusing on its functionality and structure. By examining its essential elements, users can gain insights into its operation and maintenance.

Key Features

- Durability and strength for reliable performance

- Efficient power transfer mechanisms

- Simple assembly and disassembly for maintenance

Common Components

- Drive gears that facilitate movement

- Shafts for connecting different elements

- Bearings to reduce friction and enhance longevity

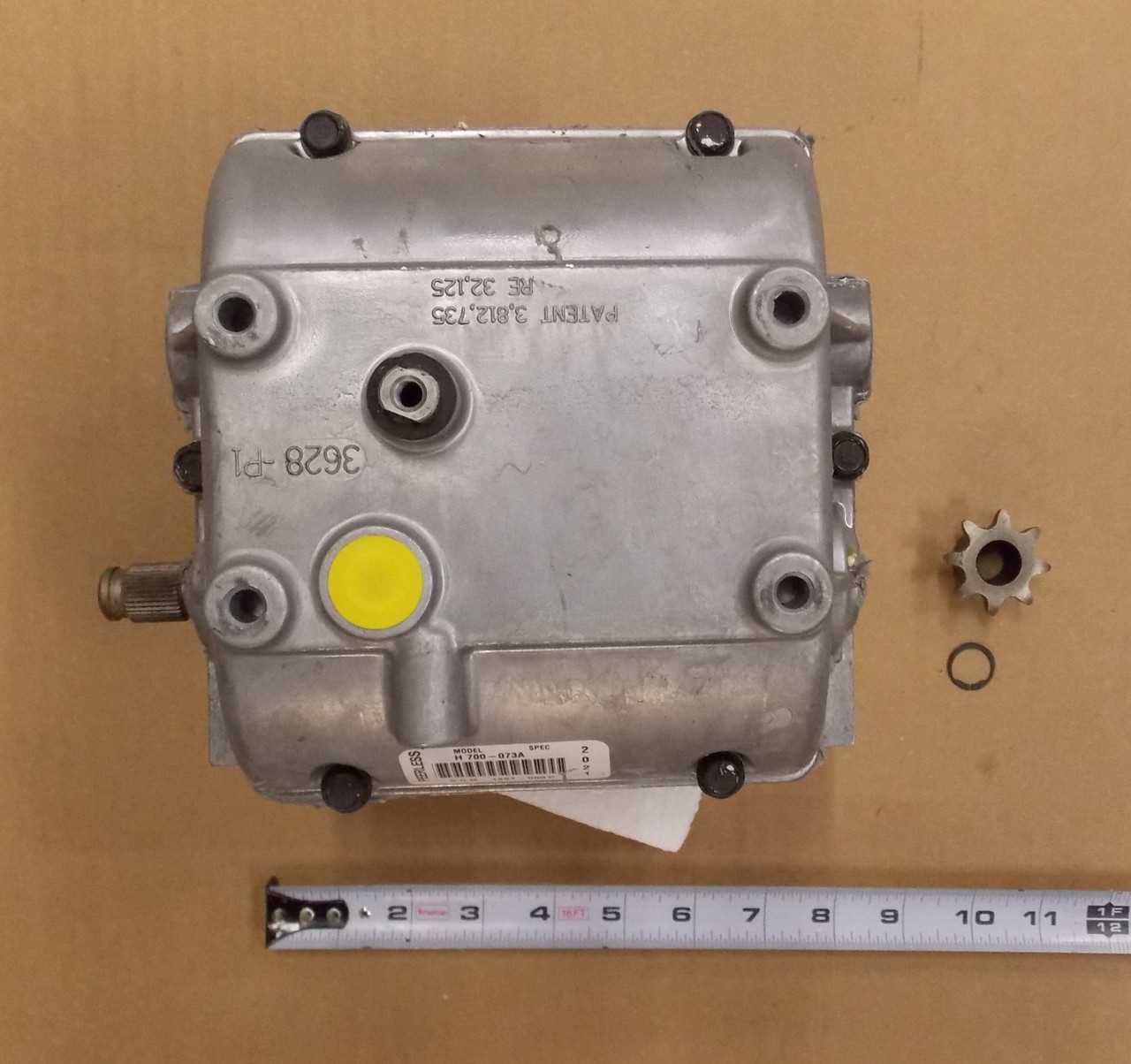

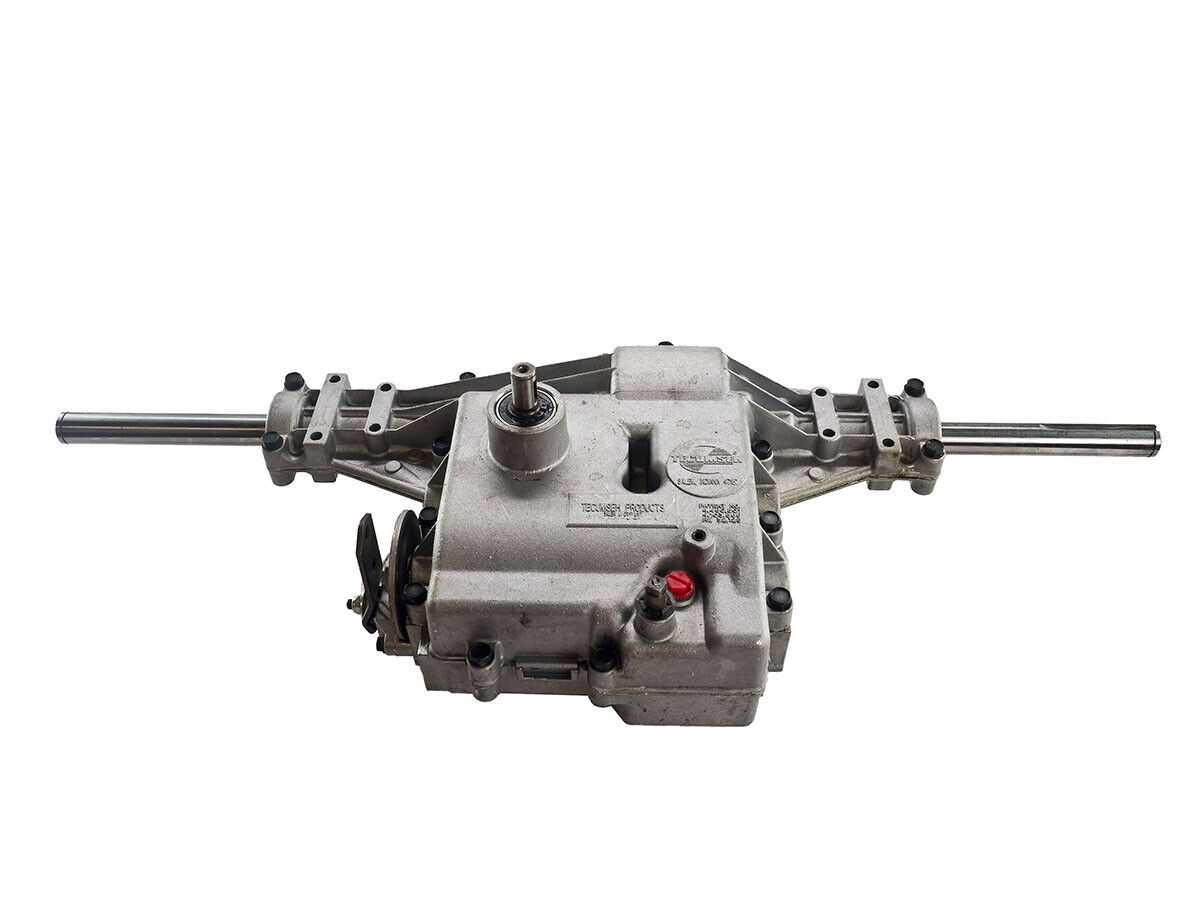

Components of the Peerless 700

This section explores the essential elements that make up a specific mechanical system designed for optimal performance. Understanding these components is crucial for anyone looking to maintain or enhance the functionality of this machinery.

Gears play a vital role in transmitting power efficiently, allowing for the necessary adjustments in speed and torque. The arrangement and type of gears directly impact the overall efficiency.

Bearings are critical for reducing friction and ensuring smooth movement between rotating parts. Their quality and placement can significantly influence the longevity and reliability of the entire assembly.

Shafts serve as the backbone of the system, transferring energy from one component to another. Their design must accommodate various stresses and rotational forces while maintaining structural integrity.

Housings protect internal mechanisms from external elements, providing a stable environment for the components to operate. The material and design of these enclosures can enhance durability and reduce noise.

Finally, linkages connect various parts, enabling coordinated movement. The effectiveness of these connections determines how well the system operates as a whole, ensuring that each element works in harmony with the others.

How to Read the Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. This visual guide illustrates the various elements and their interconnections, enabling users to identify and locate specific items easily. Familiarity with such a representation streamlines the troubleshooting process and aids in sourcing the correct replacements.

Begin by familiarizing yourself with the overall layout. Typically, components are arranged logically, often grouped by function or location. Pay attention to any labels or annotations, as these provide critical information regarding each element’s role and specifications.

Next, observe the numbering system or color coding used to differentiate between various sections. This will help you track relationships between parts, making it easier to understand how they work together. Cross-referencing the guide with a list of specifications can further enhance your comprehension.

Finally, practice by following the schematic step by step. Identify individual items and their corresponding functions, noting any connections that may not be immediately apparent. With time, you will develop a clearer understanding of how each component contributes to the overall assembly.

Common Issues with Peerless 700 Parts

Understanding the typical challenges associated with a specific mechanical assembly can greatly enhance its longevity and performance. Various components can exhibit wear or malfunction due to several factors, leading to decreased efficiency and potential failures. Identifying these common problems early can prevent more significant issues down the line.

Wear and Tear: Over time, essential components may experience significant degradation, impacting overall functionality. Regular inspection is crucial to catch these signs early.

Improper Alignment: Misalignment of internal components can cause excessive friction, leading to accelerated wear. Ensuring correct positioning during assembly is vital.

Fluid Contamination: Contaminants can compromise the effectiveness of lubricants, resulting in increased friction and overheating. Maintaining cleanliness during maintenance is essential.

Mechanical Failures: Certain elements may suffer from inherent design flaws or material fatigue, leading to unexpected breakdowns. Regularly assessing for signs of fatigue can mitigate risks.

Inadequate Maintenance: Neglecting regular upkeep can lead to numerous issues, including reduced efficiency and increased repair costs. Establishing a maintenance schedule is highly recommended.

Maintenance Tips for Longevity

Ensuring the durability of mechanical systems requires regular attention and care. Implementing a series of maintenance practices can significantly extend the lifespan of components and enhance overall performance. By following these guidelines, users can avoid premature wear and costly repairs.

First and foremost, routine inspections are essential. Regularly checking for signs of wear, leaks, or damage allows for early detection of potential issues. Additionally, adhering to a consistent lubrication schedule is vital. Proper lubrication minimizes friction, reducing wear and ensuring smooth operation.

Furthermore, it’s crucial to monitor operating conditions. Keeping the system within recommended parameters prevents overheating and excessive strain. Environmental factors such as dust and moisture should also be managed to protect sensitive components.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Look for leaks, cracks, and unusual wear. |

| Lubrication | Every 500 hours of operation | Use manufacturer-recommended lubricant. |

| Filter Replacement | Every 1000 hours of operation | Replace with OEM filters for best performance. |

| Fluid Level Check | Weekly | Maintain levels within specified range. |

Lastly, training operators on proper usage can lead to significant improvements in efficiency and lifespan. Well-informed users are less likely to misuse equipment, thus prolonging its operational integrity.

Where to Find Replacement Parts

Locating suitable components for machinery can often be a daunting task. However, several reliable avenues exist to ensure you find what you need efficiently.

- Online Retailers: Numerous websites specialize in offering a wide range of components. Popular options include:

- Amazon

- eBay

- Specialized machinery suppliers

- Local Dealerships: Visiting nearby dealers can provide immediate access to necessary components. They often have knowledgeable staff to assist you.

- Salvage Yards: Exploring salvage yards can yield valuable finds at a lower cost. Be sure to check for the condition of items.

- Manufacturer’s Websites: Directly contacting manufacturers can lead to the most accurate and specific components for your machinery.

Utilizing these resources will help you secure the essential elements required for optimal functionality.

Installation Process for New Components

Successfully integrating new elements into a mechanical system requires a systematic approach to ensure optimal performance and longevity. This process encompasses careful planning, proper tools, and adherence to best practices to facilitate a seamless installation experience.

Begin by thoroughly examining the new components to familiarize yourself with their specifications and functions. Having a clear understanding of how each piece interacts within the overall assembly is crucial. Prepare the workspace by gathering necessary tools and creating an organized environment that minimizes the risk of losing small components.

Next, carefully remove any existing components that will be replaced, ensuring to document the arrangement for reassembly. Clean the mounting areas to eliminate debris or old lubricants that could affect the integrity of the new installations. Once the area is prepared, position the new parts accurately, securing them as specified in the guidelines to avoid misalignment.

After installation, conduct a thorough inspection to confirm that everything is fitted correctly and operates smoothly. Testing the system under controlled conditions allows for the identification of any issues early on. Finally, always consult the manufacturer’s recommendations for maintenance to ensure continued efficiency.

Peerless 700 vs. Other Transmissions

This section explores the comparative advantages of one specific gear system against various alternatives in the market. By examining key features, performance metrics, and user experiences, we aim to provide insights into the suitability of each option for different applications.

When evaluating different gear mechanisms, several factors come into play:

- Durability: How well does each system withstand wear and tear over time?

- Efficiency: Which option offers superior power transfer and fuel economy?

- Maintenance: What are the upkeep requirements, and how do they compare?

- Cost: How do initial investments and long-term expenses stack up against each other?

Users often highlight the following points in their assessments:

- Performance consistency under various loads.

- Ease of installation and compatibility with different machinery.

- Availability of replacement components and aftermarket support.

Ultimately, the choice between different gear systems should be informed by specific needs and operational contexts. Each system has its unique strengths that may cater to particular preferences and requirements.

Tools Needed for Repairs

Effective maintenance and restoration of mechanical components require a variety of specialized instruments. Having the right tools on hand not only streamlines the process but also ensures precision and safety during the task. Below is a list of essential equipment to facilitate the repair work.

- Socket Set: A comprehensive socket set is crucial for loosening and tightening bolts.

- Wrenches: Both adjustable and fixed wrenches are necessary for gripping and turning nuts and bolts.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Screwdrivers: A selection of Phillips and flathead screwdrivers will cover most fastening needs.

- Pliers: Needle-nose and standard pliers are helpful for gripping and bending components.

- Hammer: A rubber or ball-peen hammer can assist in driving components into place without causing damage.

- Vice Grip: This locking plier can hold pieces firmly during assembly or disassembly.

- Work Light: Proper lighting is essential for visibility in tight spaces.

- Cleaning Supplies: Rags, brushes, and cleaning solvents are important for maintaining a tidy workspace and ensuring parts are free of debris.

By gathering these tools beforehand, you will be better prepared to tackle any challenges that arise during the repair process, making your work more efficient and effective.

Customer Reviews and Experiences

In the realm of machinery, user feedback serves as a valuable resource for potential buyers and enthusiasts alike. Insights from those who have interacted with various components can shed light on performance, reliability, and overall satisfaction. Here, we explore a collection of opinions and experiences that highlight the nuances of ownership and usage.

Performance Insights

Many users express appreciation for the smooth operation and efficiency of their equipment. One user noted, “The system operates seamlessly, providing excellent torque and responsiveness. It truly enhances the overall experience.” Such testimonials underline the importance of quality in ensuring a dependable and effective functioning unit.

Durability and Maintenance

Another key aspect often mentioned is the durability of the components. A reviewer shared, “I’ve had my unit for several years, and it shows minimal wear. Routine maintenance is straightforward, making it easy to keep everything in top shape.” This kind of feedback highlights the long-term value and user-friendliness, factors crucial for decision-making.

Upgrading Your Peerless 700 System

Enhancing your system involves a careful selection of components that can improve performance and longevity. By identifying key areas for improvement, you can significantly boost efficiency and reliability.

Start with Assessment: Analyze the current setup to pinpoint weaknesses. Consider factors such as wear and tear, functionality, and compatibility with new elements.

Choosing Upgraded Components: Opt for high-quality replacements that provide superior performance. Look for features that offer enhanced durability and better efficiency, ensuring that every new addition complements the existing structure.

Installation and Testing: After acquiring the upgraded elements, proper installation is crucial. Follow guidelines carefully, and conduct thorough testing to ensure optimal operation.

With thoughtful enhancements, your system can achieve the ultimate in performance and reliability, tailored to meet your specific needs.