Understanding the Walker Jack Parts Diagram

In the realm of mechanical devices designed for elevation and support, a thorough grasp of their individual components is essential for efficient operation and maintenance. Each segment plays a pivotal role, contributing to the overall functionality and reliability of the equipment. Familiarity with these elements not only enhances usability but also aids in troubleshooting and repairs.

The importance of knowing each element cannot be overstated, as it allows users to identify potential issues before they escalate. Comprehensive knowledge of the structure facilitates informed decisions regarding repairs or upgrades, ensuring longevity and optimal performance. This section will delve into the various components, highlighting their functions and interrelations.

By breaking down the assembly into its fundamental parts, one can appreciate the engineering that underpins these mechanisms. This understanding empowers users to engage more effectively with the technology at hand, whether for routine inspections or more extensive interventions. Engaging with the details fosters a deeper connection to the equipment, transforming users into informed operators.

Understanding Walker Jack Components

In the realm of lifting mechanisms, a variety of elements come together to ensure functionality and safety. Grasping the intricacies of these components is essential for both users and technicians. Each segment plays a crucial role in the overall operation, contributing to efficiency and reliability.

Core Elements: At the heart of these devices lies a robust framework that provides structural integrity. This base supports the entire assembly, distributing weight evenly and allowing for smooth maneuverability. Accompanying this are the actuators, which are responsible for elevating loads, ensuring that heavy objects can be lifted with minimal effort.

Control Mechanisms: Equally important are the control systems that facilitate operation. These may include levers, buttons, or remote controls, all designed to provide the user with precise handling capabilities. Proper understanding of these controls is vital for maximizing safety during use.

Mobility Features: Many lifting systems are equipped with wheels or casters, enhancing their portability. The choice of wheels can greatly affect maneuverability, making it easier to navigate different environments.

Maintenance Considerations: Regular upkeep is necessary to ensure longevity. Familiarity with each component allows for better maintenance practices, helping to prevent wear and tear that could compromise performance.

In summary, a comprehensive grasp of the various components involved in these lifting systems not only enhances user experience but also promotes safety and efficiency in their application.

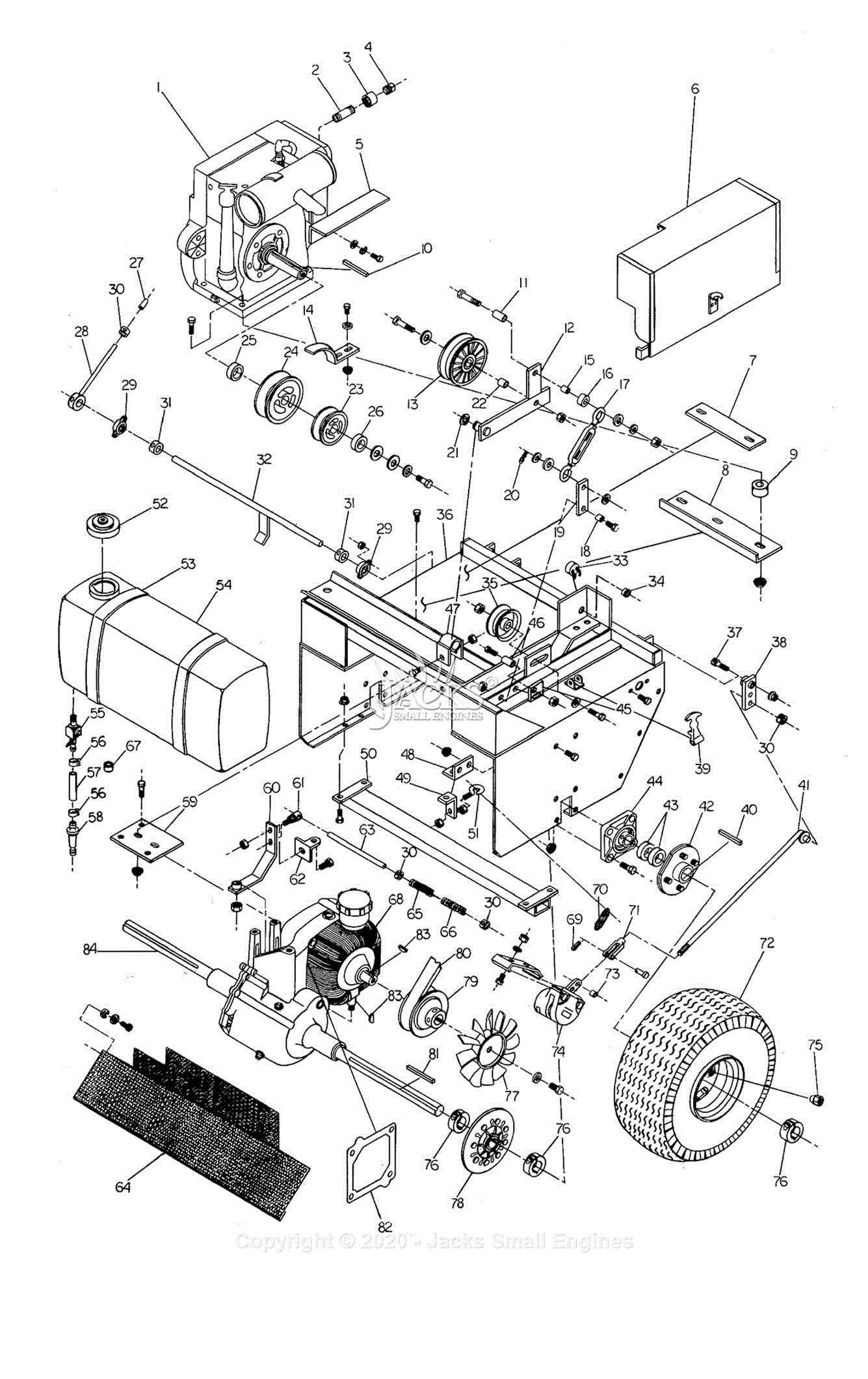

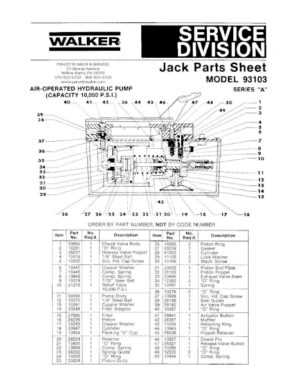

Importance of a Parts Diagram

Understanding the components of complex machinery is essential for effective maintenance and repair. A visual representation of the various elements provides clarity and assists in identifying specific parts quickly. This tool serves as a valuable reference, especially when troubleshooting issues or replacing worn-out elements.

Moreover, a well-structured illustration facilitates communication among technicians, ensuring that everyone is on the same page regarding repairs or upgrades. It can significantly reduce the time spent searching for particular pieces, leading to more efficient service and increased productivity.

Additionally, such representations are beneficial for training purposes. They allow new technicians to familiarize themselves with the equipment, enhancing their learning curve. By having a clear visual guide, individuals can better understand the assembly and functionality of the machine, ultimately leading to improved performance and longevity.

Main Functions of Each Part

This section delves into the essential roles played by each component of the device, emphasizing their contributions to overall functionality. Understanding these roles can enhance the appreciation of how the entire mechanism operates effectively.

- Base: Provides stability and support, ensuring that the entire system remains grounded during use.

- Column: Acts as a vertical support structure, allowing for height adjustments and enhancing maneuverability.

- Lever: Facilitates the lifting process, transforming manual effort into mechanical advantage for easier handling.

- Forks: Designed to secure the load, distributing weight evenly to prevent tipping or instability.

- Wheels: Enable smooth transportation, allowing for easy navigation across various surfaces.

Each of these components plays a vital role, contributing to the efficiency and safety of the entire assembly. Understanding their functions aids in better maintenance and operational effectiveness.

Common Issues in Walker Jacks

When operating lifting equipment, users may encounter various challenges that can hinder performance and safety. Understanding these common problems is essential for effective maintenance and usage. Addressing issues promptly can prolong the lifespan of the equipment and ensure a safe working environment.

1. Hydraulic Leaks: One of the most frequent complications is hydraulic fluid leakage. This can occur due to worn seals or damaged hoses, leading to reduced lifting capacity and potential hazards.

2. Stability Problems: Another concern is instability during use. If the structure is not balanced or if the wheels are uneven, it may tip over, posing risks to users. Regular inspections can help identify these issues before they escalate.

3. Difficulty in Operation: Users may also face challenges in maneuvering the device. This could stem from damaged wheels or misalignment of components, making it cumbersome to operate. Ensuring all moving parts are well-maintained can mitigate this issue.

4. Wear and Tear: Over time, components can wear out, affecting overall functionality. Regular maintenance and timely replacement of worn parts are crucial to maintaining optimal performance.

5. Noise: Unusual noises during operation can indicate underlying problems, such as friction or loose fittings. Addressing these sounds promptly can prevent further damage and enhance safety.

In summary, recognizing and addressing these common issues can lead to better performance and safer usage of lifting equipment. Regular checks and maintenance are vital to ensuring reliability and efficiency.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. These illustrations provide a detailed view of each element’s position and function within the assembly, making it easier to identify and source necessary replacements.

Key Elements to Focus On

When analyzing the illustration, pay attention to the following aspects:

| Element | Description |

|---|---|

| Labels | Clear annotations indicating each component’s name or number. |

| Connections | Lines or arrows showing how different elements interact or fit together. |

| Views | Different angles or perspectives to give a comprehensive understanding of the assembly. |

Steps for Effective Interpretation

To successfully interpret the illustration, follow these steps:

- Identify the key components by referring to their labels.

- Trace connections to understand how parts are related.

- Utilize any provided notes or legends for additional clarification.

Essential Tools for Maintenance

Regular upkeep of equipment is crucial for ensuring longevity and optimal performance. Having the right tools at hand not only simplifies the process but also enhances efficiency. This section outlines the fundamental instruments that are indispensable for any maintenance task.

Basic Hand Tools

- Wrenches: Essential for tightening and loosening fasteners, a variety of sizes is necessary.

- Screwdrivers: Both flathead and Phillips types are vital for various applications.

- Pliers: Useful for gripping, twisting, and cutting wires or other materials.

- Hammer: An essential tool for driving nails and applying force to objects.

Power Tools

- Drill: A versatile tool for creating holes and driving screws with ease.

- Saw: Ideal for cutting through various materials, including wood and metal.

- Angle Grinder: Useful for grinding, cutting, and polishing surfaces effectively.

- Impact Driver: Provides high torque for fastening applications, making tasks quicker and easier.

Equipping oneself with these essential instruments not only streamlines maintenance tasks but also ensures safety and accuracy throughout the process.

Identifying Parts by Number

Understanding components through their numerical identifiers is crucial for efficient maintenance and repair. This approach ensures that users can quickly locate the necessary elements without confusion. Each number corresponds to a specific piece, allowing for streamlined ordering and replacement processes.

Why Use Numerical Identification?

Numerical identification offers several advantages:

- Reduces ambiguity in communication.

- Facilitates quick searches in catalogs and inventories.

- Enhances accuracy in orders and shipments.

How to Identify Components

To effectively identify components by their numbers, follow these steps:

- Refer to the official catalog or manual for the numerical list.

- Match the number with the corresponding image or description.

- Ensure compatibility with your specific model before purchasing.

Ordering Replacement Components Online

In today’s digital age, acquiring essential components for machinery has never been easier. The convenience of online shopping allows users to find specific items quickly and efficiently. Understanding the process of sourcing these elements can significantly enhance maintenance and repair efforts.

Benefits of Online Ordering

- Accessibility: You can browse and purchase components from the comfort of your home or workplace.

- Variety: A wide selection of options is available, making it easier to find the exact item needed.

- Price Comparison: Online platforms enable users to compare prices across different retailers to secure the best deal.

- Customer Reviews: Many websites offer feedback from previous buyers, helping you make informed decisions.

Steps to Successfully Order Components

- Identify the Component: Clearly determine the specific item required for your equipment.

- Search Reputable Websites: Utilize trusted online retailers or specialized suppliers to find your component.

- Check Compatibility: Ensure that the selected item is compatible with your existing setup by reviewing specifications.

- Read Reviews: Assess feedback from other customers to gauge quality and reliability.

- Add to Cart and Checkout: Proceed to purchase, providing necessary shipping and payment details.

- Track Your Order: Keep an eye on the shipment progress until it arrives at your location.

Safety Considerations for Walker Jacks

Ensuring safety during the use of mobility aids is crucial for preventing accidents and injuries. Individuals and caregivers must be aware of specific guidelines and best practices to maximize stability and minimize risks while navigating various environments.

Proper Usage and Maintenance

Regular inspection of the device is essential. Check for wear and tear on components, ensuring that all elements are functioning properly. Make sure to adjust the height to suit the user’s needs, providing optimal support. Following the manufacturer’s instructions for usage and maintenance can greatly enhance safety.

Environmental Awareness

Being mindful of surroundings plays a significant role in safe mobility. Avoid uneven surfaces and obstacles that could lead to falls. Use the device on well-lit paths and ensure there is ample space for maneuvering. Consider the weather conditions as wet or icy surfaces can pose additional hazards.

Regular Maintenance Tips and Tricks

Ensuring the longevity and optimal performance of your lifting equipment requires consistent care and attention. Regular upkeep not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By adhering to a systematic maintenance routine, you can identify potential issues early and keep your device in top condition.

Routine Inspection Checklist

A well-structured inspection can help spot wear and tear before it escalates. Here are key areas to focus on during your checks:

| Component | Inspection Focus | Recommended Action |

|---|---|---|

| Hydraulic System | Leaks, fluid levels | Replace seals, top off fluids |

| Mechanical Parts | Wear on moving parts | Lubricate or replace as needed |

| Control Mechanisms | Response time, functionality | Calibrate or repair as necessary |

Best Practices for Longevity

In addition to routine inspections, incorporating these best practices can greatly extend the life of your equipment:

- Keep the environment clean and dry to prevent corrosion.

- Store the device in a designated area when not in use.

- Educate users on proper handling techniques.

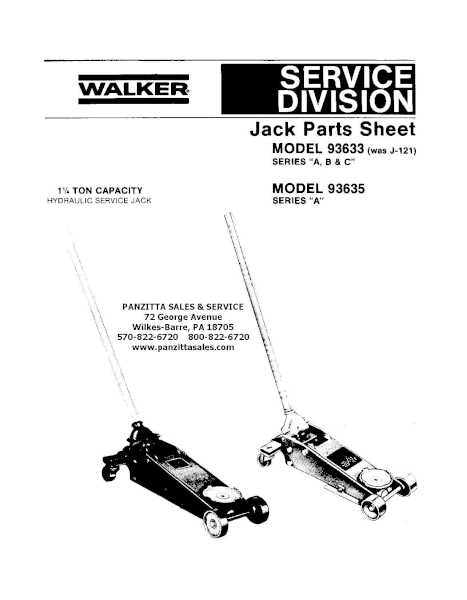

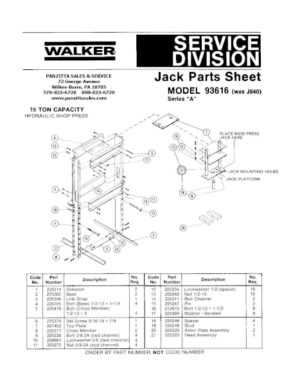

Comparing Walker Jack Models

This section explores the various iterations of a popular lifting tool, highlighting their unique features, benefits, and suitable applications. Understanding the differences among these models can aid users in selecting the most appropriate equipment for their specific needs.

Key Features

Different models come equipped with distinct functionalities that cater to various tasks. Users should consider factors such as load capacity, height adjustment capabilities, and overall weight when making a decision.

Comparison Table

| Model | Load Capacity | Height Adjustment | Weight |

|---|---|---|---|

| Model A | 2000 lbs | 5 to 10 feet | 100 lbs |

| Model B | 2500 lbs | 4 to 12 feet | 120 lbs |

| Model C | 3000 lbs | 3 to 15 feet | 150 lbs |

By evaluating these specifications, users can determine which model best suits their operational requirements and preferences, ensuring efficiency and safety in their tasks.

Resources for Further Learning

Expanding your knowledge in the field of lifting equipment and mechanisms can greatly enhance your understanding and skills. Various resources are available for individuals looking to deepen their expertise, from instructional manuals to online courses. These materials cater to different learning styles and can help you grasp the intricacies of assembly and maintenance.

Books and Manuals

Several comprehensive texts provide in-depth insights into mechanical systems and their components. These books often include detailed explanations, illustrations, and step-by-step guides that can assist both novices and experienced users. Additionally, manufacturer manuals serve as valuable references, offering specific instructions tailored to various models.

Online Courses and Tutorials

Many platforms offer online courses that cover a wide range of topics related to mechanical devices. These interactive lessons typically include video demonstrations and quizzes to reinforce learning. Furthermore, tutorial videos on platforms like YouTube provide practical demonstrations, making complex concepts more accessible and easier to understand.