Understanding the Components of a Dirt Bike Engine

The complexity of a two-wheeled machine’s internal mechanics is both fascinating and essential for its performance. Each component plays a significant role in ensuring optimal functionality, contributing to the overall effectiveness of the vehicle. Exploring these elements can provide insight into the mechanics that drive this thrilling mode of transportation.

In this section, we will delve into the various elements that come together to create a harmonious system. From the intricate mechanisms that facilitate movement to the protective structures that ensure safety, every part has a distinct purpose. Gaining knowledge about these components enhances one’s appreciation for the engineering marvels behind such dynamic vehicles.

Furthermore, understanding the roles of each element aids in maintenance and repair, allowing enthusiasts to keep their machines in peak condition. This exploration not only highlights the importance of each piece but also fosters a deeper connection with the mechanics at play.

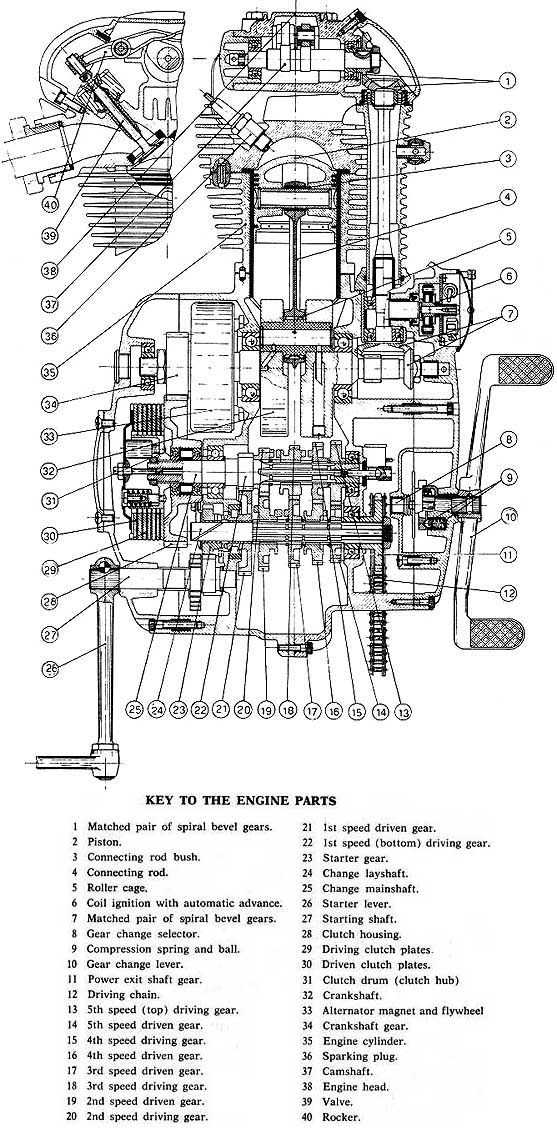

This section provides a comprehensive overview of the essential components that contribute to the functionality of off-road motorcycles. Understanding these crucial elements enhances the appreciation of how these machines operate, ensuring a smoother and more efficient riding experience. Each component plays a vital role in the overall performance, making it essential for enthusiasts and riders alike to familiarize themselves with their functions and interconnections.

| Component | Description |

|---|---|

| Cylinder | The chamber where fuel and air mix for combustion. |

| Piston | Moves up and down within the cylinder, compressing the fuel mixture. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion. |

| Carburetor | Mixes air with fuel before it enters the combustion chamber. |

| Ignition System | Generates a spark to ignite the fuel-air mixture. |

| Exhaust System | Channels exhaust gases away from the engine after combustion. |

| Valves | Control the intake of air-fuel mixture and the exhaust of gases. |

| Timing Chain/Belt | Ensures that the crankshaft and camshaft move in sync. |

| Cooling System | Prevents the engine from overheating by dissipating heat. |

| Oil Pump | Distributes oil to lubricate moving parts and reduce friction. |

| Frame | Supports the engine and provides structural integrity to the motorcycle. |

Essential Engine Components Explained

The fundamental elements that drive the performance of a high-powered machine are critical to understanding its functionality. These core components work in harmony to convert fuel into motion, showcasing the intricacies of mechanical engineering. Each element plays a unique role in ensuring efficiency and reliability.

Piston: This cylindrical piece moves up and down within a chamber, compressing the fuel-air mixture. It transforms the energy from combustion into mechanical power, making it essential for propulsion.

Crankshaft: Serving as the heart of the assembly, this rotating shaft translates the linear motion of the piston into rotational energy, which ultimately powers the wheels. Its design is vital for smooth operation and balance.

Cylinder Head: Located at the top of the chamber, this component houses valves and spark plugs. It is crucial for controlling the flow of gases in and out, thus affecting combustion efficiency and power output.

Valves: These elements regulate the intake of the air-fuel mixture and the expulsion of exhaust gases. Their precise timing and operation are vital for optimal performance and responsiveness.

Camshaft: Responsible for opening and closing the valves at the right moment, this component plays a pivotal role in timing. Its configuration can greatly influence engine characteristics such as power and torque.

Understanding the Cylinder and Piston

The cylinder and piston are fundamental components that play a crucial role in the performance of an internal combustion system. These elements work together to convert fuel into mechanical energy, driving the vehicle forward. A comprehensive grasp of their functions and interrelationships is essential for appreciating how power is generated and utilized in these machines.

The cylinder serves as the chamber where the combustion process occurs, while the piston acts as a movable element that translates the energy from the combustion into motion. This interaction between the two parts is vital for the efficiency and effectiveness of the overall system.

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process, allowing for the expansion of gases that drive the piston. |

| Piston | Moves up and down within the cylinder, converting the energy from combustion into mechanical force. |

The Role of the Crankshaft

The crankshaft is a vital component within a power unit, serving as the bridge between rotational motion and linear force. It plays an essential part in transforming the energy generated during combustion into usable power that propels the vehicle forward.

This central element operates by converting the up-and-down movement of the pistons into a circular motion. As the pistons move, the crankshaft rotates, allowing the kinetic energy produced to be transmitted to the transmission system. Without the crankshaft, the efficiency and functionality of the overall system would be significantly compromised.

Moreover, the integrity and design of the crankshaft influence performance and durability. A well-engineered crankshaft ensures smoother operation and minimizes vibrations, contributing to the longevity of the entire mechanism. Its robust construction allows it to withstand high levels of stress and pressure, highlighting its importance in maintaining optimal functionality.

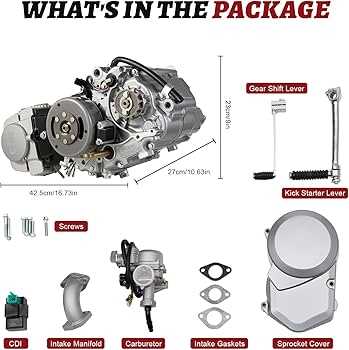

Importance of the Carburetor

The carburetor plays a crucial role in the overall functionality of a combustion mechanism, ensuring optimal performance and efficiency. This component is responsible for mixing fuel with air, creating the ideal blend necessary for effective ignition and operation. A well-functioning carburetor contributes significantly to the smooth running and longevity of the entire system.

In essence, the effectiveness of this assembly directly impacts power output, fuel consumption, and emissions. An improperly calibrated carburetor can lead to various issues, including reduced acceleration, engine stalling, and increased fuel expenditure. Therefore, understanding its function and maintenance is vital for anyone involved in mechanical upkeep.

| Function | Description |

|---|---|

| Fuel Mixing | Combines fuel with air to form a combustible mixture. |

| Airflow Regulation | Controls the amount of air entering the combustion chamber. |

| Throttle Control | Adjusts the power output based on rider input. |

| Emissions Reduction | Helps to minimize harmful exhaust gases through efficient combustion. |

Fuel Delivery Systems in Dirt Bikes

Efficient fuel delivery is crucial for optimal performance in high-powered two-wheeled vehicles. This process involves ensuring that the proper amount of fuel reaches the combustion chamber at the right time. Various systems are designed to facilitate this essential function, contributing to the overall power and efficiency of the machine.

Types of Fuel Delivery Mechanisms

There are several mechanisms used to manage the flow of fuel, each with its unique characteristics:

- Carburetors: These devices mix air and fuel in specific ratios before entering the combustion chamber. They are known for their simplicity and ease of tuning.

- Fuel Injectors: Common in modern models, these systems use electronic controls to inject precise amounts of fuel directly into the intake manifold or combustion chamber, enhancing efficiency and performance.

- Gravity Feed Systems: Utilizing gravity to move fuel from the tank to the engine, these systems are straightforward but may not provide consistent pressure.

Importance of Proper Tuning

Accurate tuning of the fuel delivery system is vital for achieving peak performance. Proper adjustments can lead to:

- Improved throttle response.

- Enhanced fuel efficiency.

- Reduced emissions.

Regular maintenance and adjustments are necessary to ensure the system operates effectively, allowing riders to enjoy a smooth and powerful experience.

Cooling Mechanisms for Engines

Effective temperature regulation is crucial for optimal performance and longevity. Various systems are employed to dissipate excess heat generated during operation, ensuring that the internal components remain within safe thermal limits. Understanding these cooling methods can provide insight into enhancing performance and reliability.

Types of Cooling Systems

- Air Cooling: This method relies on ambient air flow to remove heat. Often used in simpler designs, it is lightweight and easy to maintain.

- Liquid Cooling: Utilizing a coolant fluid, this system circulates through channels in the structure, absorbing heat and transferring it to a radiator or similar unit for dissipation.

Importance of Cooling

Maintaining an appropriate temperature prevents overheating, which can lead to severe damage and reduced efficiency. By employing the right cooling system, the overall reliability and performance of the machinery can be significantly improved.

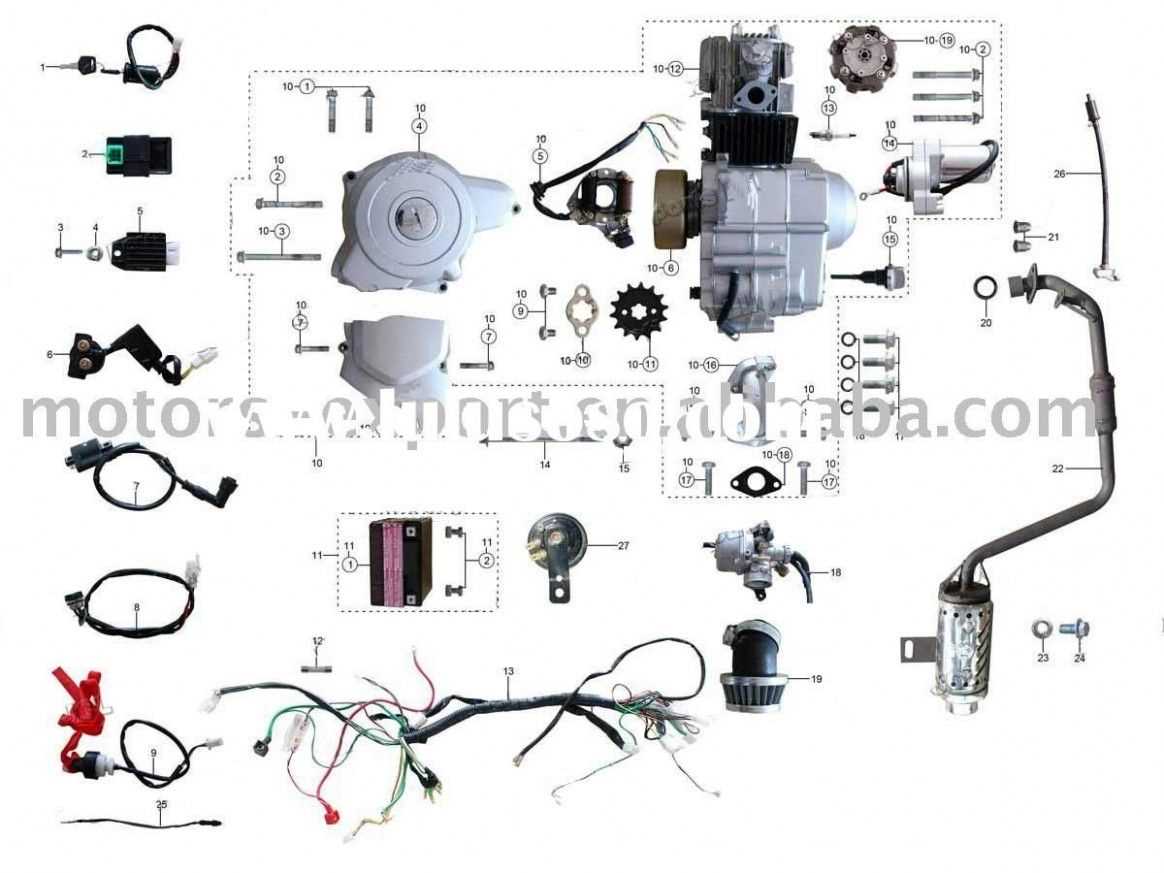

Ignition Systems and Their Function

Ignition systems play a crucial role in the operation of internal combustion mechanisms by ensuring the timely generation of sparks that ignite the fuel-air mixture. This process is vital for transforming chemical energy into mechanical power, enabling efficient propulsion and performance.

The main components of ignition systems include the ignition coil, spark plug, and control unit, each working in harmony to initiate combustion. The ignition coil transforms low voltage from the battery into high voltage, which is essential for creating a spark at the spark plug. This spark ignites the fuel-air mixture, leading to the explosion that powers the system.

Furthermore, various ignition systems can be categorized based on their design and functionality, such as contact breaker and electronic types. The latter has gained popularity due to its reliability and efficiency, often incorporating advanced features for improved performance. Understanding the intricacies of ignition systems is vital for optimizing the overall effectiveness of the propulsion mechanism.

Transmission and Gear Ratios

The transmission system plays a crucial role in determining how power is transferred from the power source to the wheels. It affects acceleration, speed, and overall performance, making it essential for optimal functionality. Understanding the intricacies of gear ratios allows riders to make informed decisions about their setup, ensuring that they achieve the desired handling characteristics and responsiveness.

Understanding Gear Ratios

Gear ratios indicate the relationship between the number of teeth on two interconnected gears. This relationship directly influences how torque and speed are managed during operation. Here are key points regarding gear ratios:

- A lower gear ratio results in higher torque but lower speed, suitable for climbing or accelerating quickly.

- A higher gear ratio provides increased speed but less torque, ideal for flat surfaces or high-speed riding.

- Optimal gear selection is essential for various riding conditions, impacting traction and stability.

Factors Influencing Performance

Several factors impact the performance of the transmission system and gear ratios:

- Rider skill and technique: Experienced riders can leverage gear ratios effectively to enhance performance.

- Terrain type: Different terrains may require specific gear setups to optimize power delivery.

- Weight distribution: Proper balance affects handling and responsiveness, making gear selection vital.

Exhaust Systems: Function and Design

The exhaust system plays a crucial role in the performance and efficiency of any motorized vehicle. It is responsible for directing waste gases away from the combustion area while minimizing noise and optimizing engine performance. Understanding the function and design of this system can significantly enhance the overall riding experience.

One of the primary functions of an exhaust system is to expel gases produced during the combustion process. Efficient removal of these gases helps maintain optimal pressure levels within the combustion chamber, contributing to improved power output and fuel efficiency. Additionally, the design of the system can influence sound levels and emissions, making it essential for manufacturers to strike a balance between performance and compliance with environmental standards.

| Design Component | Function |

|---|---|

| Header Pipe | Collects exhaust gases from the combustion chamber and directs them into the system. |

| Silencer | Reduces noise produced during exhaust gas expulsion. |

| Pipe System | Guides exhaust gases to the rear, minimizing backpressure and improving flow. |

| Outlet | Discharges gases into the atmosphere, completing the exhaust process. |

In conclusion, the design and function of exhaust systems are vital for the overall performance of any motorized vehicle. By understanding these elements, riders can make informed decisions regarding modifications and maintenance to enhance their vehicles’ capabilities.

Lubrication Systems in Dirt Bike Engines

Effective lubrication is crucial for the smooth operation and longevity of any high-performance machine. This system minimizes friction between moving components, reducing wear and tear while maintaining optimal temperatures. In these high-revving power sources, the role of a reliable lubrication mechanism becomes even more significant to ensure maximum efficiency and performance under varying conditions.

Types of Lubrication Systems

Various types of lubrication systems are employed to meet the unique demands of performance motors. The most common methods include splash lubrication, where oil is splashed onto moving parts, and pressure lubrication, which circulates oil through a pump. Each approach has its advantages, with some systems allowing for better oil distribution and enhanced cooling capabilities.

Importance of Regular Maintenance

Maintaining the lubrication system is vital to prevent overheating and mechanical failure. Regular checks of oil levels and quality help ensure that the system functions effectively. Additionally, changing the oil at recommended intervals contributes to optimal performance, extending the life of the internal components and enhancing overall reliability.

Common Maintenance Tips for Engine Parts

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle’s components. Implementing effective care practices can prevent wear and tear, reduce the likelihood of breakdowns, and enhance overall functionality. Below are some practical suggestions for maintaining your mechanical system.

- Regular Inspections: Frequently check critical components for signs of wear, corrosion, or damage.

- Fluid Levels: Keep an eye on lubrication levels; ensure they are within the recommended range to prevent friction and overheating.

- Air Filter Maintenance: Clean or replace air filtration systems regularly to promote efficient airflow and performance.

- Fuel System Care: Use high-quality fuel and consider adding a fuel stabilizer to avoid clogging and deposits.

- Component Cleaning: Clean external surfaces and connections to remove dirt and debris, enhancing performance and safety.

- Timely Replacements: Replace worn components, such as gaskets and seals, to maintain optimal sealing and prevent leaks.

- Consult the Manual: Refer to your vehicle’s manual for specific maintenance recommendations and schedules.

By following these maintenance tips, you can ensure that your machine operates smoothly and efficiently, extending its lifespan and improving your overall riding experience.