Yamaha 9.9 Four Stroke Parts Diagram Overview

In the world of marine engineering, a thorough comprehension of engine assemblies is essential for optimal performance and maintenance. This article delves into the intricate designs and configurations that make up the heart of a marine propulsion system. By exploring various components and their functions, enthusiasts and professionals alike can enhance their understanding of these powerful machines.

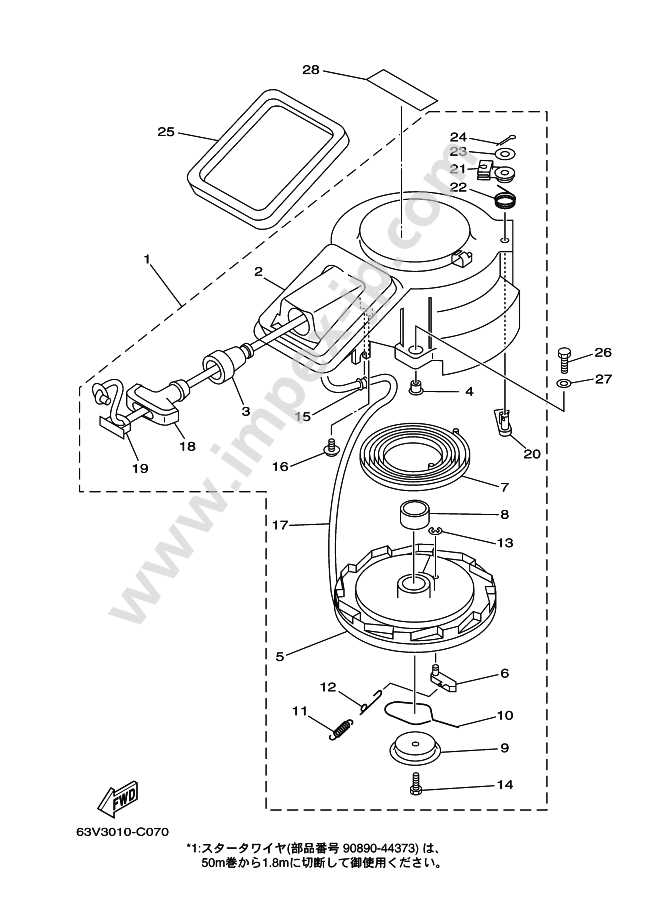

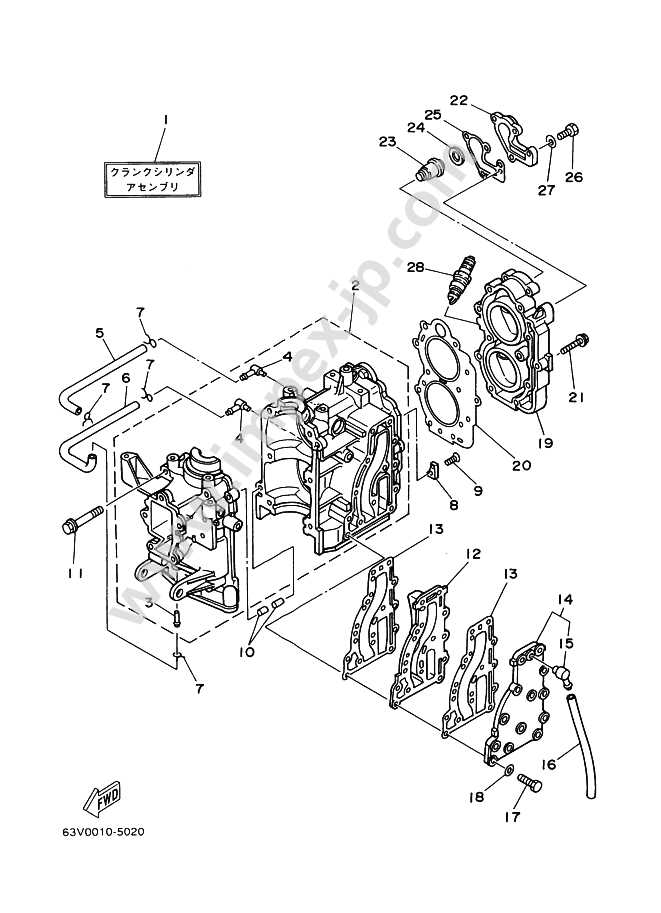

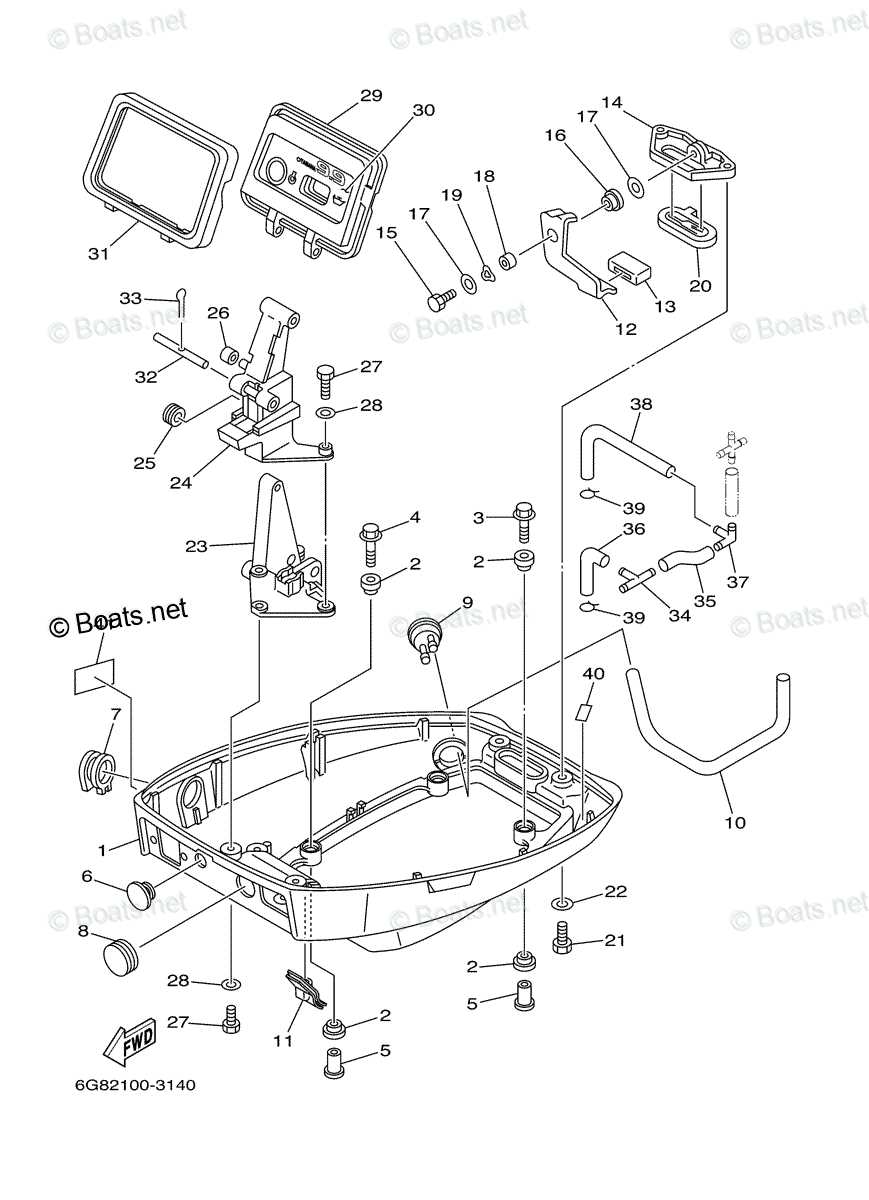

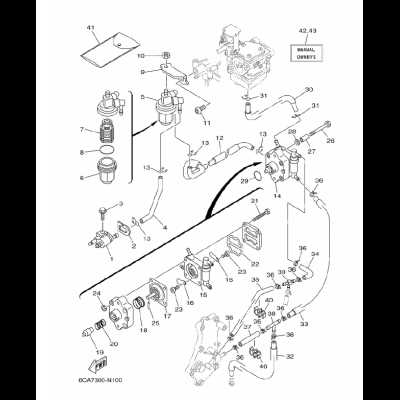

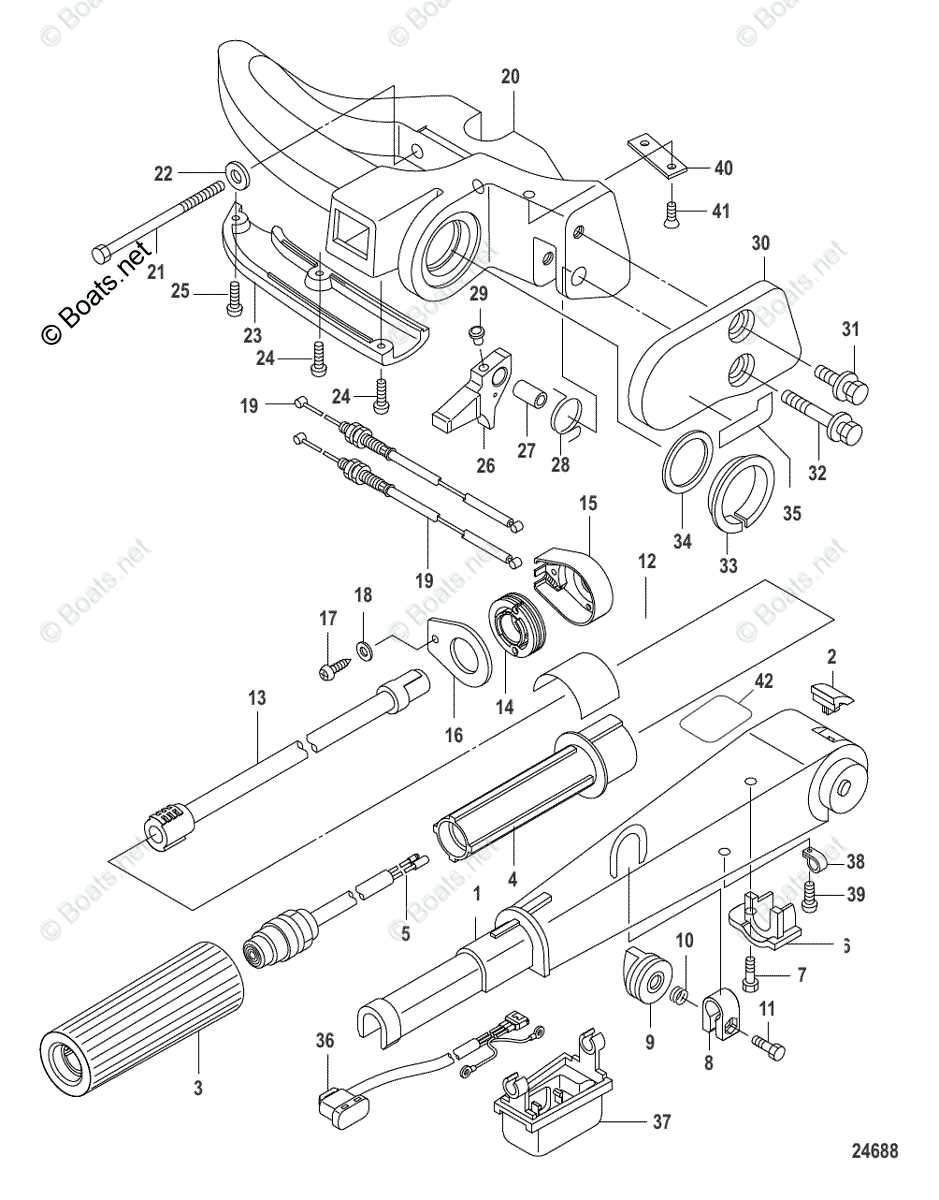

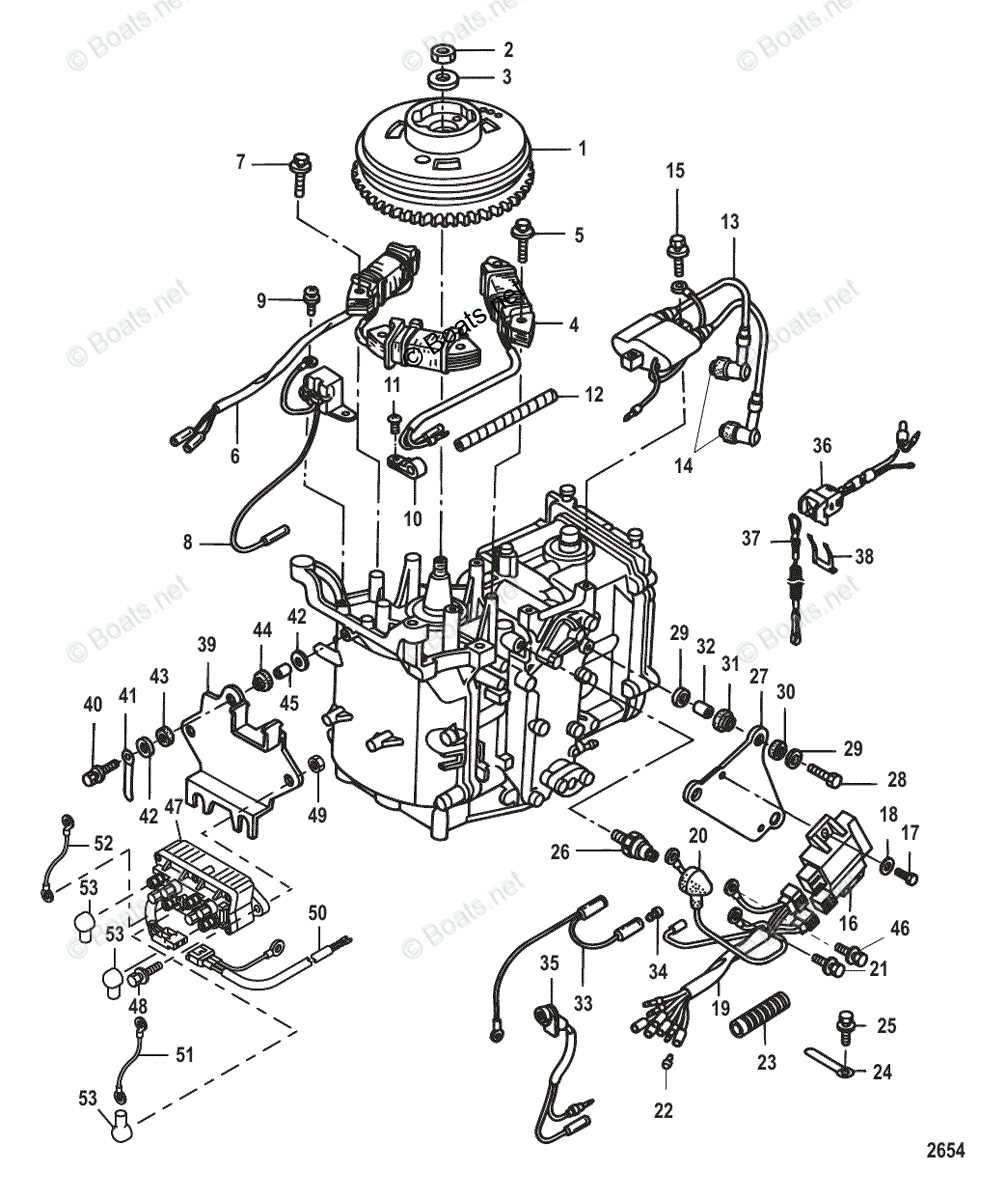

Visual representation plays a crucial role in grasping the complexities of engine mechanics. Accurate schematics not only assist in identifying individual elements but also facilitate troubleshooting and repairs. A well-structured layout allows users to pinpoint specific areas that may require attention, ensuring that any issues are addressed swiftly.

Furthermore, recognizing the interconnectivity of components enhances the overall knowledge of engine operation. Each element serves a vital purpose, and understanding how they work together is key to maintaining efficiency and longevity. As we explore the various sections and their relationships, a clearer picture of engine dynamics will emerge, providing valuable insights for both seasoned veterans and newcomers to the field.

Understanding Yamaha 9.9 Four-Stroke Engine

The four-cycle propulsion system is a marvel of engineering, designed to deliver efficiency and reliability. This engine type utilizes a sequence of four distinct phases to convert fuel into motion, ensuring optimal performance for various marine applications. Understanding its fundamental mechanics can greatly enhance the experience of those who operate and maintain it.

Key Features of the Engine

This propulsion unit is known for its robust construction and lightweight design. It offers remarkable fuel efficiency, making it an ideal choice for extended journeys on the water. The incorporation of advanced technologies allows for smoother operation and lower emissions, contributing to a cleaner environment.

Maintenance and Care

Importance of Parts Diagrams

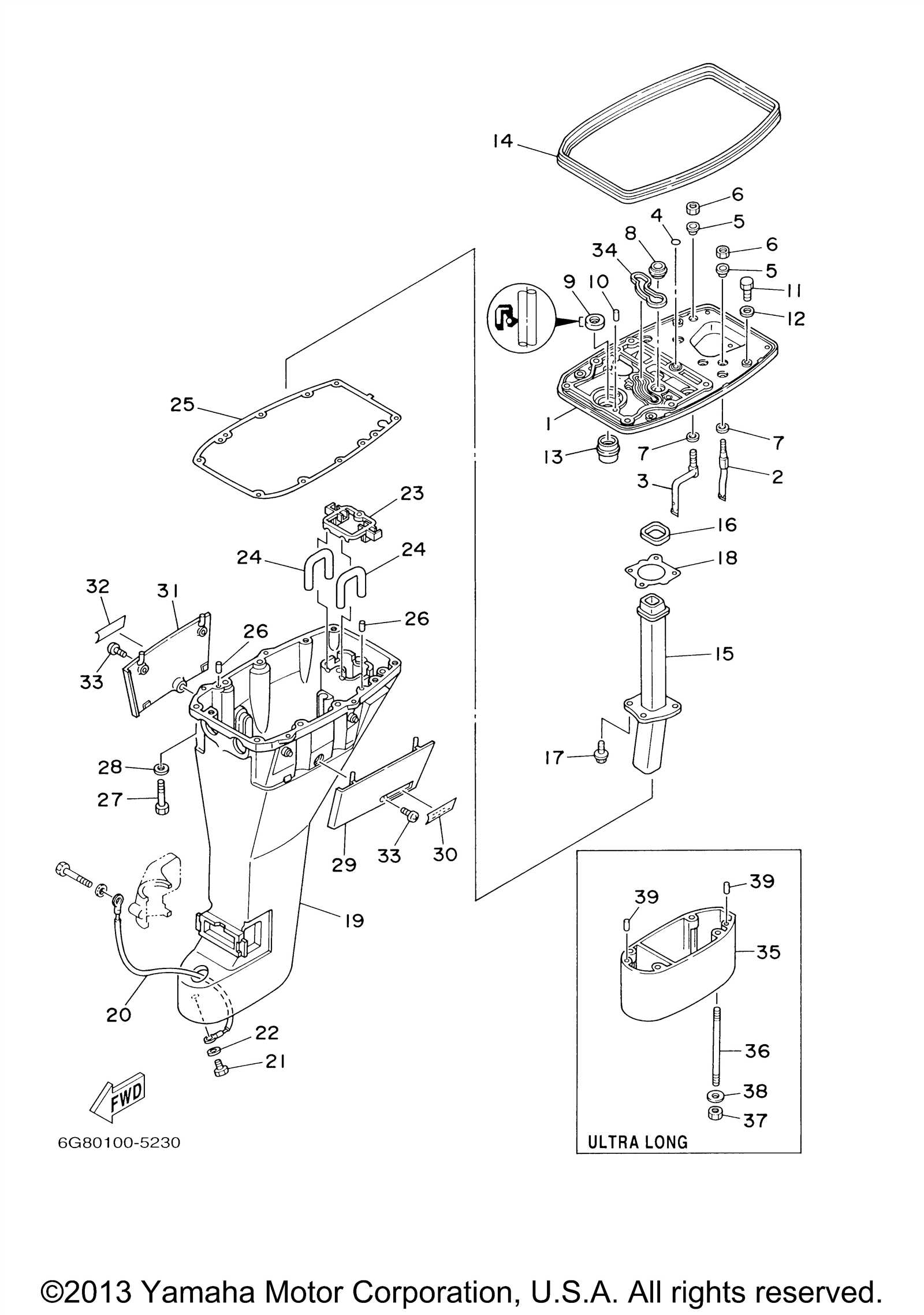

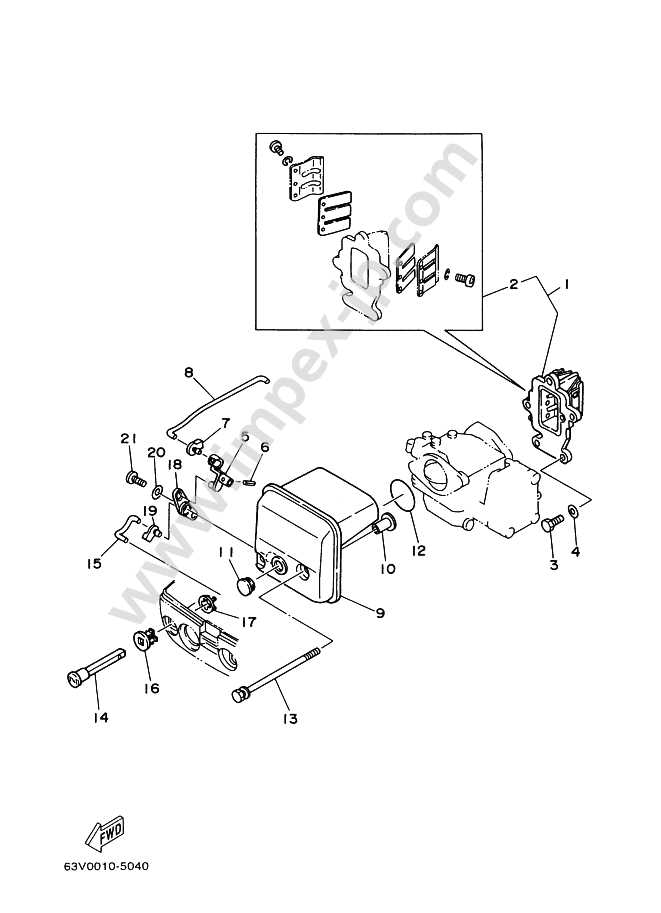

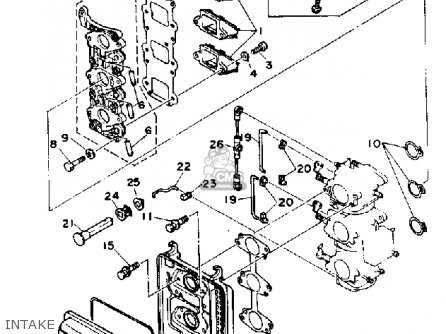

Understanding the intricacies of mechanical assemblies is crucial for maintenance and repair. Visual representations serve as invaluable tools for identifying components, ensuring accurate reassembly, and streamlining troubleshooting processes. These illustrations provide clarity in complex systems, allowing users to pinpoint specific items and their functions with ease.

Moreover, utilizing these visual aids can significantly reduce the risk of errors during repairs. They guide technicians through the disassembly and reassembly processes, making it easier to follow sequences and maintain order. This is especially beneficial when dealing with intricate machinery, where each element plays a vital role in overall performance.

| Benefits | Description |

|---|---|

| Clarity | Visual guides enhance understanding of component functions. |

| Efficiency | Streamlines the repair process, saving time and effort. |

| Accuracy | Reduces the likelihood of mistakes during assembly. |

| Accessibility | Makes information easily available for reference. |

Key Components of the Yamaha 9.9

Understanding the essential elements of a small outboard engine is crucial for effective maintenance and performance optimization. Each component plays a significant role in the overall functionality, contributing to both efficiency and reliability.

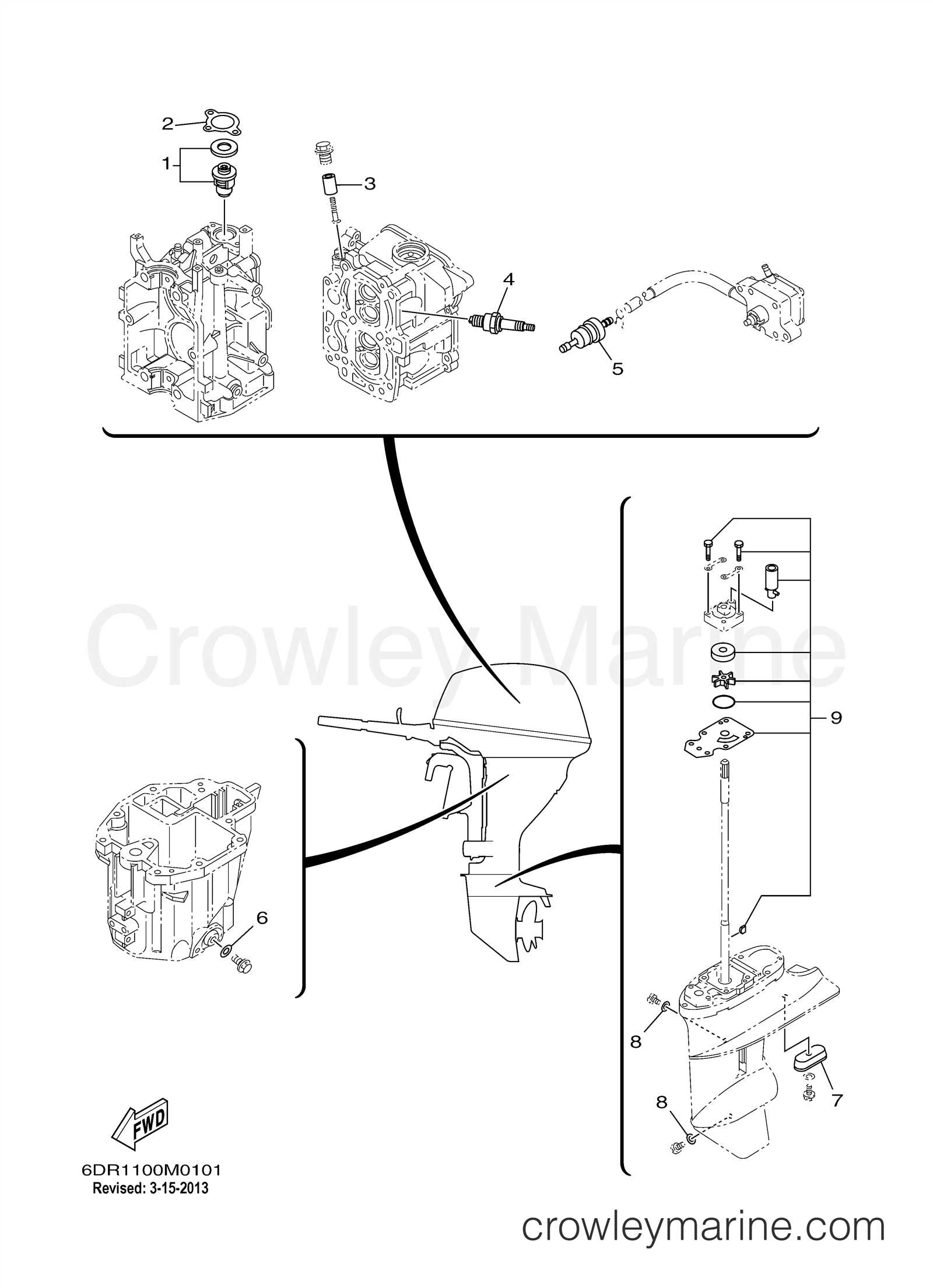

Powerhead is the heart of the engine, housing the combustion chamber and various mechanical parts that generate power. Its design impacts not only performance but also fuel efficiency.

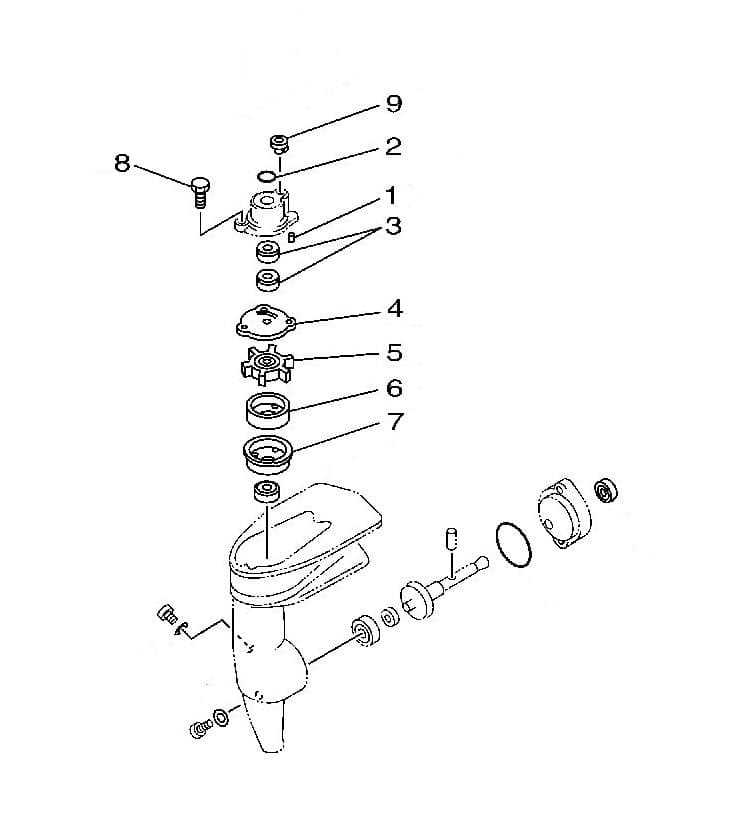

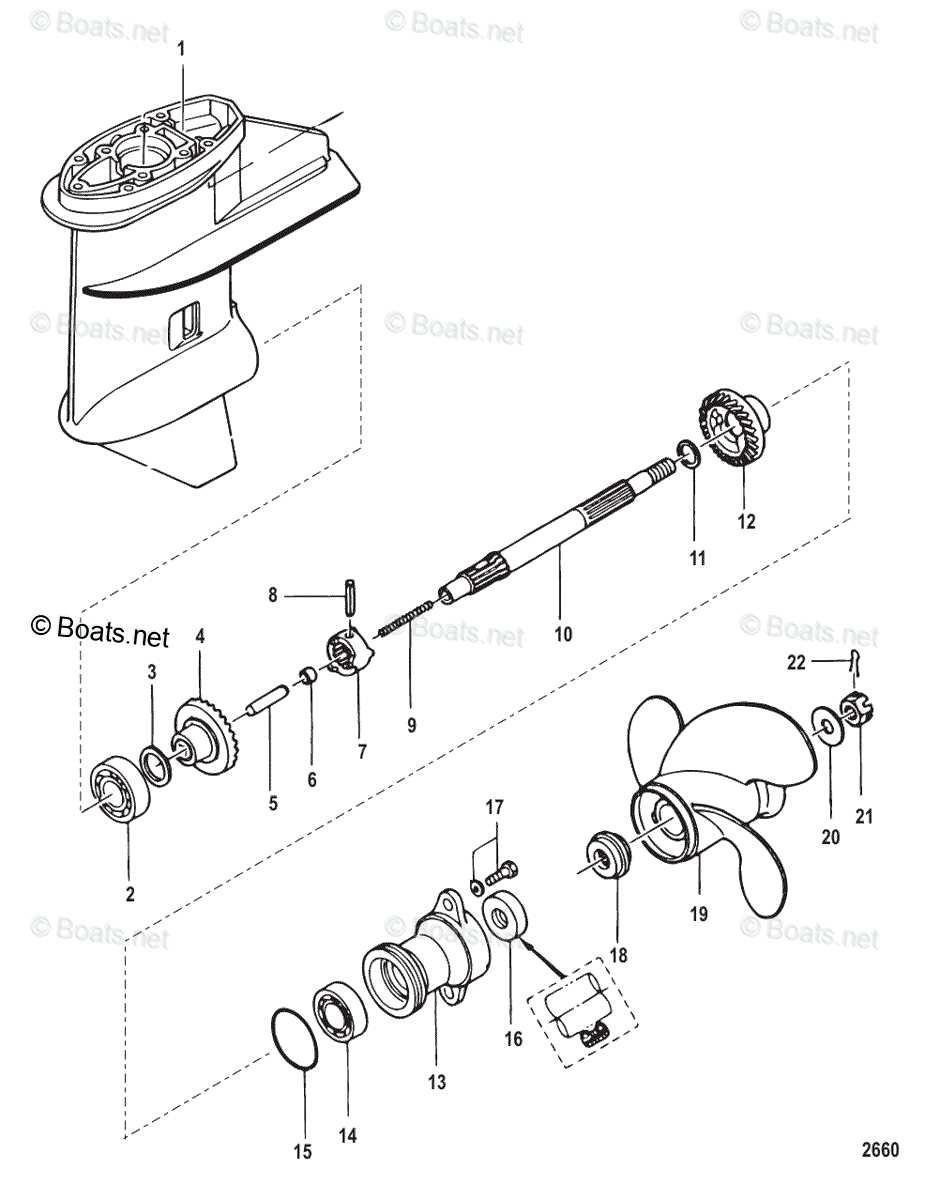

Lower Unit is responsible for transmitting power from the powerhead to the propeller. This section includes the gear system, which must be maintained to ensure smooth operation and minimize wear.

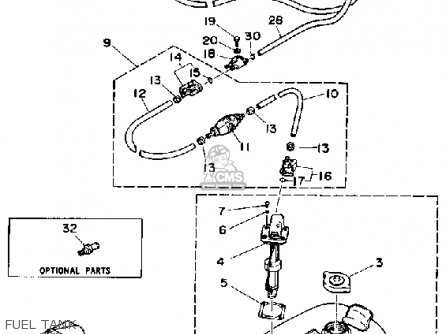

Fuel System encompasses the fuel tank, lines, and carburetor, ensuring a proper supply of fuel to the engine. Regular inspection and cleaning of these parts are vital to avoid clogging and ensure optimal performance.

Cooling System prevents overheating by circulating water through the engine. A properly functioning cooling system is essential for maintaining operational integrity and prolonging the engine’s lifespan.

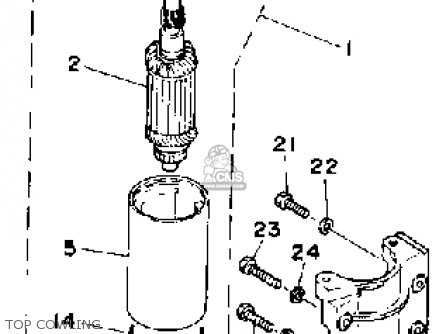

Ignition System is critical for initiating the combustion process. This includes the spark plugs and ignition coils, which must be in good condition for reliable starts and efficient running.

By familiarizing oneself with these key elements, operators can enhance the longevity and performance of their outboard engine, ensuring a reliable experience on the water.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These illustrations provide a visual guide to various elements, their relationships, and functions within a system. Familiarizing yourself with these graphics can enhance your ability to troubleshoot and assemble machinery efficiently.

1. Familiarize Yourself with Symbols: Each graphic uses specific symbols to represent different components. Take time to learn what each symbol signifies. This knowledge will help you quickly identify parts and their functions.

2. Reference the Key: Most illustrations include a key or legend that explains the symbols and numbers used. Consult this section to clarify any uncertainties regarding component identification.

3. Understand the Layout: Components are often arranged in a logical order, reflecting their placement within the assembly. Observe how parts connect to one another, as this can provide insights into their operational relationships.

4. Pay Attention to Numbering: Many graphics will include numbers next to each component. These numbers often correspond to a list or inventory of items, making it easier to order replacements or verify your stock.

5. Cross-Reference with Manuals: Use service manuals or guides alongside the visual representation to gain deeper insights into the installation or replacement processes. This combination of resources enhances your understanding and efficiency.

By mastering these elements, you can confidently interpret schematics and apply that knowledge to your maintenance tasks, ensuring optimal performance of your equipment.

Common Issues and Solutions

When operating small marine engines, users often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems and their solutions is essential for maintaining optimal function and ensuring longevity. Below are some frequent issues along with practical remedies.

| Issue | Description | Solution |

|---|---|---|

| Hard Starting | Engine fails to start easily or requires multiple attempts. | Check fuel levels, inspect spark plugs, and ensure the choke is functioning properly. |

| Overheating | Engine temperature rises beyond normal limits. | Examine the cooling system for blockages, clean the water intake, and ensure adequate coolant flow. |

| Unusual Noises | Strange sounds coming from the engine during operation. | Investigate for loose components, check for foreign objects in the casing, and lubricate moving parts. |

| Poor Acceleration | Engine struggles to gain speed when throttle is applied. | Inspect fuel filters for clogs, clean the carburetor, and ensure proper throttle cable adjustments. |

| Fuel Leaks | Visible fuel escaping from the engine. | Tighten fittings, replace worn hoses, and check for cracks in the fuel tank. |

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your marine engine requires regular upkeep and attention. By following a structured maintenance routine, you can significantly extend the lifespan of your equipment and enhance its reliability. This section outlines essential practices that will help maintain optimal functioning and prevent premature wear.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Change the oil | Every 100 hours or annually | Use high-quality oil to ensure proper lubrication. |

| Inspect the fuel system | Every season | Check for leaks and ensure filters are clean. |

| Examine the cooling system | Every 50 hours | Flush with fresh water to remove debris. |

| Check spark plugs | Every 100 hours | Replace if worn to maintain efficient combustion. |

| Inspect the propeller | Every outing | Look for dings or damage that can affect performance. |

| Clean the exterior | After each use | Prevent corrosion by washing with fresh water. |

By adhering to these guidelines and regularly inspecting your engine, you can ensure its performance and longevity, ultimately making your time on the water more enjoyable.

Where to Find Replacement Parts

Locating suitable components for your watercraft can be essential for maintaining its performance and longevity. Various sources can provide reliable options, ensuring you find the correct items to keep your machine running smoothly. Understanding where to look can save you time and effort, as well as help you make informed decisions.

Online Retailers

The internet offers a wealth of resources for acquiring components. Numerous online stores specialize in marine equipment and accessories, providing extensive catalogs. Here are some popular options:

| Retailer | Website |

|---|---|

| Marine Supply | www.marinesupply.com |

| Boat Parts Central | www.boatpartscentral.com |

| Outboard Warehouse | www.outboardwarehouse.com |

Local Dealers and Service Centers

Visiting local distributors or service centers can also be beneficial. Many have knowledgeable staff who can assist you in finding the right components. Establishing a relationship with these professionals may lead to exclusive discounts or services.

Identifying OEM vs. Aftermarket Parts

Understanding the distinction between original components and those produced by third parties is crucial for maintenance and repair. Each option has its own advantages and disadvantages, impacting performance, longevity, and cost. Being able to identify these differences can ensure optimal functioning and reliability.

Original equipment manufacturer (OEM) components are crafted by the original brand, adhering to specific standards and quality. In contrast, aftermarket alternatives are produced by independent manufacturers and may vary significantly in terms of quality and performance.

Here are some key points to consider when distinguishing between OEM and aftermarket options:

- Branding: OEM items typically bear the manufacturer’s logo, while aftermarket alternatives may feature different branding or no branding at all.

- Quality: OEM components usually guarantee a certain level of quality and performance, while aftermarket products can range from high-quality to subpar.

- Warranty: OEM components often come with a warranty from the manufacturer, whereas aftermarket items may have limited or no warranty coverage.

- Cost: Aftermarket alternatives are frequently less expensive than OEM, but this can sometimes reflect a compromise in quality.

- Availability: OEM components might be harder to find, especially for older models, whereas aftermarket options are often more readily available.

Evaluating these factors can assist in making informed decisions about which components to choose for repairs or upgrades. This approach can enhance overall satisfaction with maintenance and ensure the best performance for your equipment.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to taking apart a small marine engine, ensuring that each component is carefully handled and documented. Following these steps will facilitate maintenance and repairs, helping to prolong the life of the engine.

Begin by gathering all necessary tools, including screwdrivers, wrenches, and pliers. Having everything at hand will streamline the process and minimize interruptions. It is also advisable to have a clean workspace where parts can be organized as they are removed.

Start with the outer casing, removing any screws or bolts that secure it in place. Gently lift it off, taking care not to damage any surrounding components. Label each part as you disassemble to keep track of their order and position.

Next, focus on the internal assembly. Disconnect any electrical connections and fuel lines, ensuring that you take note of how they are arranged. Remove the ignition system, followed by the carburetor, taking special care with gaskets and seals to avoid tearing them.

Continue with the disassembly of the cylinder head, which may involve removing additional bolts or fasteners. Once removed, inspect the head for any signs of wear or damage. Carefully set it aside in a safe location.

Proceed to detach the piston assembly from the crankshaft. This step requires precision; ensure that the connecting rod is not damaged during removal. Once separated, inspect the piston rings and cylinder walls for any wear that may need attention.

Finally, review all components as they are disassembled, checking for any potential issues. Organize parts in labeled containers to facilitate reassembly later. Following this structured method will help ensure a successful reconditioning of the engine.

Reassembly: Best Practices

Proper reassembly of mechanical components is crucial for ensuring optimal performance and longevity. Following systematic procedures and adhering to best practices can significantly reduce the likelihood of errors and enhance overall reliability. This section outlines essential strategies to consider during the reassembly process.

Organization and Cleanliness

Before starting, ensure that your workspace is organized and free of debris. Keep all components clean and handle them carefully to avoid damage. Use labeled containers to sort and store smaller parts, making it easier to locate them during reassembly. A clutter-free environment minimizes the risk of losing items and helps maintain focus on the task at hand.

Step-by-Step Assembly

Follow a step-by-step approach, referring to any available documentation to guide you through the process. Start with the largest components and work your way to smaller parts, ensuring that each piece fits correctly before moving on. Take your time and avoid rushing; this will help prevent mistakes and allow for thorough inspection of each part as it is reattached.

Utilizing the correct tools and techniques for each component is also vital. Ensure that all fasteners are torqued to manufacturer specifications, and apply any necessary lubricants where indicated. By adhering to these practices, you can achieve a successful and efficient reassembly, ultimately enhancing the performance and durability of the unit.

Tools Needed for Repairs

When undertaking maintenance or repair work on a small marine engine, having the right tools is essential for achieving efficient and effective results. Proper equipment not only facilitates the repair process but also ensures safety and accuracy during work. Below is a list of commonly required tools that will help streamline the repair activities.

| Tool | Description |

|---|---|

| Socket Set | Essential for loosening and tightening various fasteners. |

| Torque Wrench | Used to apply a specific torque to fasteners, ensuring they are tightened to manufacturer specifications. |

| Screwdriver Set | Includes both flathead and Phillips screwdrivers for various screws. |

| Pliers | Useful for gripping, twisting, and cutting wires or components. |

| Wrenches | Provides the leverage needed to turn nuts and bolts of various sizes. |

| Oil Filter Wrench | Specialized tool for removing and installing oil filters without damage. |

| Multimeter | Measures electrical parameters, essential for diagnosing electrical issues. |

| Clean-Up Supplies | Rags, solvents, and other supplies for maintaining a clean working environment. |

Safety Precautions While Working

When engaging in mechanical tasks, ensuring a safe working environment is essential. Adhering to proper safety measures not only protects individuals but also promotes efficient operations. Familiarity with the tools and equipment, as well as awareness of potential hazards, is crucial in preventing accidents.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks.

- Keep the workspace tidy to prevent slips, trips, and falls.

- Ensure proper ventilation if working in confined spaces to avoid inhalation of harmful fumes.

- Be aware of your surroundings and ensure that others are at a safe distance.

Tool and Equipment Safety

- Inspect tools before use to identify any defects or damage.

- Use tools only for their intended purpose to avoid injury.

- Disconnect power sources when servicing electric tools.

- Store tools safely when not in use to prevent accidents.

By following these precautions, individuals can create a safer working atmosphere and mitigate risks associated with mechanical tasks.

Upgrading Components for Performance

Enhancing the efficiency and output of a marine engine involves a careful selection of upgraded elements. By focusing on key components, boat enthusiasts can achieve noticeable improvements in power, fuel economy, and overall responsiveness. Whether you’re seeking to increase speed or enhance reliability, strategic modifications can lead to a more satisfying experience on the water.

Key Areas for Enhancement

One of the primary focus areas is the ignition system, where advanced spark plugs and coils can significantly boost combustion efficiency. Upgrading the fuel system, including injectors and filters, ensures that the engine receives the optimal mixture for peak performance. Additionally, considering exhaust modifications can improve airflow, reducing back pressure and enhancing overall power output.

Benefits of Upgrading

Investing in quality upgrades not only improves performance but also extends the lifespan of the engine. Enhanced components often lead to better fuel efficiency, which translates to reduced operating costs. Moreover, these modifications can contribute to smoother operation, allowing for a more enjoyable and responsive boating experience. With the right upgrades, boaters can unlock the full potential of their marine engines, making each outing on the water more thrilling.