Understanding the Stihl 038 AV Parts Diagram

For enthusiasts and professionals alike, a chain saw is an invaluable tool that demands both respect and knowledge. Understanding the inner workings and individual elements of this machine can greatly enhance its performance and longevity. This section aims to provide clarity on the various components and their functions, allowing users to maintain and repair their equipment effectively.

When facing issues with your cutting device, having a comprehensive overview of its internal structure can be a game changer. Recognizing each part’s role helps in troubleshooting and ensures that your tool operates smoothly. By familiarizing yourself with the layout and functionality of these elements, you can make informed decisions about repairs and replacements.

Whether you’re a seasoned user or a newcomer to the world of chain saws, knowledge is your best ally. With the right information at hand, you can confidently address concerns, optimize performance, and prolong the life of your machine. Embrace the challenge of learning about your tool’s design, and unlock its full potential.

Understanding Stihl 038 AV Features

This section delves into the distinctive characteristics of a popular power tool, focusing on its design elements and functionalities that enhance user experience and performance. Recognizing these features can greatly assist in maintenance and optimal use.

- Engine Performance: The unit is equipped with a robust engine that ensures efficient operation, providing the necessary power for demanding tasks.

- Vibration Reduction: A notable aspect is the integrated vibration dampening system, which minimizes user fatigue during prolonged usage.

- Ergonomic Design: The tool’s design prioritizes user comfort, featuring handles that allow for a secure and comfortable grip.

- Chain Brake System: This safety feature instantly stops the chain in case of kickback, enhancing operational safety.

- Easy Maintenance: Accessibility to vital components simplifies routine checks and servicing, ensuring longevity and reliability.

Understanding these attributes allows users to fully leverage the capabilities of the tool, ensuring both efficiency and safety during operation.

Key Components of Stihl 038 AV

This section focuses on the essential elements that contribute to the functionality and performance of a well-known chainsaw model. Understanding these vital parts can enhance maintenance practices and overall efficiency.

Powerhead: The core of the machine, this unit houses the engine and is responsible for generating the necessary power. Its design ensures optimal performance under various conditions.

Bar and Chain: These components work together to facilitate cutting. The bar provides support while the chain, with its sharp teeth, performs the actual cutting action, making their compatibility crucial for effectiveness.

Fuel System: This includes the fuel tank and carburetor, essential for the proper mixing of fuel and air. A well-functioning system ensures reliable starts and consistent operation.

Ignition System: Responsible for starting the engine, this system includes the spark plug and ignition coil. Their reliability directly affects the machine’s responsiveness and performance.

Clutch: This component engages and disengages the power from the engine to the chain, allowing for safe operation during idle periods and smooth transitions during use.

Handle and Safety Features: Ergonomically designed for user comfort, the handles also include safety mechanisms that prevent accidental activation, ensuring a safer working environment.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They serve as essential tools that facilitate understanding, organization, and efficient assembly of various systems.

One key advantage of these illustrations is their ability to:

- Enhance clarity by providing a visual reference for each element.

- Streamline the repair process by simplifying identification of required components.

- Assist in troubleshooting by highlighting connections and interactions between parts.

Additionally, these resources foster a deeper understanding of the machinery’s inner workings, allowing users to:

- Recognize the function of individual components.

- Plan repairs more effectively.

- Reduce the risk of errors during reassembly.

In conclusion, visual guides are indispensable for anyone engaged in the upkeep or enhancement of equipment, ensuring that tasks are performed with precision and confidence.

How to Read Parts Diagrams

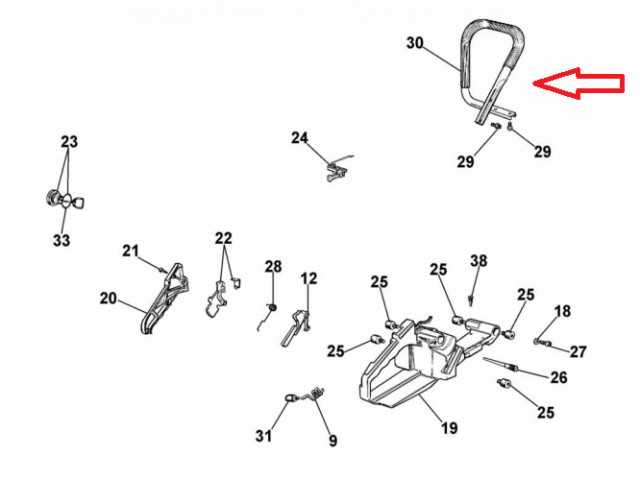

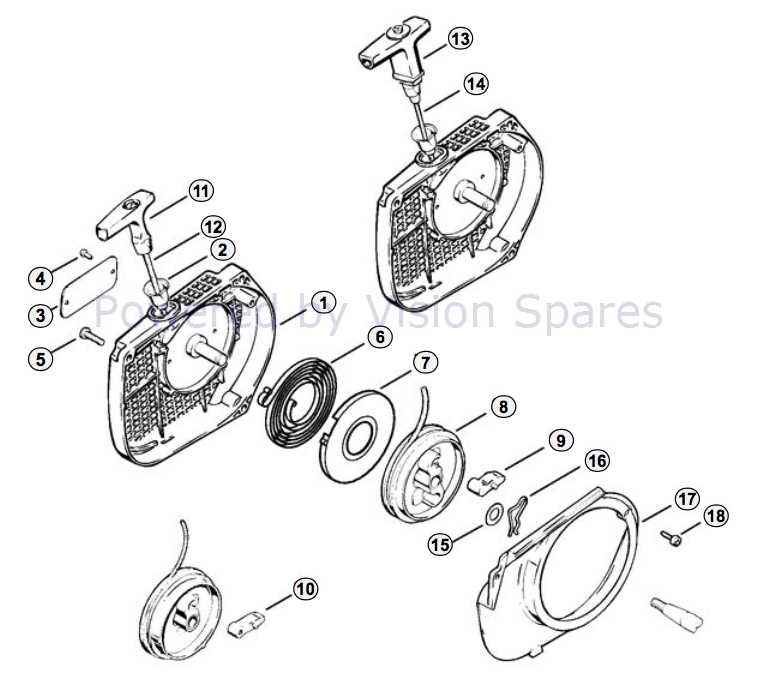

Understanding visual representations of components is crucial for efficient maintenance and repair. These illustrations provide an organized way to identify individual pieces and their relationships within a larger assembly. Mastering the ability to interpret these visuals can significantly enhance your troubleshooting and repair skills.

Key Elements to Focus On

When examining a visual representation, pay attention to the following aspects:

- Labels: Each component is typically marked with a unique identifier, which helps in locating the corresponding item in a parts list.

- Groupings: Components may be clustered to indicate functional relationships, guiding you in understanding how different pieces interact.

- Connections: Arrows or lines may illustrate how parts connect, indicating assembly order or operational flow.

Utilizing the Information

Once you have identified key elements, use the information to streamline your repair process. Cross-reference the labels with the accompanying list to ensure you have the correct items. This methodical approach not only simplifies repairs but also minimizes the risk of errors, allowing for more efficient project completion.

Common Issues with Stihl 038 AV

Owners of this popular chainsaw model often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems can help users troubleshoot effectively and maintain their equipment in optimal condition.

Engine Performance Problems

One of the primary concerns involves engine performance. Users may notice difficulties in starting the machine or irregular idling. These issues can stem from various factors, including fuel quality, air filter condition, or spark plug wear.

Chain Tension and Cutting Efficiency

Another frequent issue relates to the cutting efficiency of the device. Users might experience problems with chain tension, which can lead to uneven cuts or increased wear on the chain. Regular maintenance and adjustments are crucial for ensuring the chain operates smoothly.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Starting difficulties | Poor fuel quality, clogged filter | Use fresh fuel, clean or replace filter |

| Irregular idling | Worn spark plug, air leaks | Replace spark plug, check seals |

| Uneven cuts | Improper chain tension | Adjust tension as needed |

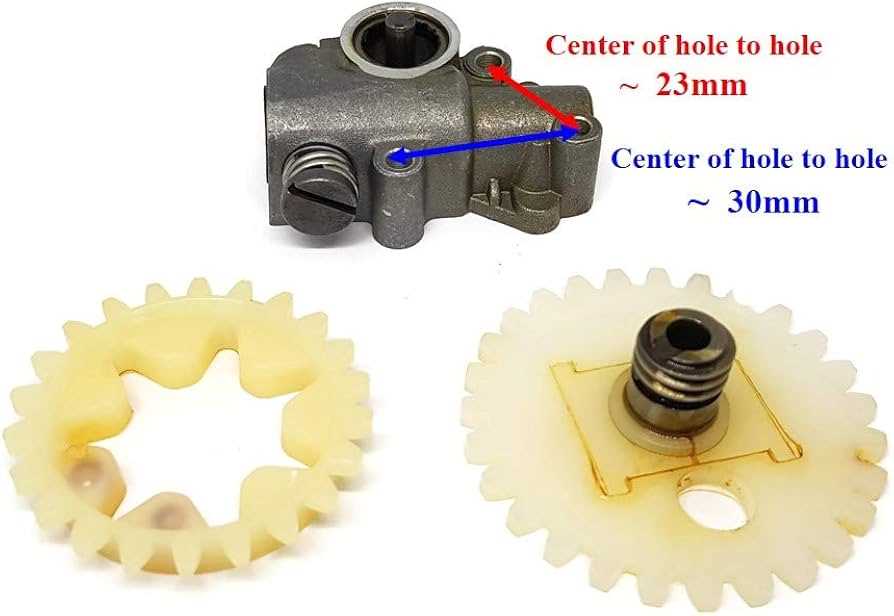

| Excessive chain wear | Dirty guide bar, lack of lubrication | Clean guide bar, ensure proper oiling |

Replacement Parts for Stihl 038

Maintaining your equipment in optimal condition is crucial for performance and longevity. When it comes to essential components, having the right replacements can make a significant difference in functionality. This section focuses on the various options available for restoring your machinery to peak efficiency.

- Engine components

- Fuel system elements

- Ignition system pieces

- Bar and chain accessories

- Air filtration systems

Choosing high-quality substitutes ensures reliability and enhances overall performance. Below are key categories to consider when looking for replacements:

- Engine Components: Critical for optimal operation, including piston kits and gaskets.

- Fuel System Elements: Replace fuel lines, filters, and carburetors to maintain fuel flow.

- Ignition System Pieces: Spark plugs and ignition coils are essential for reliable starts.

- Bar and Chain Accessories: Ensure safety and efficiency with suitable bars and chains.

- Air Filtration Systems: Keep your engine clean with quality air filters.

Investing in these alternatives not only prolongs the life of your machinery but also enhances its performance and safety. Regular maintenance and timely replacements are key to ensuring seamless operation.

Maintenance Tips for Chainsaws

Proper upkeep is essential for ensuring the longevity and performance of your cutting tool. Regular maintenance not only enhances efficiency but also promotes safety during operation. By following a few straightforward guidelines, you can keep your equipment in optimal condition and ready for use whenever needed.

Regular Cleaning

Keeping the exterior and interior components clean is vital. After each use, remove any debris, sawdust, and oil buildup. This helps prevent overheating and allows for smooth functioning. Use a soft brush or compressed air to clear out hard-to-reach areas, particularly around the air filter and cooling fins.

Routine Inspections

Conducting frequent checks on essential parts can save you from unexpected breakdowns. Inspect the chain for wear and ensure it is sharp. A dull chain can lead to increased strain on the motor. Additionally, examine the bar for damage and ensure that the tension is correctly adjusted. Regularly assess the fuel and oil levels, and replace any worn components promptly to maintain safe operation.

Identifying Parts by Diagram

Understanding the various components of a machine can greatly enhance maintenance and repair efforts. A visual representation serves as a valuable tool for recognizing individual elements and their functions, aiding users in making informed decisions during servicing.

Key Benefits of Visual References

- Facilitates easier identification of components

- Helps in understanding the assembly and disassembly processes

- Enhances troubleshooting efficiency by pinpointing potential issues

- Assists in ensuring compatibility of replacement items

Common Components to Recognize

- Engines and their respective parts

- Fuel systems and filters

- Cutting mechanisms and blades

- Starting systems and switches

- Safety features and enclosures

Familiarizing oneself with these components through visual aids can significantly simplify the repair process and extend the lifespan of the equipment.

Where to Find Stihl 038 AV Diagrams

Locating detailed illustrations for machinery can greatly enhance maintenance and repair processes. Understanding the layout and components of your equipment is crucial for effective troubleshooting and servicing. Various resources are available for those seeking comprehensive visuals that outline essential elements and their configurations.

Online Resources

The internet offers a wealth of platforms dedicated to equipment manuals and schematics. Websites specializing in outdoor power tools frequently provide downloadable resources. These platforms often include user forums where enthusiasts share insights, links, and additional visual aids. Searching through these online archives can yield high-quality diagrams that are easy to access.

Local Dealers and Service Centers

Another reliable source is your local dealership or authorized service center. These establishments typically have access to manufacturer-provided materials, including detailed schematics. Visiting in person or calling can result in obtaining printed diagrams or digital files directly from knowledgeable staff. Establishing a relationship with your dealer can also lead to valuable advice on repairs and maintenance.

Using Diagrams for Repairs

Visual representations serve as invaluable tools in the maintenance and restoration of various machinery. They provide clarity and guidance, allowing users to understand the assembly and disassembly of components. By illustrating each piece and its relationship to others, these visuals simplify complex processes, making them accessible even to those with minimal experience.

When tackling repairs, referring to a schematic can significantly enhance efficiency. Understanding the layout of parts helps in identifying issues more swiftly, while also ensuring that replacements are executed accurately. This can reduce the likelihood of errors and prolong the lifespan of the equipment.

Moreover, visual aids foster confidence among users. With a clear guide in hand, individuals can approach repairs with a systematic mindset, knowing exactly what steps to follow. This leads to a more satisfying experience and empowers users to handle future issues independently.

Benefits of Genuine Stihl Parts

Using authentic components for your machinery offers numerous advantages that enhance performance and longevity. These elements are specifically designed to fit and function seamlessly, ensuring your equipment operates at its best. The importance of reliability and quality cannot be overstated, particularly when considering the demands placed on outdoor tools.

| Benefit | Description |

|---|---|

| Durability | Genuine components are crafted from high-quality materials, resulting in superior strength and resistance to wear. |

| Performance | Authentic items ensure optimal functionality, maintaining the efficiency of your machinery over time. |

| Safety | Using original elements reduces the risk of malfunctions, promoting safer operation during use. |

| Warranty Protection | Many warranties are contingent upon using genuine components, safeguarding your investment against potential issues. |

| Compatibility | Authentic parts are engineered to work together flawlessly, minimizing the likelihood of compatibility problems. |

Upgrading Components for Better Performance

Improving the efficiency and capability of your equipment often involves enhancing specific elements that play crucial roles in overall functionality. By focusing on the right modifications, users can achieve noticeable gains in performance, longevity, and reliability. This section delves into various upgrade options that can transform ordinary machinery into high-performing tools.

Key Areas for Enhancement

When considering upgrades, it’s vital to identify the components that most significantly impact performance. Common areas for improvement include the ignition system, air intake, and exhaust mechanisms. Enhancing the ignition system can lead to better fuel combustion, resulting in increased power output. Similarly, optimizing the air intake allows for improved airflow, ensuring that the engine operates more efficiently. Lastly, upgrading the exhaust system can reduce back pressure and improve overall engine breathing.

Benefits of Upgrading

Investing in quality upgrades not only boosts performance but also contributes to the durability of your equipment. Enhanced components can lead to less wear and tear, reducing the frequency of repairs and replacements. Moreover, improved efficiency often translates to lower fuel consumption, making your operations more cost-effective. With the right upgrades, users can enjoy a smoother, more powerful experience that maximizes productivity while minimizing environmental impact.