Kubota Kommander Z125S Parts Diagram Overview

In the world of lawn maintenance, having a thorough understanding of your machinery is crucial for optimal performance. This section provides a comprehensive overview of the various components that make up a popular model designed for efficiency and precision in garden care. By familiarizing yourself with these elements, you can enhance the longevity and functionality of your equipment.

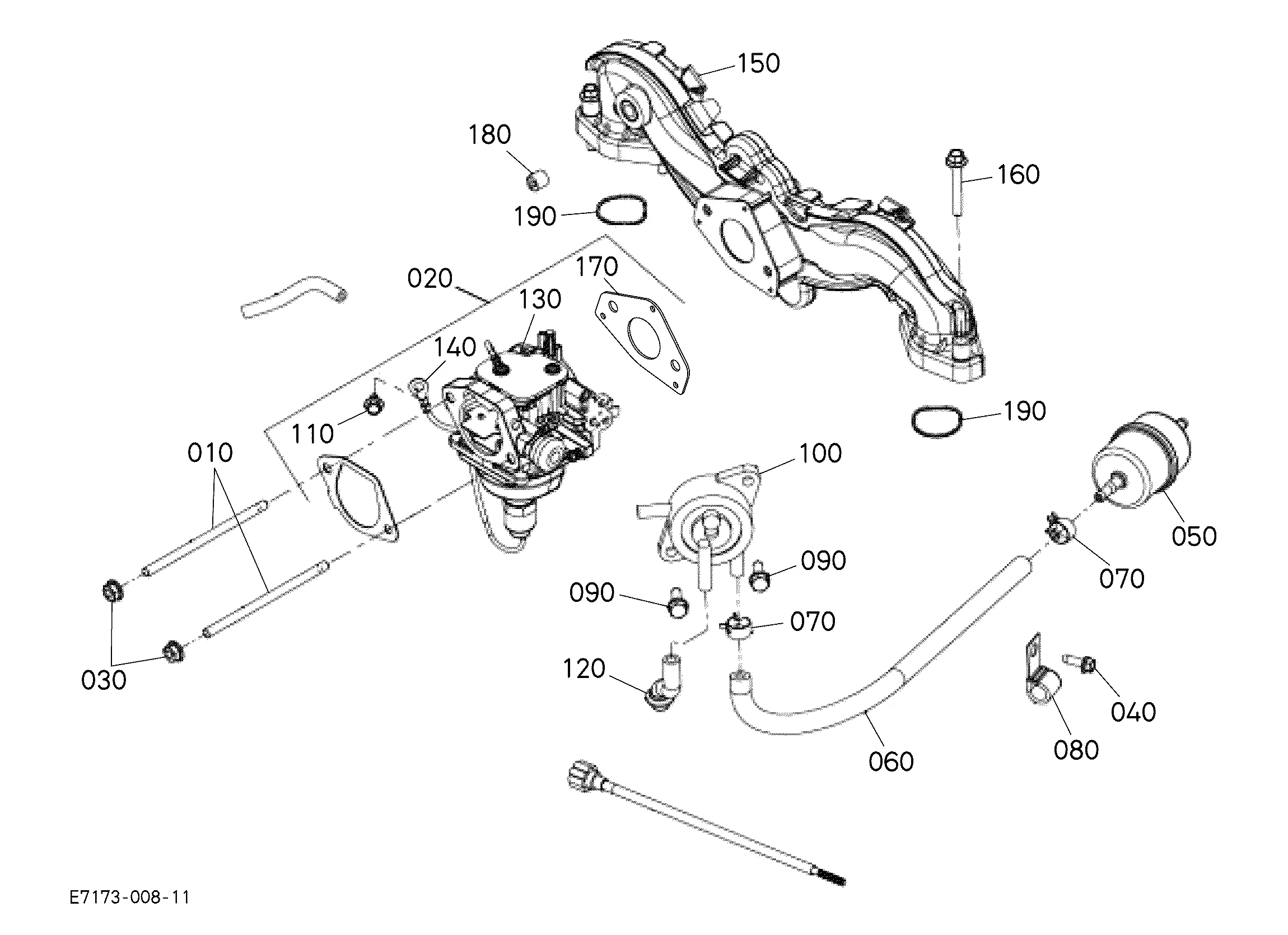

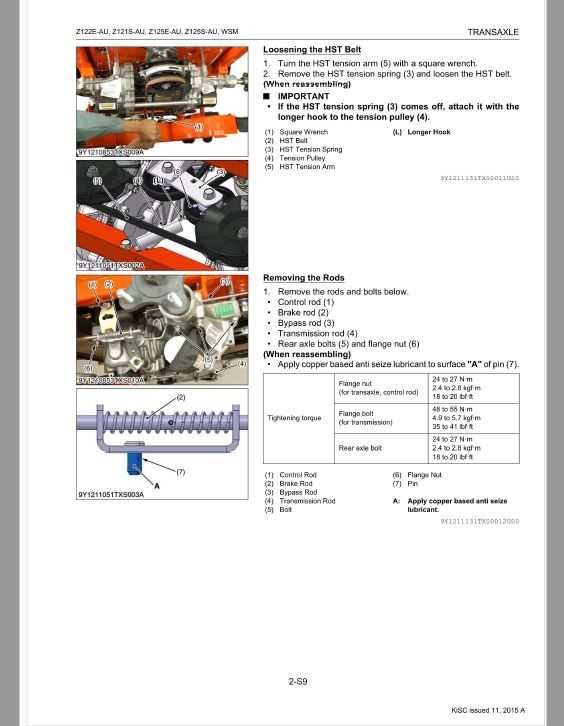

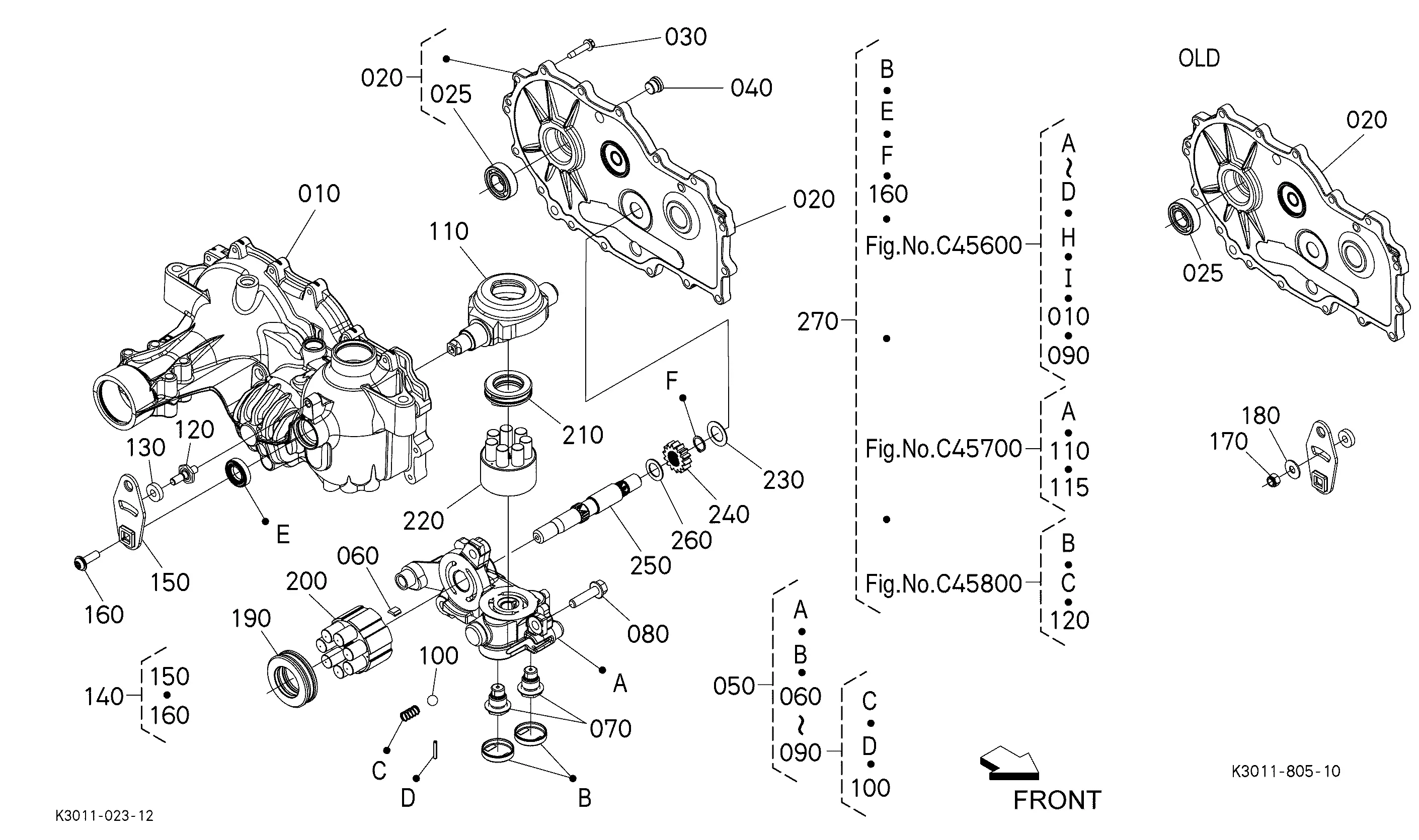

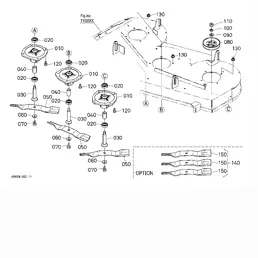

Detailed visual representations play a vital role in identifying each component and its purpose. These illustrations not only assist in recognizing the layout but also facilitate easier maintenance and troubleshooting. With clear labels and organized structures, you can quickly pinpoint parts that may require attention or replacement.

Whether you’re a seasoned professional or a weekend warrior, knowing the intricacies of your machinery empowers you to tackle challenges effectively. This knowledge not only saves time but also ensures that your lawn care endeavors yield the best possible results. Explore the visual resources available to enhance your understanding and make informed decisions about upkeep and repairs.

Kubota Kommander Z125S Overview

This section provides a comprehensive look at a powerful and efficient mowing solution designed for both residential and commercial applications. With a focus on durability and performance, this machine is engineered to meet the demands of users seeking reliability and ease of operation.

Key Features

Featuring a robust engine and advanced cutting technology, this model delivers exceptional results in various terrains. Its maneuverability allows for precise navigation around obstacles, making it suitable for landscaped areas. Additionally, the ergonomic design enhances user comfort, ensuring a pleasant mowing experience.

Maintenance and Support

Regular upkeep is essential for optimal performance. The availability of quality components and service support ensures that users can maintain their equipment with ease. Understanding the operational aspects and following maintenance guidelines contribute to the longevity of this mowing machine.

Key Features of Z125S Model

This model stands out for its exceptional performance and user-friendly design, making it a top choice for those seeking efficiency and reliability in outdoor tasks. With a blend of advanced technology and robust construction, it caters to a variety of landscaping needs.

Powerful Engine: The unit is equipped with a high-performance engine that ensures smooth operation and impressive torque, allowing users to tackle tough terrain effortlessly.

Ergonomic Design: Featuring a comfortable seat and intuitive controls, the layout is designed for ease of use, minimizing operator fatigue during extended periods of operation.

Durable Build: Constructed from high-quality materials, this model boasts a sturdy frame that enhances longevity and withstands rigorous use in various environments.

Efficient Maneuverability: With a compact design, it offers excellent maneuverability, making it ideal for navigating tight spaces while maintaining stability and control.

Versatile Attachments: The ability to accommodate various attachments enhances its functionality, enabling users to customize their equipment for specific tasks and improve productivity.

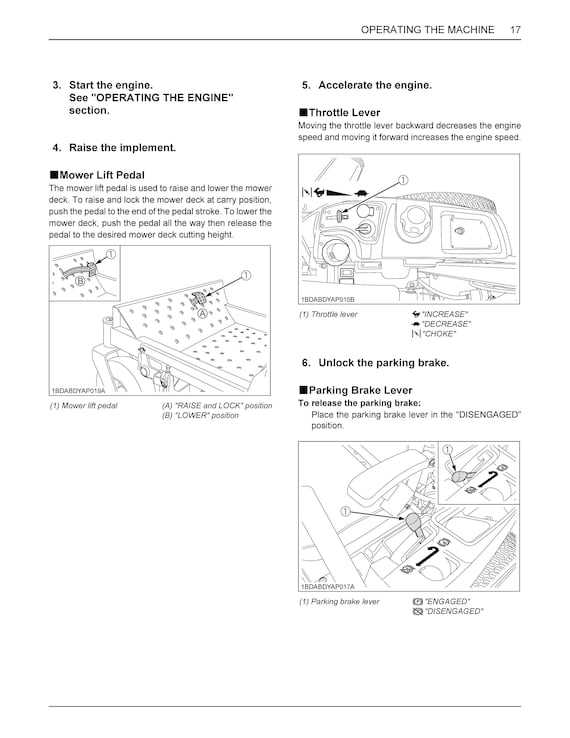

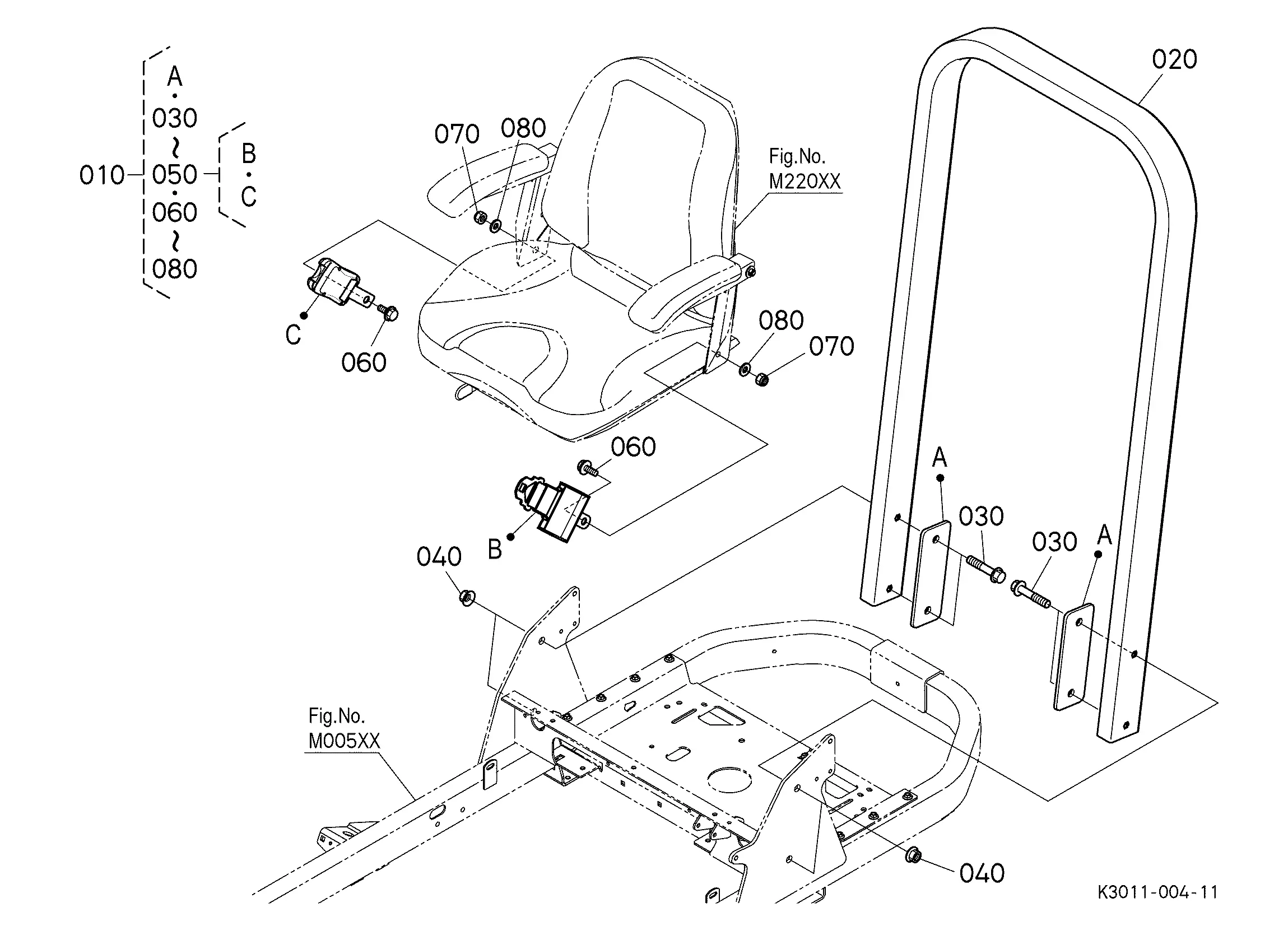

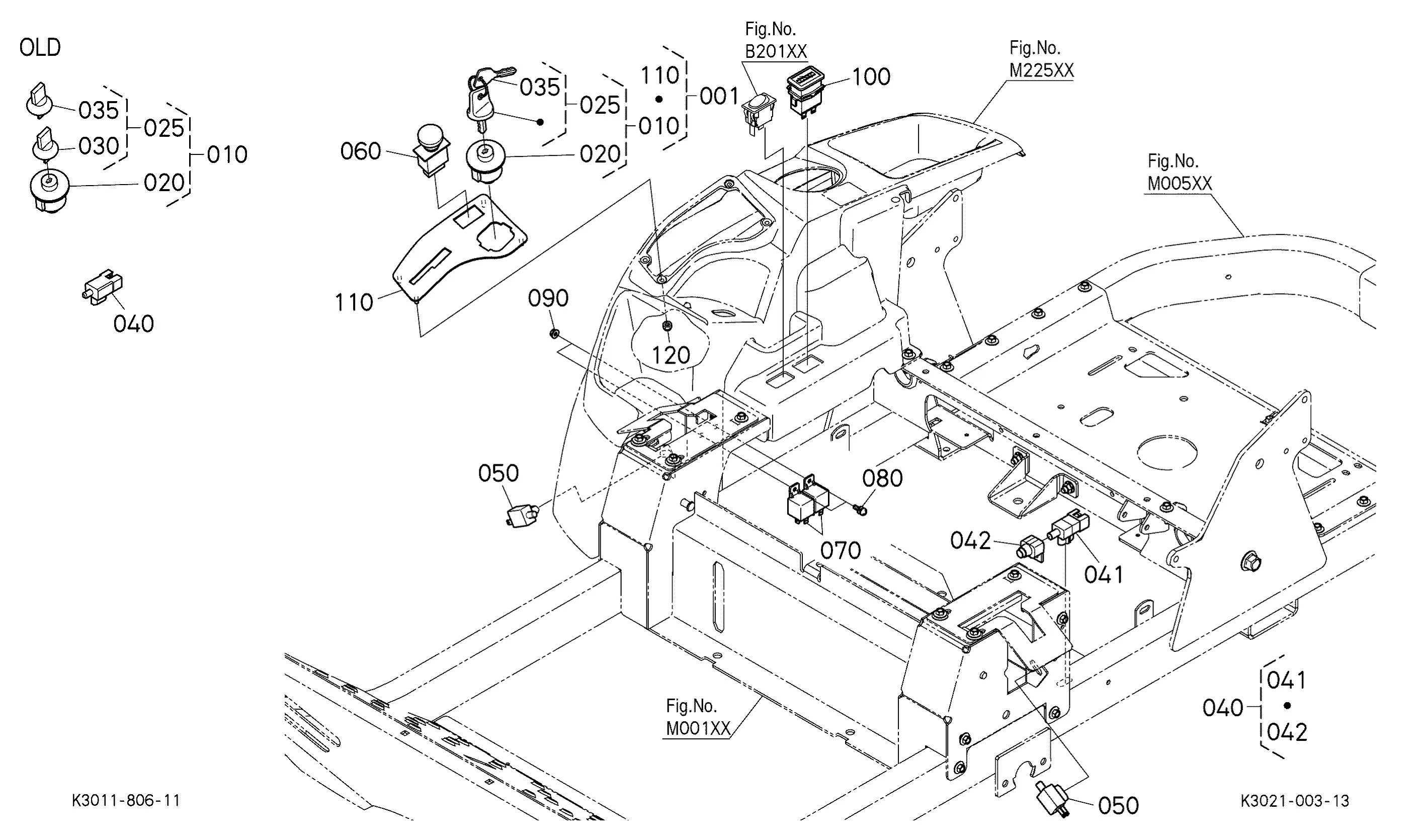

Understanding the Parts Diagram

Grasping the layout of components within a machine is essential for effective maintenance and repair. This visual representation serves as a vital tool, allowing users to identify individual elements and their functions, ensuring that everything operates smoothly. By examining this illustration, one can easily locate specific parts and understand their relationships within the system.

Key Benefits of Familiarizing with the Component Layout

- Enhanced troubleshooting abilities

- Efficient ordering of replacements

- Improved assembly and disassembly processes

- Better understanding of machine functionality

Tips for Interpreting the Layout

- Start with an overview of the entire assembly to get a sense of its structure.

- Focus on individual sections to understand specific groupings of components.

- Take note of any labeled parts, as they provide crucial information for identification.

- Cross-reference with user manuals for detailed descriptions and specifications.

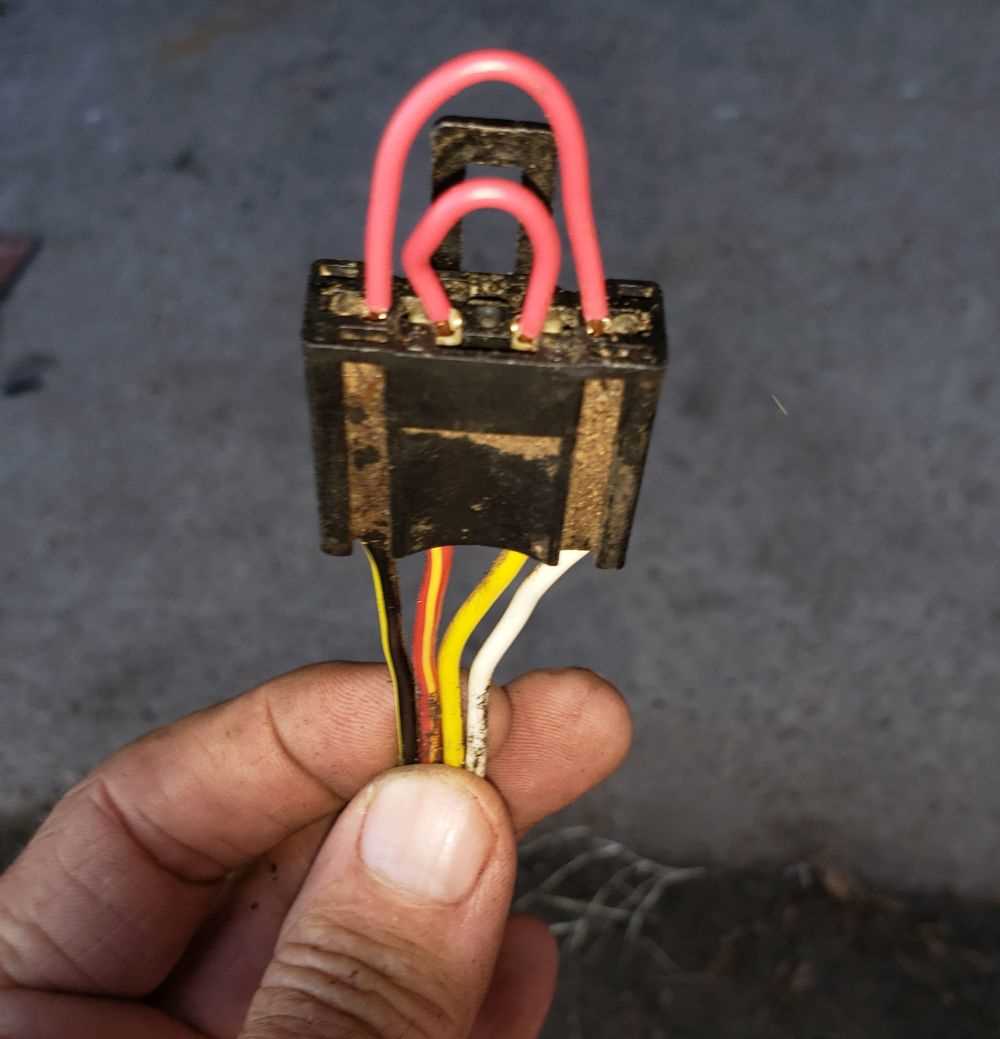

Common Issues with Z125S Components

When operating lawn care machinery, certain components may experience issues that can affect performance and efficiency. Understanding these common problems can help users maintain their equipment effectively and prolong its lifespan.

- Fuel System Failures:

- Clogged fuel filters

- Leaking fuel lines

- Faulty fuel pumps

- Electrical Problems:

- Dead batteries

- Corroded connections

- Malfunctioning ignition switches

- Transmission Issues:

- Slipping gears

- Overheating

- Leaking hydraulic fluid

- Blade and Deck Concerns:

- Dull or damaged blades

- Uneven cutting height

- Deck rust and corrosion

Addressing these common issues promptly can ensure smoother operation and better performance of your equipment.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of any outdoor equipment. By following a few key practices, you can enhance the functionality of your machinery and minimize the risk of unexpected breakdowns. This section provides valuable insights into routine care that will keep your unit running smoothly.

Routine Checks

Performing frequent inspections is vital. Examine the various components to identify any wear and tear. Pay special attention to the following:

| Component | Check Frequency | Recommended Action |

|---|---|---|

| Oil Level | Weekly | Top up or change as needed |

| Air Filter | Monthly | Clean or replace if clogged |

| Blades | After every use | Sharpen or replace as necessary |

| Tires | Weekly | Inspect for proper inflation |

Seasonal Maintenance

In addition to routine checks, seasonal maintenance is crucial. Prepare your equipment for changing weather conditions to ensure optimal performance throughout the year. Key tasks include:

- Draining fuel before long-term storage to prevent degradation.

- Applying protective coatings to prevent rust.

- Checking battery health and connections, especially before winter.

Replacement Parts Availability and Sources

When it comes to maintaining and enhancing outdoor machinery, ensuring access to essential components is crucial. A wide array of suppliers offers various options, from original equipment to aftermarket alternatives, catering to diverse needs and preferences.

Local Dealers often provide authentic replacements, ensuring compatibility and quality. Engaging with these businesses can also yield valuable insights into the latest offerings and upgrades.

Online Retailers have become increasingly popular, providing the convenience of browsing extensive inventories from home. Websites dedicated to outdoor equipment frequently feature user reviews, which can guide informed decisions.

Salvage Yards present another avenue for sourcing components. These establishments can be treasure troves of hard-to-find items at reduced prices, perfect for those willing to delve into the hunt.

Lastly, joining community forums can foster connections with fellow enthusiasts who may share insights on sourcing specific components or even selling their own. Engaging in these communities can enhance the search for the ultimate replacements.

Installation Guide for Z125S Parts

This section provides a comprehensive approach to assembling components of your lawn care machine, ensuring optimal performance and longevity. Proper installation techniques can significantly enhance functionality and reduce the likelihood of future issues.

Preparation Steps

Before you begin, gather all necessary tools and components. Review the user manual for specific instructions related to each element. Make sure to work in a well-lit environment and wear appropriate safety gear.

Installation Process

Start by aligning the new components with existing structures, ensuring they fit snugly. Use manufacturer-recommended fasteners to secure each piece, and double-check connections for stability. Following these guidelines will not only improve your machine’s efficiency but also extend its operational life.

Comparative Analysis with Other Models

This section delves into the examination of a specific lawn care equipment model in relation to its counterparts in the market. By evaluating various features, performance metrics, and user experiences, we aim to provide a comprehensive overview that highlights strengths and weaknesses, assisting potential buyers in making informed decisions.

Key Features Comparison

- Engine Performance:

- Power output and efficiency

- Noise levels during operation

- Cutting Capability:

- Deck size and blade types

- Height adjustment options

- Ergonomics:

- Seat comfort and adjustability

- Control layout and ease of use

User Feedback and Reliability

- Customer Satisfaction:

- Ratings from online reviews

- Common praise or complaints

- Durability:

- Long-term performance under different conditions

- Maintenance frequency and ease

In summary, analyzing this model against similar offerings provides valuable insights into its market position and functionality, aiding users in selecting the right equipment for their specific needs.

Tools Required for Repairs

Proper maintenance and repair of machinery require specific instruments to ensure efficiency and accuracy. Utilizing the right tools not only simplifies the process but also enhances the longevity of the equipment. Below is a comprehensive list of essential instruments that can aid in conducting effective repairs.

Essential Instruments

| Tool | Purpose |

|---|---|

| Wrench Set | Used for tightening or loosening bolts and nuts. |

| Screwdriver Set | Essential for removing or inserting screws. |

| Socket Set | Allows for more torque and access to hard-to-reach areas. |

| Pliers | Useful for gripping, twisting, and cutting wires or components. |

| Torque Wrench | Ensures that bolts are tightened to the correct specification. |

Additional Considerations

Having a well-organized toolbox with these instruments can significantly improve the repair experience. Regularly checking and maintaining your tools will also contribute to successful and safe repairs.

Cost Considerations for Parts Replacement

When it comes to replacing components in machinery, understanding the financial implications is crucial. Various factors can influence overall expenses, from the choice of materials to the complexity of the installation process.

Factors Affecting Costs

- Quality of Materials: Higher-quality replacements may offer better durability but at a premium price.

- Labor Costs: Professional installation can add significant expenses, especially for intricate systems.

- Availability: Rare or specialized components may incur higher shipping and handling fees.

Budgeting Tips

- Research various suppliers to compare pricing.

- Consider purchasing in bulk for discounts.

- Factor in long-term savings of investing in quality.

User Reviews and Feedback on Z125S

This section explores the thoughts and experiences of users who have interacted with this particular model. By examining their insights, potential buyers can gain a clearer understanding of its performance and reliability.

Positive Feedback

- Excellent maneuverability in tight spaces.

- Robust build quality that stands the test of time.

- Easy to operate, even for beginners.

- Impressive cutting efficiency, saving time on lawn care.

Areas for Improvement

- Some users reported issues with the fuel efficiency.

- Initial setup can be complex for first-time users.

- Availability of replacement parts can be limited in certain regions.