Comprehensive Parts Diagram for John Deere 690B Excavator

In the realm of construction and heavy-duty machinery, the intricate interplay of various elements is crucial for optimal performance and longevity. A thorough comprehension of these components allows operators and technicians to ensure seamless operation and maintenance of their equipment. This section delves into the essential aspects of identifying and understanding the crucial segments that contribute to the overall functionality of these powerful machines.

Familiarity with the structure and arrangement of individual components can significantly enhance the efficiency of repair and upkeep tasks. By visualizing how these pieces fit together, users can better diagnose issues and implement effective solutions. The goal is to equip operators with the knowledge needed to keep their machinery running smoothly and to extend its service life.

Whether you are a seasoned professional or a newcomer to the field, having access to comprehensive breakdowns of machinery systems can be an invaluable resource. This guide aims to provide clarity and insight into the various elements that make up these formidable machines, ensuring that users can make informed decisions and maintain their equipment with confidence.

Understanding the John Deere 690B Excavator

This section delves into the essential aspects of a well-known construction machine, highlighting its functionalities, features, and overall significance in the industry. Recognized for its efficiency and reliability, this heavy equipment plays a vital role in various applications, from digging to lifting heavy loads.

Key Features

- Robust hydraulic system for enhanced performance

- Durable construction ensuring longevity

- Versatile attachments for multiple tasks

- Operator-friendly controls for ease of use

Common Applications

- Site preparation and grading

- Trenching for utility installation

- Demolition of structures

- Landscaping and earthmoving projects

Understanding this machine’s capabilities allows operators to maximize its potential and optimize workflow on job sites.

Key Features of the 690B Model

This machine is renowned for its exceptional performance and durability, making it a reliable choice for various heavy-duty applications. Its design incorporates advanced technology and engineering, ensuring efficiency and ease of use.

- Robust Structure: Built with high-quality materials, providing resilience under tough working conditions.

- Powerful Engine: Equipped with a strong powertrain that delivers impressive torque and horsepower.

- Hydraulic System: Features a state-of-the-art hydraulic system that enhances lifting and digging capabilities.

- Operator Comfort: Designed with an ergonomic cabin, ensuring operator comfort during extended work hours.

- Versatile Attachments: Compatible with a wide range of attachments, allowing for various tasks from digging to lifting.

These characteristics combine to make this model a formidable option for contractors and construction professionals looking for reliability and performance in their machinery.

Importance of Excavator Parts Diagrams

Understanding the components of heavy machinery is crucial for maintenance and repair. Visual representations of these elements play a significant role in ensuring that operators and technicians can identify and manage issues effectively.

Such illustrations provide numerous advantages:

- Enhanced Clarity: Visual aids simplify complex systems, making it easier to comprehend how each element interacts.

- Efficient Troubleshooting: Quick identification of faulty components helps in addressing problems promptly, reducing downtime.

- Accurate Repairs: Detailed visuals guide users during repairs, ensuring correct assembly and disassembly procedures are followed.

- Improved Training: New operators can learn about machinery functions more effectively with clear visual references.

Incorporating these representations into maintenance practices can lead to better performance and longevity of machinery. Overall, they are invaluable resources for anyone involved in the operation or upkeep of heavy equipment.

Common Components in the 690B Diagram

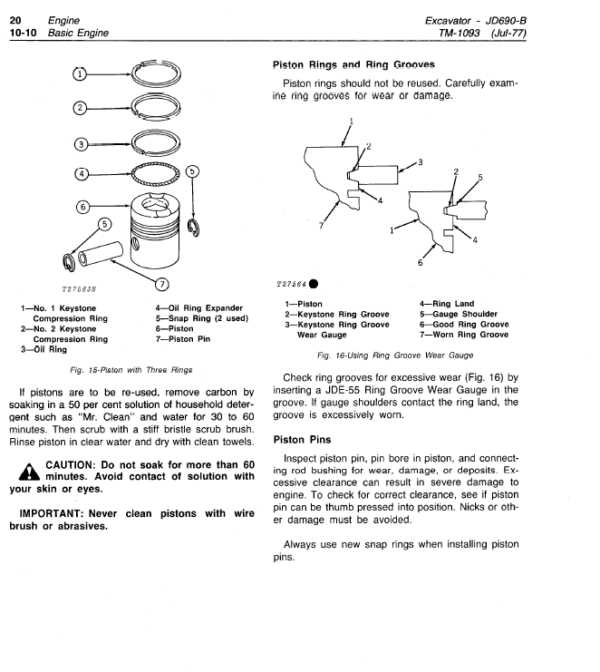

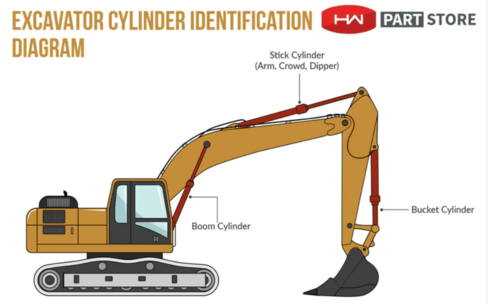

Understanding the key elements in heavy machinery schematics is essential for effective maintenance and operation. These essential parts work in unison to ensure optimal performance and durability, making it crucial to familiarize oneself with their functions and placements within the layout.

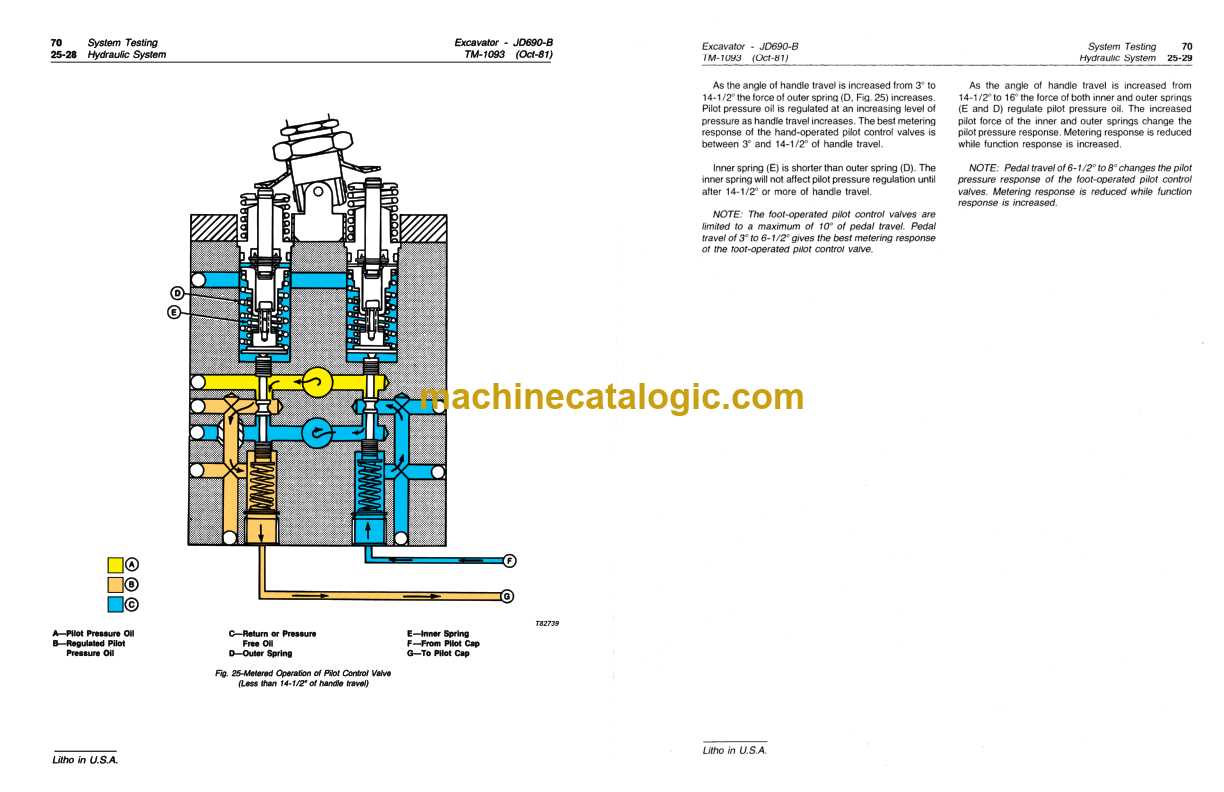

Among the vital components, the hydraulic system stands out, facilitating movement and power transfer throughout the machine. Coupled with the undercarriage, which provides stability and mobility, these elements are fundamental to the overall efficiency of the equipment.

The control panel plays a significant role, allowing operators to manage various functions seamlessly. Additionally, the powertrain components, including the engine and transmission, ensure that the machine operates smoothly under different conditions.

Finally, the attachment interface is critical for connecting various tools, enabling the equipment to perform a wide range of tasks. Familiarity with these components enhances troubleshooting and repair efforts, ensuring longevity and reliability in operations.

Maintenance Tips for 690B Parts

Proper upkeep of machinery components is essential for optimal performance and longevity. Regular attention not only enhances efficiency but also minimizes the risk of costly breakdowns. Here are some valuable practices to ensure the reliability of your equipment.

1. Regular Inspections: Conduct routine checks to identify any signs of wear or damage. Pay special attention to moving parts, seals, and connections. Early detection can prevent more significant issues down the line.

2. Lubrication: Ensure that all necessary components are adequately lubricated. Using the right type of lubricant can significantly reduce friction and wear, extending the life of critical elements.

3. Cleanliness: Keep all areas free from dirt and debris. Contaminants can lead to premature wear and affect performance. Regular cleaning routines should be part of your maintenance schedule.

4. Replacement Schedule: Adhere to a replacement schedule for consumable items. Timely swapping out of worn or damaged components will prevent unexpected failures and maintain efficiency.

5. Documentation: Keep detailed records of maintenance activities. This will help in tracking performance over time and planning future upkeep more effectively.

6. Professional Servicing: When in doubt, consult with a professional. Expert advice can provide insights into specific issues and advanced maintenance techniques, ensuring your machinery operates at its best.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as a valuable resource, offering insights into the structure and arrangement of various elements. By learning to interpret these visuals, you can efficiently identify necessary items and their relationships within a complex system.

Familiarize Yourself with the Symbols

The first step in mastering these illustrations is to become acquainted with the commonly used symbols and notations. Each symbol corresponds to a specific component or function, and recognizing them will enhance your comprehension. Often, there will be a legend or key included to help you decode the meanings behind the various icons.

Analyze the Layout and Flow

Next, focus on the overall layout and flow of the illustration. Components are usually arranged logically to depict how they interact with one another. Look for connecting lines that indicate relationships or pathways, as these can provide insight into the operational dynamics. Understanding how elements are interconnected will aid you in troubleshooting and assembling parts more effectively.

Finding Replacement Parts Easily

Locating suitable components for machinery can often feel like a daunting task. However, with the right approach, the process can become more streamlined and efficient. Knowing where to search and understanding the essential terminology can significantly enhance your ability to find what you need without unnecessary delays.

Utilizing Online Resources

The internet serves as an invaluable tool for sourcing components. Specialized websites offer extensive catalogs, allowing users to browse various options by inputting model specifications. User reviews and ratings can further aid in selecting reliable suppliers. Additionally, online forums and communities can provide insights and recommendations from experienced operators.

Consulting Local Dealers

Local dealerships often stock essential components and can provide expert advice. Establishing a relationship with a trusted dealer ensures access to quality items and potentially expedited ordering processes. Many dealerships also offer warranty options, which can provide peace of mind when purchasing replacements.

Comparative Analysis with Other Models

This section provides an insightful comparison between various heavy machinery units, focusing on their unique features, capabilities, and overall performance. By examining different models, we can identify strengths and weaknesses, allowing for informed decisions when selecting equipment for specific tasks.

Key Features Comparison

- Engine Power: Different machines come equipped with varying engine specifications that impact their operational efficiency and load capacity.

- Hydraulic System: The effectiveness of the hydraulic systems can differ significantly, influencing lifting and digging capabilities.

- Control Systems: Advanced control mechanisms can enhance precision and ease of use, which is essential for complex operations.

Performance Metrics

- Digging Depth: Compare the maximum digging depths across models to determine suitability for specific projects.

- Lift Capacity: Analyzing lift capacities helps in selecting the right equipment for handling heavy materials.

- Fuel Efficiency: Evaluate the fuel consumption rates to assess operational costs and environmental impact.

Through this comparative analysis, users can better understand how each model stacks up against the others, ensuring they make the best choice for their operational needs.

Common Issues and Solutions

When operating heavy machinery, users often encounter various challenges that can affect performance and efficiency. Identifying these issues promptly and implementing effective solutions is crucial for maintaining optimal functionality. This section highlights frequent problems and practical remedies to ensure smooth operations.

Hydraulic System Failures

One of the most prevalent issues involves hydraulic system malfunctions, which can lead to reduced power and responsiveness. Common causes include fluid leaks, air contamination, and worn-out seals. Addressing these problems swiftly can prevent further complications.

| Issue | Solution |

|---|---|

| Fluid Leak | Inspect hoses and connections; replace damaged components. |

| Air Contamination | Change filters regularly; ensure proper sealing. |

| Worn Seals | Replace seals to restore system integrity. |

Engine Overheating

Overheating can lead to severe engine damage and is often caused by coolant leaks, clogged radiators, or faulty thermostats. Monitoring engine temperatures and maintaining cooling systems are essential for preventing overheating.

| Issue | Solution |

|---|---|

| Coolant Leak | Inspect hoses and connections; top up coolant levels. |

| Clogged Radiator | Clean or replace radiator to improve airflow. |

| Faulty Thermostat | Test and replace thermostat if necessary. |

Where to Buy Genuine Parts

When it comes to maintaining machinery, acquiring authentic components is crucial for optimal performance and longevity. Finding reliable sources for these essential items can significantly impact the efficiency of your equipment.

Here are some recommended avenues to explore when searching for authentic components:

- Official Distributors: Many manufacturers have authorized distributors who specialize in genuine parts. These suppliers ensure you receive high-quality items that meet industry standards.

- Online Retailers: Reputable online marketplaces often offer a wide selection of authentic components. Look for sellers with verified ratings and customer reviews.

- Local Dealers: Check with local dealerships that specialize in heavy machinery. They often carry a range of genuine items and can provide expert advice.

- Manufacturer’s Website: Visiting the official website of the machinery brand can lead you to their recommended suppliers and exclusive offers.

Ensuring the authenticity of the components you purchase not only enhances your machinery’s performance but also extends its lifespan, ultimately saving you time and money in the long run.

Resources for Repair and Service Manuals

Accessing reliable resources for maintenance and repair documentation is essential for anyone working with heavy machinery. These guides provide valuable information on troubleshooting, servicing, and optimizing performance, ensuring that operators can effectively manage their equipment.

Below are some recommended sources for obtaining service manuals:

- Manufacturer Websites: Most equipment manufacturers offer downloadable manuals directly on their official sites. These documents are often the most accurate and detailed.

- Online Retailers: Websites specializing in machinery parts and accessories frequently sell printed or digital copies of service manuals.

- Forums and Communities: Online forums dedicated to machinery enthusiasts can be a treasure trove of shared resources. Members often share links or even their own manuals.

- Library Archives: Local libraries or technical colleges may have collections of manuals available for reference, including historical documents for older models.

- Third-Party Publishers: Some publishers specialize in creating comprehensive service manuals for various equipment types, often including detailed diagrams and troubleshooting tips.

Utilizing these resources can significantly enhance the ability to maintain and repair machinery efficiently, prolonging its lifespan and improving performance.