Understanding the Stihl MS 360 Parts Diagram for Better Maintenance

The intricate assembly of a chainsaw is crucial for its efficient operation and longevity. Each element plays a vital role, contributing to the overall functionality and performance of the machine. By exploring the various segments, users can gain valuable insights into maintenance and repair practices.

In this guide, we will delve into the essential components that make up a chainsaw. Recognizing how these parts interact can lead to better troubleshooting and improved user experience. Whether you are a seasoned professional or a novice, understanding these elements is the ultimate key to effective upkeep.

Moreover, familiarizing yourself with the layout of each section can simplify the process of ordering replacements and performing repairs. Knowledge is power, and with a clear understanding of your equipment, you can enhance its durability and efficiency.

Understanding Stihl MS 360 Overview

This section aims to provide a comprehensive understanding of a specific model in the world of power tools, focusing on its essential features, capabilities, and operational aspects. Recognizing the significance of quality machinery is vital for both professional users and enthusiasts alike, and this model exemplifies reliability and performance in various applications.

Key Features

One of the standout characteristics of this equipment is its robust engine, designed for efficiency and longevity. The combination of power and lightweight construction allows for ease of handling, making it suitable for a range of tasks, from casual use to more demanding projects. Additionally, the innovative technology integrated into the design enhances user experience, ensuring optimal performance with minimal maintenance.

Applications and Uses

Versatility is a hallmark of this tool, allowing it to excel in different environments, such as forestry, landscaping, and construction. Whether for cutting firewood or tackling larger trees, its adaptability makes it a valuable asset. Users appreciate the balance between power and control, enabling precise cuts and reducing fatigue during extended operations.

In summary, this model represents a blend of advanced engineering and practical design, catering to a wide audience seeking dependable and efficient equipment for their tasks.

Key Features of the Stihl MS 360

This section explores the essential attributes of a popular cutting tool designed for efficiency and durability. Users appreciate its performance in various environments, making it a favored choice among professionals and enthusiasts alike.

- Powerful Engine: Delivers high torque and speed for efficient cutting.

- Lightweight Design: Enhances maneuverability without sacrificing strength.

- Ergonomic Handle: Provides comfort during extended use, reducing fatigue.

- Easy Start System: Simplifies the ignition process, making it user-friendly.

- Durable Components: Built to withstand rigorous conditions, ensuring longevity.

These features collectively contribute to the tool’s reputation as a reliable and effective choice for various cutting tasks.

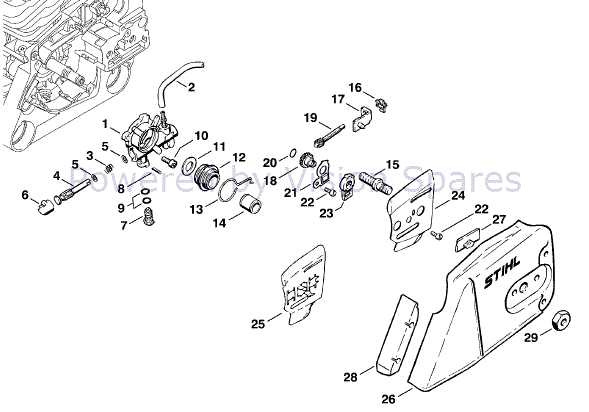

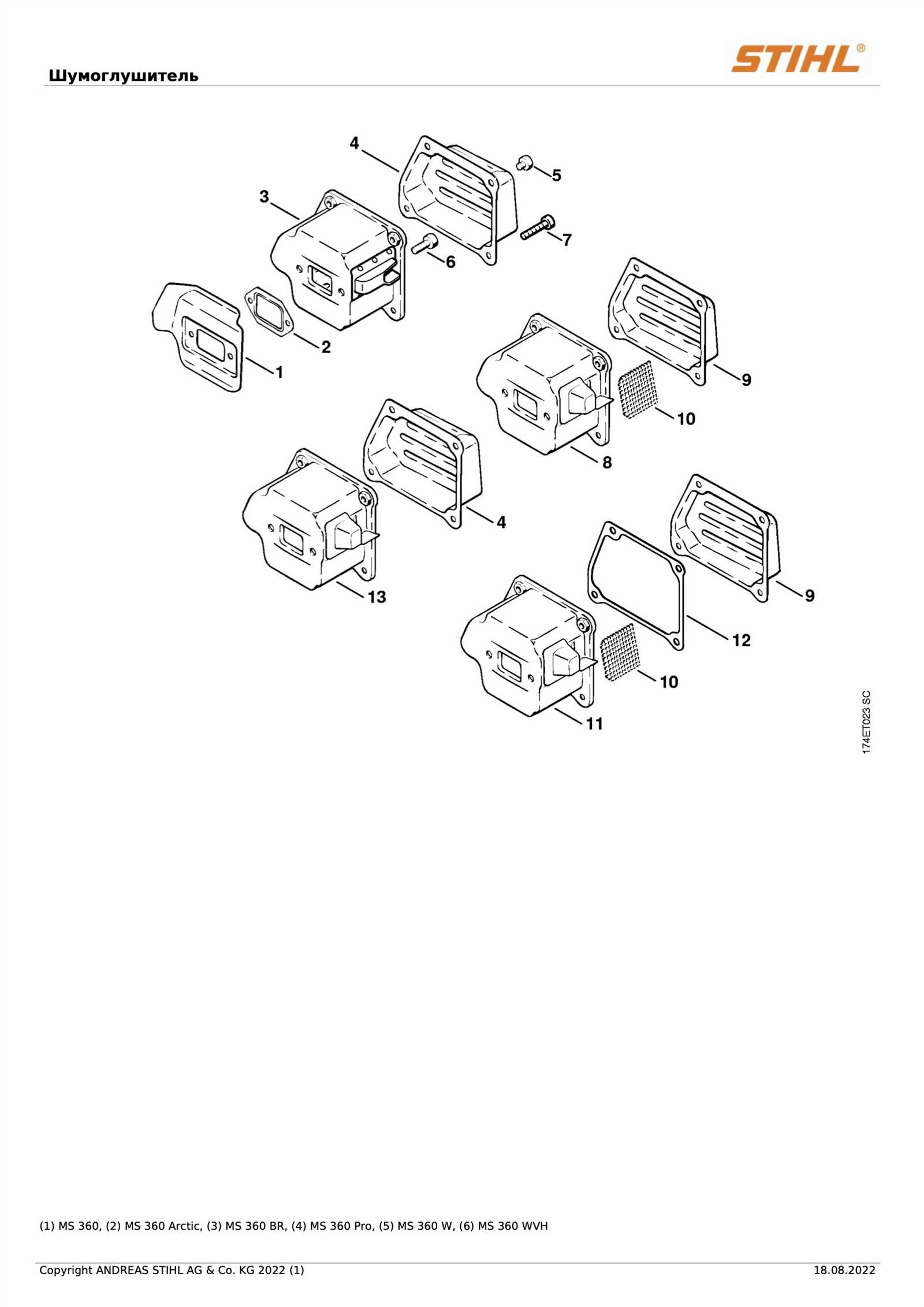

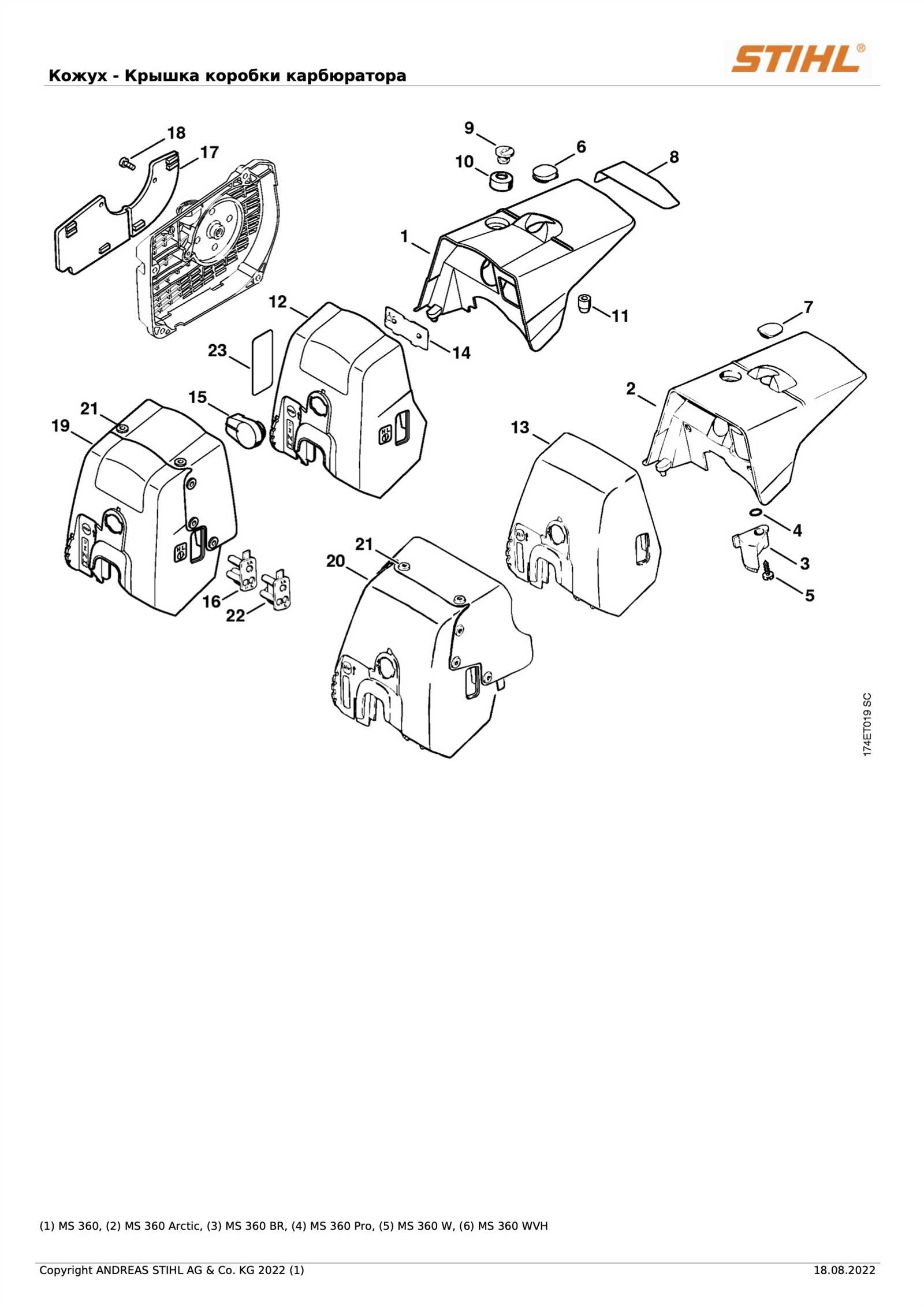

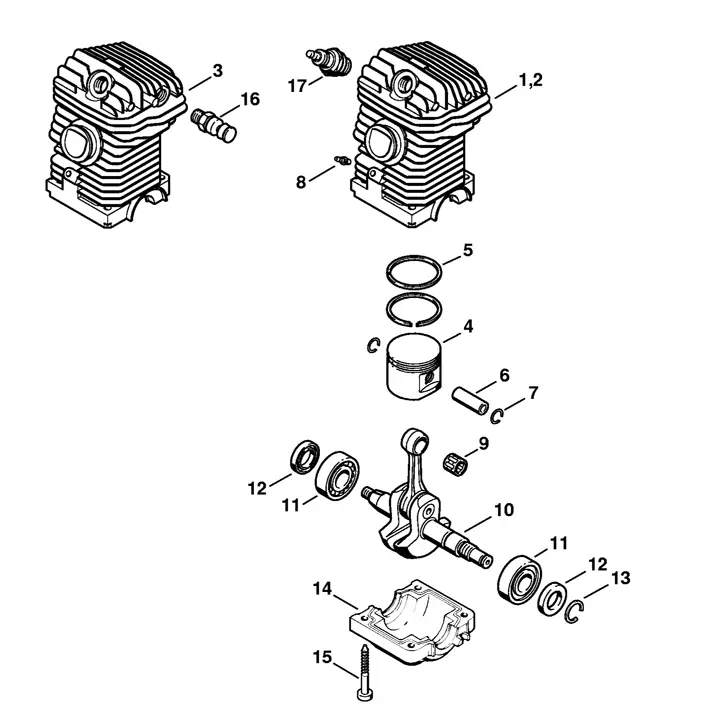

Parts Breakdown of Stihl MS 360

This section provides a detailed examination of the various components that make up the equipment, helping users understand the relationships and functions of each element. A thorough knowledge of these individual pieces is essential for maintenance and troubleshooting, ensuring optimal performance and longevity.

Key Components Overview

The machine consists of several critical sections, including the power unit, cutting system, and operational controls. Each segment is designed to work harmoniously, contributing to the overall efficiency of the tool. For instance, the engine serves as the powerhouse, while the cutting assembly directly influences performance during operation.

Maintenance Considerations

Regular upkeep is crucial for sustaining functionality. Key areas to focus on include the air filtration system, fuel delivery components, and the cutting apparatus. Ensuring these elements are clean and in good condition can prevent common issues and enhance operational efficiency. Replacing worn or damaged parts promptly is vital to maintain the effectiveness and safety of the tool.

Common Issues with Stihl MS 360

Power equipment users often encounter a range of challenges that can impact performance and reliability. Understanding these common problems can aid in troubleshooting and maintenance, ensuring the longevity of the machinery.

One frequent issue is difficulty starting the engine, which may stem from fuel-related problems or ignition failures. Additionally, users may notice reduced power output during operation, often linked to a clogged air filter or dull cutting components. Overheating can also occur, typically due to insufficient lubrication or blocked cooling fins.

Vibrations can be another concern, possibly caused by imbalanced components or worn mounts. Lastly, fuel leaks can pose safety hazards, generally resulting from deteriorated seals or hoses. Addressing these issues promptly can enhance the overall functionality of the equipment.

Maintenance Tips for MS 360

Regular upkeep is essential for optimal performance and longevity of your equipment. By adhering to a consistent maintenance schedule, you can ensure that your machine operates smoothly and efficiently, minimizing the risk of breakdowns and costly repairs.

Essential Maintenance Tasks

Focus on these crucial tasks to keep your tool in prime condition:

| Task | Frequency |

|---|---|

| Clean air filter | Every 10 hours |

| Inspect spark plug | Every 20 hours |

| Sharpen chain | As needed |

| Check bar oil level | Daily |

Storage Recommendations

When not in use, proper storage is vital. Keep the machine in a dry, cool location and consider draining fuel to prevent gumming in the fuel system. Regular checks for signs of wear can prevent minor issues from becoming major headaches.

How to Access the Parts Diagram

Understanding the components of your equipment is essential for effective maintenance and repairs. Accessing a visual reference can greatly assist in identifying and locating specific elements, ensuring your tool operates at its best.

Here are some steps to obtain the necessary visual reference:

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Look for the option related to manuals or schematics.

- Enter the model number of your tool for a tailored search.

- Download or view the available visual reference in PDF format.

Additionally, consider consulting local dealers or service centers for physical copies or expert advice on the parts layout.

Essential Tools for Repairing MS 360

When it comes to maintaining and fixing outdoor power equipment, having the right tools is crucial. A well-equipped toolkit not only simplifies the repair process but also enhances the efficiency and effectiveness of each task. Below are some key instruments that every technician should consider for optimal repairs.

Basic Hand Tools

- Socket Set – Essential for loosening and tightening various components.

- Screwdriver Set – A variety of sizes and types for different screws.

- Wrenches – Both adjustable and fixed for various nut sizes.

- Pliers – Useful for gripping and twisting wires or components.

Specialized Equipment

- Torque Wrench – Ensures bolts are tightened to the correct specifications.

- Feeler Gauge – Helps in adjusting gaps and settings accurately.

- Compression Tester – Evaluates engine performance and health.

- Multimeter – Essential for diagnosing electrical issues.

Identifying Genuine Stihl Parts

Ensuring the authenticity of components is essential for maintaining the efficiency and longevity of your equipment. Genuine items are crafted with precision and adhere to the highest standards, offering reliability that aftermarket alternatives often cannot match.

Here are key aspects to consider when verifying authenticity:

- Packaging: Original products typically come in branded packaging with clear labeling.

- Markings: Check for manufacturer logos or specific identifiers on the component itself.

- Quality: Authentic parts are made from durable materials and exhibit superior craftsmanship.

- Retailer: Purchase from authorized dealers to ensure you receive genuine items.

By paying attention to these details, you can delve deeper into the quality of your components and make informed decisions for optimal performance.

Comparative Analysis with Other Models

In this section, we will explore the distinctions and similarities between various chainsaw models, highlighting key features that influence performance and usability. By examining these aspects, users can make informed decisions tailored to their specific needs.

Engine Power: When comparing engine outputs, certain models exhibit superior torque and efficiency, making them ideal for heavy-duty tasks. Others may prioritize lightweight design, enhancing maneuverability.

Weight and Balance: The ergonomic design plays a crucial role in user comfort. Some units are heavier but provide added stability, while others offer a lightweight alternative for extended use without fatigue.

Fuel Efficiency: Variations in fuel consumption can impact long-term operating costs. Models with advanced technology tend to maximize fuel usage, appealing to those who value sustainability and efficiency.

Maintenance Requirements: Different designs come with varying maintenance needs. Some are engineered for easy upkeep, which is advantageous for frequent users, while others may require more meticulous care.

Price Range: Budget considerations are paramount. While premium models often offer advanced features, more economical options may provide adequate performance for casual users.

Ultimately, understanding these comparative elements allows for a deeper appreciation of available choices, guiding users toward the model that best fits their operational demands.

Upgrades and Modifications for Performance

Enhancing the capabilities of your power tool can significantly improve efficiency and durability. By carefully selecting components and making strategic adjustments, you can optimize performance to meet specific needs, whether for professional use or personal projects.

Consider the following upgrades to boost your tool’s performance:

| Upgrade | Description |

|---|---|

| High-Performance Carburetor | Improves fuel-air mixture for better combustion and power output. |

| Enhanced Air Filter | Allows for increased airflow, leading to improved engine performance and longevity. |

| Upgraded Exhaust System | Reduces back pressure and increases exhaust flow for enhanced efficiency. |

| Lightweight Materials | Using lighter components reduces overall weight, enhancing maneuverability and reducing fatigue. |

| Tuning Kits | Provides adjustments for optimal engine performance tailored to specific applications. |

Implementing these modifications can ultimately lead to a noticeable improvement in your tool’s functionality, making tasks easier and more efficient.

Finding Stihl MS 360 Parts Online

Locating essential components for your equipment can be a straightforward process with the right approach. The digital marketplace offers a plethora of options, allowing users to source what they need efficiently.

Here are some effective strategies:

- Utilize specialized online retailers that focus on outdoor equipment.

- Explore manufacturer websites for authentic items and detailed specifications.

- Check local forums and community groups for recommendations on trusted sellers.

- Take advantage of auction sites for potentially lower prices on used components.

Ultimately, thorough research and comparison will lead you to the best solutions for your machinery needs.

Community Resources for Stihl Users

Enthusiasts and professionals often seek a wealth of resources to enhance their experience and knowledge about their tools. Communities dedicated to these devices offer invaluable support, sharing insights, troubleshooting tips, and maintenance advice. Engaging with fellow users can lead to discovering best practices and innovative techniques.

Online Forums and Discussion Groups

Many online platforms feature forums where users can ask questions and share experiences. These spaces foster collaboration and allow members to delve into specific issues, ensuring everyone benefits from collective knowledge. Participating in discussions can be the ultimate way to gain practical advice.

Local Workshops and Events

Many communities host workshops and events tailored for device enthusiasts. These gatherings provide hands-on experience, allowing participants to learn from experts and connect with others who share their passion. Such interactions can greatly enhance one’s understanding and skills.