Comprehensive Guide to Honda GXH50 Engine Parts Diagram

The functionality of small machinery relies heavily on the intricate interplay of various components. Each element plays a critical role in ensuring optimal performance and longevity of the entire system. This section delves into the essential features of these mechanisms, shedding light on their arrangement and interaction.

Having a comprehensive overview of how each component fits together is vital for maintenance and troubleshooting. Whether you are a seasoned technician or a DIY enthusiast, familiarizing yourself with the layout of these parts will enhance your ability to address issues effectively. With this knowledge, you can ensure that your equipment runs smoothly and efficiently.

In the upcoming sections, we will explore the specific features and functionalities of these crucial elements, providing you with a valuable resource for better understanding and managing your machinery. A detailed breakdown will assist in recognizing common problems and facilitate timely interventions, ultimately extending the lifespan of your tools.

Understanding the Honda GXH50 Engine

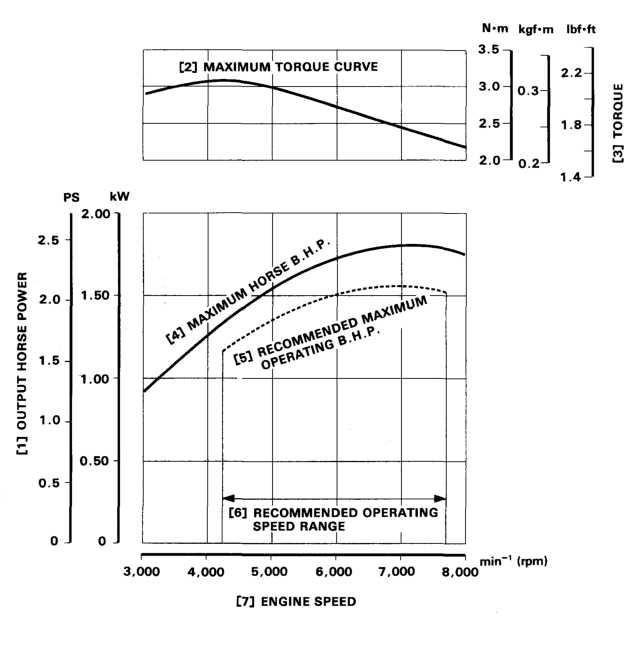

This section delves into the intricacies of a specific power unit widely recognized for its reliability and efficiency. Designed for various applications, it showcases engineering excellence that caters to both casual users and professionals alike.

Key features include:

- Compact design for easy integration

- High performance with optimal fuel consumption

- Durable construction to withstand demanding environments

When exploring the components of this power unit, several critical elements stand out:

- Fuel System: Responsible for delivering the necessary energy.

- Cooling Mechanism: Ensures the unit operates within safe temperature limits.

- Ignition Setup: Initiates the combustion process efficiently.

- Crankshaft and Cylinder: Vital for converting fuel energy into mechanical work.

Each part plays a crucial role in maintaining performance and longevity. Understanding these components can significantly enhance maintenance practices and operational efficiency.

Key Components of the GXH50 Engine

Understanding the crucial elements of this power unit is essential for efficient operation and maintenance. Each component plays a significant role in the overall functionality, contributing to performance, reliability, and longevity.

Major Elements

Among the principal components, the crankshaft stands out as it transforms linear motion into rotational energy. This part is integral for delivering power to the output shaft. Another key element is the cylinder head, which houses valves and plays a pivotal role in the combustion process. Its design influences both efficiency and performance.

Supporting Components

Supporting parts such as the carburetor and ignition system are also vital. The carburetor mixes air and fuel in the correct ratio, ensuring optimal combustion. Meanwhile, the ignition system is responsible for generating the spark needed to ignite the fuel-air mixture, making it crucial for smooth operation.

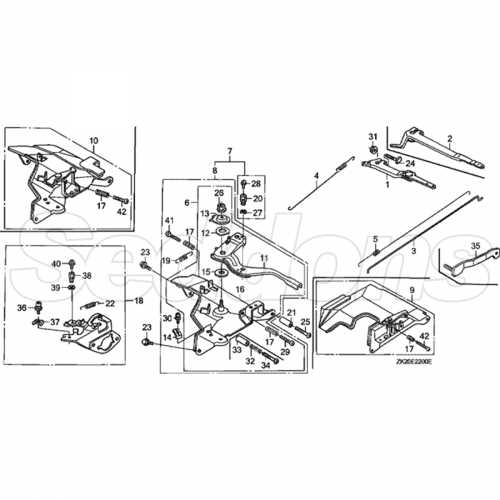

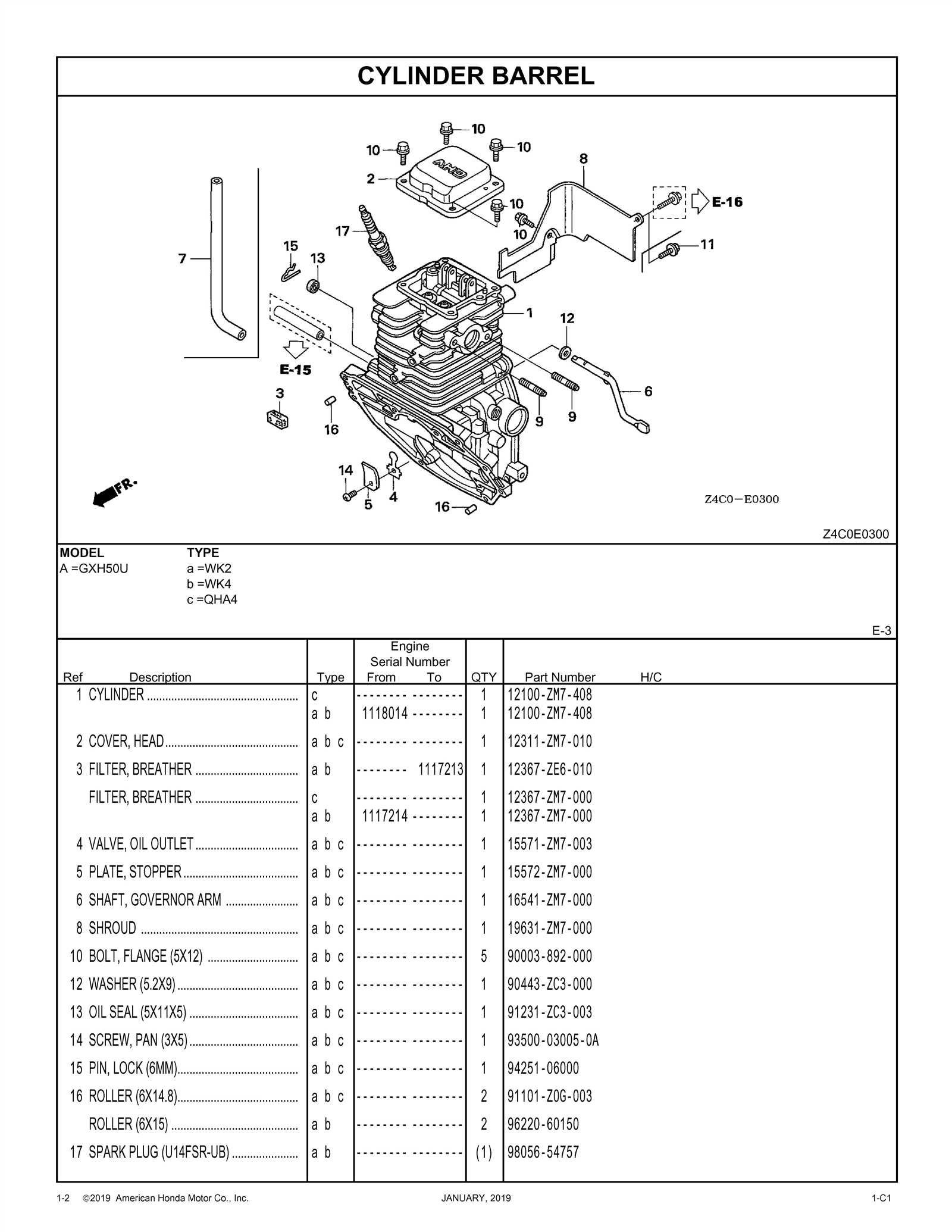

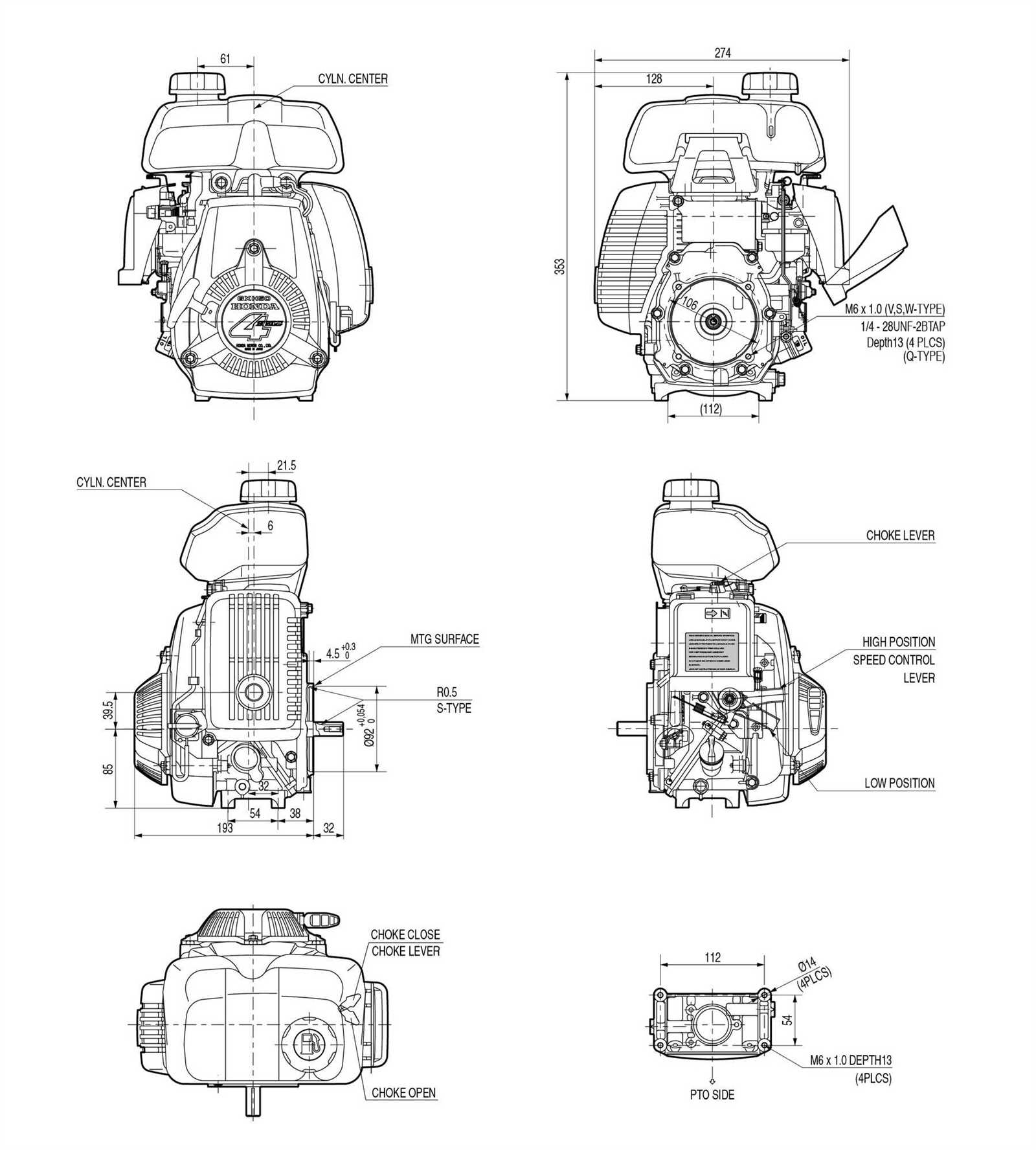

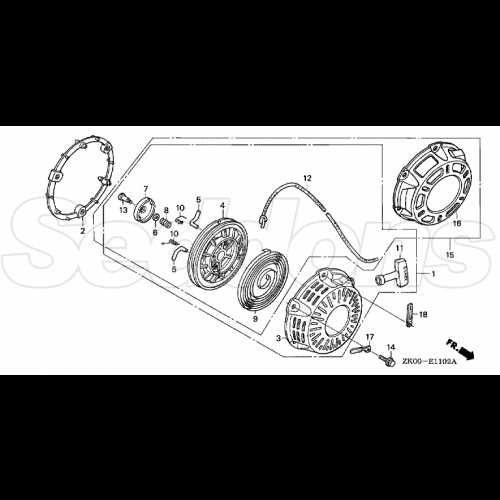

Exploring the Parts Diagram

This section delves into the intricate layout of components that constitute a specific mechanical unit. Understanding this arrangement is essential for anyone looking to service or repair the machinery effectively. A visual representation aids in identifying each segment’s role and significance, promoting a thorough comprehension of how they interact.

By examining the various elements, users can easily pinpoint necessary replacements or maintenance needs. The clarity of such illustrations enhances the ability to troubleshoot issues, ensuring optimal functionality.

| Component Name | Description | Function |

|---|---|---|

| Cylinder | Main housing for combustion | Holds fuel-air mixture for ignition |

| Piston | Movable component within the cylinder | Converts fuel energy into mechanical work |

| Crankshaft | Rotating shaft connected to the piston | Transforms linear motion into rotational motion |

| Valves | Regulate intake and exhaust flow | Control air and fuel entry, and exhaust exit |

| Carburetor | Mixes fuel with air | Ensures proper fuel-air ratio for combustion |

Understanding this configuration not only facilitates repairs but also enriches one’s knowledge of the unit’s overall operation. Thus, familiarizing oneself with these visual guides can lead to more informed decisions in maintenance practices.

Importance of Each Engine Part

Understanding the significance of every component within a mechanical assembly is crucial for optimal performance and longevity. Each element plays a vital role in the overall functionality, ensuring that the system operates smoothly and efficiently. Recognizing how these individual pieces interact can lead to better maintenance and troubleshooting strategies.

Key Components and Their Functions

Below is a summary of essential elements and their primary roles:

| Component | Function |

|---|---|

| Piston | Translates combustion energy into mechanical movement. |

| Crankshaft | Converts linear motion from the piston into rotational energy. |

| Valves | Regulate the intake of air and fuel and the expulsion of exhaust gases. |

| Cylinder | Houses the piston and facilitates the combustion process. |

| Ignition System | Initiates the combustion process by igniting the fuel-air mixture. |

Interdependence of Components

The interaction between these elements is essential for achieving peak efficiency. A failure in one component can lead to a cascade of issues affecting the entire assembly. Regular inspection and understanding of these relationships enhance performance and reliability.

How to Read the Diagram Effectively

Understanding visual representations of mechanical components is crucial for efficient maintenance and repairs. These illustrations serve as a guide, helping users identify various elements and their relationships. Familiarizing yourself with the structure of these visuals can significantly enhance your ability to troubleshoot and assemble machinery.

Identify Key Elements

Begin by locating the essential components within the visual. Each part is typically labeled with a unique identifier, which is crucial for reference. Pay attention to the symbols used, as they often convey specific information about the function or orientation of each element. Notations and legends accompanying the illustration can provide additional context, making it easier to interpret the information accurately.

Follow the Flow and Connections

Next, examine how the various elements are interconnected. Understanding the flow of energy or movement is vital for grasping how the assembly operates as a whole. Trace the lines or arrows that indicate relationships between components, as they reveal how parts interact and the sequence of operations. This insight is key for successful troubleshooting and effective reassembly.

Common Issues with GXH50 Parts

When working with small power units, certain challenges often arise that can impact performance and longevity. Understanding these typical problems can help in identifying and resolving issues effectively. Regular maintenance and keen observation can make a significant difference in keeping these units running smoothly.

Wear and Tear: Over time, components may experience degradation due to friction and exposure to various elements. This can lead to decreased efficiency and potential failure if not addressed promptly.

Fuel System Troubles: Issues in the fuel delivery mechanism are common, such as clogging or leaks. Ensuring clean fuel and proper connections is vital for optimal function.

Cooling Difficulties: Insufficient cooling can lead to overheating, which is detrimental to the overall operation. It is essential to regularly check for blockages and ensure that the cooling system is functioning properly.

Electrical Failures: Components responsible for ignition or starting can fail due to wear or faulty connections. Regular inspection and testing can help mitigate these issues before they lead to breakdowns.

Vibration and Noise: Excessive vibration or unusual sounds can indicate misalignment or loose fittings. Addressing these concerns promptly can prevent further damage and enhance performance.

By being aware of these common issues, users can take proactive steps to maintain their units, ensuring they operate efficiently and effectively for years to come.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your machinery requires regular upkeep and attention to detail. By adhering to specific maintenance practices, you can significantly extend the lifespan of your equipment and enhance its reliability over time.

Regular Inspection

Conducting routine checks is crucial for identifying potential issues before they escalate. Consider the following:

- Examine fluid levels and quality regularly.

- Inspect belts and hoses for wear and tear.

- Check for any unusual noises or vibrations during operation.

Proper Cleaning

Keeping your machinery clean not only improves performance but also prevents the buildup of harmful substances. Follow these tips:

- Remove debris and dirt after each use.

- Use appropriate cleaning agents for sensitive components.

- Ensure air filters are clean and unobstructed.

By implementing these simple yet effective maintenance strategies, you can ensure that your equipment operates smoothly and lasts longer, ultimately saving time and resources in the long run.

Replacement Parts Overview

This section provides a comprehensive look at essential components that are crucial for maintaining optimal performance and longevity of small machinery. Understanding the significance of these elements can aid in ensuring smooth operation and preventing potential issues.

High-quality replacements are vital for restoring functionality and efficiency. Various options are available, ranging from original equipment to aftermarket alternatives. Each type has its advantages, and selecting the right one depends on specific needs and usage conditions.

When considering replacements, it is important to assess compatibility and durability. Factors such as material quality, design precision, and manufacturer reputation play a key role in the decision-making process. By choosing wisely, users can enhance reliability and extend the life of their machinery.

Finding Genuine Honda Components

When maintaining your machinery, ensuring the use of authentic components is essential for optimal performance and longevity. Quality replacements not only enhance efficiency but also preserve the integrity of the entire system. This section explores how to identify and procure genuine items for your equipment, ensuring reliable operation and peace of mind.

Benefits of Authentic Components

Utilizing original replacements brings numerous advantages. Durability is a primary factor; genuine items are designed to withstand the rigors of operation, reducing the risk of failures. Additionally, these components often come with a warranty, providing assurance against defects. Moreover, they ensure proper compatibility with your system, which can help maintain consistent performance and reduce wear on surrounding elements.

Where to Source Authentic Items

To acquire genuine components, start by visiting authorized dealers or certified retailers. These sources often carry a full range of products that meet stringent quality standards. Furthermore, online platforms affiliated with recognized manufacturers can also provide a reliable avenue for procurement. Always check for authenticity seals or documentation to ensure you are getting what you pay for.

Aftermarket Options for GXH50

Exploring alternative solutions can significantly enhance performance and longevity. Numerous aftermarket offerings are available to cater to various needs, ensuring users can find the right fit for their machinery.

When considering these alternatives, it’s essential to evaluate a few key areas:

- Quality and durability of materials

- Compatibility with existing systems

- Performance enhancements

- Warranty and customer support

Here are some popular categories of aftermarket options:

- Filters: Upgraded air and oil filters can improve efficiency and prolong service intervals.

- Carburetors: Performance carburetors offer better fuel atomization, leading to improved power output.

- Ignition Systems: Enhanced ignition components can lead to better starting and smoother operation.

- Exhaust Systems: Aftermarket exhaust options can reduce weight and increase airflow, promoting better performance.

Investing in these alternatives not only optimizes functionality but can also lead to cost savings in maintenance over time. Always ensure to choose reputable brands to guarantee satisfaction and reliability.

Tools Needed for Engine Repair

When tackling mechanical restoration tasks, having the right implements is crucial for a successful outcome. Various tools enable precise work, ensuring that each component is handled properly. Understanding the essential instruments required can significantly enhance efficiency and safety during the process.

Wrenches are fundamental in loosening and tightening bolts. A variety of sizes is necessary to accommodate different fittings, ensuring a snug grip and preventing stripping. Screwdrivers of various types, including flathead and Phillips, are also vital for accessing hard-to-reach areas and removing screws with ease.

Pliers come in handy for gripping and manipulating small components, while socket sets provide versatility for more complex tasks, allowing for quick changes between sizes. An oil filter wrench can be invaluable for maintenance, simplifying the removal of filters.

Finally, having a reliable torque wrench ensures that all fasteners are tightened to the manufacturer’s specifications, preventing potential damage from over-tightening. A well-equipped workspace promotes a smoother and more effective restoration experience.

DIY Repairs: Step-by-Step Guide

This section aims to provide a comprehensive approach for individuals looking to tackle repairs on their own. By following a structured methodology, you can efficiently resolve issues, save time, and reduce costs while gaining a deeper understanding of your machinery.

Gathering Tools and Materials

Before beginning any repair task, it’s essential to assemble the necessary tools and materials. This includes screwdrivers, wrenches, and any specific components you may need. Ensure that your workspace is organized and well-lit, as this will help facilitate a smoother repair process.

Identifying Issues and Troubleshooting

The next step involves diagnosing the problem accurately. Carefully inspect the unit for signs of wear, damage, or malfunction. Utilizing a manual or reference guide can assist in pinpointing the source of the issue. Once identified, develop a clear plan of action to address the repair efficiently.

FAQs About GXH50 Engine Parts

This section addresses common inquiries regarding components associated with a specific small motor model. Understanding these elements can enhance maintenance and troubleshooting efforts, ensuring optimal performance and longevity of the machinery.

Common Questions

Here are some frequently asked questions regarding the components related to this motor:

| Question | Answer |

|---|---|

| What types of components are essential for operation? | Key elements include the ignition system, fuel delivery components, and the cooling system. |

| How can I identify worn components? | Look for signs such as unusual noises, reduced efficiency, or physical damage. |

| Are there specific maintenance tips to follow? | Regularly check oil levels, replace filters, and clean the air intake to maintain functionality. |

| Where can I find replacement components? | Replacement items can typically be sourced from specialized retailers or online platforms. |

Maintenance Best Practices

Adhering to best practices can prolong the lifespan of crucial components. Regular inspections and timely replacements of worn items are vital in preventing larger issues.