Understanding the Air Arms S510 Parts Diagram

The intricate assembly of high-performance devices relies on a detailed understanding of their individual elements. Enthusiasts and technicians alike seek clarity in how these components interact to optimize functionality. This exploration delves into the essential layout that enhances the overall performance of these specialized mechanisms.

In the realm of precision tools, recognizing the role of each segment is crucial. By comprehending the configuration and relationships among the various elements, users can ensure effective maintenance and upgrades. This knowledge fosters a deeper appreciation for the engineering involved and empowers users to make informed decisions.

Moreover, having access to comprehensive visual representations of these layouts aids in troubleshooting and assembly processes. Such insights not only enhance practical skills but also cultivate a sense of confidence when working with complex systems. As we investigate the structure and arrangement of these key components, the potential for improved performance becomes evident.

Air Arms S510 Parts Overview

This section provides a comprehensive look at the various components that contribute to the functionality and performance of a specific model in the airgun category. Understanding these elements is essential for maintenance, upgrades, and effective use.

Key Components

- Barrel Assembly

- Trigger Mechanism

- Power Source

- Loading System

- Optics Mount

Maintenance Tips

- Regularly inspect the barrel for obstructions.

- Lubricate the trigger mechanism to ensure smooth operation.

- Check seals and O-rings for wear and tear.

- Keep the loading system clean for reliable performance.

Exploring the Key Components

Understanding the essential elements of a precision shooting device can enhance both performance and maintenance. Each component plays a crucial role in ensuring optimal functionality and reliability, contributing to the overall shooting experience.

Barrel: The barrel is vital for accuracy, guiding the projectile towards its target. Its design influences the trajectory and speed of the shot.

Action: This mechanism is responsible for loading, firing, and ejecting. A smooth action is key to quick follow-up shots and overall ease of use.

Stock: The stock provides stability and comfort, allowing for better control. Ergonomics and fit can significantly impact handling during use.

Sights: Proper aiming devices are essential for precision. The choice between iron sights or optical scopes can affect targeting capabilities.

Trigger: A well-designed trigger ensures a clean break, enhancing accuracy and user confidence. Adjustability can cater to personal preferences.

Delving into these components reveals the ultimate synergy needed for superior performance. Each part contributes uniquely, highlighting the intricate craftsmanship behind these sophisticated devices.

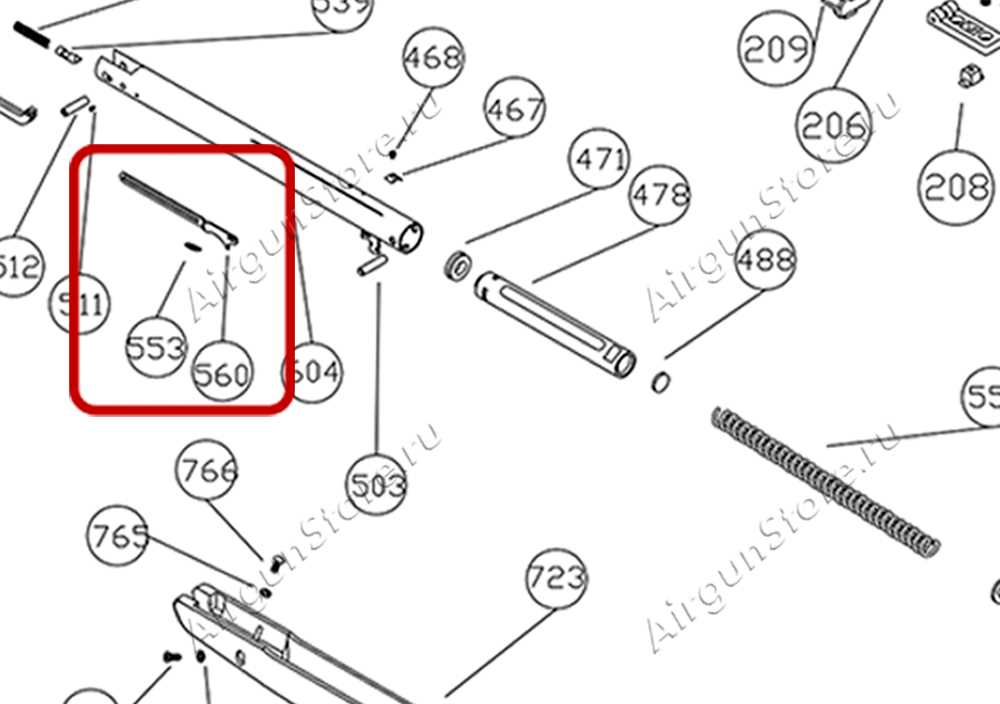

Understanding the Trigger Mechanism

The trigger mechanism is a crucial component in any precision shooting device, playing a vital role in ensuring accuracy and control. It serves as the interface between the shooter’s intention and the firing process, allowing for precise engagement and disengagement.

At its core, this mechanism consists of various elements that work in harmony to deliver a smooth and consistent experience. The primary components include the trigger itself, sear, and spring assemblies, each contributing to the overall functionality. The design and configuration of these parts can significantly influence the responsiveness and feel of the shooting experience.

A well-engineered trigger mechanism enhances the user’s ability to make accurate shots by minimizing unnecessary movement during the firing sequence. This results in improved stability and focus, ultimately leading to better performance. Understanding the intricacies of this system allows enthusiasts and professionals alike to appreciate the craftsmanship involved in creating a reliable shooting instrument.

Barrel Construction and Functionality

The construction of a shooting tube plays a critical role in determining the performance and accuracy of a projectile-launching device. It serves as a conduit through which the projectile is propelled, influencing factors such as speed, stability, and overall trajectory. Understanding its design and operational characteristics is essential for both enthusiasts and professionals alike.

Materials and Design

The choice of materials in the creation of the tube significantly affects its durability and effectiveness. Commonly utilized materials include high-grade steel and aluminum, which provide the necessary strength while keeping the weight manageable. The internal surface finish is also crucial; a smooth finish reduces friction, allowing for a more efficient launch. The design may incorporate specific features, such as rifling, which imparts spin to the projectile, enhancing accuracy and distance.

Operational Mechanics

During the launching process, the projectile travels through the tube, where it is subject to various forces. The design ensures a controlled environment that maximizes propulsion. The length and diameter of the tube are tailored to optimize performance based on the intended use. As the projectile exits the muzzle, the characteristics of the tube directly influence its flight path and impact precision.

In summary, the effective design and construction of a shooting tube are pivotal in achieving desired performance outcomes. By understanding these elements, users can better appreciate the engineering behind their devices and make informed choices regarding maintenance and upgrades.

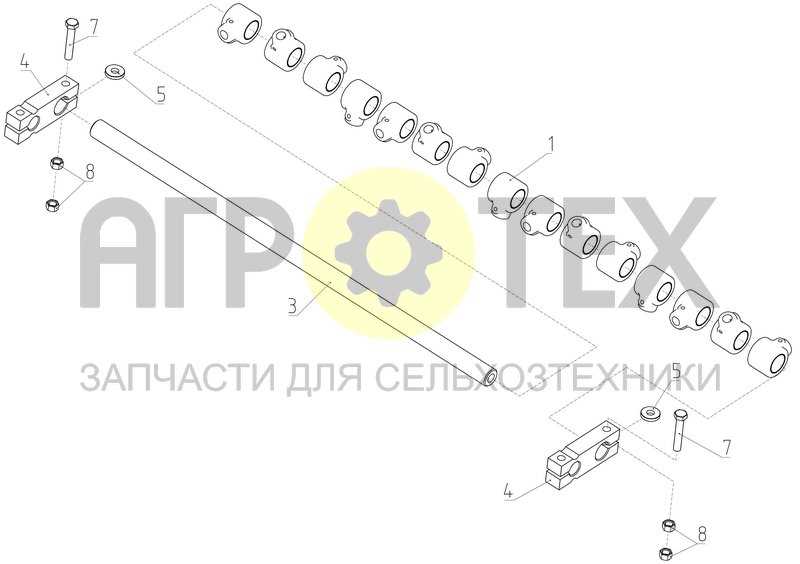

Regulator System Breakdown

This section explores the intricate mechanisms that govern pressure control in pneumatic systems, ensuring optimal performance and efficiency. Understanding these components is essential for maintenance and troubleshooting.

- Main Regulator: Central unit responsible for stabilizing pressure.

- Secondary Regulators: Used for fine-tuning output pressure.

- Pressure Gauges: Provide real-time pressure readings.

- Seals and Diaphragms: Critical for preventing leaks and ensuring reliability.

By examining these elements, one can delve into the ultimate functions and potential points of failure within the system, facilitating better understanding and effective repairs.

Air Cylinder Features and Design

The functionality of a pressure vessel is crucial in various applications, providing the necessary force to propel projectiles or perform tasks efficiently. Understanding its characteristics and construction is essential for optimizing performance and ensuring reliability.

Material Composition: The choice of materials significantly influences the durability and weight of the vessel. Commonly, lightweight yet strong substances such as aluminum or composite materials are utilized to balance resilience with portability.

Pressure Regulation: An effective design incorporates mechanisms to manage internal pressure, ensuring safety and consistency. Regulators and valves play vital roles in maintaining optimal conditions for operation.

Sealing Mechanisms: Proper sealing is essential to prevent leaks and maintain integrity. Advanced gaskets and O-rings are employed to enhance airtightness and withstand varying environmental conditions.

Dimensional Specifications: The size and shape of the vessel are tailored to specific requirements, affecting the overall performance. A well-engineered design considers both capacity and ergonomics for user-friendliness.

In summary, a deep understanding of these features facilitates the creation of an efficient and reliable pressure vessel, essential for achieving ultimate performance in its intended use.

Magazine Operation and Details

The functionality of the loading mechanism is crucial for ensuring smooth performance and reliability in shooting activities. Understanding the components involved and their interactions enhances the user experience and accuracy of the device.

Loading Mechanism

The mechanism allows for the seamless insertion and ejection of ammunition, facilitating quick reloads during use. This efficiency plays a significant role in maintaining shooting rhythm and minimizing downtime.

Maintenance Tips

Regular upkeep of the loading system is essential for optimal performance. Ensuring cleanliness and checking for wear and tear can prevent malfunctions and prolong the lifespan of the device.

| Component | Function |

|---|---|

| Spring | Provides tension for ammunition feeding |

| Follower | Guides rounds into position |

| Body | Houses and protects the loading mechanism |

Stock Design and Material Choices

The design and materials utilized in the construction of the stock play a crucial role in the overall functionality and aesthetic appeal of precision shooting equipment. Choices in these elements not only affect the weight and balance of the device but also influence comfort and handling during use. A well-crafted stock can enhance the user experience, allowing for better aim and control.

Material Options

Various materials are available for stock construction, each offering unique advantages. Wood, for instance, is often favored for its traditional feel and aesthetic qualities, providing a warm touch and natural beauty. However, synthetic materials like polymer and composite provide enhanced durability and resistance to environmental factors, making them suitable for diverse conditions.

Ergonomic Design

Ergonomics is another key consideration in stock design. Features such as adjustable cheek pieces and butt pads can greatly improve comfort, allowing users to maintain a stable and comfortable position during extended use. A well-designed stock not only enhances performance but also reduces fatigue, making it an essential element for serious enthusiasts.

Scope Mounting Points Explained

Understanding the optimal locations for attaching optical devices is crucial for achieving precision and accuracy. The right mounting points not only enhance the functionality of the equipment but also contribute to a balanced setup, allowing for better performance during use.

| Mounting Point | Description |

|---|---|

| Rear Ring | This position stabilizes the scope and helps maintain alignment with the target, ensuring a consistent sight picture. |

| Front Ring | Secures the front of the scope, providing additional support and reducing movement that could affect accuracy. |

| Base | Serves as the foundation for the scope, allowing for a solid connection to the firearm and minimizing vibrations. |

| Offset Mounts | Allows for customization in positioning, offering flexibility for different shooting styles and preferences. |

Safety Mechanism Insights

Understanding the safety features of pneumatic devices is crucial for both operators and manufacturers. These systems are designed to prevent accidental discharge and ensure safe handling, making them an essential aspect of any model. Exploring the mechanisms behind these safeguards can shed light on their effectiveness and reliability.

Types of Safety Features

Various safety mechanisms can be implemented in pneumatic systems. Each type serves a specific purpose and contributes to the overall security of the equipment. Here is a breakdown of some common safety features:

| Feature | Description |

|---|---|

| Manual Safety | A physical switch that must be engaged to enable operation, preventing unintended use. |

| Trigger Lock | A mechanism that locks the trigger in place, ensuring it cannot be pulled inadvertently. |

| Automatic Safety | A system that engages automatically when the device is not in use, preventing accidental activation. |

Importance of Maintenance

Regular maintenance of safety mechanisms is vital for ensuring their functionality. Over time, components can wear out or become misaligned, compromising safety. Adhering to recommended inspection schedules and promptly addressing any issues will enhance the reliability of these critical systems.

Customizing with Replacement Parts

Enhancing your equipment with new components can significantly improve its performance and functionality. By opting for high-quality replacements, enthusiasts can tailor their gear to better suit their individual needs and preferences, creating a more personalized experience. This process not only boosts performance but also extends the lifespan of the gear.

Benefits of Upgrading Components

Upgrading elements can lead to various advantages, including improved accuracy, enhanced durability, and increased efficiency. Customization allows users to adapt their equipment to specific conditions or usage styles, making it a vital aspect for serious hobbyists and professionals alike.

Popular Replacement Options

| Component | Purpose | Advantages |

|---|---|---|

| Barrel | Enhances precision | Increased accuracy and range |

| Trigger | Improves responsiveness | Smoother pull and better control |

| Stock | Adjusts fit | Comfort and stability during use |

| Scope | Enhances targeting | Improved visibility and focus |

Exploring and integrating new components can transform your experience, providing the edge you need to excel in various activities. Whether for competition or recreational use, customization opens a realm of possibilities to optimize your setup.

Common Upgrades and Accessories

Enhancing your shooting experience often involves exploring various enhancements and attachments that can significantly improve performance and user satisfaction. From precision components to aesthetic additions, the right upgrades can elevate functionality and enjoyment.

Performance Enhancements

Upgrading specific components can lead to greater accuracy and consistency. High-quality optics are essential for improved targeting, while custom triggers can offer a more responsive shooting experience. Additionally, regulators can stabilize pressure, leading to more reliable shots.

Aesthetic and Functional Accessories

Accessories not only add to the visual appeal but also enhance usability. Options like slings and custom grips can improve handling, while silencers provide stealth during use. Personalizing your setup reflects individual style and enhances comfort during prolonged sessions.

Maintaining Your Air Arms S510

Proper upkeep of your precision equipment is crucial for ensuring its longevity and performance. Regular attention to details can prevent issues and enhance accuracy, ultimately leading to a more enjoyable experience. Understanding the components involved and their care will facilitate effective maintenance.

Regular Cleaning: Keeping the interior and exterior free from debris is essential. Use appropriate cleaning solutions and tools designed for your specific model to avoid damage.

Inspecting Components: Periodic checks of all essential elements are vital. Look for wear and tear, and ensure seals and connections are intact to maintain optimal functionality.

Lubrication: Utilizing suitable lubricants will keep moving parts functioning smoothly. Avoid over-lubricating, as this can attract unwanted particles.

Storage: Proper storage conditions are important. Protect your equipment from extreme temperatures and humidity to preserve its integrity.

Consulting Manuals: Always refer to the manufacturer’s guidelines for specific maintenance recommendations. This resource is invaluable for addressing any unique care requirements.