Understanding the Engine Parts Diagram of the 2002 Honda CR-V

Exploring the intricate assembly of a timeless utility vehicle unveils a wealth of knowledge for enthusiasts and mechanics alike. A comprehensive examination of its inner workings reveals not only the design philosophy behind the vehicle but also the essential elements that contribute to its performance and reliability.

Visualizing the Structure of such a vehicle is crucial for anyone seeking to maintain or enhance its functionality. A detailed representation of the various components provides insight into how each part interconnects, ensuring optimal operation and longevity.

Through this exploration, understanding the interplay between different mechanisms can significantly aid in troubleshooting and repairs. Whether you’re a seasoned technician or a curious owner, familiarizing yourself with these essential features will enhance your appreciation for the engineering marvel that is this classic model.

Understanding Honda CR-V 2002 Engine Parts

When exploring the intricate machinery of a vehicle, one must recognize the vital components that contribute to its overall functionality. Each element plays a crucial role in ensuring smooth operation and reliability. Familiarity with these individual units can enhance maintenance practices and improve performance.

Central to the vehicle’s operation is the assembly that generates power, which relies on various mechanisms working in harmony. This includes elements responsible for combustion, air intake, and exhaust management. Understanding these systems can help in diagnosing issues and implementing effective repairs.

Additionally, the supporting structures within the system, such as belts and hoses, are essential for the seamless transfer of energy and fluids. Knowledge of their locations and functions aids in preventative maintenance, ultimately prolonging the lifespan of the vehicle.

In conclusion, a comprehensive understanding of these integral components not only empowers owners but also enhances the driving experience. Recognizing how each piece interacts fosters a deeper appreciation for automotive engineering.

Overview of Engine Components

This section aims to provide a comprehensive look at the essential elements that work together to power a vehicle. Understanding these components is crucial for anyone interested in automotive mechanics or looking to enhance their knowledge about how an automobile functions. Each part plays a vital role in ensuring optimal performance and efficiency.

Core Components

The main elements include the block, which houses the cylinders; the pistons that move up and down to create power; and the crankshaft, which converts linear motion into rotational motion. Additionally, the cylinder head is responsible for sealing the top of the cylinders, allowing for controlled combustion. Together, these components form the heart of the power-producing system.

Supporting Systems

Alongside the core components, various supporting systems contribute to overall functionality. The fuel delivery system ensures the right mixture reaches the combustion chamber, while the ignition system creates the necessary spark for ignition. Furthermore, the cooling system prevents overheating, and the lubrication system minimizes friction, enabling smooth operation. Each of these systems is intricately linked, working in harmony to ensure the vehicle runs efficiently.

Key Functions of Each Part

This section explores the essential roles of various components within the mechanical assembly, highlighting their contributions to overall functionality.

- Power Generation: This element converts fuel into energy, initiating the entire system’s operation.

- Air Intake: This component regulates airflow, ensuring optimal combustion efficiency.

- Fuel Delivery: It ensures the precise distribution of fuel, crucial for maintaining performance.

- Cooling System: This mechanism prevents overheating, maintaining a stable operating temperature.

- Exhaust Management: It channels emissions away, reducing harmful outputs and enhancing efficiency.

Understanding these functions provides insights into the intricate interplay of elements that drive performance and reliability.

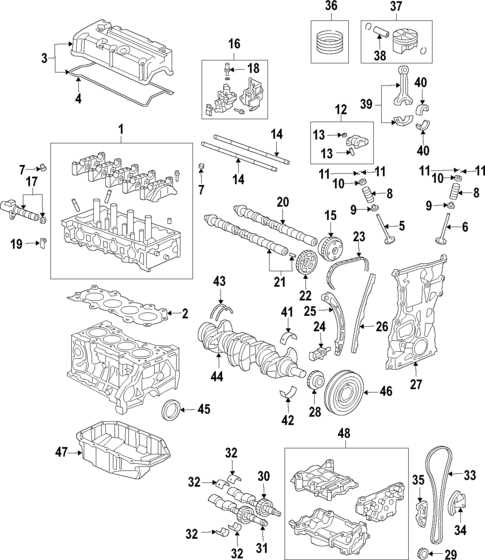

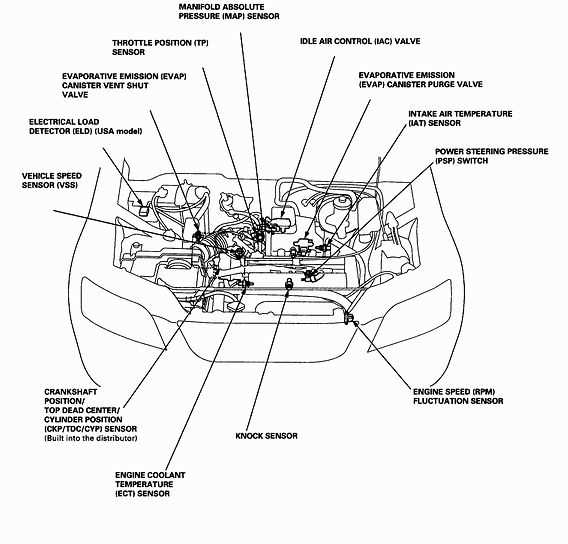

Visual Representation of Engine Layout

This section aims to provide a comprehensive visual overview of the arrangement and components that make up the power unit of a specific vehicle model. Understanding this layout is crucial for mechanics and enthusiasts alike, as it facilitates the identification and diagnosis of potential issues, as well as informs maintenance practices.

The graphical depiction serves not only as an educational tool but also as a reference guide for those involved in repairs or upgrades. Each element is strategically positioned, reflecting its role in the overall function and performance of the vehicle. By examining this illustration, one can gain insight into the intricate relationships between various components, highlighting how they work together seamlessly.

Through this visual representation, users can better appreciate the complexity of automotive design and the engineering principles that underpin it. Whether you are a seasoned professional or a curious novice, this layout provides valuable knowledge to enhance your understanding and skills in automotive care.

Common Issues with Engine Parts

Every vehicle has components that can develop problems over time, leading to performance issues and potential failures. Understanding these common challenges can help in early detection and prevention, ensuring a smoother operation and longevity of the machine.

Wear and Tear

Age and mileage play a significant role in the deterioration of various components. Parts such as belts and hoses are prone to cracking and fraying, while bearings may exhibit signs of wear. Regular inspections can identify these issues before they escalate.

Contamination and Deposits

Accumulation of dirt, oil sludge, and other contaminants can impede performance. Cleaning and maintaining the cleanliness of systems is essential. Neglecting this can lead to clogged filters and reduced efficiency, impacting overall functionality.

Maintenance Tips for Engine Longevity

Ensuring the durability and efficiency of your vehicle’s core system requires a proactive approach to care and maintenance. Regular attention to various components can significantly enhance performance and lifespan.

1. Regular Oil Changes: Frequent replacement of lubricant is crucial. Clean fluid reduces friction, enhancing overall function.

2. Monitor Fluid Levels: Keeping an eye on all necessary fluids–like coolant and transmission fluid–prevents overheating and ensures smooth operation.

3. Inspect Filters: Air and fuel filters should be checked regularly. Clean filters improve airflow and fuel efficiency.

4. Check Belts and Hoses: Inspecting these components for wear and tear can avert serious issues. Replace them as needed to maintain optimal function.

5. Maintain Proper Temperature: Avoid excessive heat by ensuring the cooling system is functioning well, preventing potential damage.

6. Regular Tune-Ups: Scheduled professional check-ups can catch problems early, ensuring all systems work harmoniously.

By following these guidelines, you can significantly enhance the longevity and reliability of your vehicle’s core systems.

How to Read an Engine Diagram

Understanding a visual representation of mechanical components is essential for anyone working with automotive machinery. Such illustrations provide insights into the relationships and functions of various elements, allowing for effective troubleshooting and maintenance.

To begin, familiarize yourself with the symbols used in the illustration. Each symbol represents a specific component, and recognizing these will aid in navigating the layout. Common elements may include valves, pistons, and belts, each depicted with unique shapes and lines.

Next, pay attention to the labels. These typically indicate the names of parts and may also include numerical references. Reading these annotations carefully can help clarify the function of each component and its place in the overall system.

Additionally, examine the connections between different components. Lines or arrows often illustrate how parts interact with one another, showing the flow of energy or motion. Understanding these links is crucial for diagnosing issues or planning repairs.

Finally, take note of any color codes or shading used in the illustration. These can signify different systems or highlight specific areas of interest, further enhancing comprehension. By mastering these aspects, one can effectively utilize the visual guide to improve mechanical knowledge and skills.

Replacing Worn-Out Engine Components

Maintaining optimal performance of a vehicle requires regular attention to its internal mechanisms. Over time, certain elements may deteriorate due to wear and tear, affecting overall functionality. Timely replacement of these components is crucial for ensuring longevity and efficiency.

Identifying Signs of Wear

Common indicators of deterioration include unusual noises, decreased power, and increased fuel consumption. Regular inspections can help catch these issues early, allowing for proactive measures.

Replacement Process

Once components are identified as worn, the replacement process should follow a systematic approach. It involves careful removal, replacement with quality parts, and thorough reassembly to avoid future complications.

| Component | Signs of Wear | Replacement Tips |

|---|---|---|

| Piston Rings | Excessive oil consumption | Ensure proper clearance |

| Timing Belt | Cracks or fraying | Replace every 60,000 miles |

| Water Pump | Leaks or noise | Check gasket integrity |

Upgrades for Improved Engine Performance

Enhancing the functionality of your vehicle’s powertrain can lead to a noticeable boost in overall efficiency and responsiveness. Various modifications can optimize performance, increase power output, and improve fuel economy. Below are several recommended enhancements to consider.

- Cold Air Intake System: This modification allows for a greater volume of cooler air to enter the combustion chamber, improving combustion efficiency.

- High-Performance Exhaust: Upgrading to a less restrictive exhaust system can enhance the flow of gases, reducing back pressure and improving horsepower.

- ECU Tuning: Adjusting the engine control unit settings can fine-tune fuel delivery and ignition timing for better performance.

- Aftermarket Spark Plugs: Using high-quality spark plugs can improve ignition efficiency and overall combustion performance.

- Performance Fuel Injectors: Upgrading to more efficient injectors can provide a better fuel atomization and improved power output.

Each of these modifications can contribute to a more robust and responsive driving experience, making your vehicle more enjoyable and efficient. Consider consulting with a professional to determine the best combination of upgrades tailored to your specific needs.

Tools Needed for Engine Repairs

Repairing a motor requires a variety of specialized implements to ensure efficiency and precision. Having the right tools at your disposal not only streamlines the process but also enhances the quality of the work performed. Whether tackling minor adjustments or major overhauls, equipping yourself with the necessary instruments is crucial for successful maintenance.

Basic Hand Tools: A comprehensive set of hand tools is essential for any mechanical task. This includes wrenches, sockets, and screwdrivers of various sizes. A quality ratchet set can make quick work of removing fasteners, while pliers and cutters will assist in handling wires and small components.

Diagnostic Equipment: Utilizing diagnostic tools such as OBD-II scanners can help identify issues within the system. These devices provide error codes that guide the repair process, making it easier to pinpoint malfunctioning parts.

Specialty Tools: Some repairs may necessitate specialized tools like torque wrenches or pullers. These are designed to apply the correct amount of force or to extract components without damage, ensuring precision in reassembly.

Safety Gear: Always prioritize safety by wearing appropriate gear. Safety glasses, gloves, and ear protection are vital to safeguard against potential hazards while working on machinery.

Equipping yourself with the right tools not only simplifies the repair process but also enhances your ability to perform high-quality work. Investing in quality instruments will pay off in the long run, making each project more manageable and efficient.

Resources for Honda CR-V Owners

For enthusiasts and caretakers of their vehicles, a wealth of information is crucial for effective maintenance and repairs. Access to reliable resources can enhance understanding, provide guidance, and ensure optimal performance of the vehicle over time.

Online forums and community groups serve as excellent platforms where owners can exchange experiences, seek advice, and share solutions. These interactive spaces foster a sense of belonging and offer invaluable insights from fellow drivers.

Additionally, comprehensive service manuals provide detailed instructions on various aspects of maintenance and troubleshooting. These documents are essential for anyone looking to delve deeper into the workings of their automobile.

Moreover, video tutorials on popular platforms can visually guide users through specific tasks, making even complex repairs manageable for the average owner. These resources bridge the gap between novice and expert, empowering all to take charge of their vehicles.