Comprehensive Yamaha F300 Parts Diagram for Easy Reference

Exploring the intricate workings of marine engines is essential for any enthusiast or professional. A thorough grasp of the various elements that comprise these powerful machines allows for better maintenance, repair, and overall performance enhancement. By delving into the specifics of each component, one can ensure that their vessel operates at peak efficiency.

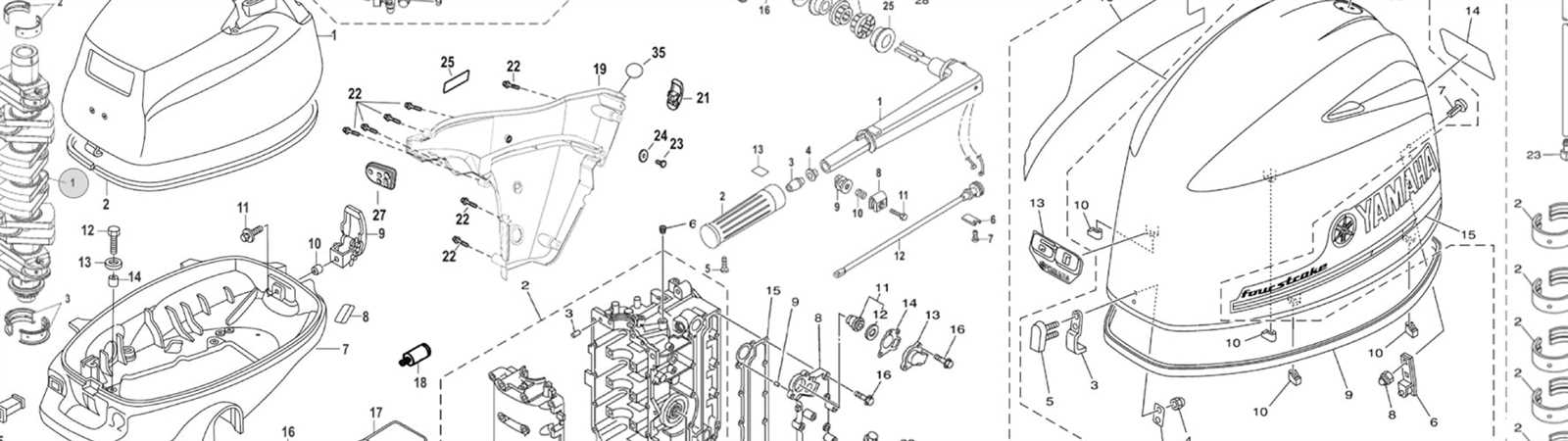

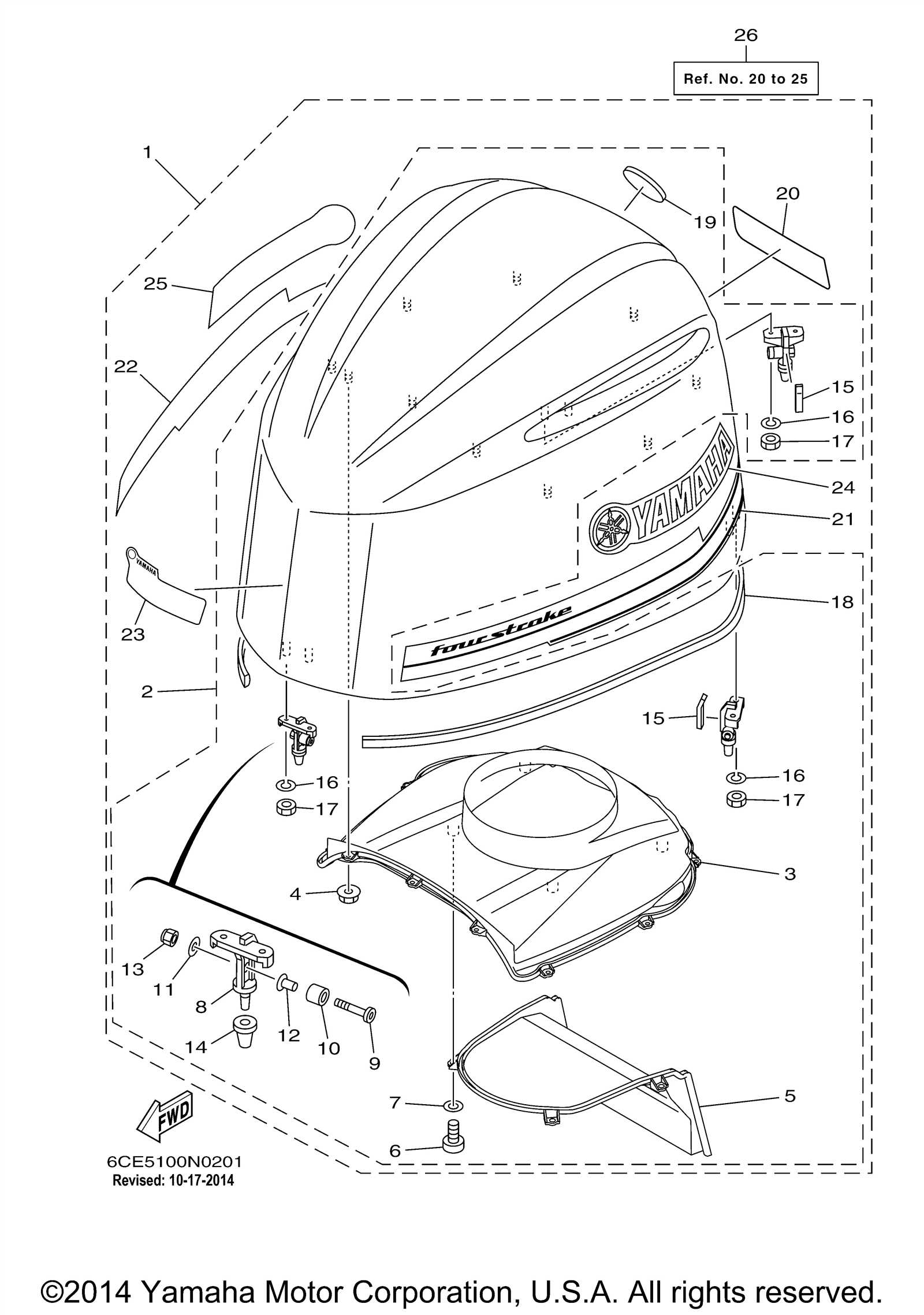

For those seeking to identify the individual parts and their arrangement within the engine, visual aids can be invaluable. These resources not only highlight the relationships between different sections but also facilitate a clearer understanding of how each piece contributes to the system’s functionality. An organized representation serves as a guide, simplifying complex assemblies and making troubleshooting more accessible.

Furthermore, recognizing the importance of each part aids in the selection of suitable replacements or upgrades. When issues arise, knowing the precise function and location of each element empowers users to make informed decisions, minimizing downtime and enhancing the overall experience on the water. Engaging with these resources equips boaters with the knowledge necessary to tackle any challenge that may arise.

Understanding Yamaha F300 Parts Diagram

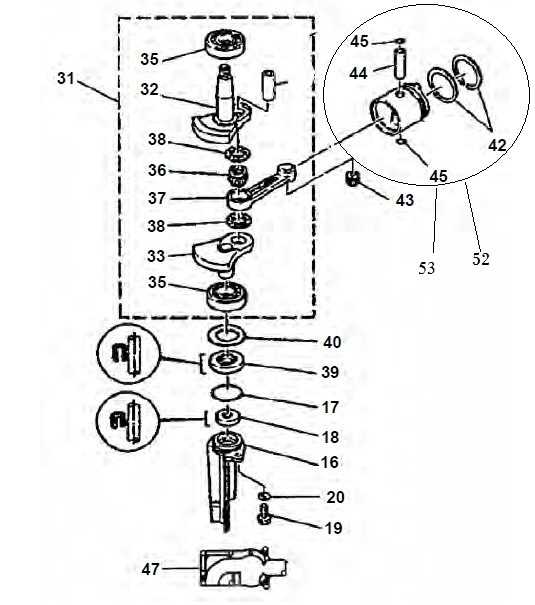

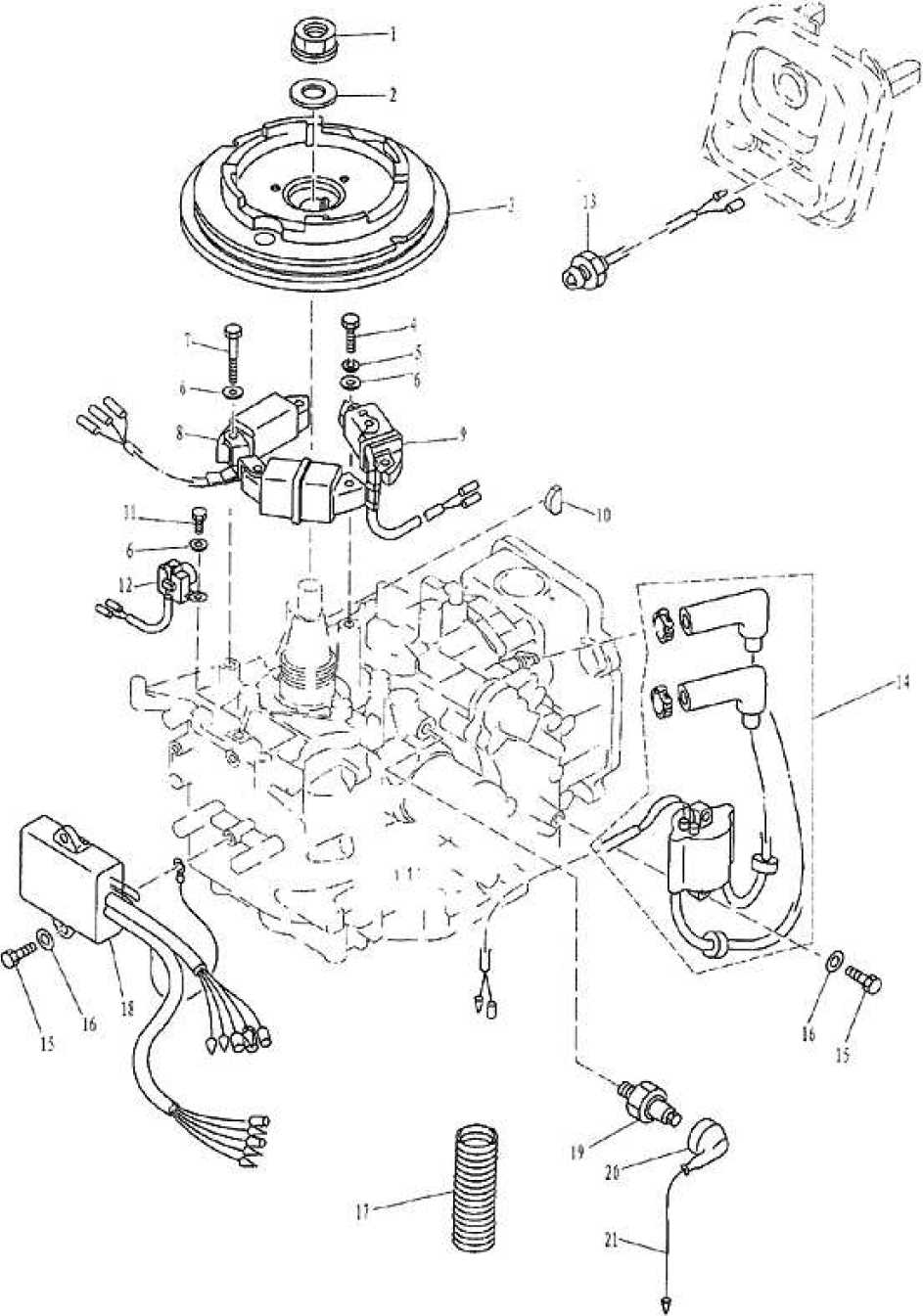

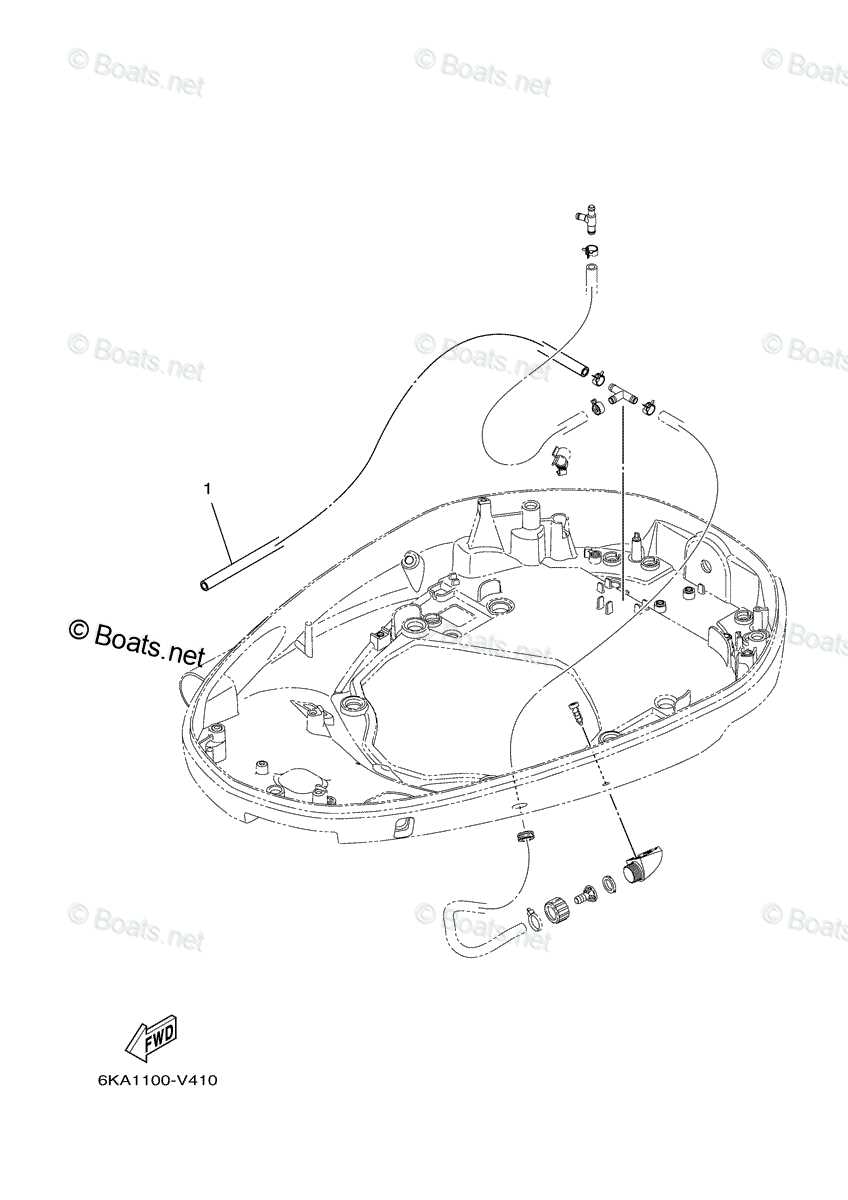

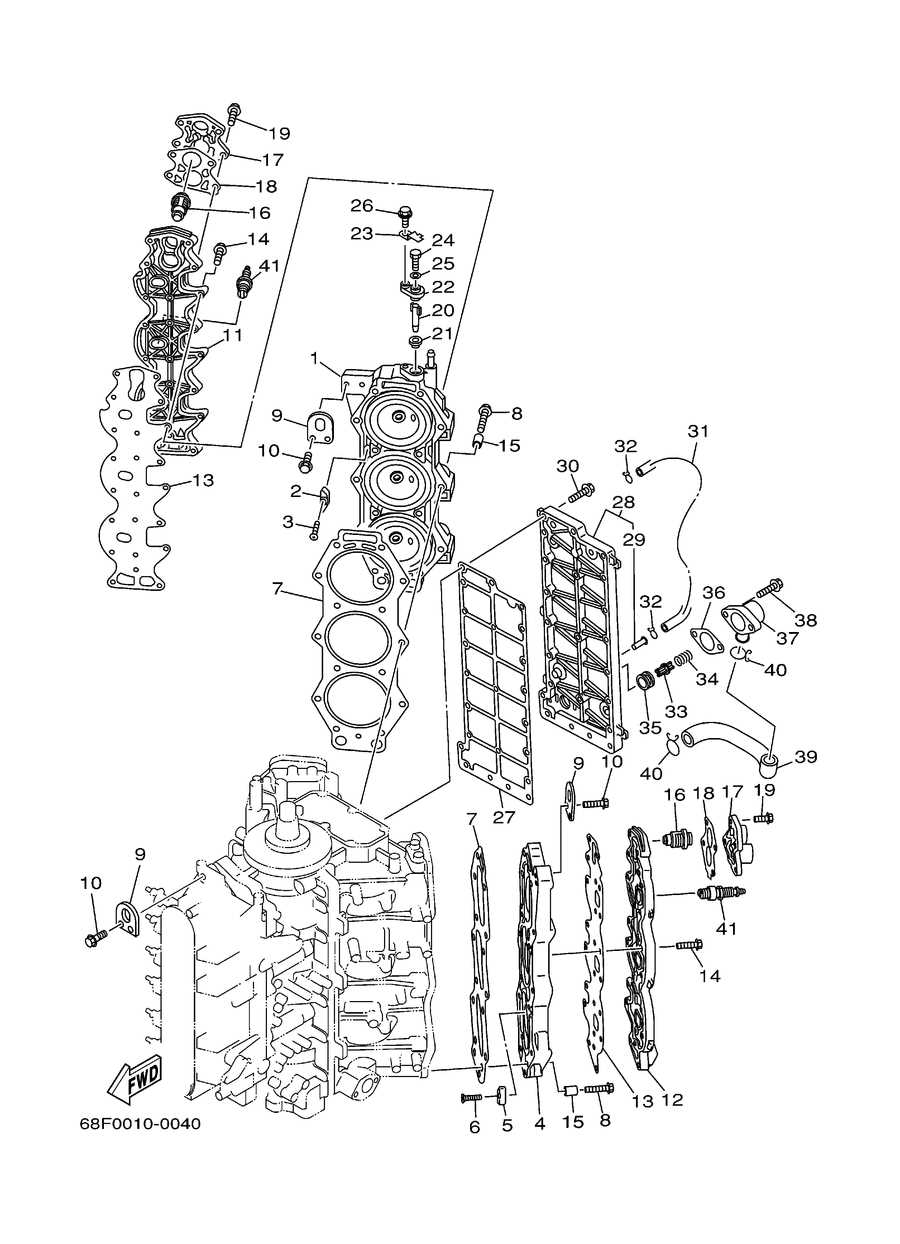

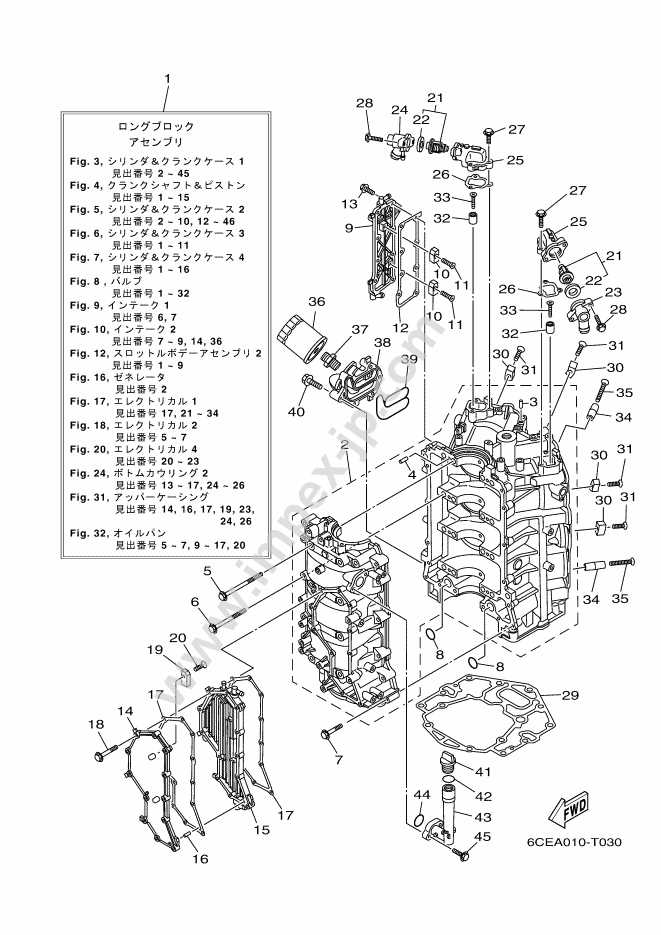

Comprehending the layout of engine components is essential for effective maintenance and repair. This visual representation serves as a crucial tool, offering insights into the intricate relationships between various elements of the machinery. By examining this schematic, users can identify each piece’s function and location, facilitating a more streamlined approach to servicing.

The illustration provides a clear overview, showcasing the assembly and arrangement of the key constituents. Each section is labeled to aid in recognizing parts quickly, which is invaluable for both novice and experienced technicians. This clarity helps in troubleshooting issues and ensuring that replacements are made accurately, contributing to the overall efficiency of the unit.

Moreover, understanding this layout enhances the ability to perform preventative maintenance. Familiarity with each component encourages regular checks and adjustments, ultimately prolonging the lifespan of the engine. A well-maintained machine not only performs better but also reduces the risk of costly repairs in the future.

In summary, mastering the visual representation of engine components is a fundamental aspect of upkeep. It empowers users to navigate repairs confidently, enhances operational efficiency, and fosters a proactive maintenance approach.

Key Components of Yamaha F300

The intricate design of this outboard engine comprises several essential elements that work in harmony to ensure optimal performance. Understanding these components is crucial for maintenance and enhancement of functionality.

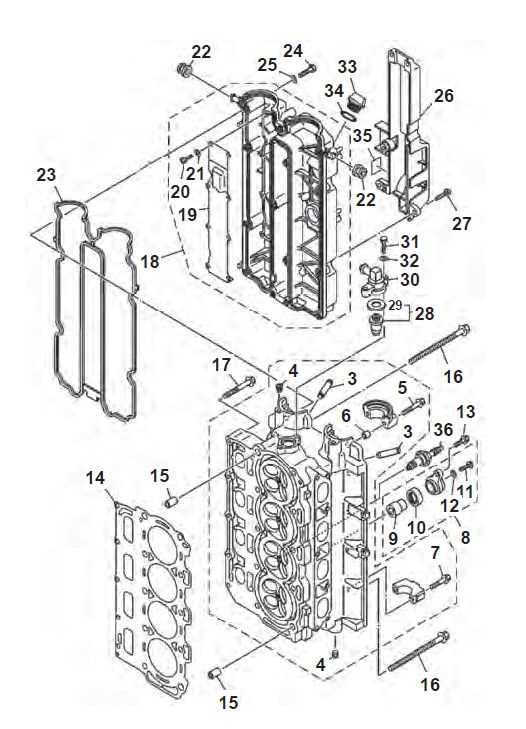

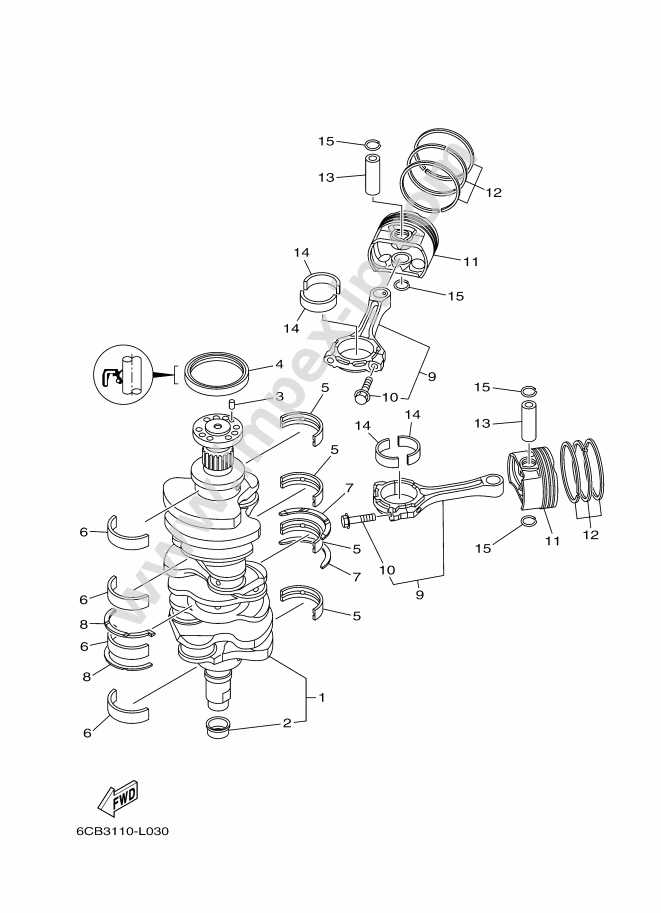

Powerhead serves as the heart of the engine, housing the combustion chamber and vital accessories. Its efficiency directly influences the overall output and reliability during operation.

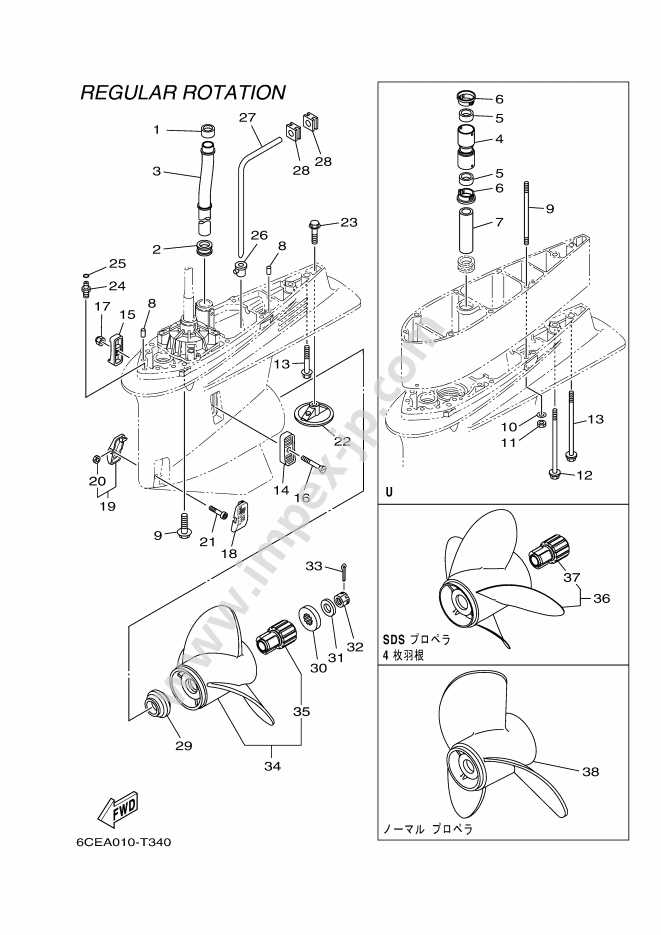

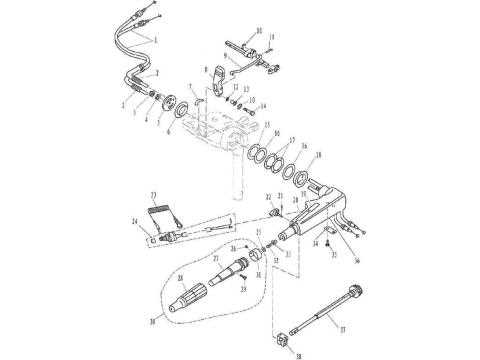

Lower Unit plays a critical role in propulsion, containing gears and shafts that transmit power to the propeller. This section is essential for smooth navigation and maneuverability on the water.

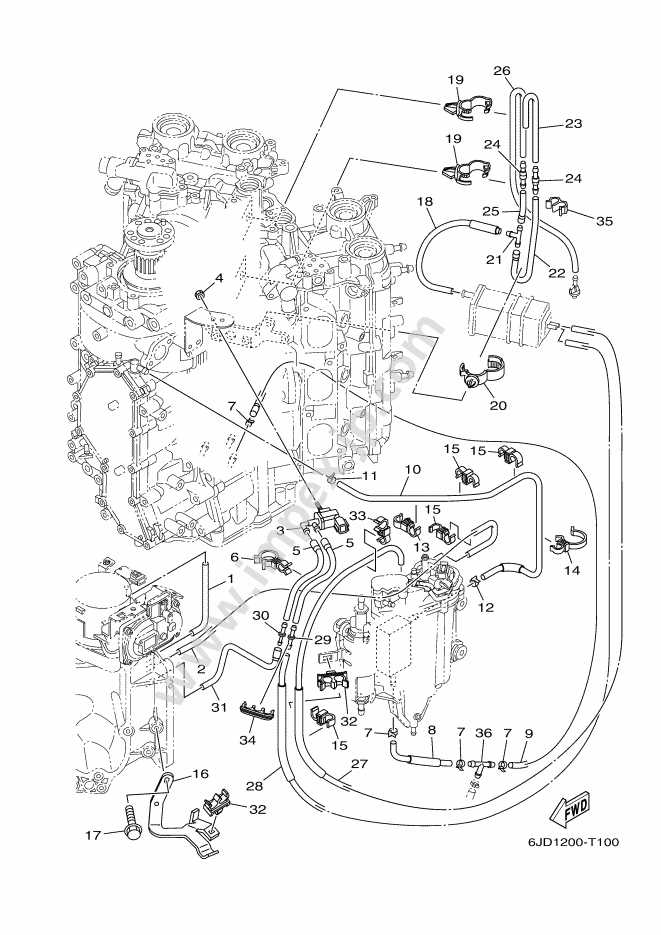

Fuel System is responsible for delivering the necessary energy for combustion. It includes injectors, filters, and pumps that ensure a consistent supply of fuel, maximizing efficiency and minimizing emissions.

Cooling System maintains optimal temperatures during operation, preventing overheating. This component circulates coolant, protecting sensitive parts and ensuring longevity.

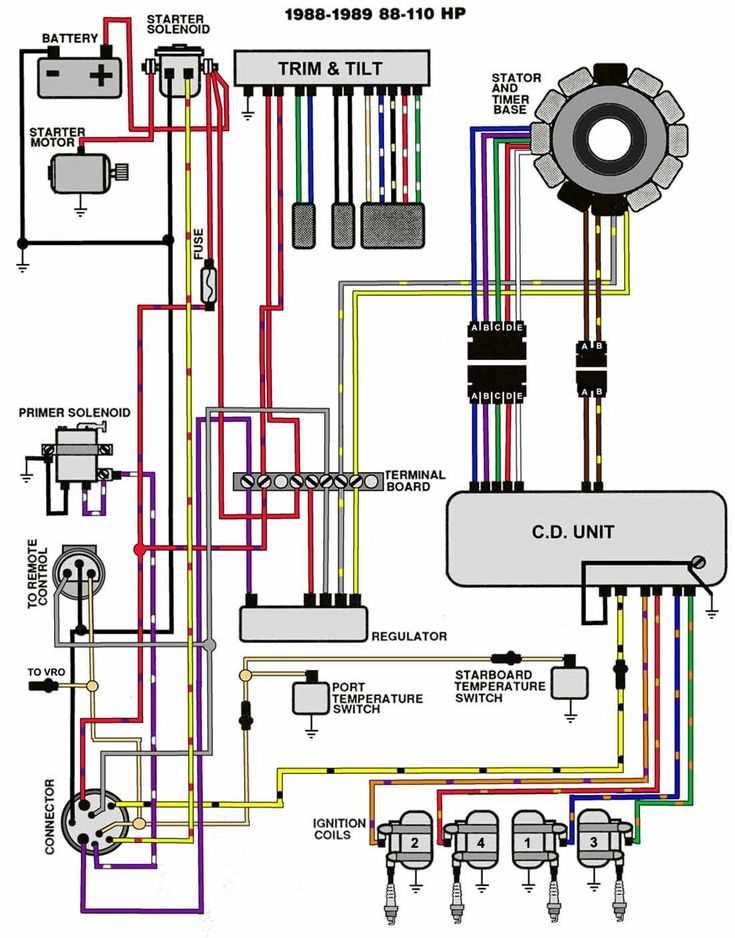

Electrical System supports ignition and operational functionality, integrating battery, wiring, and control modules. A reliable electrical setup is vital for starting and sustaining engine performance.

Steering Mechanism allows for precise navigation and control, enhancing safety and responsiveness while operating in various conditions. Its design contributes significantly to user experience and handling.

Each of these components is integral to the overall functionality, and understanding their roles can aid in effective maintenance and troubleshooting, ultimately ensuring a smooth experience on the water.

Importance of Accurate Parts Identification

Proper identification of components is crucial in maintaining the efficiency and longevity of any machinery. When each element is correctly recognized, it ensures that replacements are suitable, thereby minimizing the risk of malfunctions or damage. This meticulous approach not only enhances performance but also extends the lifespan of the equipment.

Precision in identifying each component allows for effective troubleshooting and maintenance. When technicians can pinpoint specific items, they can address issues swiftly, reducing downtime and increasing productivity. Moreover, understanding the exact specifications aids in selecting compatible replacements, avoiding the pitfalls of generic solutions.

The role of accurate identification goes beyond immediate repairs; it fosters a deeper understanding of the machinery’s overall functioning. When individuals familiarize themselves with each element, they become more adept at recognizing wear and tear, leading to proactive measures that can prevent costly repairs in the future.

In summary, recognizing the importance of precise component identification cannot be overstated. It is a fundamental practice that safeguards equipment integrity, enhances operational efficiency, and promotes informed decision-making in maintenance and repairs.

Common Issues with F300 Parts

When it comes to marine engines, certain components may encounter issues that can affect performance and reliability. Understanding these common problems can help in identifying early signs of wear or failure, ultimately leading to timely maintenance and repairs.

Here are some frequent concerns that users may face:

- Corrosion: Saltwater exposure can lead to rust and degradation of metal components.

- Fuel system troubles: Clogs or leaks can disrupt fuel delivery, causing poor engine performance.

- Electrical failures: Wiring issues or battery problems may result in starting difficulties.

- Cooling system blockages: Overheating can occur if the cooling passages are obstructed.

- Wear and tear: Regular usage can lead to component fatigue, necessitating replacements.

It is essential to routinely inspect these elements to maintain optimal functionality and prevent more significant issues down the line.

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone looking to maintain or repair machinery. These illustrations provide a clear representation of components and their interrelations, helping users identify the parts they need to work with. By familiarizing yourself with how to interpret these images, you can streamline the repair process and ensure that you are selecting the correct items for your needs.

Familiarize Yourself with Symbols and Labels

Most schematics employ a standard set of symbols and annotations. These can include various shapes to represent specific components, along with numerical identifiers. Take the time to study the legend that accompanies the illustration, as it will clarify what each symbol signifies. This foundational knowledge will enable you to navigate the graphic effectively.

Identify Key Components and Their Relationships

Once you understand the symbols, focus on identifying major elements and how they interact. Pay attention to connecting lines and arrows that illustrate movement or flow between parts. Recognizing these relationships is crucial for diagnosing issues and planning repairs, as it highlights which components may need attention or replacement.

Tools Required for Parts Replacement

When undertaking a replacement of components, having the right instruments on hand is crucial for a successful and efficient process. Proper tools not only facilitate the task but also help to avoid potential damage to the equipment. Below is a list of essential tools needed for this type of maintenance.

- Socket Wrench Set

- Phillips and Flathead Screwdrivers

- Pliers (Needle Nose and Standard)

- Torque Wrench

- Rubber Mallet

Additionally, certain tasks may require specialized tools:

- Gasket Scraper

- Oil Filter Wrench

- Multimeter for Electrical Components

- Inspection Mirror

- Parts Cleaning Brush

Ensure all tools are in good working condition before beginning the replacement procedure. This preparation will enhance efficiency and safety during the task.

Finding Genuine Yamaha Parts

Acquiring authentic components for your machinery is crucial for maintaining optimal performance and longevity. Ensuring that you choose high-quality items can significantly enhance reliability and safety. This section focuses on strategies to identify and secure genuine products that meet your specific needs.

Benefits of Using Authentic Components

Opting for original items offers numerous advantages, including:

- Enhanced durability and performance

- Guaranteed compatibility with existing systems

- Access to manufacturer warranties and support

- Improved resale value of the equipment

Where to Find Authentic Items

Locating genuine components can be streamlined by following these tips:

- Visit official dealerships or authorized retailers.

- Utilize online platforms that specialize in original merchandise.

- Participate in community forums and groups where experts share trusted resources.

- Check for certification and verification of products from sellers.

By following these guidelines, you can ensure that your equipment remains in top condition while using the highest quality components available.

Maintenance Tips for Yamaha F300

Regular upkeep is essential for ensuring optimal performance and longevity of your marine engine. Implementing a consistent maintenance routine not only enhances efficiency but also minimizes the likelihood of costly repairs. Here are some valuable tips to help you keep your engine in peak condition.

Routine Checks

Performing periodic inspections is crucial. Check the oil levels and replace the oil as recommended by the manufacturer. Ensure that the fuel system is clean and free of contaminants. Inspect the cooling system for blockages and make sure that the coolant is at the appropriate level. Regularly examine hoses and connections for wear and tear, and address any issues promptly.

Seasonal Maintenance

Before and after the boating season, conduct a thorough check. This includes cleaning or replacing the air filter, inspecting the battery, and ensuring that the propeller is in good condition. Store the engine in a dry and safe environment during off-seasons to protect it from the elements. A well-maintained engine will deliver reliable performance when you need it most.

Comparing F300 with Other Models

This section delves into the nuances of a specific engine variant in relation to its contemporaries. Understanding the differences and similarities between various models can aid in making informed decisions for potential buyers and enthusiasts alike.

When evaluating performance characteristics, several key factors stand out:

- Power Output: Each model may offer different horsepower ratings, impacting acceleration and overall performance.

- Fuel Efficiency: Variations in fuel consumption can influence operational costs, making some options more attractive for extended use.

- Weight: The overall weight affects maneuverability and installation processes, which can be crucial depending on the intended application.

In terms of design and construction, here are some aspects to consider:

- Materials Used: The choice of materials can affect durability and maintenance requirements.

- Technology Integration: Some models may feature advanced technology for improved performance and ease of use.

- Cooling Systems: Variations in cooling mechanisms can influence the reliability and efficiency during operation.

Ultimately, conducting a thorough comparison allows users to select an engine that aligns with their specific needs, whether for recreational use or professional applications.

DIY Repair: Step-by-Step Guide

Undertaking repairs on your equipment can be both rewarding and cost-effective. With the right approach and tools, you can troubleshoot issues, replace faulty components, and restore functionality without the need for professional help. This guide will walk you through a systematic process to handle common repairs, ensuring that you feel confident in your DIY skills.

Before starting any repair, it’s essential to prepare adequately. Here are the steps to follow:

- Gather Necessary Tools: Ensure you have all required tools handy. This may include:

- Wrenches

- Screwdrivers

- Replacement parts

- Multimeter

- Lubricants

- Identify the Problem: Conduct a thorough inspection to diagnose the issue. Look for:

- Unusual noises

- Leaks or drips

- Electrical faults

- Physical wear and tear

- Consult Resources: Utilize manuals or online resources to find specific guidance for your model.

- Disassemble Carefully: Begin the disassembly process, taking care to:

- Document the order of removal

- Store screws and parts systematically

- Handle components with care to avoid damage

- Replace or Repair Components: Once you have access to the problematic area, you can either:

- Replace damaged parts with new ones

- Perform repairs where feasible

- Reassemble: Carefully reassemble the unit, following your documentation. Ensure all parts are securely fastened.

- Test Your Work: After reassembly, conduct a thorough test to ensure everything is functioning correctly.

By following these steps, you can gain a deeper understanding of your equipment and save time and money on repairs. Happy fixing!

Resources for Yamaha F300 Owners

For enthusiasts and owners of high-performance marine engines, having access to reliable resources is essential for optimal maintenance and operation. This section provides a curated list of valuable tools and information tailored to help users navigate their engine’s needs effectively.

Online Forums and Communities: Engaging with fellow boaters and engine aficionados can offer insights and shared experiences. Online platforms dedicated to marine discussions often have threads focused on troubleshooting, upgrades, and best practices.

Official Manufacturer Websites: The manufacturer’s site typically features comprehensive resources including manuals, service bulletins, and recall information. These documents are crucial for understanding specifications and ensuring that the engine operates smoothly.

Technical Service Manuals: Investing in a detailed service manual can provide in-depth guidance on maintenance and repairs. These manuals often include diagrams and step-by-step instructions that simplify complex procedures.

Local Dealers and Service Centers: Building a relationship with authorized dealers can be beneficial for accessing genuine components and expert advice. Service centers staffed by trained technicians can offer professional maintenance tailored to specific models.

Online Retailers: Numerous e-commerce platforms specialize in marine equipment, offering a wide array of accessories and replacement components. Shopping online provides convenience and often more competitive pricing.

Video Tutorials: Platforms like YouTube are rich with instructional videos demonstrating various maintenance tasks. These visual guides can be incredibly helpful for those who prefer hands-on learning.

Utilizing these resources will ensure that owners can keep their marine engines in top condition, enhancing both performance and longevity.

Frequently Asked Questions About F300 Parts

This section aims to address common inquiries regarding components associated with the specific model. Understanding the essential elements can help ensure optimal performance and maintenance. Here, we provide answers to frequent questions, clarifying various aspects of these crucial items.

What are the key components of this model?

The essential elements include items such as the engine, transmission, and electrical systems. Each plays a vital role in the overall functionality, and knowing their specifics can aid in troubleshooting and repairs.

How can I identify a faulty component?

Signs of wear or malfunction may include unusual noises, decreased performance, or warning lights. Regular inspections and familiarity with typical operation can help in early identification of issues.

| Common Issue | Potential Cause | Recommended Action |

|---|---|---|

| Unusual Noise | Worn Bearings | Inspect and replace if necessary |

| Decreased Performance | Clogged Filters | Clean or replace filters |

| Warning Light | Sensor Malfunction | Run diagnostics and replace faulty sensor |