Comprehensive Guide to Briggs and Stratton 675EXI Parts Diagram

In the realm of small engine maintenance, a comprehensive grasp of the various elements is crucial for optimal performance. Enthusiasts and professionals alike benefit from familiarizing themselves with the intricate arrangements of engine components. This knowledge not only enhances repair efficiency but also extends the longevity of the machinery.

Utilizing visual aids can significantly simplify the troubleshooting process. By studying these illustrations, one can easily identify parts and their respective functions within the engine system. A well-structured layout serves as a valuable reference, guiding users through maintenance tasks and repairs.

Whether you are a seasoned technician or a casual user, having access to clear depictions of engine assemblies can make a substantial difference in your repair endeavors. Understanding each component’s role empowers you to tackle issues with confidence, ensuring that your equipment runs smoothly and reliably.

Understanding Briggs and Stratton 675EXi

This section explores the core features and operational insights of a specific engine model, providing a comprehensive overview of its functionality and components. Understanding these elements is crucial for optimal performance and maintenance.

Key Features

- Efficient power output

- Innovative design for easy starting

- Durability for various applications

Maintenance Tips

- Regularly check oil levels.

- Inspect air filters and replace as needed.

- Keep spark plugs clean for effective ignition.

By delving into these aspects, users can achieve the ultimate performance from their engine, ensuring longevity and reliability.

Key Components of the Engine

Understanding the essential elements that make up a small engine can greatly enhance maintenance and repair efforts. These components work in harmony to ensure optimal performance and reliability. Familiarity with these parts will empower users to diagnose issues effectively and keep their machinery running smoothly.

1. Cylinder and Piston

The cylinder serves as the core area where combustion occurs, while the piston moves up and down, transforming the energy from fuel into mechanical work. This interaction is crucial for the engine’s overall functionality.

2. Fuel System

The fuel system is responsible for delivering the right mixture of fuel and air to the combustion chamber. Proper operation of this system is vital for efficient engine performance. Regular checks can prevent common fuel-related issues.

Importance of Regular Maintenance

Consistent upkeep of machinery is vital for optimal performance and longevity. Neglecting regular care can lead to decreased efficiency, unexpected breakdowns, and costly repairs. A proactive approach ensures that all components function smoothly and remain in top condition.

Enhancing Performance

Regular inspections and servicing can significantly improve the functionality of your equipment. This attention to detail helps in identifying minor issues before they escalate, thereby maintaining high operational standards. When all parts are well-maintained, the overall productivity is enhanced.

Cost-Effectiveness

Investing time and resources into routine maintenance can save money in the long run. By preventing major malfunctions, owners can avoid expensive repairs and replacements. Furthermore, well-maintained equipment tends to consume less fuel and operate more efficiently, contributing to lower operational costs.

How to Access Parts Diagrams

Accessing component illustrations is crucial for effective maintenance and repair. These visuals help identify each part, ensuring a smooth replacement process and enhancing overall machine performance. Whether you’re a novice or an experienced technician, knowing where to find these resources can save time and reduce frustration.

Online Resources

Many manufacturers provide online portals where users can view and download component illustrations. By visiting the official website, you can typically search for specific models and access comprehensive resources.

Local Dealerships

Your local authorized dealership can also be a valuable resource. They often have printed materials available and can assist with obtaining the necessary illustrations for your specific model.

| Resource Type | Description |

|---|---|

| Manufacturer Website | Official online portal with downloadable visuals. |

| Local Dealership | Printed resources and expert assistance. |

| Repair Manuals | Comprehensive guides that include illustrations. |

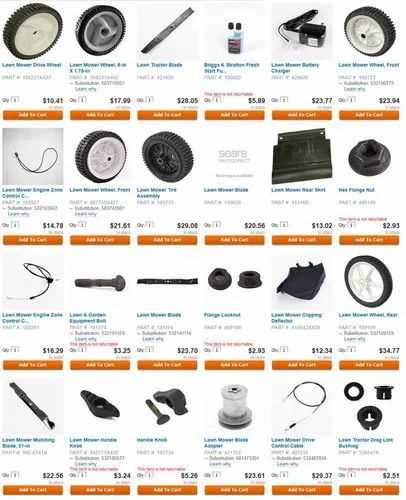

Common Replacement Parts Overview

Understanding the essential components that may require substitution is crucial for maintaining the efficiency and longevity of your outdoor power equipment. This section highlights key elements that often need attention, ensuring optimal performance and reliability.

Key Components

Among the most frequently replaced elements are the air filter, spark plug, and fuel filter. The air filter plays a vital role in keeping debris from entering the engine, while the spark plug is essential for igniting the fuel mixture. The fuel filter ensures that contaminants do not clog the fuel system, which can lead to operational issues.

Maintenance Tips

Regular inspections and timely replacements of these components can significantly enhance the functionality of your machine. Keeping an eye on wear and tear will help you address potential problems before they escalate, ensuring a smooth and effective operation during use.

Identifying Engine Issues Quickly

Recognizing problems in small engines can save time and prevent costly repairs. Understanding the common symptoms and their potential causes allows for swift diagnosis. Effective troubleshooting starts with a keen observation of the engine’s behavior during operation.

Listening for Unusual Noises: Pay attention to any irregular sounds that may indicate internal damage or wear. For instance, a knocking noise could suggest a failing component, while a high-pitched squeal may point to a belt issue.

Monitoring Performance: If the engine struggles to start or loses power during use, it could be a sign of fuel delivery or ignition problems. Regularly checking the air filter and fuel system can help maintain optimal performance.

Checking for Leaks: Fluid leaks can indicate serious issues. Examine the ground beneath the engine for any signs of oil or fuel, as these can lead to significant damage if left unaddressed.

Inspecting Spark Plug Condition: A worn or fouled spark plug can cause misfires or poor ignition. Regular inspection and replacement of the spark plug ensure reliable engine operation.

By keeping an eye on these key indicators, you can effectively pinpoint engine troubles early, facilitating timely interventions and maintenance.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments on hand is crucial for efficiency and success. A well-equipped toolkit can significantly simplify the repair process, ensuring that each component can be addressed with precision. Various tools will assist in disassembly, inspection, and reassembly, enabling a thorough job.

Essential items include a set of wrenches for loosening and tightening bolts, screwdrivers for adjusting and removing screws, and pliers for gripping and manipulating small parts. Additionally, a torque wrench may be necessary for applying specific pressure to fasteners, ensuring proper assembly without damage. It’s also beneficial to have a workbench or sturdy surface to provide a stable area for repairs.

Furthermore, protective gear such as gloves and safety goggles should not be overlooked, as they safeguard against injuries during the repair process. By assembling the appropriate tools and safety equipment, one can approach repair projects with confidence and proficiency.

Tips for Safe Disassembly

Disassembling machinery requires careful attention to detail to ensure safety and efficiency. Following specific guidelines can help avoid accidents and damage during the process.

- Always wear appropriate safety gear, including gloves and goggles.

- Work in a well-lit, clutter-free environment to maintain focus.

- Disconnect power sources before starting any work to prevent accidental activation.

- Use the right tools for the job to avoid stripping screws or damaging components.

Additionally, consider the following:

- Take photos of each step to assist with reassembly.

- Label parts and screws to keep everything organized.

- Follow the manufacturer’s guidelines for disassembly procedures.

- Keep small parts in containers to prevent loss.

Ordering Genuine Replacement Parts

Acquiring authentic components is essential for maintaining the efficiency and longevity of your equipment. Opting for original pieces ensures compatibility and reliability, ultimately enhancing performance.

Benefits of Genuine Components

- Superior quality and durability

- Perfect fit for seamless installation

- Increased reliability and performance

How to Order

- Identify the specific component needed.

- Visit the official website or authorized retailer.

- Provide the model number for accurate results.

- Review options and place your order.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves a series of essential practices that promote optimal functionality and prevent premature wear. By committing to regular upkeep, you can enhance performance and minimize costly repairs.

1. Regular Cleaning: Keep your machine free from dirt and debris. A clean exterior prevents corrosion and maintains efficient operation.

2. Oil Changes: Frequent oil replacements are crucial. Fresh lubricant reduces friction and extends engine life, so check the manufacturer’s recommendations for intervals.

3. Air Filter Maintenance: Inspect and replace the air filter as needed. A clean filter ensures proper airflow, improving combustion efficiency and engine performance.

4. Spark Plug Checks: Periodically examine the spark plugs for wear. Replacing them when necessary helps maintain smooth ignition and reduces fuel consumption.

5. Fuel Quality: Use high-quality fuel to prevent engine deposits. Stale or contaminated fuel can lead to performance issues and damage components.

6. Storage Practices: When not in use, store equipment in a dry and sheltered place. Proper storage protects it from environmental factors that can cause deterioration.

7. Seasonal Inspections: Before heavy usage, conduct thorough checks to identify potential issues. Addressing problems early can save time and expense later.

Implementing these strategies will not only ensure peak performance but also maximize the lifespan of your valuable machinery.

Frequently Asked Questions on 675EXi

This section addresses common inquiries related to the engine model in question. Users often seek clarification on various aspects, from maintenance to troubleshooting. Below are some of the most frequently posed questions.

- What is the recommended maintenance schedule?

Regular maintenance is essential for optimal performance. Generally, it’s advisable to check the oil level before each use and change the oil every 50 hours of operation. Additionally, air filters should be inspected and cleaned regularly.

- How do I troubleshoot starting issues?

If the engine fails to start, consider the following steps:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for damage or wear.

- Ensure the choke is in the correct position.

- Examine the battery connections, if applicable.

- Where can I find replacement components?

Replacement components can typically be sourced from local hardware stores, specialized retailers, or online marketplaces. Always ensure that the components are compatible with your specific model.

- What should I do if I notice excessive smoke?

Excessive smoke can indicate several issues, such as:

- Overfilled oil reservoir

- Worn piston rings

- Faulty fuel mixture

If the problem persists, consult a professional for assistance.

- How can I enhance fuel efficiency?

Improving fuel efficiency can be achieved through:

- Regular maintenance and tune-ups

- Using high-quality fuel

- Avoiding prolonged idle time

These FAQs serve as a guide for users to better understand and maintain their engines, ensuring longevity and reliability.