Understanding the Exmark Turf Tracer Parts Diagram for Effective Maintenance

When it comes to maintaining and optimizing the efficiency of your lawn maintenance equipment, having a clear visual representation of its components can be invaluable. Such illustrations serve as a guide, helping you identify each part and understand its function within the overall machinery. This knowledge empowers users to tackle repairs and replacements with confidence, ensuring that the equipment operates smoothly and effectively.

Each piece of equipment consists of various elements, each playing a crucial role in the machine’s performance. Familiarizing yourself with these elements not only aids in troubleshooting but also enhances your ability to perform routine maintenance. This proactive approach can extend the lifespan of your equipment, saving both time and resources in the long run.

By exploring the intricate layout of these components, users can gain insight into how everything fits together, leading to a deeper understanding of their machine. Whether you are a seasoned professional or a novice gardener, having access to a comprehensive visual guide can make a significant difference in your maintenance practices.

Understanding Exmark Turf Tracer Parts

Having a thorough comprehension of the various components that make up a lawn maintenance machine is essential for effective operation and maintenance. Familiarity with each element not only aids in troubleshooting issues but also enhances the overall performance of the equipment. This section delves into the crucial elements, their functions, and the importance of regular maintenance.

Key Components

- Engine: The powerhouse of the machine, responsible for providing the necessary energy for operation.

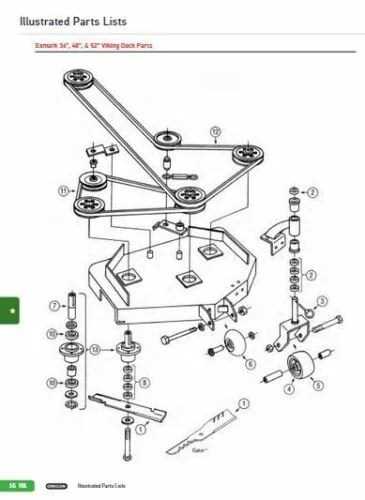

- Deck: The cutting unit that houses the blades, designed to deliver a clean and even cut.

- Wheels: Essential for mobility, these components ensure smooth navigation across various terrains.

- Controls: The interface for the operator, allowing for adjustments in speed and direction.

- Chassis: The frame that supports all other components, providing stability and structure.

Maintenance Tips

- Regularly check and change the oil to ensure optimal engine performance.

- Inspect and sharpen the blades to maintain cutting efficiency.

- Examine belts and cables for wear and tear to prevent unexpected breakdowns.

- Clean the deck after each use to prevent grass buildup and corrosion.

- Check tire pressure and condition for safe and efficient movement.

By understanding the key components and adhering to maintenance practices, operators can ensure their equipment remains in peak condition, ready to tackle any lawn care challenge.

Importance of Parts Diagrams

Understanding the intricate components of any machinery is essential for maintenance and repair. Visual representations serve as vital resources, enabling users to identify and locate essential elements efficiently. This clarity can significantly enhance the repair process and ensure that machinery operates at its best.

Enhancing Repair Efficiency

Having a visual guide allows technicians and users to pinpoint specific items quickly. This reduces the time spent searching for particular components, streamlining the overall maintenance process. With clear illustrations, identifying wear and tear becomes easier, leading to timely replacements and minimizing downtime.

Facilitating Communication

Illustrated guides improve communication between team members, especially in collaborative settings. When discussing repairs or upgrades, referring to a shared visual reference eliminates confusion and fosters a clearer understanding of what needs attention. This ensures everyone is on the same page, enhancing teamwork and productivity.

In summary, visual guides are indispensable tools for anyone involved in the upkeep of machinery. They not only simplify the repair process but also promote effective communication among users.

Overview of Turf Tracer Models

This section provides an in-depth look at various models within a popular range of mowing equipment designed for efficient lawn care. Each variant showcases unique features tailored to meet diverse landscaping needs, ensuring optimal performance across different environments.

Key Features of Different Models

- Engine Performance: Varying horsepower options to suit various yard sizes.

- Mowing Decks: Different cutting widths and configurations for precise trimming.

- Control Systems: Innovative steering and throttle controls for ease of use.

- Durability: Robust construction designed to withstand heavy-duty use.

Model Comparisons

- Standard Model: Ideal for residential lawns, offering balance between power and maneuverability.

- Commercial Model: Engineered for professional landscapers with enhanced speed and capacity.

- Compact Model: Suitable for tight spaces and smaller properties, providing agility without compromising quality.

Understanding the distinct characteristics of each model aids users in selecting the most appropriate machine for their specific landscaping requirements, ensuring efficiency and satisfaction with every cut.

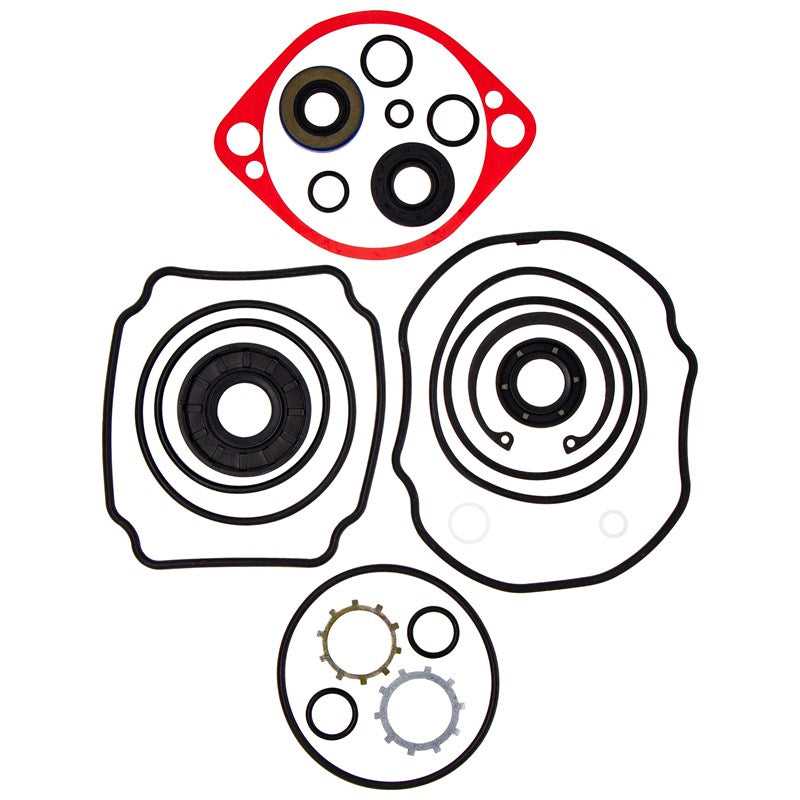

Common Replacement Parts Explained

When it comes to maintaining outdoor machinery, understanding the components that may require frequent replacement is crucial. Knowing which elements are prone to wear and tear can help ensure optimal performance and longevity of the equipment.

Blades

Blades are essential for achieving a clean cut. Over time, they can become dull or chipped, affecting the quality of the lawn. Regularly checking and replacing blades can enhance cutting efficiency and reduce the risk of damage to the grass.

Filters

Filters play a vital role in keeping the engine running smoothly. Air and oil filters need to be inspected periodically and replaced as necessary to prevent debris from causing engine wear. Maintaining clean filters helps improve fuel efficiency and overall performance.

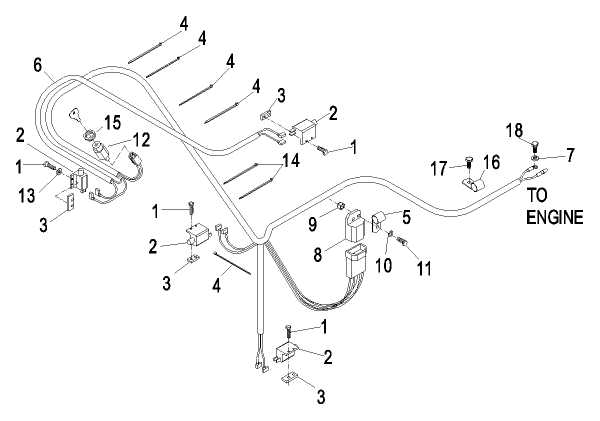

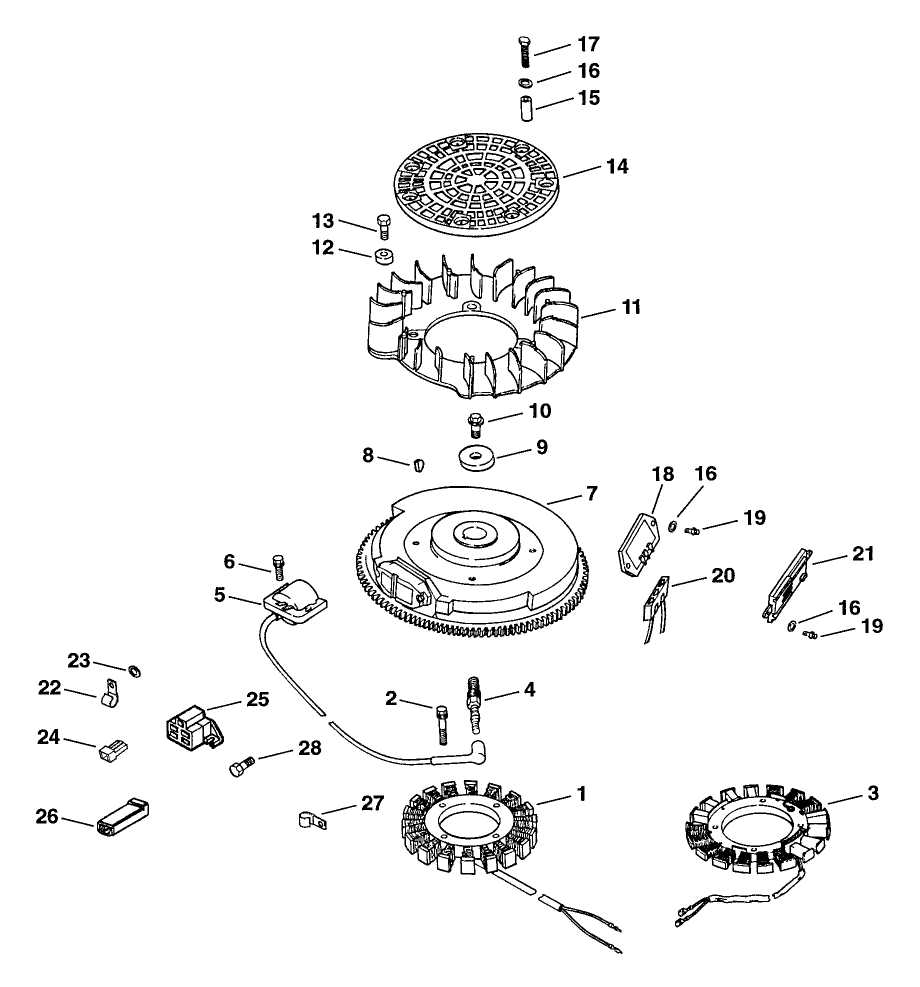

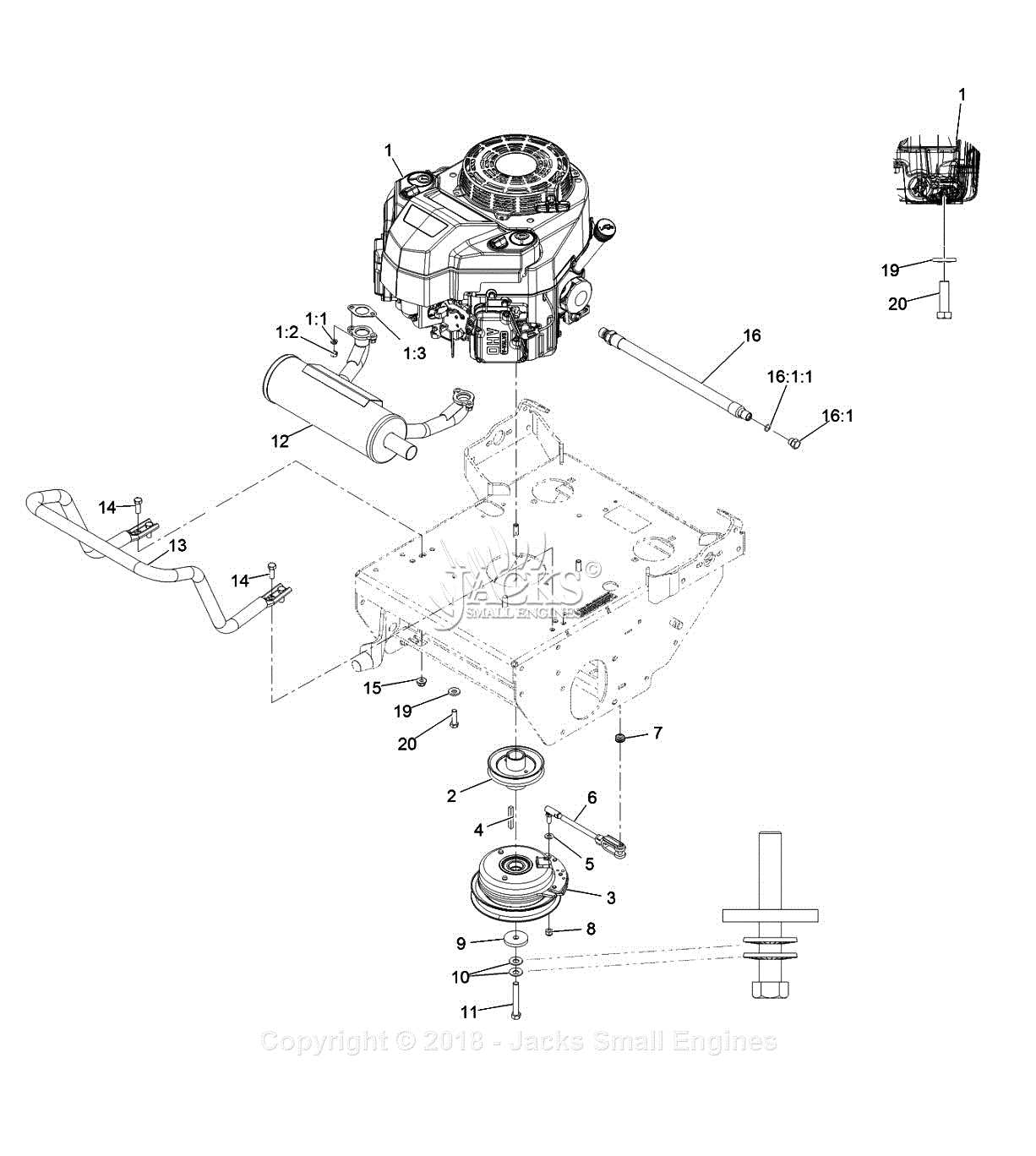

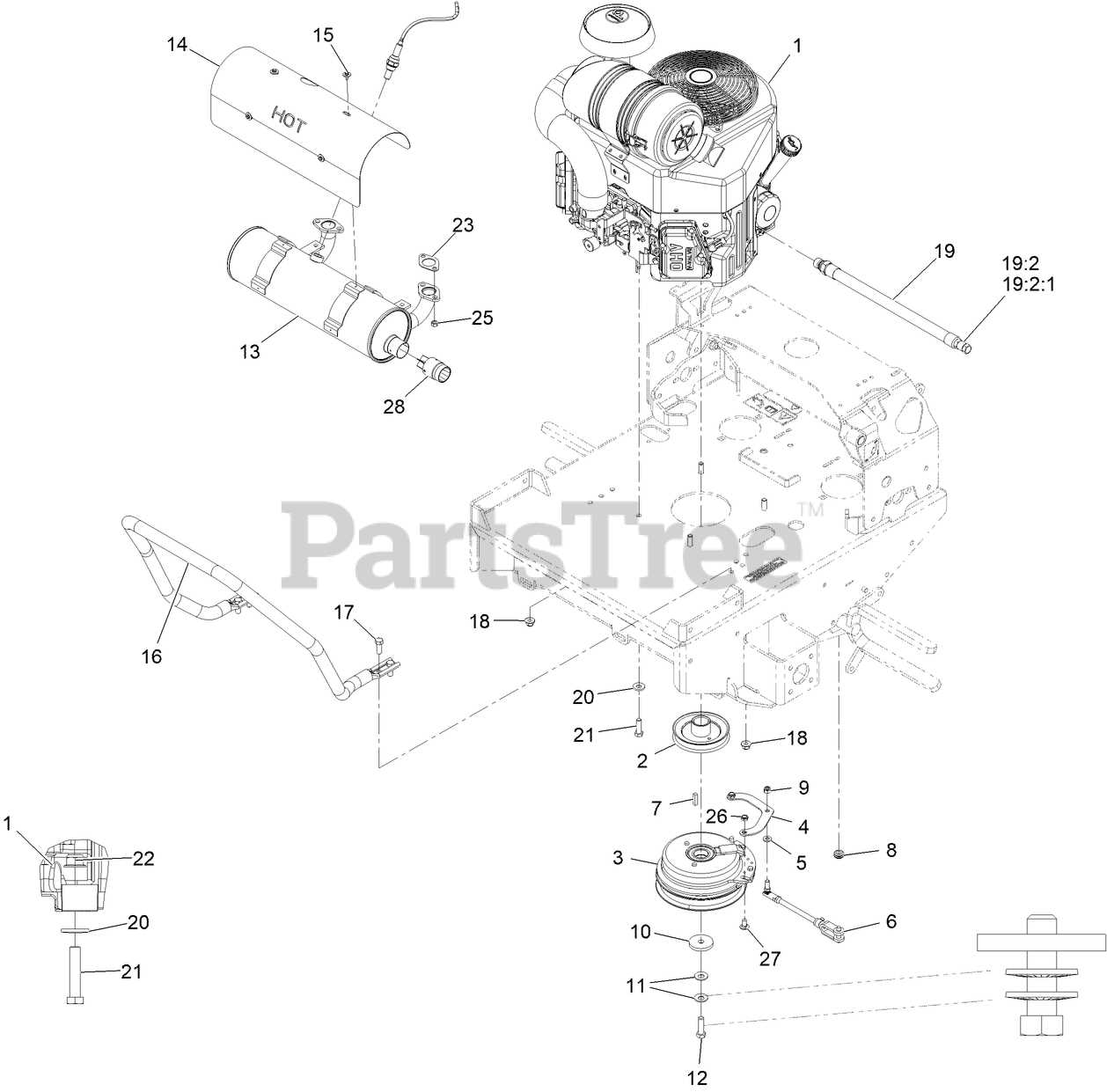

How to Read Parts Diagrams

Understanding visual schematics can significantly enhance your ability to identify and acquire necessary components for machinery. These illustrations provide a clear and concise representation of various elements and their relationships, enabling users to navigate complex systems with ease. Mastering this skill is essential for effective maintenance and repairs.

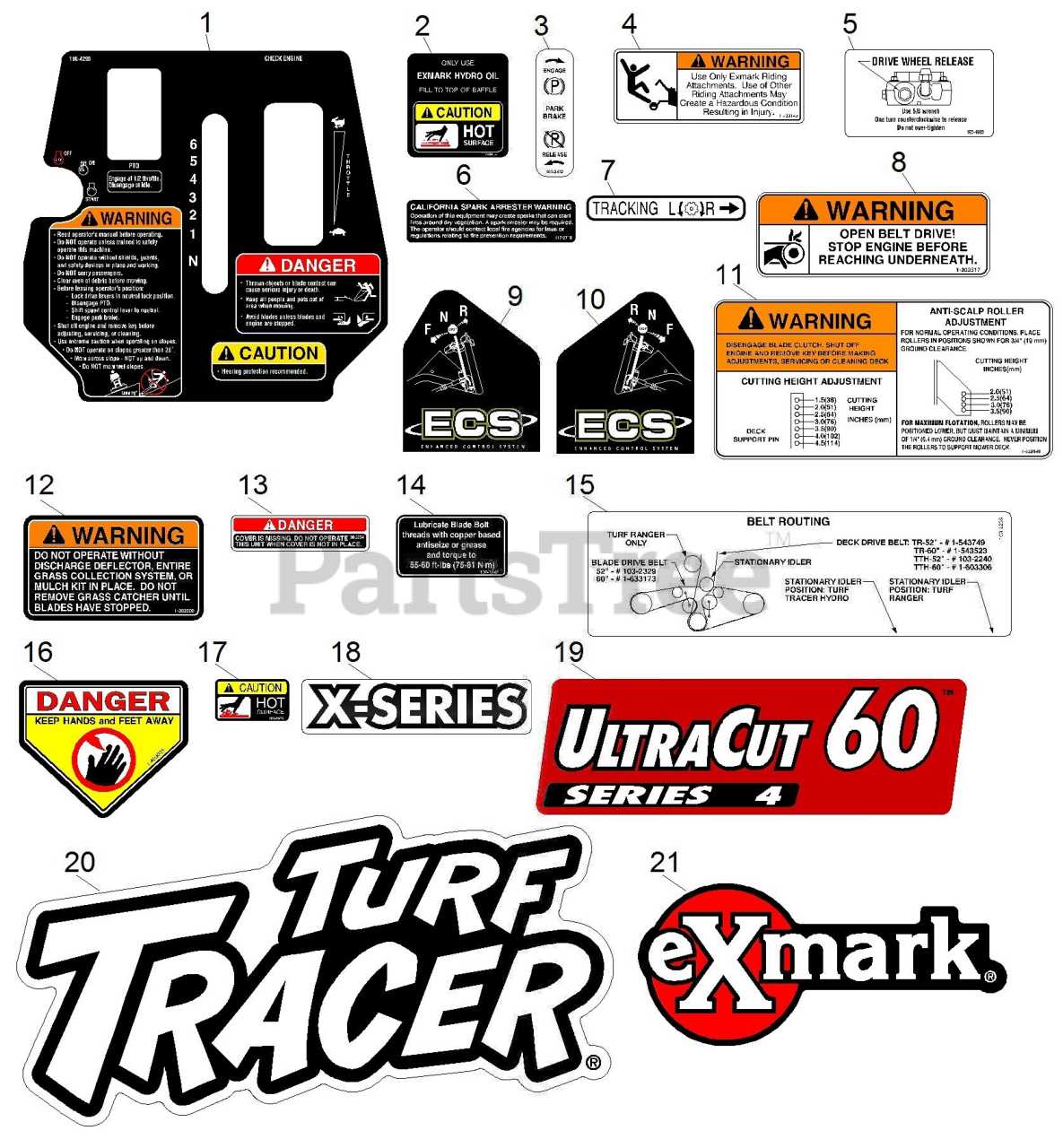

Interpreting Symbols and Labels

Each illustration typically includes a set of symbols and labels that represent specific elements. Familiarizing yourself with these icons is crucial for accurate identification. Pay attention to any accompanying text, as it often provides valuable information regarding the component’s function or part number. Highlighting key elements will streamline your search for the correct item.

Following the Flow of the System

Another important aspect is understanding how the components interact within the overall system. Look for directional arrows or lines that indicate connections between parts. This visual guidance helps in grasping the operational sequence, allowing you to see how each element contributes to the machinery’s performance. By following these connections, you can troubleshoot issues more effectively and ensure all parts are functioning harmoniously.

Finding Authentic Exmark Parts

When it comes to maintaining your landscaping equipment, sourcing genuine components is crucial for optimal performance and longevity. Counterfeit items may seem appealing due to lower costs, but they often compromise efficiency and safety. Ensuring that you acquire legitimate elements not only enhances functionality but also protects your investment over time.

Identifying Genuine Components

To distinguish authentic elements from imitations, always look for trusted suppliers who provide clear information about the origin and quality of their merchandise. Examine the packaging for official branding and verify the serial numbers against manufacturer records. These steps can save you from potential frustrations and costly repairs down the line.

Where to Purchase

Reputable dealerships and authorized online platforms are your best bet for finding original items. Additionally, engaging with local service providers can offer insights and recommendations tailored to your specific needs. Investing time in research will pay off by ensuring that your machinery operates at its best, safeguarding both your equipment and your projects.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By adopting proper maintenance practices, you can significantly extend the lifespan of your machinery while optimizing performance. Below are essential strategies to keep your equipment in peak condition.

Regular Inspections

Conducting frequent checks is crucial for identifying potential issues before they escalate. Pay attention to the following:

- Examine belts and cables for signs of wear.

- Check fluid levels and top off as necessary.

- Inspect tires for proper inflation and tread wear.

- Look for loose bolts and fasteners.

Cleaning and Lubrication

Keeping your machinery clean and well-lubricated helps prevent rust and reduces friction, enhancing overall functionality. Consider these tips:

- Clean debris from components after each use.

- Use appropriate lubricants on moving parts regularly.

- Remove any accumulated dirt or grass clippings.

- Ensure air filters are free from obstructions.

By following these maintenance tips, you will not only prolong the life of your equipment but also ensure that it operates smoothly and efficiently for years to come.

Identifying Wear and Tear Issues

Recognizing signs of deterioration in machinery is crucial for maintaining optimal performance and longevity. Regular inspections can help detect minor issues before they escalate into significant problems, ensuring your equipment operates efficiently. Understanding the common areas where wear can occur will empower you to take proactive measures.

Common Signs of Deterioration

Various components may exhibit signs of wear over time. Key indicators include unusual noises, reduced efficiency, or physical damage. Identifying these symptoms early can save time and resources in repairs and replacements.

Inspection Checklist

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Blades | Chipping, dull edges | Sharpen or replace |

| Belt | Fraying, cracking | Replace immediately |

| Wheels | Flat spots, cracks | Inspect and replace if necessary |

| Engine | Excessive noise, vibrations | Check for loose parts |

By routinely examining these elements, you can maintain the functionality of your equipment and prevent costly downtime. Regular maintenance not only enhances performance but also extends the lifespan of your machinery.

Tools Required for Part Replacement

When it comes to replacing components in machinery, having the right tools is essential for a successful and efficient process. Utilizing the proper equipment not only ensures safety but also enhances the longevity and performance of the machine. Below, we outline the key tools necessary for undertaking replacement tasks effectively.

Basic Hand Tools

To begin with, a selection of basic hand tools is crucial. A wrench set allows for the loosening and tightening of various fasteners, while a screwdriver set provides the ability to handle different types of screws. Additionally, a hammer can be useful for gentle persuasion, and pliers can help grasp and manipulate smaller components. Having these tools readily available can streamline the replacement process significantly.

Specialized Equipment

In some cases, specialized equipment may be required to complete the job effectively. A socket set is invaluable for tackling stubborn bolts, while a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications. Furthermore, a mechanic’s creeper can provide comfort and mobility when working under machinery, making the entire operation smoother and more efficient.

Step-by-Step Repair Guide

This guide is designed to assist you in troubleshooting and fixing common issues with your outdoor equipment. By following a systematic approach, you can identify problems and execute repairs effectively, ensuring optimal performance.

1. Gather Necessary Tools and Materials

Before you start, collect all essential tools such as wrenches, screwdrivers, and replacement components. Having everything on hand will streamline the process.

2. Safety First

Always prioritize safety. Disconnect the power source and wear protective gear, including gloves and goggles, to prevent injuries during the repair.

3. Identify the Issue

Carefully observe the equipment to determine the exact problem. Listen for unusual sounds, check for leaks, and look for signs of wear or damage.

4. Consult the Manual

Refer to the user manual for detailed information on the specific model. This will provide insights into common issues and recommended troubleshooting steps.

5. Disassemble with Care

Begin the disassembly process by removing screws and bolts systematically. Keep track of all parts, using labeled containers if necessary to avoid confusion during reassembly.

6. Inspect Components

Thoroughly examine each part for damage. Look for cracks, rust, or wear that may affect functionality. Replace any compromised components as needed.

7. Reassemble the Equipment

Once repairs are completed, carefully reassemble the equipment in reverse order of disassembly. Ensure all screws and bolts are tightened securely to prevent future issues.

8. Test the Equipment

Reconnect the power source and conduct a test run. Monitor performance to confirm that the repairs were successful and that everything operates smoothly.

9. Regular Maintenance

Implement a routine maintenance schedule to keep your equipment in top condition. Regular checks can prevent issues from arising and extend the lifespan of your machinery.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and their maintenance, providing clarity for users seeking information on functionality and compatibility. Understanding these elements can enhance the overall performance and longevity of your equipment.

What are the most common issues with components?

Users often encounter wear and tear, which can lead to reduced efficiency. Common issues include malfunctioning blades, faulty belts, and degraded filters. Regular inspections can help identify these problems early, ensuring smoother operation.

How can I find the right replacement components?

To ensure compatibility, always refer to the manufacturer’s guidelines or part numbers. Utilizing reputable suppliers and consulting with professionals can also aid in selecting the appropriate replacements for your specific model.

Comparing Turf Tracer Models

When assessing various models of professional lawn maintenance equipment, it’s crucial to consider the unique features and specifications that set them apart. Each model caters to specific needs, offering different capabilities, engine options, and overall performance. Understanding these distinctions can help users select the right machine for their landscaping tasks.

Key Features

One of the primary aspects to examine is the engine performance. Different variants may come with varying horsepower ratings, impacting their efficiency in handling diverse terrains. Additionally, cutting widths can differ significantly, affecting the time taken to complete a job. For example, some models may feature a wider deck, allowing for quicker mowing, while others may offer better maneuverability in tight spaces.

Durability and Maintenance

Another essential factor to consider is the build quality and ease of maintenance. High-quality materials can lead to increased longevity and less frequent repairs. Furthermore, some designs incorporate user-friendly features that simplify routine servicing, ensuring that equipment remains in optimal condition. Comparing the maintenance requirements of each model can reveal which options are more suited for regular use.

Where to Buy Turf Tracer Parts

Finding components for your landscaping equipment can be straightforward if you know where to look. Whether you need replacements or upgrades, various sources offer quality items tailored to your machine’s specifications. Here are some effective options for acquiring the necessary equipment parts.

Authorized Dealers

One of the most reliable sources for quality components is through authorized dealers. They often carry a comprehensive selection of items that meet manufacturer standards. This ensures compatibility and reliability for your machinery.

Online Retailers

Numerous online platforms specialize in machinery components, providing a vast array of options. These retailers often have user-friendly interfaces that allow for easy searching and comparison. Additionally, customer reviews can guide your purchasing decisions.

| Source Type | Pros | Cons |

|---|---|---|

| Authorized Dealers | Quality assurance, expert advice | Higher prices |

| Online Retailers | Wide selection, competitive pricing | Shipping times, variable quality |

| Local Repair Shops | Convenient, personal service | Limited inventory |

By exploring these options, you can ensure that your equipment remains in optimal condition and continues to perform efficiently. Always consider factors such as quality, price, and availability when making your selection.