Understanding the Surface Cleaner Parts Diagram for Optimal Performance

The intricate assembly of cleaning apparatus plays a pivotal role in maintaining efficiency and effectiveness in various tasks. Each segment of this machinery contributes uniquely to its overall functionality, ensuring optimal performance during use.

Identifying the individual elements is essential for users aiming to enhance their understanding and skills in handling such devices. By examining these components, one can uncover the underlying mechanics that drive these machines and appreciate their design.

Furthermore, a comprehensive grasp of the specific functions each piece serves can lead to better maintenance practices, ultimately extending the lifespan of the equipment. Delving into these details provides invaluable insights for both novice and experienced users.

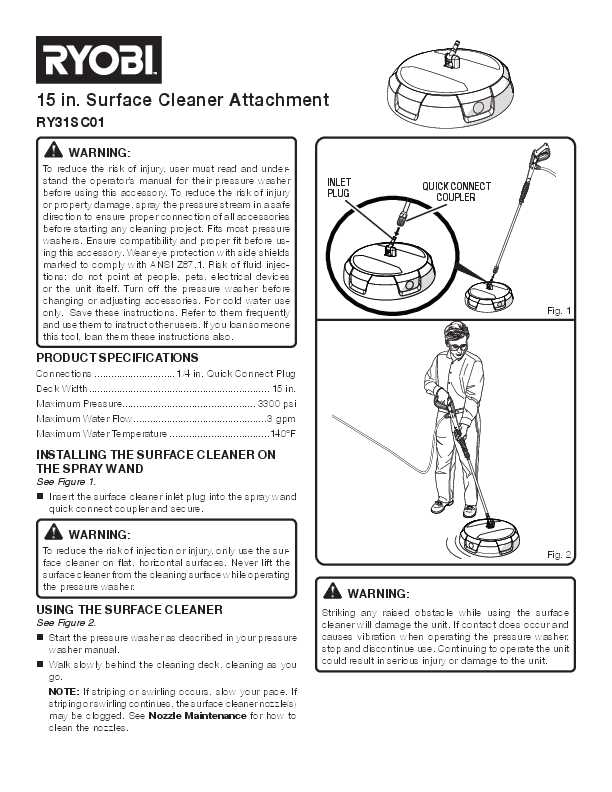

Understanding Surface Cleaners

When it comes to maintaining outdoor areas, the right equipment can make all the difference. These specialized tools are designed to enhance efficiency and deliver superior results, transforming tedious tasks into manageable ones. By understanding their components and functions, users can maximize their effectiveness and ensure longevity.

Key Components

- Rotary mechanism: This element spins at high speeds, allowing for thorough coverage.

- Nozzles: Strategic placement of these outlets ensures even distribution of water or cleaning solution.

- Handle: Provides control and maneuverability, making it easier to navigate different surfaces.

- Housing: The protective outer shell shields internal mechanisms from damage and wear.

Benefits of Effective Usage

- Time-saving: Completing large areas quickly reduces labor costs and effort.

- Uniform results: Achieving consistent cleanliness enhances the appearance of surfaces.

- Versatility: Adaptable for various tasks, from driveways to patios, making it a valuable tool in any maintenance arsenal.

- Eco-friendly options: Many models allow for the use of less water and chemical solutions, promoting sustainability.

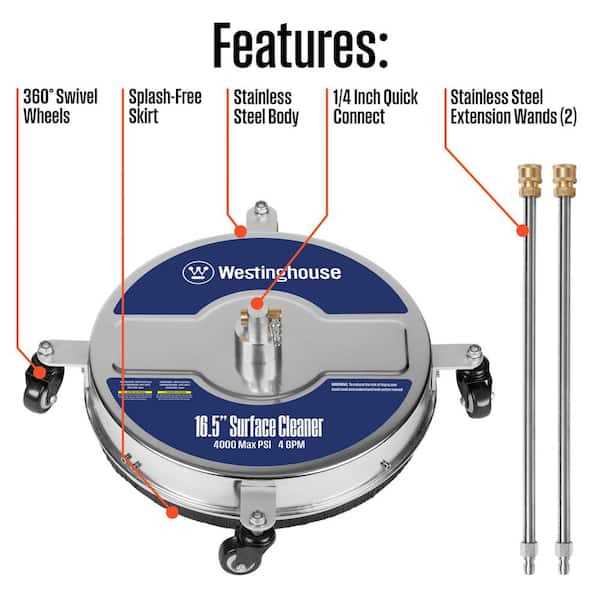

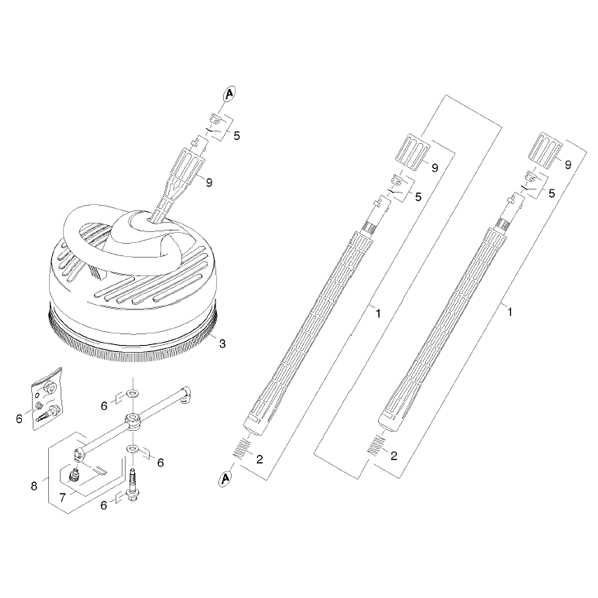

Components of Surface Cleaners

This section delves into the essential elements that contribute to the effective operation of cleaning devices designed for flat surfaces. Understanding these components can enhance the user’s ability to maintain and optimize their performance, ensuring a thorough and efficient cleaning process.

Main Elements

The core elements play a crucial role in the functionality and efficiency of these cleaning machines. Each component serves a specific purpose that contributes to the overall cleaning action.

| Component | Description |

|---|---|

| Housing | The outer shell that protects internal components and enhances durability. |

| Rotary Mechanism | Enables circular movement, allowing for effective scrubbing and debris removal. |

| Nozzles | Directs the flow of cleaning solution or water, ensuring even coverage. |

| Wheels | Facilitates smooth movement across surfaces, minimizing user effort. |

| Handles | Provides control and maneuverability, allowing the user to guide the device easily. |

Supporting Features

Additional features can enhance the versatility and usability of these cleaning tools. Understanding these supportive elements helps in selecting the right device for specific tasks.

| Feature | Benefit |

|---|---|

| Adjustable Pressure | Allows customization of cleaning intensity for different surface types. |

| Detachable Parts | Facilitates easy cleaning and maintenance of the device itself. |

| Built-in Storage | Provides convenient space for storing cleaning solutions and tools. |

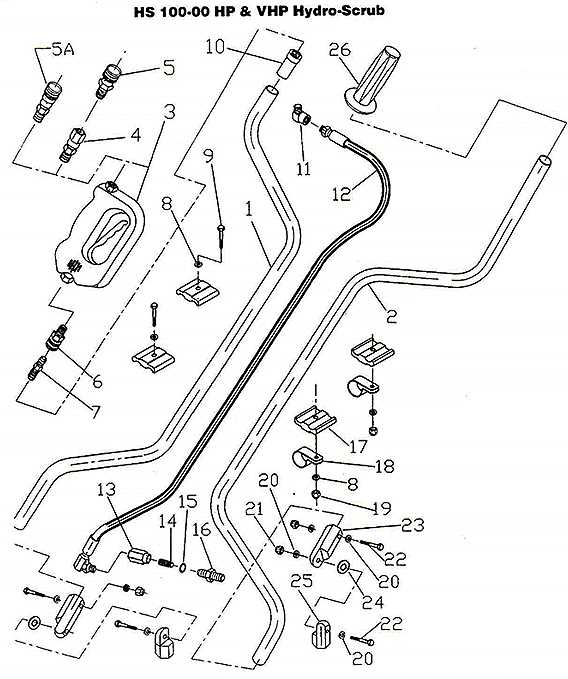

Importance of Maintenance Diagrams

Understanding the components and their arrangement is crucial for effective upkeep and longevity of any machinery. Clear representations guide users in recognizing essential elements, ensuring proper care and functionality. Regular reference to these visuals can prevent costly breakdowns and enhance operational efficiency.

Enhanced Understanding

Visual aids provide clarity, making it easier for users to identify individual elements and their roles. This comprehension is vital for troubleshooting and repairs, as it allows for quicker diagnosis and resolution of issues.

Prevention of Errors

Referencing maintenance visuals minimizes the risk of mistakes during servicing. By following established layouts, users can ensure they are handling components correctly, reducing the chance of damage and extending the lifespan of the equipment.

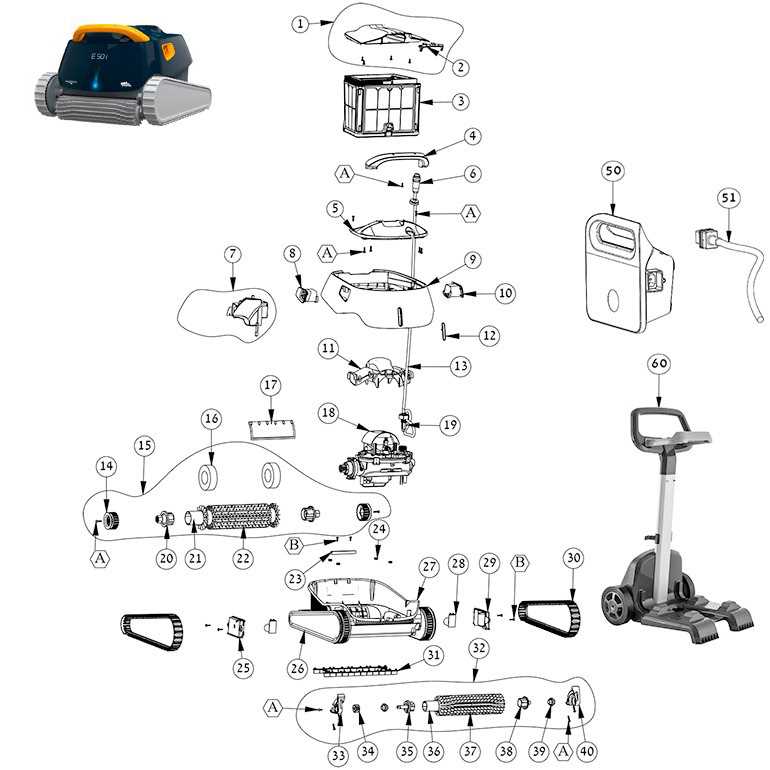

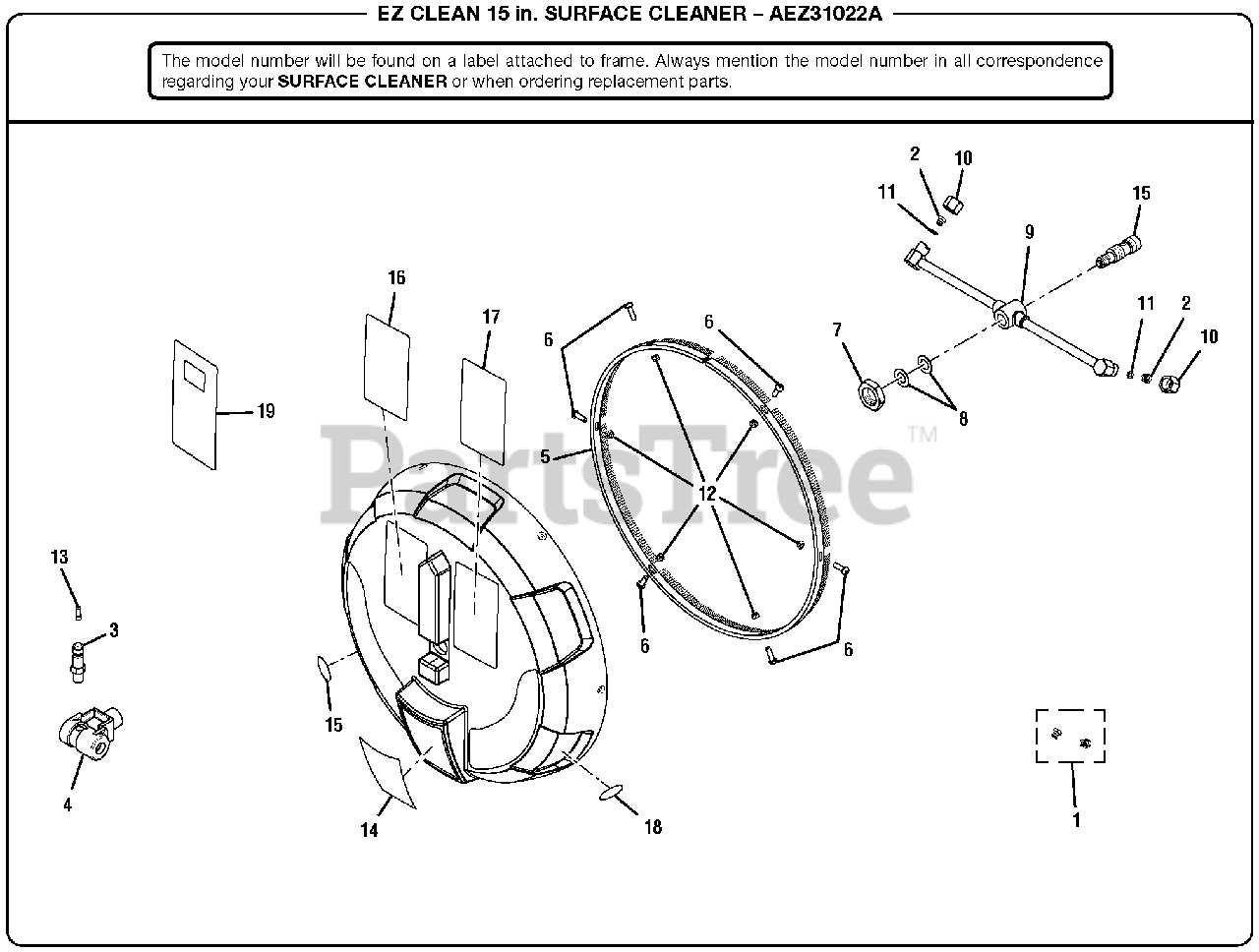

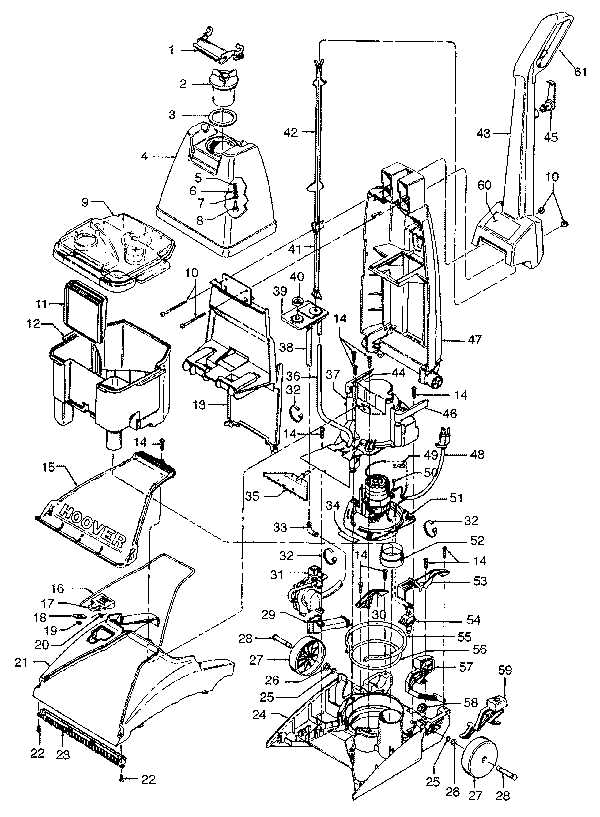

How to Read Parts Diagrams

Understanding illustrations that depict components of machinery is essential for effective maintenance and repair. These visual representations provide valuable insights into the arrangement and function of various elements within a device, aiding users in identifying and sourcing the necessary pieces for replacement or repair tasks.

Identifying Key Elements

Begin by familiarizing yourself with the legend or key, which often accompanies these illustrations. This section usually explains the symbols and lines used, helping you decode the information presented. Pay attention to labels and numbers that correspond to specific items, as they are crucial for locating replacements or understanding how parts fit together.

Understanding Relationships

Next, analyze how different components interact with one another. The layout often reveals connections and dependencies, highlighting how one piece may affect another’s functionality. Look for arrows or lines indicating movement or attachment points, which can clarify the assembly and disassembly processes. Recognizing these relationships is key to effective troubleshooting and repairs.

Common Issues with Surface Cleaners

Regular maintenance tools often face a variety of challenges that can affect their efficiency and performance. Understanding these issues is crucial for effective troubleshooting and ensuring longevity. Users frequently encounter problems related to uneven performance, clogs, and wear over time.

One prevalent issue is uneven cleaning results, which can arise from improper technique or faulty components. If the equipment isn’t used consistently or at the correct angle, it can lead to streaks or missed spots. Additionally, blockages in hoses or nozzles can impede flow, resulting in reduced effectiveness.

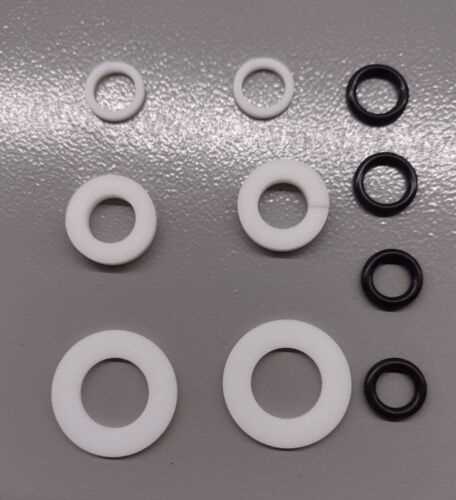

Wear and tear on seals and bearings is another common concern. Over time, these elements may degrade, causing leaks or reduced mobility. Regular inspection and replacement of these components can help maintain optimal functionality.

Lastly, inconsistent water pressure can lead to ineffective operation. Users should ensure their water supply is steady and meets the necessary requirements for the equipment in use. Addressing these common challenges will enhance overall performance and reliability.

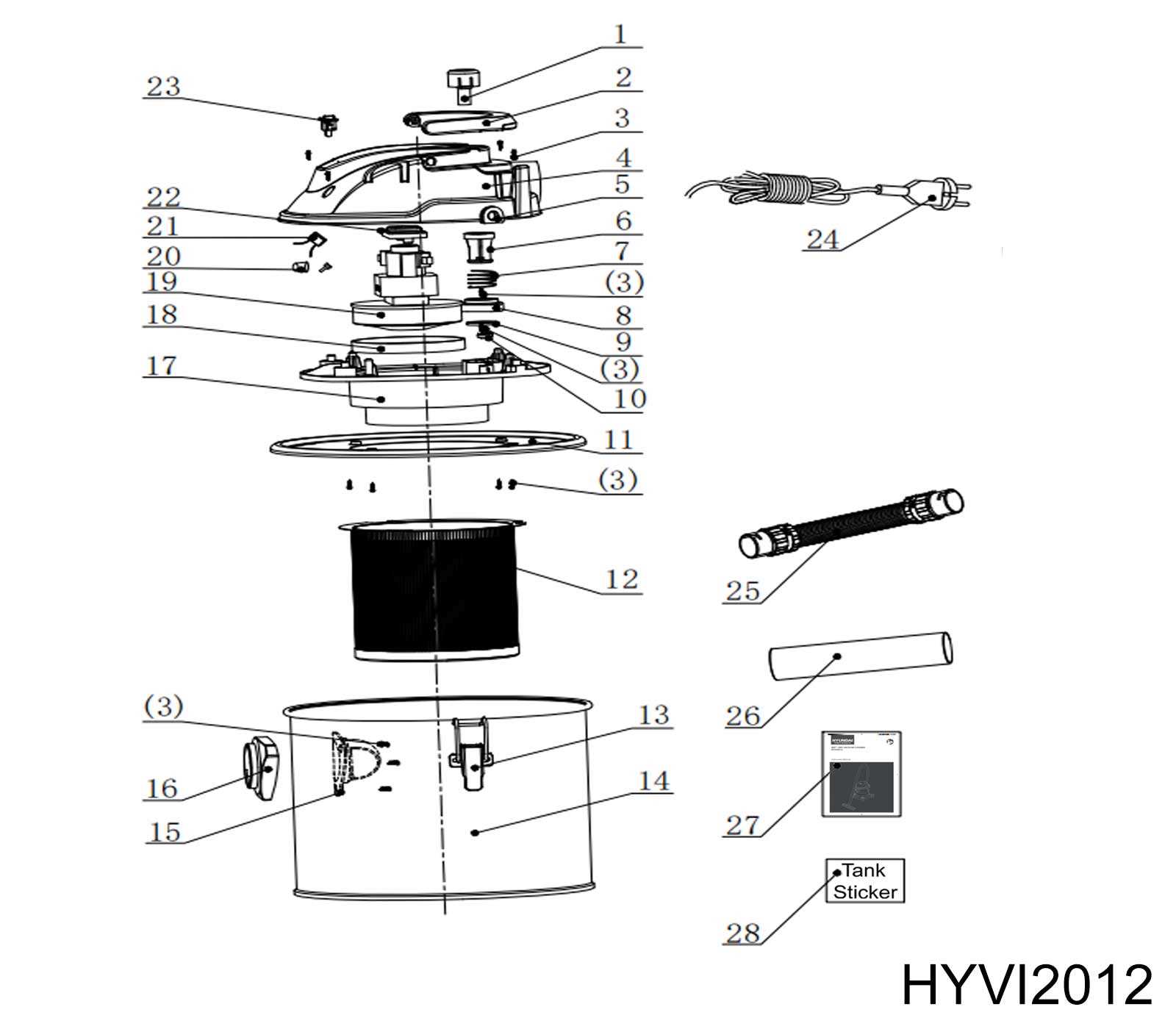

Identifying Key Parts and Functions

This section aims to explore the essential components of a cleaning apparatus and their respective roles in ensuring optimal performance. Understanding these elements can enhance user experience and maintenance, leading to more effective usage.

Core Components

Each device comprises various key elements that contribute to its efficiency. The motor, for instance, serves as the driving force, converting electrical energy into mechanical power. Meanwhile, the nozzle is designed to direct the flow, targeting specific areas for maximum effect.

Supporting Mechanisms

In addition to the main elements, supporting mechanisms like filters and tanks play crucial roles. Filters trap debris and ensure a clean output, while tanks store liquids, providing the necessary supply for various tasks. Together, these components work harmoniously to achieve the ultimate goal of cleanliness.

Repairing and Replacing Components

Maintaining the functionality of your equipment involves understanding the nuances of its individual elements. Whether due to wear and tear or accidental damage, addressing issues promptly can enhance performance and prolong the lifespan of the device. This section delves into the essential aspects of mending and substituting crucial components to ensure seamless operation.

Identifying Issues

Recognizing when a part requires attention is fundamental. Common indicators include unusual noises, diminished efficiency, or visible damage. Conducting regular inspections can help pinpoint problematic areas early on. Listening for irregular sounds and observing any changes in functionality can save time and resources in the long run.

Repair Techniques

For minor issues, repairs may involve simple adjustments or the application of lubricants. In more severe cases, replacing specific elements might be necessary. When opting for replacements, it’s crucial to select high-quality alternatives to maintain the integrity of the overall system. Always consult the manufacturer’s guidelines for compatibility and installation procedures.

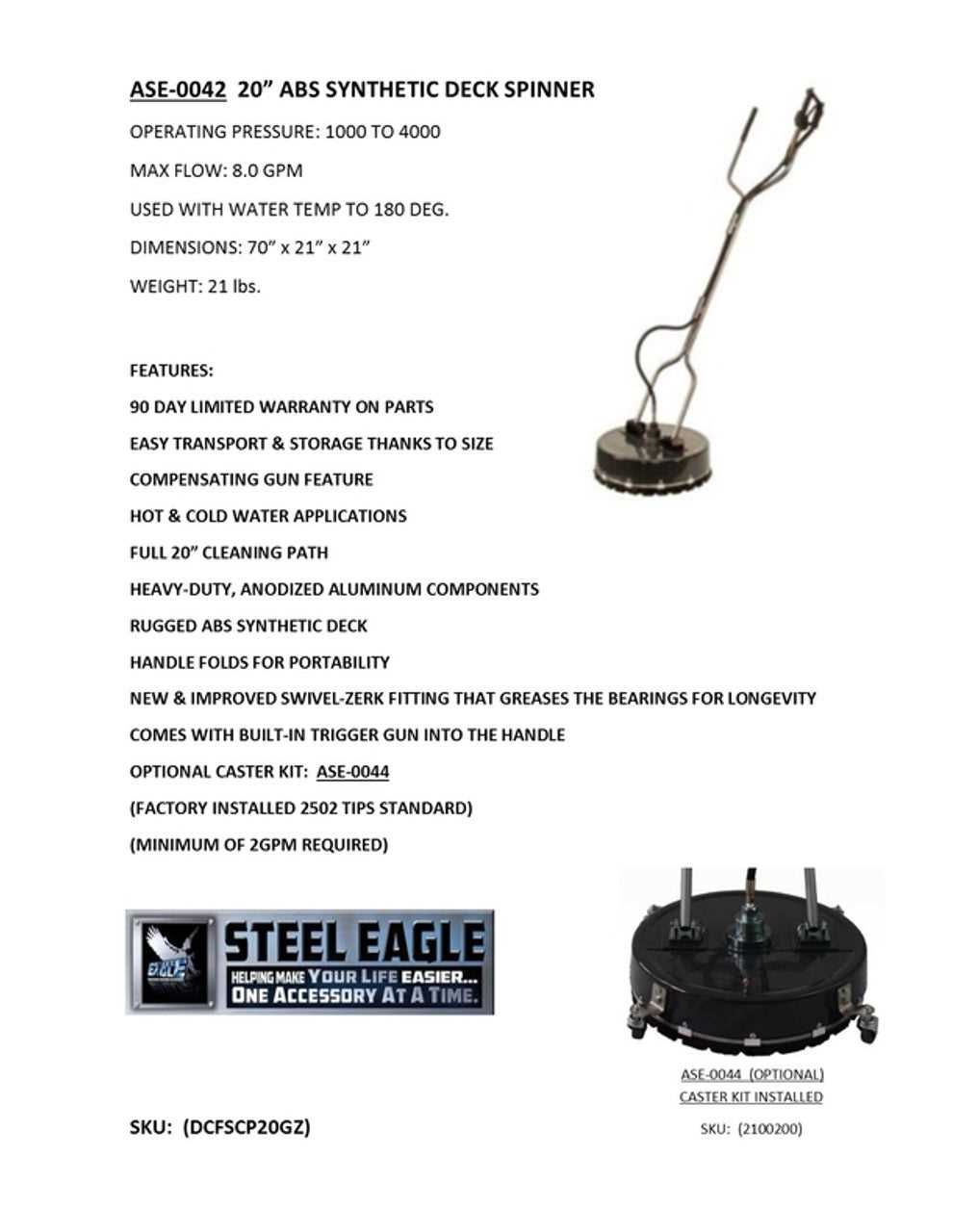

Choosing the Right Surface Cleaner

Selecting the appropriate equipment for cleaning surfaces can significantly impact efficiency and results. With various options available, understanding key factors can lead to a more informed decision, ensuring optimal performance for specific tasks.

Key Considerations

- Surface Type: Different materials require different approaches. Assess whether the area is concrete, wood, or another material to choose the right tool.

- Size of the Area: Larger spaces may benefit from models with wider cleaning paths, while smaller areas might be best served with compact versions.

- Water Pressure: Evaluate the necessary pressure levels for effective cleaning without causing damage.

- Portability: Consider whether a lightweight model is needed for ease of movement, especially for extensive jobs.

Additional Features

- Adjustable Settings: Models with adjustable pressure settings allow for versatile use across different surfaces.

- Interchangeable Accessories: Compatibility with various attachments can enhance functionality and ease of use.

- Durability: Investing in robust construction ensures longevity and reliability for frequent use.

- Ease of Maintenance: Look for options that simplify upkeep to keep performance at its best.

By considering these aspects, individuals can make a well-informed choice, leading to effective and efficient cleaning outcomes tailored to their specific needs.

Tools Needed for Assembly

When undertaking the task of putting together a cleaning device, having the right equipment is crucial for ensuring efficiency and precision. A well-prepared toolkit not only streamlines the assembly process but also minimizes the risk of errors.

Essential Equipment

Gathering the necessary tools beforehand can greatly enhance your assembly experience. Below is a list of items you’ll need:

| Tool | Purpose |

|---|---|

| Screwdriver | For tightening and loosening screws. |

| Wrench | To secure bolts and nuts effectively. |

| Pliers | To grip and manipulate small components. |

| Measuring Tape | For ensuring accurate dimensions and fit. |

| Utility Knife | For cutting packaging or materials as needed. |

Optional Tools

In addition to the essentials, a few optional items can further enhance your assembly process:

| Tool | Purpose |

|---|---|

| Level | To ensure proper alignment and balance. |

| Lubricant | For easing movement of moving parts. |

| Flashlight | To illuminate hard-to-reach areas. |

Safety Precautions While Cleaning

Ensuring a safe environment during the process of removing dirt and grime is essential. By adhering to specific guidelines, you can minimize risks and enhance the overall effectiveness of your efforts.

General Guidelines

Always prioritize personal protection by wearing suitable gear. This may include gloves, masks, and eyewear to shield against harmful substances and debris.

Handling Chemicals

When using cleaning agents, it’s vital to read labels carefully and follow instructions. Store these materials securely and avoid mixing different products to prevent hazardous reactions.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use gloves, masks, and eyewear to protect yourself. |

| Read Labels | Understand the instructions and warnings of all products. |

| Avoid Mixing | Never combine different cleaning solutions to prevent toxic reactions. |

| Keep Area Ventilated | Ensure good airflow to reduce inhalation of fumes. |

Upgrading Surface Cleaner Parts

Enhancing the efficiency and performance of your equipment can significantly improve your cleaning tasks. By selecting high-quality components, you can ensure better durability and effectiveness during operation. Upgrading not only revitalizes your device but also extends its lifespan, making it a worthwhile investment.

Identifying Weak Points: Before proceeding with upgrades, assess the current state of your device. Look for areas that show signs of wear or inefficiency. This analysis will guide you in selecting the most beneficial components for enhancement.

Choosing Quality Components: Opt for reputable brands known for their reliability. High-performance alternatives can provide superior results and often come with warranties, ensuring peace of mind with your upgrades.

Installation Process: Follow the manufacturer’s instructions for each new component to ensure proper installation. If needed, consult professional help to guarantee everything is set up correctly and safely.

In conclusion, prioritizing upgrades can lead to a transformative experience in your cleaning efforts, ultimately achieving better results and satisfaction.

Benefits of Using Diagrams

Utilizing visual representations significantly enhances comprehension and communication. These illustrations serve as effective tools for conveying complex information in a simplified manner, making them invaluable in various fields.

| Advantage | Description |

|---|---|

| Clarity | Visuals clarify intricate concepts, reducing ambiguity. |

| Engagement | Images capture attention, increasing retention of information. |

| Efficiency | Diagrams allow for quicker understanding compared to text. |

| Accessibility | Visual aids cater to different learning styles and needs. |