Comprehensive Guide to Lb7 Parts Diagram

In the realm of automotive engineering, comprehending the intricate assembly of a well-known powertrain is crucial for enthusiasts and professionals alike. The ability to visualize and analyze each element within this mechanical marvel can significantly enhance maintenance and performance. This section delves into the essential structure that forms the backbone of a high-performance engine.

Every engine is a complex amalgamation of various elements, each playing a pivotal role in its functionality. By dissecting these individual components, one gains insight into how they interact and contribute to the overall efficiency and reliability of the machine. Understanding these relationships is not only beneficial for troubleshooting but also for optimizing performance and longevity.

Furthermore, having a clear representation of the assembly allows for informed decisions when it comes to upgrades or repairs. Whether you are a seasoned mechanic or a curious hobbyist, grasping the layout and functions of these components will empower you to tackle any challenges that arise in your automotive endeavors. Embracing this knowledge fosters a deeper appreciation for the engineering feats that drive our vehicles forward.

Understanding the Lb7 Engine Components

The intricate workings of a diesel engine involve a variety of essential elements that contribute to its overall performance and efficiency. Each component plays a unique role in ensuring smooth operation and reliability, making it crucial for enthusiasts and professionals alike to familiarize themselves with these mechanisms.

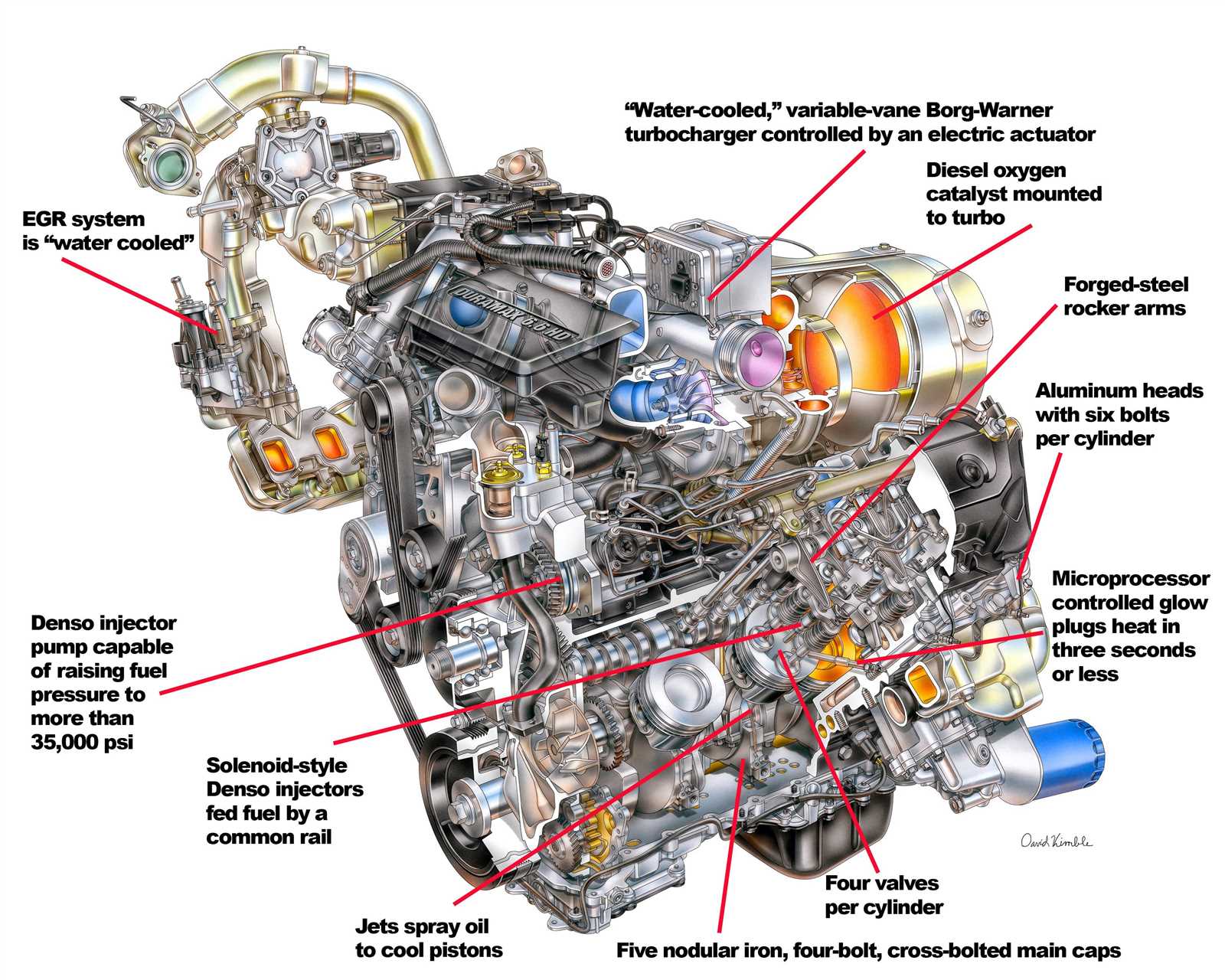

The heart of any engine is its core assembly, which includes the cylinder block, crankshaft, and pistons. These elements work together to convert fuel into mechanical energy, driving the vehicle forward. The design of these components significantly influences the engine’s power output and durability.

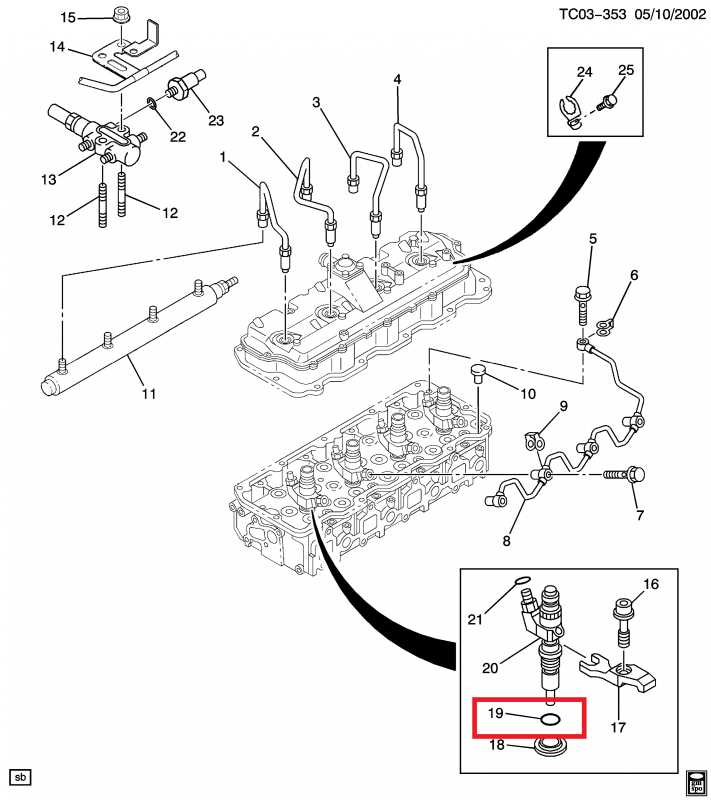

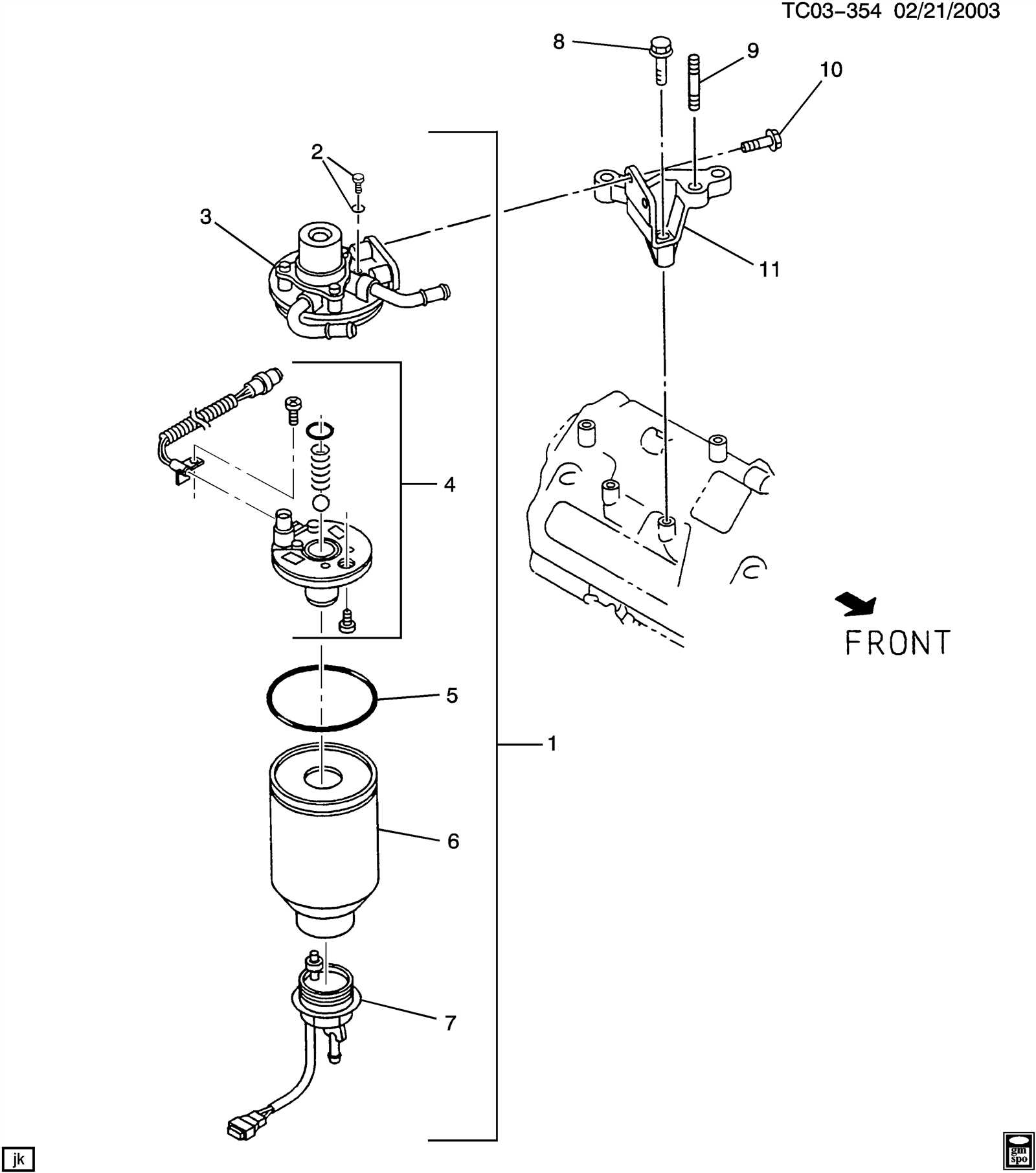

Another critical aspect is the fuel delivery system, which encompasses the injectors and fuel pump. This system ensures that the right amount of fuel reaches the combustion chamber at the correct timing, optimizing performance and reducing emissions. Understanding how these systems interact is vital for troubleshooting and enhancing engine efficiency.

Additionally, the cooling and lubrication systems are integral to maintaining optimal operating temperatures and minimizing friction. Components like the radiator, oil pump, and filters must be in good condition to prevent overheating and wear, thereby prolonging the engine’s lifespan.

Lastly, the exhaust system plays a significant role in managing emissions and noise levels. Key parts such as the turbocharger and catalytic converter help in transforming exhaust gases into less harmful substances, reflecting the engine’s efficiency and adherence to environmental standards.

Overview of Lb7 Parts Diagram

This section aims to provide a comprehensive understanding of the components and their interrelationships within a specific mechanical system. By examining the intricate layout, users can gain insights into functionality, maintenance, and potential troubleshooting techniques.

Understanding the Components

The collection of elements within the assembly plays a crucial role in ensuring optimal performance. Each piece is designed to fulfill a unique function, contributing to the overall efficiency of the mechanism.

Interrelationships and Functionality

Analyzing how these components interact reveals essential insights into the system’s operation. Recognizing these connections is vital for effective repairs and enhancements, allowing for a deeper comprehension of the entire setup.

Common Issues with Lb7 Components

In the realm of diesel engine performance, various components can present challenges that affect overall efficiency and reliability. Understanding these common problems is essential for proper maintenance and longevity of the system.

Fuel System Complications

One prevalent issue involves the fuel delivery mechanism. Clogged injectors can lead to poor engine performance, resulting in misfires or rough idling. Regular cleaning and inspection are crucial to prevent these malfunctions.

Electrical Failures

Another frequent concern pertains to electrical components. Faulty sensors can cause incorrect readings, leading to improper fuel mixtures and reduced power output. Ensuring that all connections are secure and that the sensors are functioning properly can mitigate these risks.

Importance of Accurate Parts Identification

Precision in recognizing components is crucial for optimal functionality and longevity of machinery. Misidentification can lead to inefficiencies, increased costs, and potential damage, ultimately compromising the overall performance.

Understanding each element’s role helps in ensuring proper maintenance and replacement, thereby enhancing reliability. Accurate identification allows for better troubleshooting and repair processes, minimizing downtime.

Moreover, having a clear grasp of specifications facilitates communication among technicians, suppliers, and manufacturers, fostering a more effective workflow. This clarity is essential in obtaining the correct replacements and avoiding unnecessary errors.

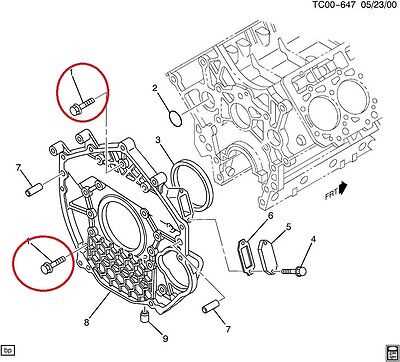

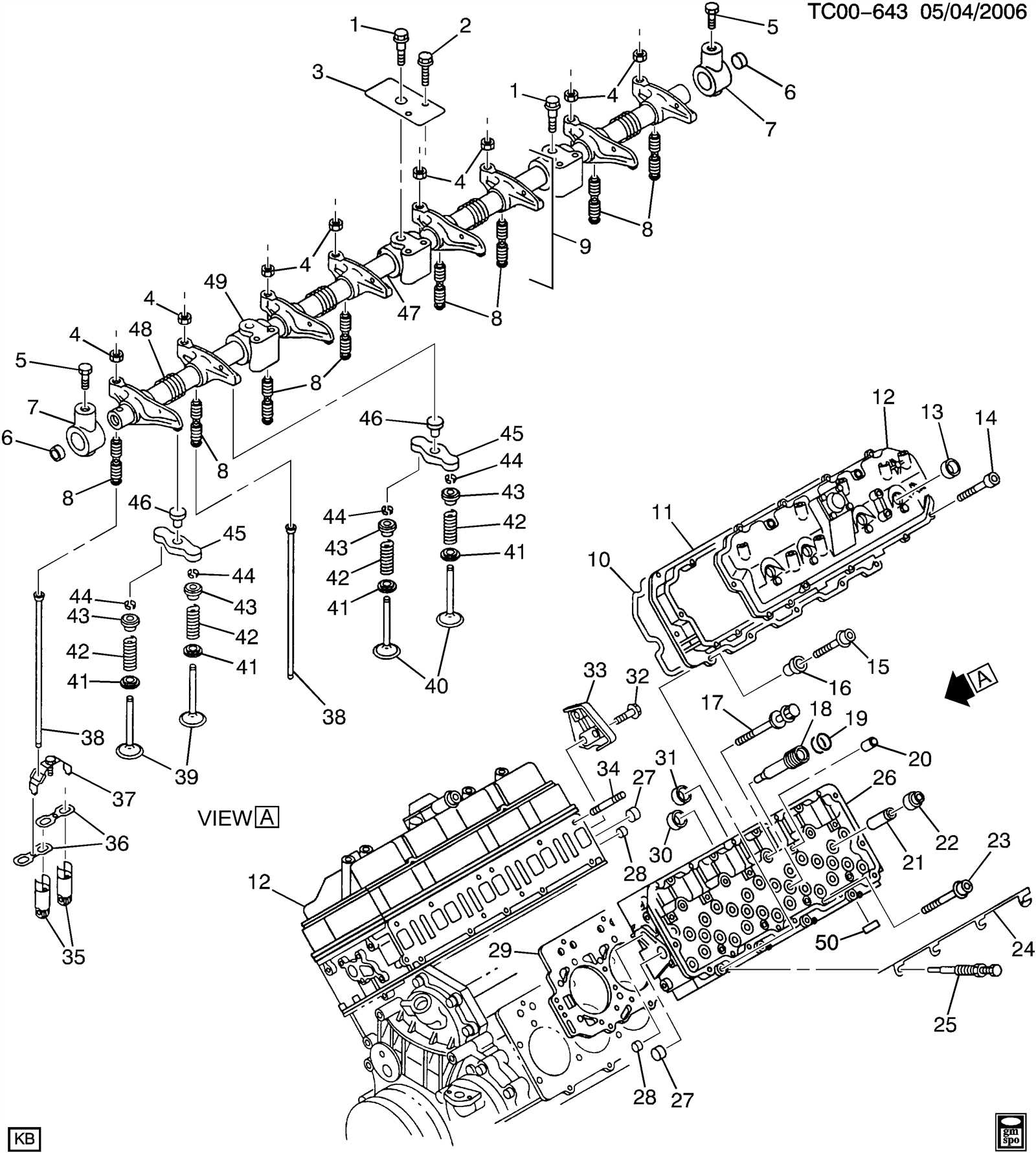

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for efficient maintenance and repair. By interpreting these visuals, you can identify each element and its function within the system, ensuring a smoother workflow.

Key Components to Focus On

- Labels: Look for annotations that indicate the name and specifications of each item.

- Connections: Observe how each element interacts with others; this reveals the overall system design.

- Numbers: Numerical references often correlate with specific lists or catalog entries, providing further detail.

Steps to Analyze Effectively

- Familiarize yourself with the legend or key to understand symbols used.

- Follow the flow from one component to another to see how they relate.

- Consult additional resources if certain elements are unclear.

Essential Tools for Lb7 Repairs

When tackling maintenance and restoration tasks, having the right instruments is crucial for ensuring efficiency and precision. This guide outlines the fundamental equipment needed to handle repairs effectively.

Basic Hand Tools

- Wrenches

- Screwdrivers

- Pliers

- Socket Set

Diagnostic Equipment

- OBD-II Scanner

- Multimeter

- Compression Tester

Equipping yourself with these essential tools will ultimately enhance your ability to manage repairs successfully.

Maintenance Tips for Lb7 Engines

Regular upkeep of your diesel engine is crucial for ensuring optimal performance and longevity. Following a systematic maintenance schedule can help you avoid costly repairs and enhance the overall efficiency of your vehicle.

- Oil Changes: Regularly changing the oil is essential. Use high-quality oil and adhere to the manufacturer’s recommended intervals.

- Fuel Filter Replacement: Replace the fuel filter at regular intervals to ensure clean fuel supply and prevent clogging.

- Air Filter Inspection: Check the air filter frequently and replace it as needed to maintain proper airflow and engine efficiency.

In addition to these fundamental practices, there are several other steps you can take to enhance the lifespan of your engine.

- Coolant Level Check: Ensure the coolant is at the appropriate level to prevent overheating.

- Belt and Hose Inspection: Regularly inspect belts and hoses for signs of wear or damage to avoid breakdowns.

- Battery Maintenance: Keep the battery clean and check connections to prevent starting issues.

By adhering to these maintenance tips, you can ensure your engine runs smoothly and efficiently, ultimately extending its operational life.

Aftermarket vs. OEM Parts Explained

When it comes to vehicle components, the choice between original and alternative options can significantly impact performance and reliability. Understanding the nuances of these offerings is essential for making informed decisions regarding maintenance and upgrades.

Original Equipment Manufacturer (OEM) components are made by the same company that produced the vehicle’s original parts. They are typically designed to meet the exact specifications of the manufacturer, ensuring a perfect fit and compatibility. On the other hand, aftermarket alternatives are created by third-party companies, often with the aim of providing more cost-effective solutions or enhanced features. While they can offer varying degrees of quality, they may also introduce risks related to performance and longevity.

Ultimately, the decision between these options hinges on factors such as budget, desired quality, and personal preference. For those who prioritize assurance and reliability, OEM might be the better choice. Conversely, individuals seeking innovation or lower costs may opt for aftermarket solutions, provided they conduct thorough research on the products available.

Cost Factors for Lb7 Components

When evaluating the financial aspects of various vehicle components, several key factors come into play. Understanding these elements is essential for making informed decisions regarding maintenance, repairs, and upgrades. This analysis focuses on aspects such as material quality, manufacturing processes, and market demand, all of which significantly influence pricing.

| Factor | Description | Impact on Cost |

|---|---|---|

| Material Quality | The durability and performance characteristics of the materials used. | Higher quality materials typically lead to increased costs. |

| Manufacturing Processes | The techniques and technologies employed in production. | Advanced methods can enhance precision but raise manufacturing expenses. |

| Market Demand | The overall demand for specific components in the market. | Higher demand can drive up prices due to scarcity. |

| Brand Reputation | The perceived value associated with a manufacturer. | Well-known brands may charge a premium for their products. |

| Warranty and Support | The extent of coverage offered with the component. | Longer warranties often increase initial costs but provide long-term value. |

By considering these factors, vehicle owners and enthusiasts can better understand the pricing landscape and make choices that align with their needs and budgets.

Popular Upgrades for Lb7 Engines

Enhancing engine performance is a common pursuit among enthusiasts looking to maximize power and efficiency. Various modifications can significantly improve acceleration, towing capacity, and overall driving experience. This section explores some of the most sought-after enhancements that can transform a standard engine into a high-performance powerhouse.

ECM Tuning: Reprogramming the engine control module can unleash additional horsepower and torque. Optimized settings adjust fuel delivery and ignition timing, allowing for more efficient combustion and improved responsiveness.

Improved Air Intake Systems: Upgrading the air intake can increase airflow, enhancing engine efficiency. High-performance filters and larger diameter tubing reduce restrictions, promoting better air movement and potentially increasing power output.

Exhaust System Upgrades: A free-flowing exhaust system minimizes backpressure, improving engine efficiency and sound. Upgraded headers and high-performance mufflers can lead to noticeable gains in horsepower and torque.

High-Performance Fuel Injectors: Replacing stock injectors with high-capacity alternatives ensures optimal fuel delivery, particularly when paired with other modifications. This upgrade is essential for those aiming for significant power increases.

Intercooler Improvements: A larger or more efficient intercooler can dramatically reduce intake temperatures, leading to better performance and reliability. Cooler air increases density, enhancing combustion and overall engine efficiency.

Transmission Enhancements: Upgrading transmission components, such as torque converters or clutches, ensures that the drivetrain can handle increased power levels. This is crucial for maintaining reliability and performance during heavy-duty use.

By considering these modifications, enthusiasts can significantly enhance their engines’ performance, ensuring a more dynamic driving experience while achieving their desired goals.

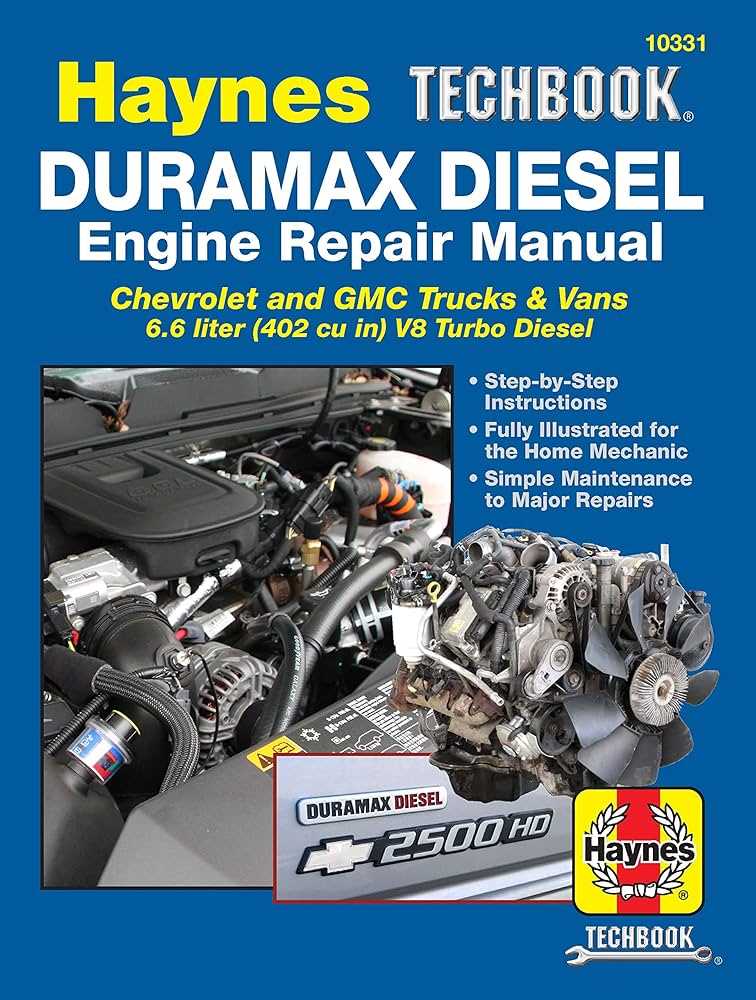

Resources for Lb7 Repair Manuals

Accessing reliable information is crucial for effective maintenance and repair of vehicles. Numerous resources exist that provide comprehensive guides and manuals tailored to specific engine models, ensuring that enthusiasts and professionals alike can perform necessary repairs with confidence.

Online Platforms: Many websites specialize in automotive repair documentation, offering downloadable manuals and user guides. Websites like AutoZone and Haynes provide valuable insights and step-by-step instructions for various repair tasks. Forums and community groups dedicated to automotive enthusiasts also serve as excellent resources for sharing knowledge and troubleshooting tips.

Books and Publications: Traditional print manuals remain a valuable resource. Publishers such as Chilton and Motorbooks produce extensive guides that cover everything from routine maintenance to complex repairs. These books often include illustrations and diagrams, aiding in understanding intricate systems.

Videos and Tutorials: The rise of video content has transformed how individuals learn about repairs. Platforms like YouTube host countless channels dedicated to automotive repair, where experienced mechanics demonstrate various procedures. These visual aids can be particularly helpful for visual learners.

Local Libraries and Workshops: Many public libraries stock repair manuals and related literature. Additionally, local community colleges or vocational schools may offer workshops or courses focusing on engine maintenance, providing hands-on experience and expert guidance.

Impact of Modifications on Performance

Enhancements to a vehicle’s system can significantly alter its efficiency and responsiveness. By exploring various upgrades, enthusiasts can optimize their rides for better power delivery, improved fuel economy, or enhanced handling. The balance between aesthetic changes and functional upgrades often determines the overall effectiveness of these modifications.

Engine modifications often yield the most noticeable improvements. Upgrading components such as the intake and exhaust systems can lead to increased airflow, allowing for better combustion and greater horsepower. Additionally, tuning the engine management system can further fine-tune performance characteristics to match the new specifications.

Suspension upgrades also play a critical role in a vehicle’s dynamics. By altering the suspension setup, drivers can achieve better traction and stability, especially during cornering. These changes not only enhance safety but also provide a more engaging driving experience.

Ultimately, the impact of modifications lies in the careful selection and integration of components. Enthusiasts should consider the synergy between upgrades to avoid compromising reliability while maximizing performance potential.

Community Forums for Lb7 Owners

Online communities serve as invaluable resources for enthusiasts and owners of specific vehicle models. These platforms provide a space for individuals to share experiences, seek advice, and connect with like-minded individuals who share a passion for their vehicles. Engaging in these forums can significantly enhance one’s understanding and enjoyment of ownership.

On these discussion boards, users can post inquiries about performance enhancements, maintenance tips, and troubleshooting issues. Veteran owners often contribute their knowledge, helping newcomers navigate common challenges. This collaborative atmosphere fosters a sense of camaraderie among members, creating lasting friendships based on a shared interest.

Furthermore, these forums frequently feature sections dedicated to modifications and upgrades. Users can showcase their projects, providing inspiration and ideas for others looking to personalize their rides. Whether it’s upgrading components or enhancing aesthetics, the community offers support and encouragement, making every journey more enjoyable.

In addition to technical discussions, many forums host events and meet-ups, allowing members to connect in person. These gatherings strengthen community bonds and offer opportunities to learn from one another in a hands-on environment. Overall, participating in these online spaces can enrich the ownership experience and provide valuable insights for any enthusiast.