Kubota 60 Mower Deck Parts Diagram Overview

In the world of outdoor maintenance, comprehending the various components that contribute to a machine’s functionality is essential for optimal performance. Each segment plays a pivotal role, ensuring the equipment operates smoothly and efficiently. Whether you are a professional landscaper or a weekend warrior, having a clear grasp of these elements can significantly enhance your user experience.

By exploring the intricate layout of each assembly, users can identify the relationship between different pieces and how they work together to achieve the desired results. This knowledge not only aids in effective troubleshooting but also empowers operators to conduct maintenance with confidence. The intricacies of these arrangements reveal a well-thought-out design that maximizes both durability and efficiency.

Familiarity with these configurations enables operators to make informed decisions regarding repairs and replacements, thereby prolonging the lifespan of their equipment. With a clear visual representation, one can easily navigate through the various sections, pinpointing specific components that require attention. Such insights are invaluable for ensuring that your outdoor machinery remains in peak condition for years to come.

Kubota 60 Mower Deck Overview

This section provides a comprehensive look at a specific cutting system designed for efficiency and durability. With its robust construction and innovative features, it aims to deliver optimal performance in maintaining outdoor spaces.

Key Features

- High-strength materials for long-lasting use

- Precision engineering for even cutting

- Compatibility with various models

- Easy maintenance and accessibility

Benefits of the System

- Enhanced maneuverability in tight spaces

- Reduced vibration for operator comfort

- Improved grass discharge for a clean finish

- Time-saving capabilities with wider cutting width

Understanding the design and function of this cutting apparatus is essential for anyone looking to achieve professional results in lawn care and landscaping tasks.

Importance of Maintenance for Mowers

Proper upkeep of outdoor equipment is crucial for ensuring optimal performance and longevity. Regular maintenance helps in identifying potential issues before they escalate, ultimately saving time and money in repairs. By adhering to a maintenance routine, users can enhance efficiency and achieve better results during operation.

Benefits of Regular Upkeep

- Enhanced Performance: Well-maintained machinery operates more smoothly and effectively, providing superior results.

- Increased Lifespan: Regular care can significantly extend the life of equipment, allowing for more seasons of reliable service.

- Cost Savings: Preventive maintenance reduces the likelihood of costly repairs by addressing small issues early.

- Safety: Ensuring all components are in good condition minimizes the risk of accidents during operation.

Key Maintenance Tasks

- Inspection: Regularly check for wear and tear on all components.

- Cleaning: Remove debris and dirt buildup to prevent operational issues.

- Lubrication: Apply lubricant to moving parts to ensure smooth functionality.

- Sharpening: Keep blades sharp for effective cutting and reduced strain on the machine.

By prioritizing these essential maintenance tasks, users can enjoy improved performance and durability from their equipment, ensuring they are ready for any challenge that lies ahead.

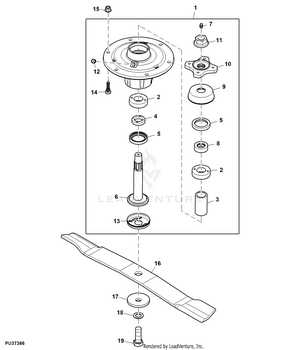

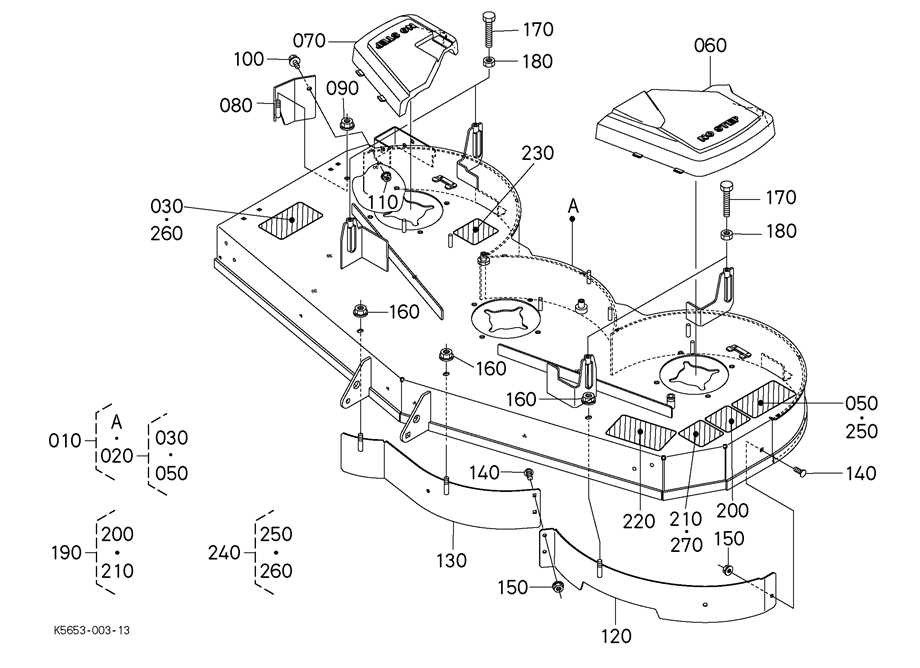

Key Components of Mower Deck

The functionality of any cutting apparatus relies heavily on its essential elements, each contributing to overall performance and efficiency. Understanding these crucial components is vital for maintaining and optimizing operation.

| Component | Description |

|---|---|

| Blades | Sharp, rotating elements that cut through grass and other vegetation with precision. |

| Spindle Assembly | Houses the blades and facilitates their rotation, ensuring smooth and consistent cutting. |

| Housing | Protective casing that encases the blades and other components, providing safety and durability. |

| Mounting Brackets | Support structures that secure the assembly to the main unit, ensuring stability during operation. |

| Belts | Transfer power from the engine to the rotating elements, essential for functionality. |

| Wheels | Facilitate movement and maneuverability, allowing for easy navigation across various terrains. |

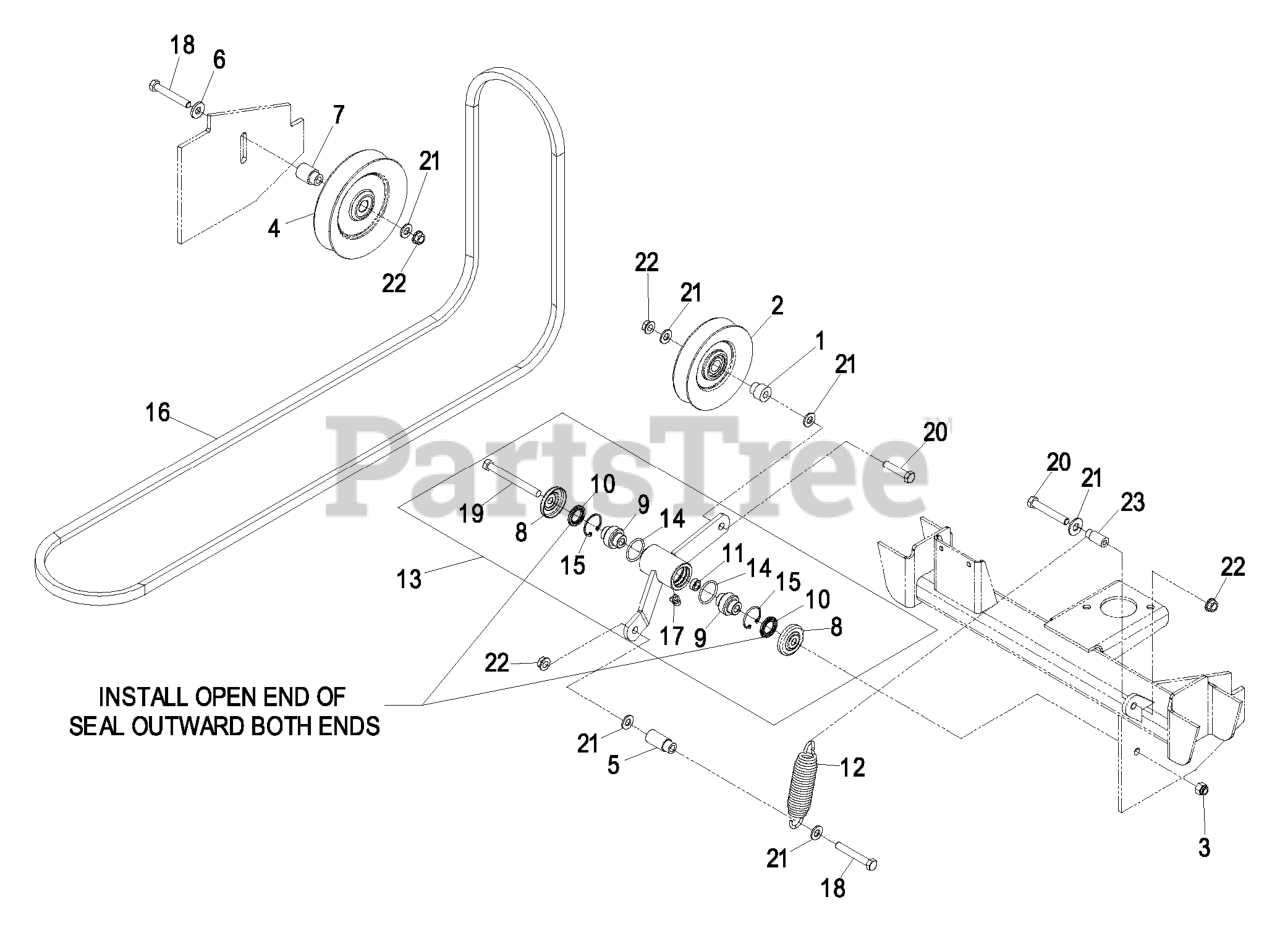

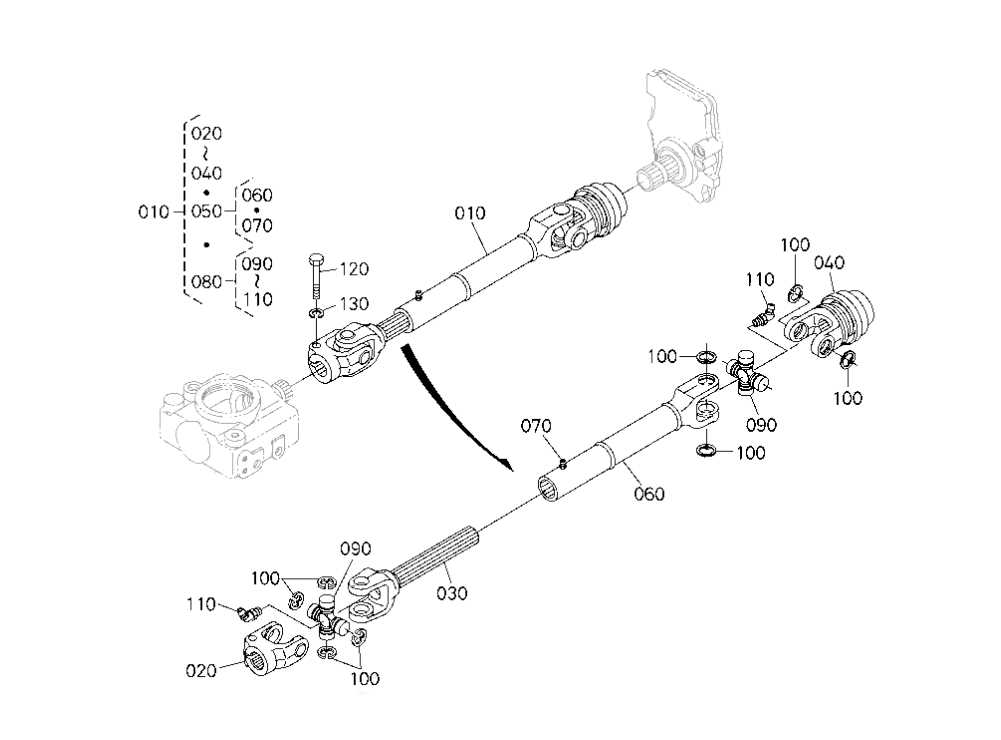

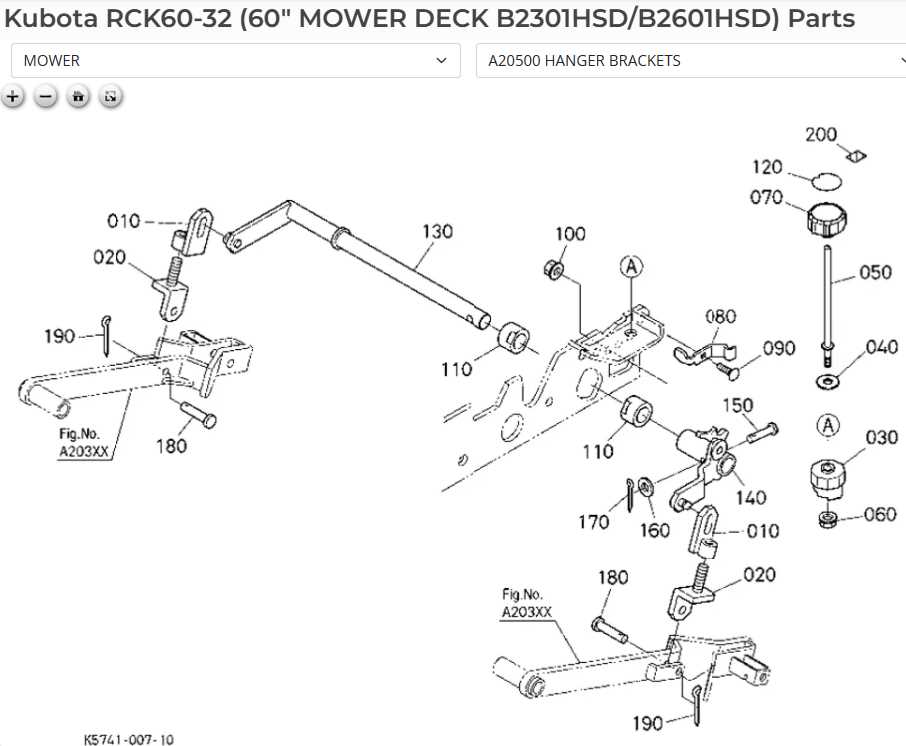

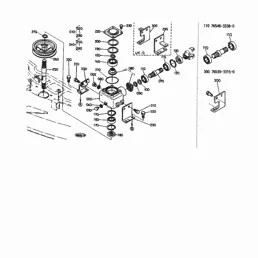

Understanding the Parts Diagram

A visual representation of components is crucial for anyone looking to maintain or repair their equipment effectively. This illustration serves as a guide, highlighting the various elements and their relationships, facilitating a deeper understanding of the machinery’s functionality. Grasping the layout enables users to identify parts more efficiently and aids in troubleshooting common issues.

Key Components Explained

Each section of the illustration corresponds to a specific group of elements that contribute to the overall performance. Recognizing these components and their roles can significantly streamline maintenance tasks. Users should pay close attention to labels and connections, as they reveal how different pieces work in harmony.

Benefits of Familiarity

Acquainting oneself with the visual layout not only enhances operational knowledge but also empowers users to perform repairs with confidence. A solid grasp of the schematic promotes proactive care, helping to extend the life of the equipment while reducing downtime and repair costs.

Common Issues with Mower Decks

Maintaining cutting equipment can often lead to various challenges that affect performance and efficiency. Understanding these common problems is essential for ensuring smooth operation and longevity of the machine. Below are some frequently encountered issues and their potential solutions.

Frequent Problems

- Uneven Cutting: This can result from dull blades or uneven wheel heights.

- Clogging: Grass buildup can occur, especially in wet conditions, impacting effectiveness.

- Noisy Operation: Unusual sounds may indicate loose components or worn bearings.

- Inconsistent Height Adjustment: Difficulty in setting cutting height can stem from faulty adjustment mechanisms.

Maintenance Tips

- Regularly sharpen and replace blades to ensure clean cuts.

- Clean the underside after each use to prevent clogs.

- Check all fasteners and components for wear and tighten as necessary.

- Inspect height adjustment mechanisms for any signs of damage.

By addressing these common issues proactively, operators can enhance the functionality and lifespan of their equipment, leading to better results in their lawn care efforts.

Replacing Worn-Out Parts

Maintaining equipment in optimal condition is crucial for ensuring efficiency and longevity. Over time, components may degrade due to regular use, environmental factors, or lack of maintenance. Timely replacement of these items not only enhances performance but also prevents further damage.

Identifying Signs of Wear

Recognizing when components need to be replaced is essential. Look for the following indicators:

- Unusual noises during operation

- Visible cracks or breaks in the structure

- Decreased efficiency or performance

- Difficulty in operation or handling

Steps for Replacement

Follow these steps to effectively replace damaged components:

- Turn off and disconnect the equipment from power sources.

- Carefully inspect the area to locate the worn-out items.

- Remove the affected components using appropriate tools.

- Install new replacements, ensuring they fit securely.

- Test the equipment to verify proper operation.

Regular checks and timely replacements will ensure that your machinery remains in peak condition, ultimately saving time and costs in the long run.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right tools at your disposal is essential. Proper instruments not only streamline the repair process but also ensure that tasks are completed efficiently and safely. Below is a list of commonly required tools that will aid in any repair job.

Essential Tools

- Wrenches: Both adjustable and fixed types for loosening and tightening various fasteners.

- Screwdrivers: A selection of flathead and Phillips screwdrivers to tackle different screws.

- Socket Set: Useful for reaching bolts in tight spaces and ensuring a secure fit.

- Pliers: For gripping, twisting, and cutting wires or other materials.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

Safety Equipment

- Safety Glasses: Protects your eyes from debris during repairs.

- Gloves: Provides hand protection while handling sharp or rough components.

- Ear Protection: Useful when working with loud machinery or power tools.

Having these tools ready will help ensure that your repair work is both effective and safe, allowing you to maintain your equipment in peak condition.

Safety Precautions During Repairs

When undertaking maintenance on any mechanical equipment, prioritizing safety is essential to prevent accidents and injuries. Understanding potential hazards and following best practices can ensure a secure working environment. Proper preparation and the use of appropriate safety gear play critical roles in facilitating safe repairs.

Use Protective Gear

Always wear suitable protective equipment such as gloves, goggles, and sturdy footwear. Gloves safeguard against cuts and abrasions, while goggles protect your eyes from debris. Additionally, wearing non-slip shoes reduces the risk of accidents while working in potentially hazardous conditions.

Maintain a Clean Workspace

Keeping your work area organized is vital for safety. Remove any unnecessary tools or materials that could cause tripping or distractions. Ensure that the workspace is well-lit to enhance visibility. A tidy environment not only promotes efficiency but also minimizes risks during the repair process.

Finding OEM Replacement Parts

When it comes to maintaining outdoor machinery, sourcing high-quality components is essential for ensuring optimal performance and longevity. Original equipment manufacturer items offer the assurance of compatibility and reliability, making them the preferred choice for many operators.

To begin the search for these authentic components, it’s advisable to consult the user manual of your machine. This resource typically provides a comprehensive list of required components and their specifications. Additionally, authorized dealers and specialized retailers often have extensive catalogs that can aid in identifying the correct replacements.

Utilizing online platforms can also enhance your search. Many manufacturers provide detailed databases that allow users to input model numbers to find specific components quickly. Furthermore, online forums and communities dedicated to machinery maintenance can be invaluable for recommendations and experiences shared by fellow users.

It’s important to verify the authenticity of the components before making a purchase. Opting for trusted suppliers and checking for certifications can help ensure that the items you receive are genuine and of the highest quality. Investing in OEM alternatives ultimately contributes to the efficient functioning and durability of your equipment.

Benefits of Regular Inspections

Conducting routine evaluations of equipment is essential for maintaining optimal performance and longevity. Regular checks not only help identify potential issues before they escalate but also contribute to enhanced efficiency and safety. Here are several advantages of adhering to a consistent inspection schedule.

1. Early Problem Detection

Frequent assessments allow for the early identification of wear and tear or malfunctions. This proactive approach can prevent minor issues from developing into significant, costly repairs. Key benefits include:

- Minimizing downtime by addressing problems quickly.

- Reducing repair costs by fixing issues before they worsen.

- Extending the lifespan of machinery through timely interventions.

2. Enhanced Safety

Regular inspections contribute significantly to operational safety. Ensuring that all components are functioning correctly mitigates risks associated with equipment failure. Safety benefits include:

- Protecting operators from potential hazards.

- Maintaining compliance with safety regulations.

- Improving overall workplace safety standards.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for anyone looking to maintain or repair equipment. These visual aids provide essential information about components, their arrangement, and how they interact with one another. By familiarizing yourself with the structure of these illustrations, you can streamline the process of identifying and ordering necessary components.

Key Elements of Technical Illustrations

Every illustration typically includes specific symbols and annotations. Recognizing these elements will enhance your ability to interpret the visuals effectively:

| Element | Description |

|---|---|

| Numbers | Often indicate the specific components or items in the visual. |

| Lines | Show connections or relationships between different elements. |

| Labels | Provide names or specifications for the components shown. |

| Reference Keys | Guide you to additional information, such as maintenance notes or ordering details. |

Steps to Effectively Interpret Visuals

To make the most out of these illustrations, follow these steps:

- Start by examining the overall layout to get a sense of the arrangement.

- Look for numbered components and match them with the corresponding list or key.

- Pay attention to lines and arrows to understand how elements are connected.

- Refer to any supplementary information provided in the margins or notes.

By mastering the art of reading these technical illustrations, you can ensure a smoother repair and maintenance process, saving both time and resources.

Tips for Efficient Mower Operation

Maximizing performance and ensuring longevity of your equipment can greatly enhance your mowing experience. By following a few essential strategies, you can improve efficiency, reduce wear, and achieve optimal results. Here are some valuable insights to help you operate your machinery more effectively.

Regular Maintenance

- Check and change oil regularly to keep the engine running smoothly.

- Inspect the blades frequently for sharpness; dull blades can damage grass and reduce effectiveness.

- Clean the undercarriage after each use to prevent grass buildup.

- Examine belts and cables for signs of wear and replace them as needed.

Smart Operating Techniques

- Adjust the cutting height based on grass type and season to promote healthy growth.

- Mow when the grass is dry to prevent clumping and ensure a cleaner cut.

- Plan your mowing pattern to minimize overlap and save time.

- Use a slower speed when navigating uneven terrain to maintain control.

Resources for Mower Maintenance Guides

Maintaining outdoor equipment is essential for ensuring longevity and optimal performance. Having access to comprehensive guides can significantly aid in this process, offering detailed instructions and helpful tips. Whether you’re a novice or an experienced user, these resources provide valuable information to keep your machinery in excellent condition.

Online Manuals and Video Tutorials

Numerous websites host a plethora of online manuals that can be easily downloaded. These documents often include step-by-step instructions, maintenance schedules, and troubleshooting advice. Additionally, video tutorials available on platforms like YouTube can visually demonstrate maintenance techniques, making it easier to follow along.

Community Forums and Support Groups

Engaging with online communities can be a rich source of knowledge. Forums and support groups allow users to share experiences, tips, and solutions to common issues. Participating in discussions can provide insights that are often not found in official manuals, helping users tackle challenges more effectively.