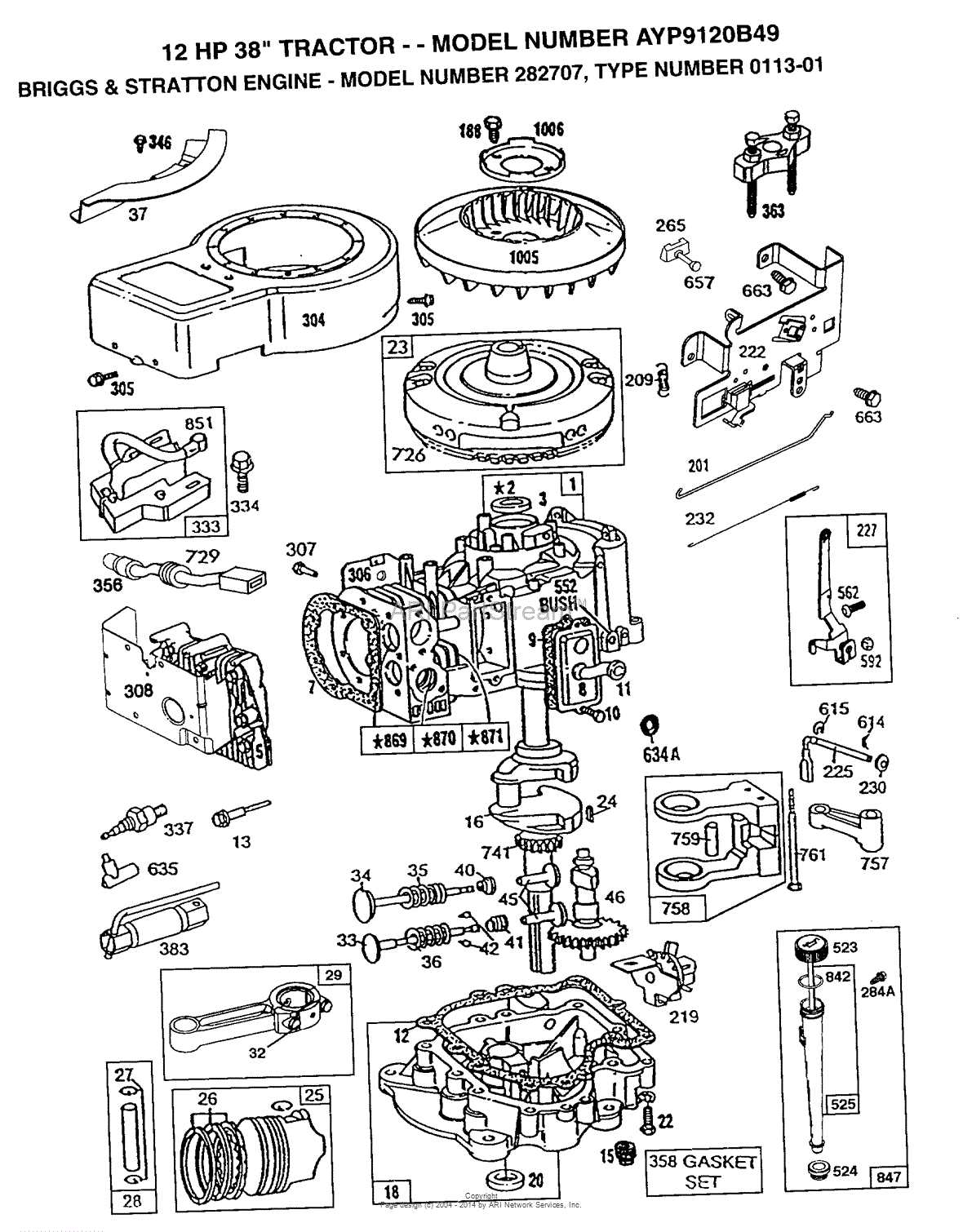

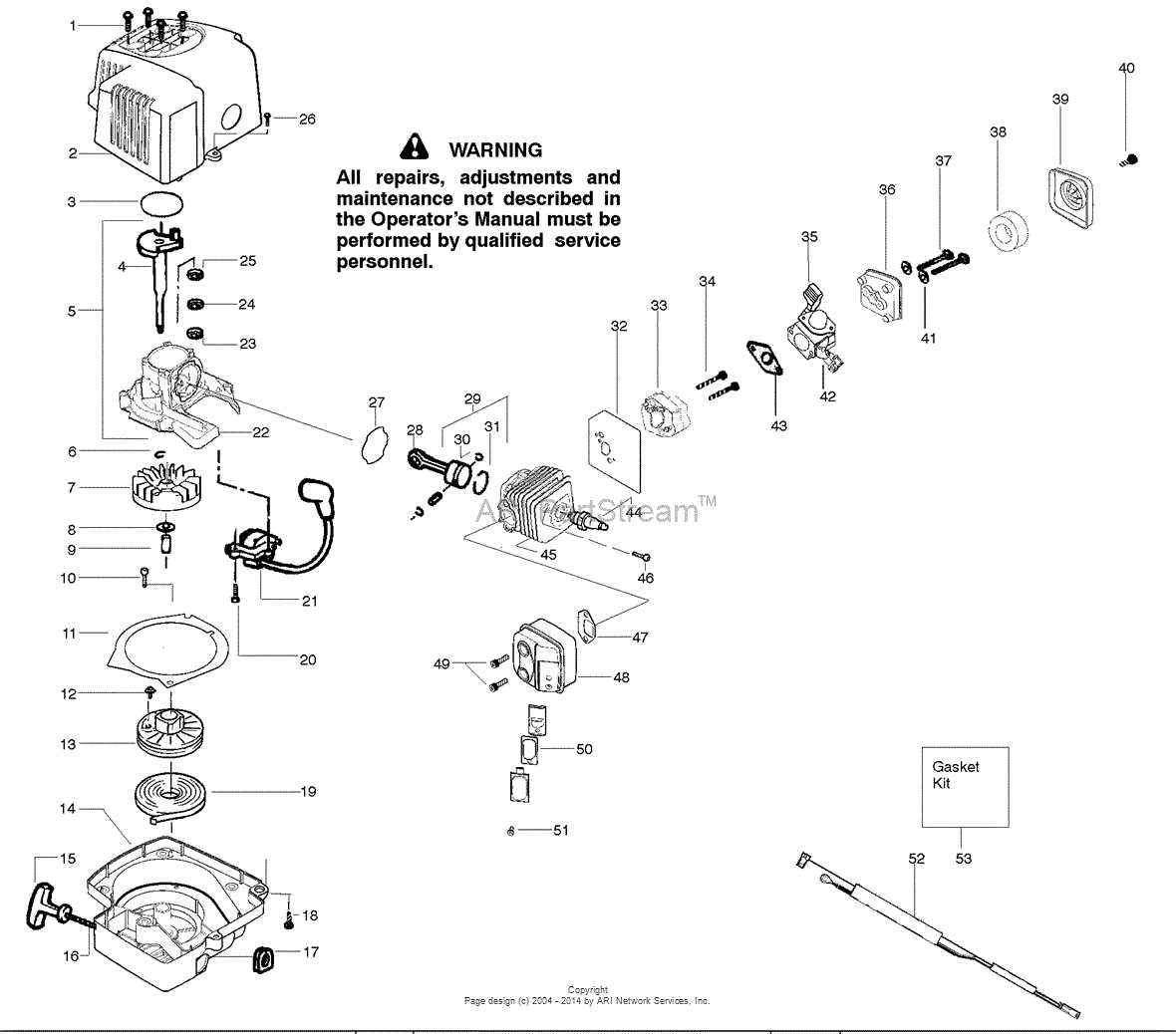

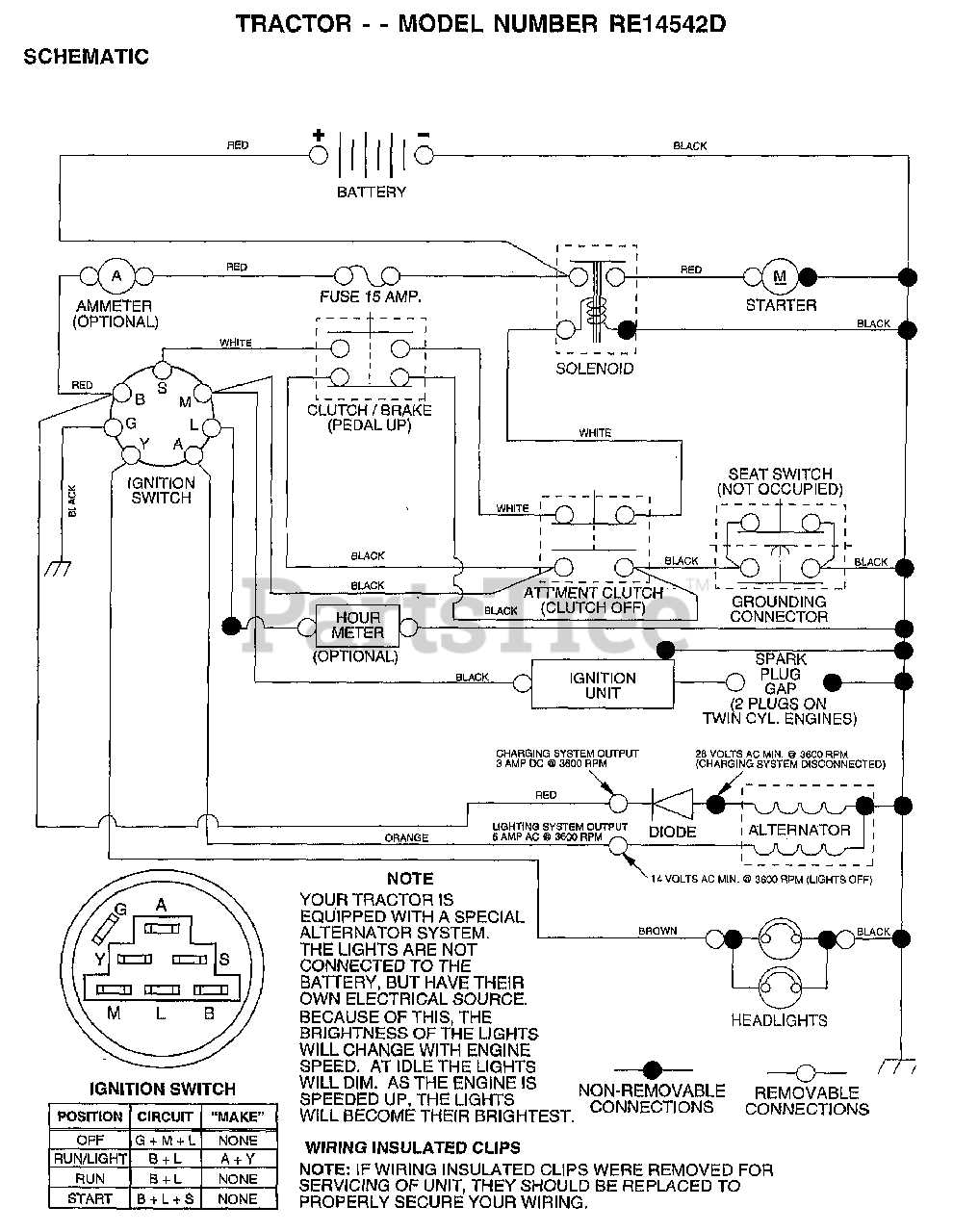

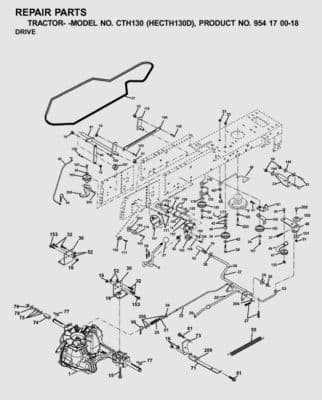

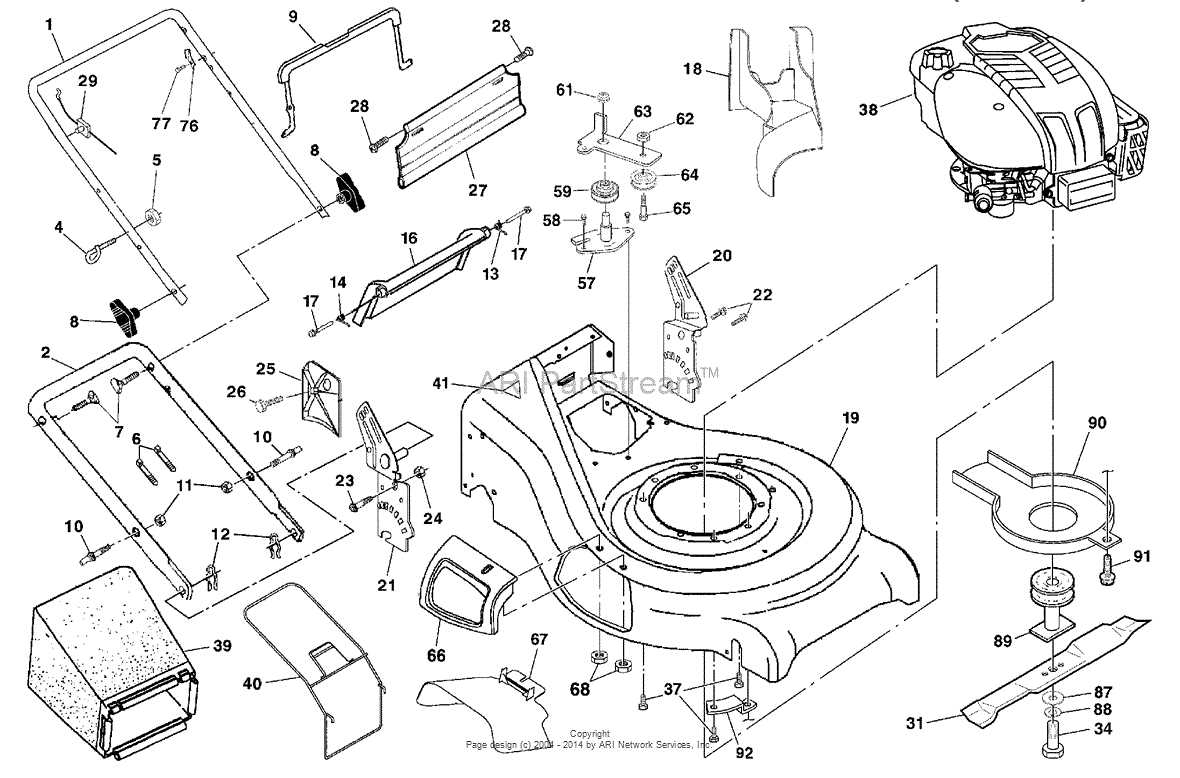

Ayp Parts Diagram for Optimal Understanding

In the world of machinery and equipment, a clear representation of various elements is essential for effective maintenance and troubleshooting. This visual guide serves as a critical tool for users, helping them identify and understand the relationship between different segments. By providing a comprehensive overview, it enhances clarity and aids in efficient repair processes.

Exploring the intricacies of these layouts reveals the interconnectedness of each element within a system. Such insights are invaluable for both seasoned technicians and novices alike. With a focus on visual clarity, these representations simplify complex structures, making it easier to locate specific components and understand their functions.

As users delve deeper into these illustrations, they uncover not only the practical aspects of assembly and disassembly but also the underlying principles that govern operation. This knowledge empowers individuals to engage more confidently with their equipment, fostering a greater sense of competence and independence in maintenance tasks.

Understanding AYP Parts Diagrams

Interpreting technical illustrations is essential for effective maintenance and repair of machinery. These visual representations offer a clear overview of components, their arrangements, and interconnections. Gaining familiarity with these illustrations enables users to identify necessary elements quickly, facilitating troubleshooting and replacement tasks.

Importance of Clarity in Technical Illustrations

Clear visuals play a critical role in ensuring that operators can efficiently comprehend complex assemblies. Each symbol and label contributes to a comprehensive understanding of how various components interact. This clarity helps prevent errors during repairs, enhancing both safety and performance.

Navigating the Visual Information

When examining these illustrations, it’s vital to approach them systematically. Start by identifying the main sections and their relationships to one another. Familiarity with standard symbols and terminology used in these visuals will significantly ease the process of locating specific components and understanding their functions.

Importance of Accurate Diagrams

Clear and precise representations are crucial in any technical field. They serve as a visual guide, helping users understand complex systems, components, and their interrelations. When these illustrations are accurate, they enhance communication and reduce the likelihood of errors during assembly, maintenance, or troubleshooting.

Moreover, reliable visuals contribute significantly to efficiency. When workers can easily interpret and follow detailed schematics, the overall workflow improves. This leads to faster project completion and minimizes downtime caused by misunderstandings or misinterpretations.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Accurate visuals clarify complex information, making it accessible to all users. |

| Reduced Errors | Clear guides help prevent mistakes that could lead to costly rework or failures. |

| Increased Efficiency | Streamlined processes result from better comprehension of the tasks at hand. |

| Improved Training | New users can quickly learn and adapt when provided with accurate resources. |

In conclusion, the significance of precise representations cannot be overstated. They are foundational tools that facilitate effective operation and communication within any technical domain.

Common Components in AYP Machinery

Understanding the key elements of various machines is crucial for effective maintenance and operation. These essential components work in harmony to ensure functionality and reliability, making it important to recognize their roles and interconnections.

Key Elements

- Engine: The heart of the machine, responsible for generating power.

- Transmission: This system transmits power from the engine to the wheels, influencing speed and torque.

- Chassis: The frame that supports all other components, providing structural integrity.

- Hydraulic System: Often utilized for lifting and moving parts, it enhances operational efficiency.

- Control System: Governs the machine’s functions, allowing the operator to manage settings and performance.

Additional Components

- Fuel System: Delivers fuel to the engine, crucial for performance.

- Cooling System: Prevents overheating by regulating temperature.

- Electrical System: Powers lights, ignition, and other electronic components.

- Body and Covers: Protect internal mechanisms and enhance durability.

Familiarity with these fundamental components can greatly improve maintenance practices and operational knowledge, ensuring machines run smoothly and efficiently.

How to Read AYP Diagrams

Understanding the layout of a complex system is essential for effective maintenance and troubleshooting. This guide will help you interpret visual representations that depict various components and their relationships, enabling you to navigate technical information with confidence.

Key Elements to Identify

Familiarize yourself with the common features found in these illustrations. Look for symbols that denote specific elements and lines that indicate connections. Recognizing these elements is crucial for grasping the overall functionality.

Interpreting Connections

Pay attention to how components are linked, as these relationships often reveal the flow of energy or information. Understanding these connections can lead to insights about how to resolve issues or enhance performance.

| Symbol | Meaning |

|---|---|

| Circle | Connection point |

| Arrow | Direction of flow |

| Square | Component or unit |

Identifying Key Parts and Functions

Understanding the fundamental components and their roles within a system is crucial for effective maintenance and operation. Each element serves a specific purpose, contributing to the overall functionality and efficiency. By recognizing these elements, users can troubleshoot issues and enhance performance.

Key components can be categorized into several groups based on their functions:

- Power Supply: Provides energy to the entire mechanism.

- Control System: Manages operations and regulates performance.

- Transmission Elements: Facilitates movement and power transfer between parts.

- Safety Features: Ensures secure operation and prevents accidents.

Each of these categories encompasses various individual components, each with its unique role:

- Power Supply:

- Batteries

- Transformers

- Control System:

- Sensors

- Microcontrollers

- Transmission Elements:

- Gears

- Belts

- Safety Features:

- Emergency Stops

- Protective Shields

By thoroughly examining and understanding these crucial components, users can optimize the functionality of the system and ensure its longevity.

Common Issues and Solutions

When working with mechanical systems, users often encounter a range of challenges that can impact performance and efficiency. Identifying these obstacles is crucial for effective maintenance and repair, ensuring that everything functions smoothly. This section explores prevalent problems and their corresponding solutions to enhance understanding and streamline the troubleshooting process.

Frequent Malfunctions

One of the most typical issues is wear and tear, which can lead to decreased efficiency or failure to operate altogether. Regular inspection and timely replacement of worn components can mitigate these concerns, ensuring longevity and optimal performance.

Connection Problems

Another common challenge arises from loose or damaged connections that disrupt functionality. Ensuring all connections are secure and free from damage, alongside periodic checks, can significantly reduce the risk of malfunctions and improve overall reliability.

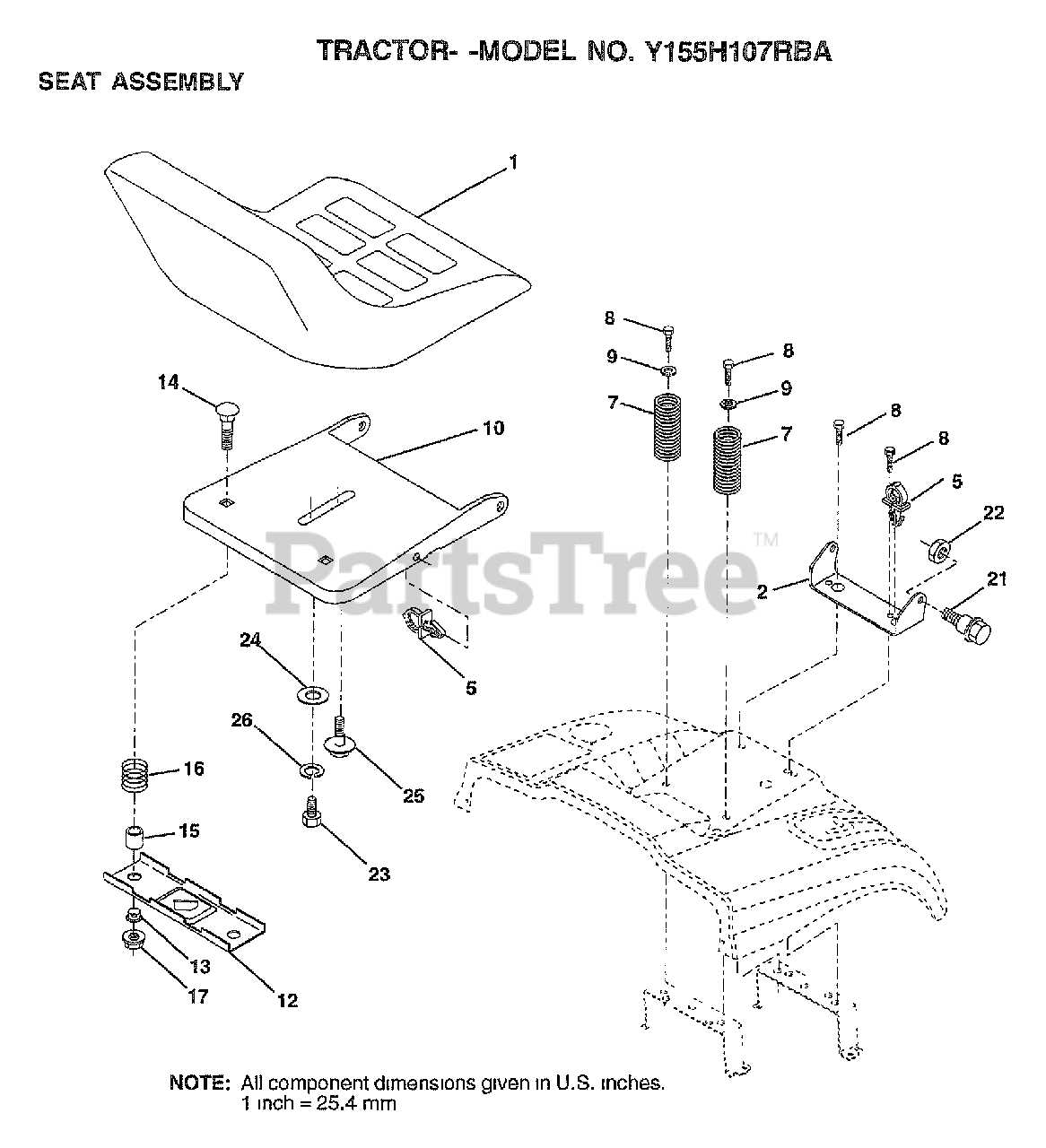

Comparing AYP Models and Diagrams

This section delves into the intricacies of various models and their corresponding representations, highlighting their similarities and differences. Understanding these variations is crucial for effective maintenance and troubleshooting, as each design offers unique features and functionalities.

When analyzing different configurations, it becomes evident that while some share foundational elements, others are distinctly tailored for specific applications. Variations in size, shape, and component arrangement can greatly influence performance and compatibility with various machinery.

Furthermore, comprehending the visual schematics associated with each model can enhance one’s ability to quickly identify components and their roles. This familiarity not only aids in repairs but also empowers users to make informed decisions when selecting equipment or replacement items.

Ultimately, a thorough comparison of these systems equips operators and technicians with the knowledge needed to optimize their use, ensuring efficiency and longevity in their operations.

Maintenance Tips for AYP Equipment

Regular upkeep of outdoor machinery is essential to ensure optimal performance and longevity. Adopting a proactive approach to maintenance can prevent costly repairs and enhance the efficiency of your tools. Here are some key tips to keep in mind for your equipment.

Routine Checks

- Inspect the machine regularly for any signs of wear or damage.

- Check fluid levels, including oil and fuel, to ensure they are within the recommended ranges.

- Examine belts and hoses for cracks or fraying, and replace them if necessary.

Cleaning and Storage

- Clean the equipment after each use to remove dirt and debris.

- Store machinery in a dry, sheltered area to protect it from the elements.

- Cover the tools with protective tarps or covers when not in use.

Implementing these practices will help maintain the efficiency and functionality of your equipment for years to come.

Resources for AYP Parts Information

When it comes to maintaining outdoor machinery, having access to reliable sources of information is crucial. This section provides various avenues to explore when seeking details about components and their specifications. Understanding the nuances of each resource can significantly enhance the maintenance and repair process.

Online Resources

The internet hosts a wealth of information regarding machinery components. Various websites offer manuals, schematics, and forums where users share insights and solutions. Here are some notable online platforms:

| Website | Description |

|---|---|

| Manufacturer’s Website | Official resources, including manuals and specifications directly from the producer. |

| Online Retailers | Stores that provide catalogs with detailed descriptions and customer reviews of specific items. |

| User Forums | Community-driven platforms where enthusiasts exchange tips and troubleshooting advice. |

Printed Resources

For those who prefer traditional methods, printed materials can be invaluable. Catalogs and repair manuals available in bookstores or through specialized suppliers often include diagrams and part numbers that assist in the identification process.

| Resource Type | Details |

|---|---|

| Service Manuals | In-depth guides that cover various models and their components, often with troubleshooting sections. |

| Catalogs | Comprehensive listings of available items along with pricing and compatibility information. |

| Repair Guides | Step-by-step instructions for common repairs, often supplemented with illustrations. |

Finding Replacement Parts Effectively

Locating suitable components for your equipment can often seem daunting, but with the right strategies, it becomes a streamlined process. Understanding where to seek information and how to evaluate your options is key to ensuring that you acquire the right items without unnecessary delays.

One of the most effective methods is to utilize online resources. Websites dedicated to machinery and tools often provide comprehensive catalogs that allow you to search by model number, specifications, or even manufacturer. Moreover, engaging with community forums can yield valuable insights from experienced users who may have faced similar challenges.

| Strategy | Description |

|---|---|

| Online Search | Utilize manufacturer websites and specialized marketplaces for detailed catalogs. |

| Community Engagement | Join forums or social media groups where enthusiasts share advice and experiences. |

| Local Suppliers | Visit or contact local distributors who may have the items in stock. |

| Maintenance Manuals | Consult manuals for specific recommendations on compatible components. |

By combining these methods, you can enhance your search efficiency and ensure that you find the necessary replacements with minimal hassle.

DIY Repairs Using AYP Diagrams

Embarking on home repairs can be a rewarding venture, allowing individuals to take charge of maintenance tasks while saving on costs. With the right visual guides, enthusiasts can easily navigate the complexities of machinery and tackle repairs effectively.

Benefits of Using Visual Guides

- Clarity in identifying components

- Step-by-step instructions enhance understanding

- Encourages confidence in tackling repairs

Steps for Successful Repairs

- Gather necessary tools and materials.

- Refer to visual guides for accurate identification.

- Follow the outlined steps methodically.

- Test the machinery after completing repairs.

By utilizing these resources, anyone can delve into DIY repairs and achieve ultimate satisfaction in their accomplishments.

Professional Services for AYP Machinery

Ensuring the optimal functionality of specialized equipment requires not only quality components but also expert services tailored to meet specific operational needs. Professional assistance plays a crucial role in maintaining efficiency, enhancing performance, and extending the lifespan of machinery. This section outlines the various services available to support the effective operation of your machinery.

Types of Professional Services

Comprehensive services can be categorized into several key areas, each designed to address different aspects of equipment maintenance and repair.

| Service Type | Description |

|---|---|

| Installation | Expert installation ensures that equipment is set up correctly for optimal performance and longevity. |

| Maintenance | Regular maintenance services help prevent breakdowns and prolong the life of machinery through routine checks and adjustments. |

| Repair | Timely repair services address any malfunctions quickly, minimizing downtime and restoring functionality. |

| Consultation | Professional consultation provides guidance on best practices for operation and maintenance, tailored to specific equipment types. |

Benefits of Professional Support

Engaging professional services offers numerous advantages, including improved reliability, reduced operational costs, and enhanced safety. By leveraging expert knowledge and experience, operators can ensure their equipment functions at its best, ultimately contributing to greater productivity and efficiency in their operations.

Future Trends in AYP Technology

The landscape of technological innovation is evolving rapidly, presenting new opportunities for efficiency and functionality. Emerging advancements are set to redefine how components are designed and utilized, ultimately enhancing user experiences and operational performance. As industries seek greater integration and automation, the future looks promising for these developments.

Smart Integration and Automation

One of the most significant trends is the rise of smart integration, where devices communicate seamlessly with each other. This interconnectedness allows for real-time data analysis and improved decision-making processes, making systems more adaptive and responsive to user needs.

Sustainability and Eco-Friendliness

Another crucial trend is the focus on sustainability. Innovations are being driven towards eco-friendly materials and energy-efficient designs, aligning with global efforts to reduce environmental impact. This shift not only benefits the planet but also appeals to a growing demographic of environmentally conscious consumers.