The internal structure and individual elements of a chainsaw play a crucial role in its operation and efficiency. A thorough understanding of these elements can make it easier to maintain and repair the machine, ensuring that it functions properly for years to come. Whether you’re an expert or a beginner, knowing the core features of such tools helps optimize their performance.

Every mechanical tool has a combination of key elements that contribute to its functionality. Knowing how these pieces connect and work together allows for more effective troubleshooting when issues arise. Detailed knowledge of these systems can also help prolong the life of your tool by allowing for timely and accurate repairs.

By gaining insights into the structure of your device, you’ll be equipped to handle both minor adjustments and major repairs, making your tool more reliable and efficient in the long run.

Understanding the critical elements of a high-performance chainsaw is key to maintaining its efficiency and durability. The machine’s main systems work together seamlessly, ensuring smooth operation even in demanding conditions. Each component plays a vital role in overall functionality, contributing to the power, control, and safety features that are expected from such tools.

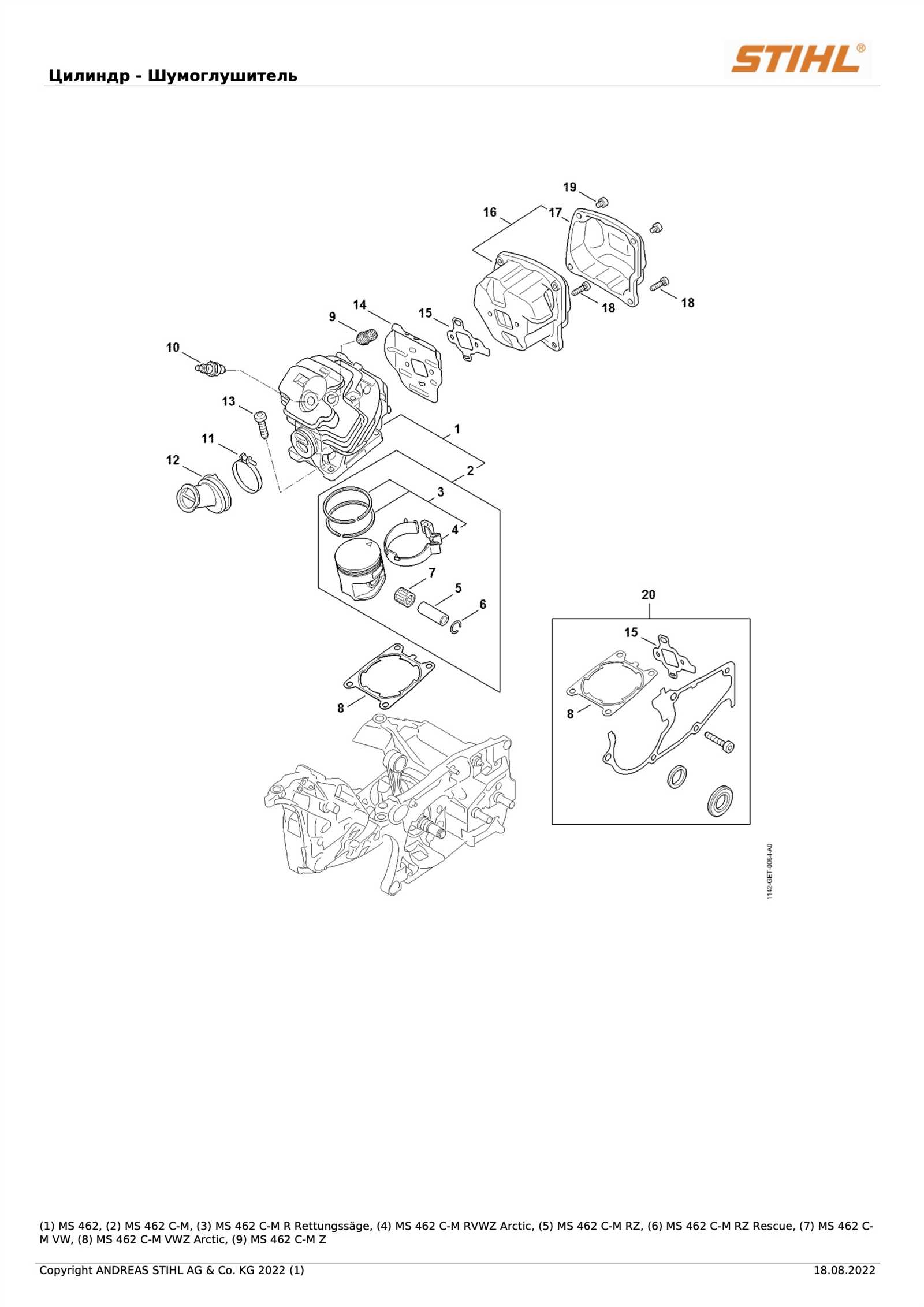

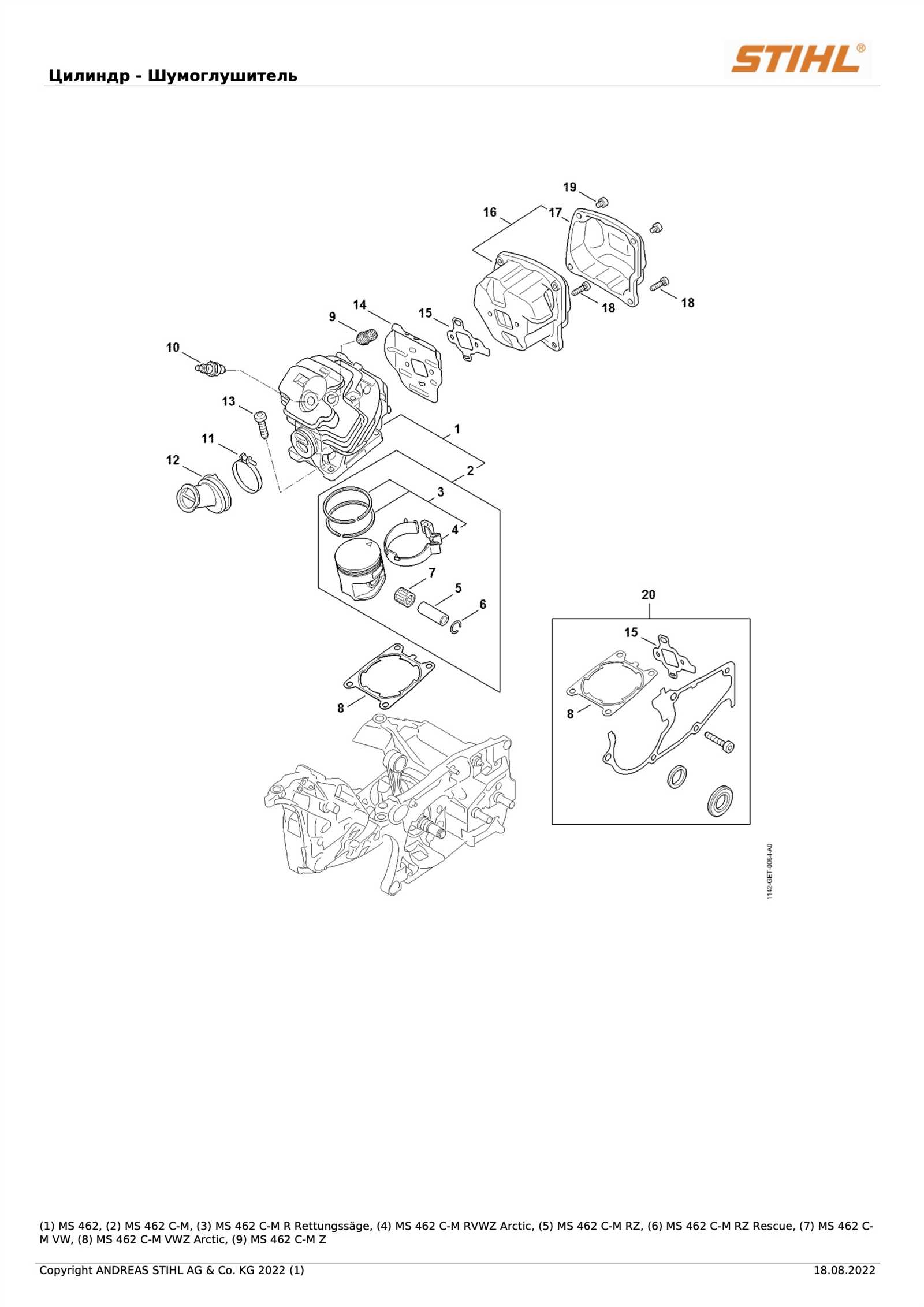

Understanding the core components of a two-stroke motor is essential for maintaining its performance and reliability. Each section plays a key role in ensuring smooth operation, from fuel intake to exhaust release, contributing to overall efficiency and power output.

The main elements involved in the functioning of this type of engine include the cylinder, crankshaft, piston, and carburetor. These parts work together to create the internal combustion process, which drives the motor. Proper alignment and condition of these pieces are crucial for long-term durability.

Other important components are the ignition system, which is responsible for generating the necessary spark, and the cooling mechanism that helps regulate temperature during operation. Both systems need regular checks to prevent overheating or ignition failure.

| Component |

Function |

| Cylinder |

Houses the piston and facilitates combustion |

| Piston |

Moves within the cylinder to generate power |

| Crankshaft |

Converts linear motion to rotational force |

| Carburetor |

Mixes air and fuel for combustion |

| Ignition System |

Provides the spark to ignite the air-fuel mixture |

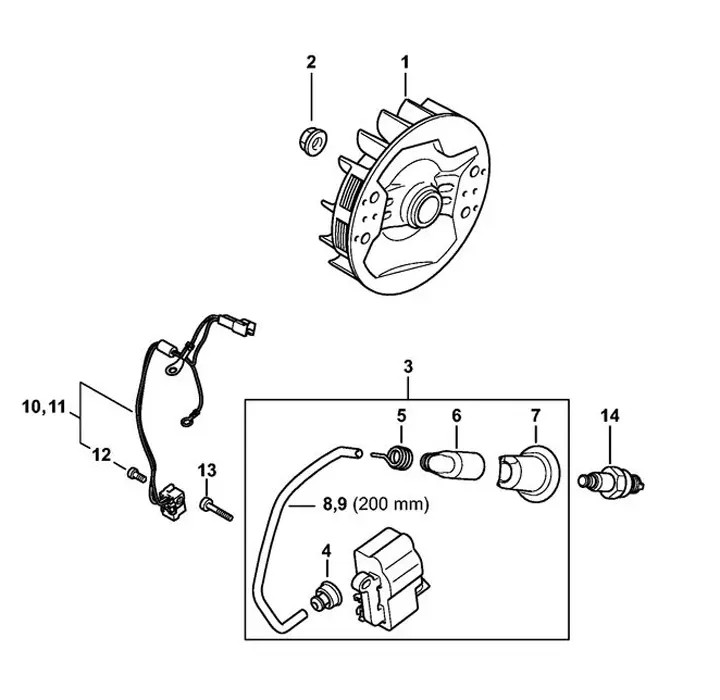

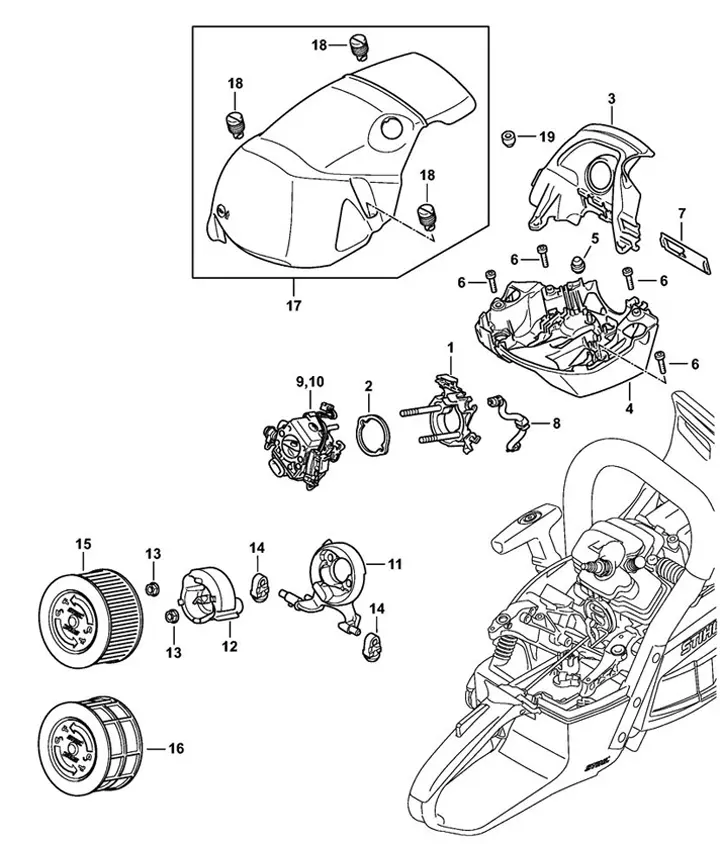

Key Features of the Ignition System

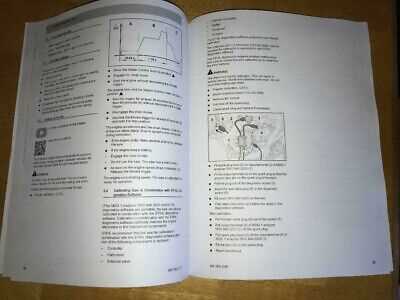

The ignition system plays a crucial role in ensuring reliable engine performance. Its primary function is to initiate combustion by delivering the necessary spark at the right moment, allowing for smooth operation and efficient power generation. Understanding the key components and their functionality within the system can help in diagnosing issues and maintaining optimal performance.

A modern ignition setup often includes advanced electronic control, which improves precision and timing. This leads to better fuel efficiency and reduced emissions. Durability is also a core feature, with components designed to withstand extreme conditions while providing consistent output over extended periods.

Additionally, the system is typically easy to maintain, requiring minimal intervention, but regular checks can help prevent potential malfunctions. Whether for professional or personal use, ensuring that the ignition is functioning correctly is essential for long-term reliability.

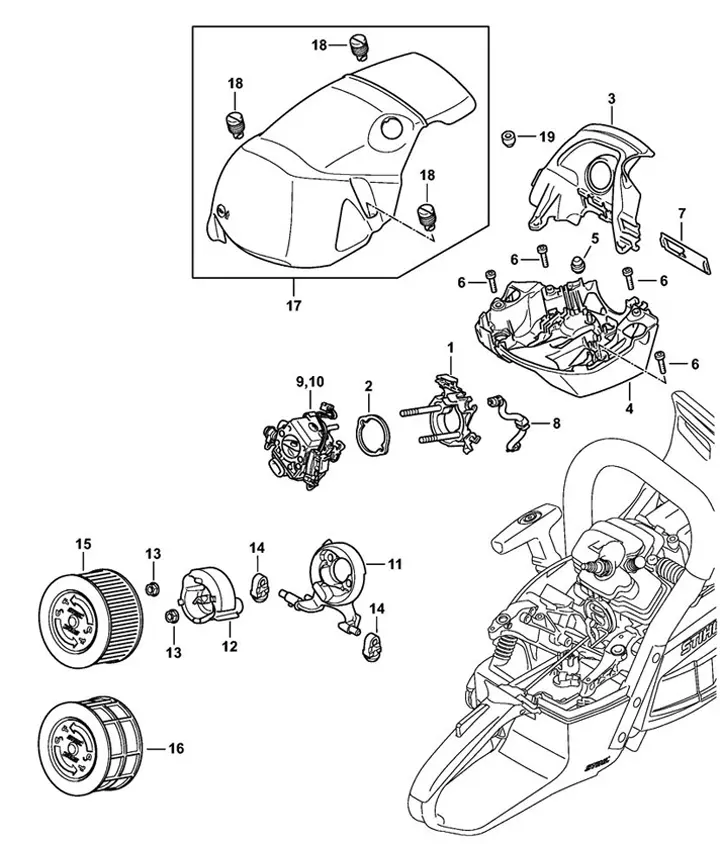

Carburetor Assembly and Functionality

The carburetor plays a critical role in the engine’s performance by managing the air-fuel mixture. Understanding its structure and how each part interacts is key to maintaining engine efficiency and resolving potential operational issues.

At the core, the carburetor consists of various components that regulate the intake of air and fuel, ensuring the right balance for optimal combustion. These components include the throttle, fuel jets, and air passages, each of which contributes to maintaining the engine’s performance under varying conditions.

Regular maintenance and adjustments to the carburetor can significantly impact fuel efficiency and overall engine responsiveness. By ensuring that the airflow and fuel supply are correctly balanced, you can avoid many common operational problems such as stalling or uneven acceleration.

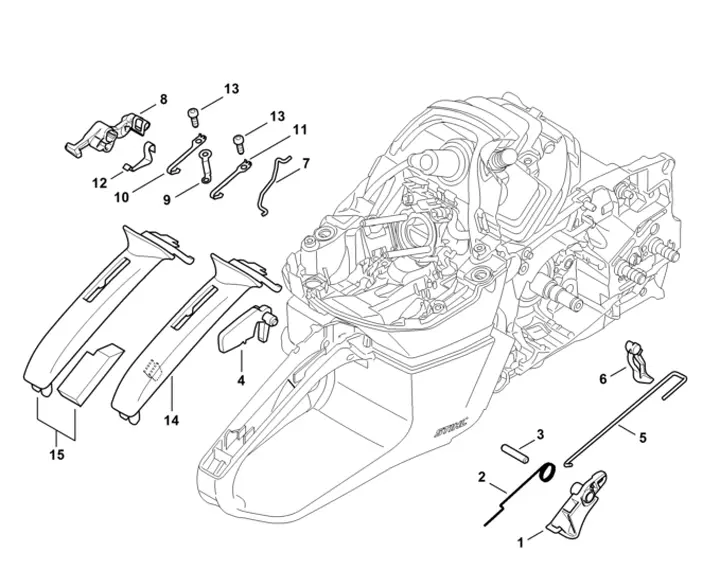

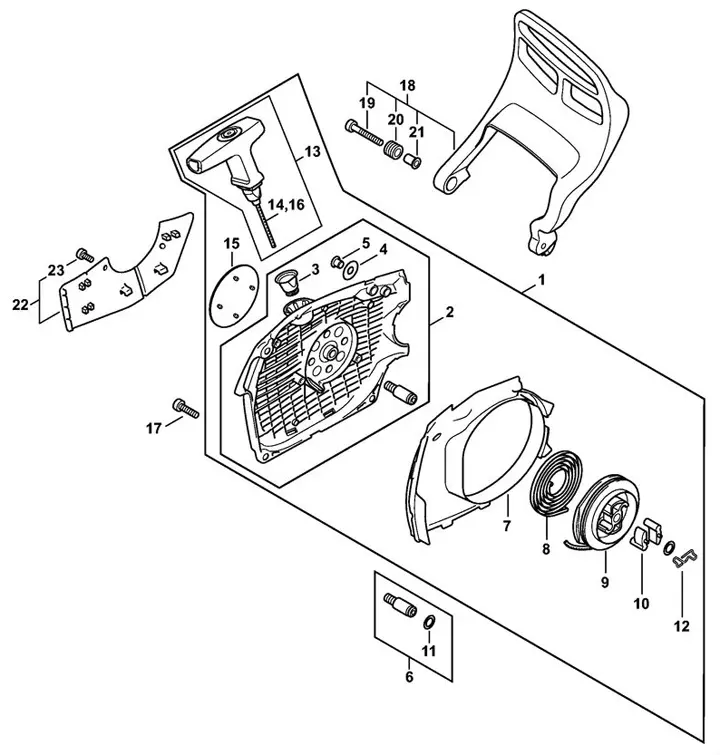

Chain Brake Mechanism Explained

The chain brake mechanism is a crucial safety feature that halts the movement of the chain during specific conditions. Designed to protect the user from potential accidents, it engages swiftly, reducing the risk of injury while working with the equipment. Understanding how it works can help in maintaining optimal safety and performance.

This system is typically activated by force from sudden movements, such as a kickback. The mechanism engages by disconnecting the chain from the drive system, stopping it almost instantly. This process is mechanical, relying on a combination of levers, springs, and friction components to ensure quick activation when necessary.

Proper maintenance of the chain brake ensures reliable function. Periodically checking and cleaning the components that trigger the mechanism can help prevent malfunctions, keeping the brake responsive in critical situations. Additionally, regular inspection of the brake band and other related parts is essential for long-term safety and performance.

Understanding the Muffler and Exhaust System

The muffler and exhaust system play a crucial role in the overall performance and efficiency of a combustion engine. This section explores the components, functions, and importance of this system, shedding light on how it contributes to the effective operation of the engine while minimizing noise and emissions.

Key Components of the Exhaust System

- Muffler: This component reduces engine noise and directs exhaust gases away from the engine.

- Exhaust Pipe: Responsible for transporting exhaust gases from the engine to the tailpipe.

- Catalytic Converter: Converts harmful pollutants into less harmful emissions before they exit the exhaust system.

- Exhaust Manifold: Collects exhaust gases from the engine cylinders and channels them into the exhaust pipe.

Importance of Maintenance

- Noise Reduction: A properly functioning muffler minimizes noise pollution.

- Efficiency: Regular maintenance ensures optimal performance and fuel efficiency.

- Emissions Control: Keeping the exhaust system in good condition helps reduce harmful emissions, meeting environmental regulations.

- Engine Longevity: Proper exhaust flow is essential for engine health, preventing overheating and damage.

Air Filter Maintenance and Replacement

Proper upkeep of the air filtration system is essential for optimal engine performance and longevity. Regular attention to the air filter ensures that the engine receives clean air, preventing dust and debris from causing damage. Neglecting this vital component can lead to reduced efficiency and increased fuel consumption.

Checking the Air Filter

Replacing the Air Filter

To replace the air filter, first ensure the engine is turned off and cool. Carefully remove the old filter, taking note of how it fits in place. Install the new filter by aligning it properly within the housing. Secure it in place, making sure it fits snugly to prevent any air leaks. Regular replacement, as recommended by the manufacturer, will help maintain peak performance.

Guide to Fuel System Components

The fuel system is a crucial part of any engine, responsible for delivering the necessary mixture of fuel and air to ensure optimal performance. Understanding its various elements is essential for effective maintenance and troubleshooting. This section will explore the primary components of the fuel system, shedding light on their functions and importance.

Fuel Tank: The fuel tank stores the gasoline or fuel required for the engine. It is designed to prevent leaks and maintain pressure, ensuring a steady supply of fuel to the system.

Fuel Pump: This component is responsible for transferring fuel from the tank to the carburetor or fuel injection system. It maintains the correct fuel pressure and flow, which is vital for engine operation.

Fuel Filter: The fuel filter removes impurities and contaminants from the fuel before it reaches the engine. Keeping the fuel clean helps prolong the life of the engine and ensures efficient combustion.

Carburetor or Fuel Injector: These components mix fuel with air in the correct ratio for combustion. The carburetor does this mechanically, while fuel injectors use electronic control for precision delivery, enhancing performance and efficiency.

Fuel Lines: Fuel lines connect the various components of the fuel system, facilitating the flow of fuel. They must be properly sealed and in good condition to prevent leaks and ensure consistent fuel delivery.

By familiarizing yourself with these essential parts, you can better understand how to maintain and troubleshoot the fuel system, ensuring your engine runs smoothly and efficiently.

Handlebar and Anti-Vibration Elements

The handlebar and anti-vibration components are crucial for ensuring a comfortable and safe operating experience with power tools. These elements work together to provide stability while minimizing the effects of vibrations, which can lead to user fatigue and discomfort during prolonged use.

Handlebars are designed to offer a secure grip, enabling precise control over the tool’s movement. Their ergonomic shape helps distribute force evenly, reducing strain on the user’s hands and arms. It is essential to regularly inspect the handlebar for any signs of wear or damage, as this can impact overall handling and safety.

Anti-vibration systems play a vital role in dampening the vibrations produced by the engine and cutting mechanisms. These systems typically include specially designed mounts or cushions that absorb shocks, allowing users to operate their equipment with reduced physical strain. Proper maintenance of these components is necessary to ensure their effectiveness and longevity.

Protective Covers and Their Importance

Protective coverings play a vital role in safeguarding equipment from environmental factors and wear. These components are essential in maintaining the functionality and longevity of tools, ensuring they remain in optimal condition during use and storage.

Benefits of Protective Covers

One of the primary advantages of using protective coverings is their ability to shield machinery from dust, moisture, and debris. By acting as a barrier, they help prevent damage that can lead to costly repairs and replacements. Additionally, these coverings often enhance safety by reducing the risk of accidents caused by exposed parts.

Choosing the Right Protective Cover

Selecting the appropriate protective covering is crucial for achieving maximum protection. Factors such as material, fit, and intended use should be considered to ensure the cover provides adequate shielding. Investing in high-quality coverings can lead to significant savings in maintenance and repair costs over time.

Oil Pump and Lubrication System

The oil pump and lubrication system play a crucial role in maintaining the efficiency and longevity of a power tool. This system ensures that all moving components receive adequate lubrication, minimizing friction and wear during operation. Proper functioning of the lubrication mechanism is essential for optimal performance and reliability.

Typically, the oil pump is responsible for delivering a consistent flow of lubricant to various parts of the engine, especially the chain and bar, which are prone to high levels of stress. Effective lubrication not only protects these components but also enhances cutting efficiency and overall productivity.

Understanding the mechanics behind the oil delivery system is vital for troubleshooting and maintenance. Regular inspection and timely replacement of worn-out parts ensure that the lubrication system operates smoothly, preventing potential damage and extending the tool’s lifespan.

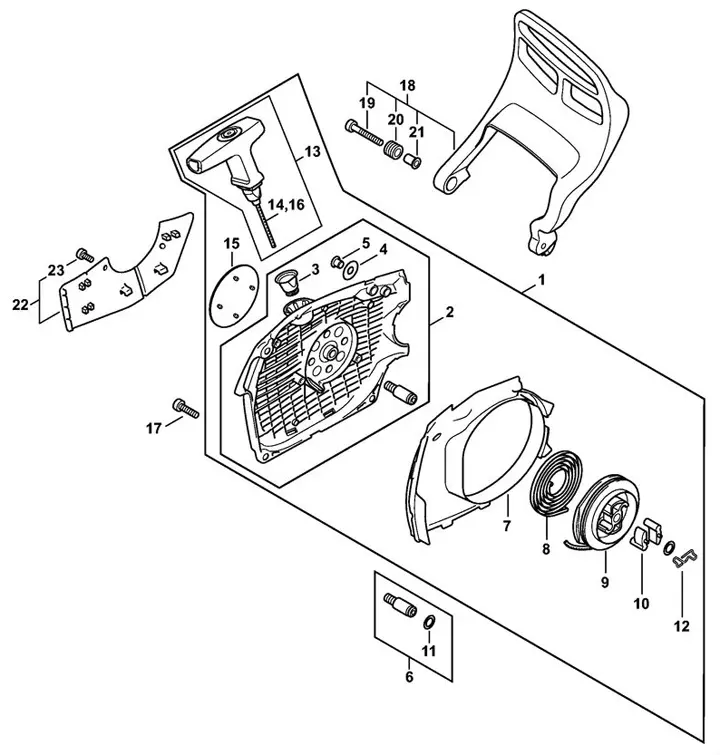

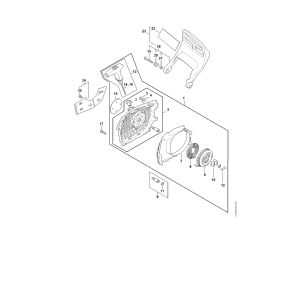

Recoil Starter and Starting Mechanism

The recoil starter is a crucial component in the ignition system of outdoor power equipment. It is designed to initiate the engine’s operation by employing a manual pull mechanism, enabling the user to start the machine efficiently. Understanding the functionality and structure of this assembly is essential for effective maintenance and troubleshooting.

Key features of the recoil starter include:

- Spring Mechanism: Utilizes a coiled spring to store energy during the pull, which is released to rotate the engine’s flywheel.

- Starter Rope: A durable cord that connects to the grip handle, allowing the user to pull and engage the starter.

- Housing: Protects the internal components and provides a guide for the starter rope, ensuring smooth operation.

The starting mechanism involves several interconnected parts working in unison to initiate combustion. Here are the primary components:

- Flywheel: The part that rotates when the starter engages, creating the necessary momentum for the engine to start.

- Pawl: A lever that engages with the flywheel, helping to transfer the rotational force generated by the recoil action.

- Starter Cup: The section of the flywheel that captures the pawl during operation, allowing for an efficient start.

Regular inspection and maintenance of the recoil starter and its associated mechanisms are vital for ensuring reliable engine performance. Attention to wear and tear can prevent starting issues and enhance the longevity of the equipment.