Understanding the Parts Diagram of Husqvarna Backpack Sprayers

Every gardener or landscaper knows that the effectiveness of their tools relies heavily on the quality and maintenance of their components. Having a comprehensive understanding of each element involved in the operation can significantly enhance efficiency and prolong the lifespan of the equipment.

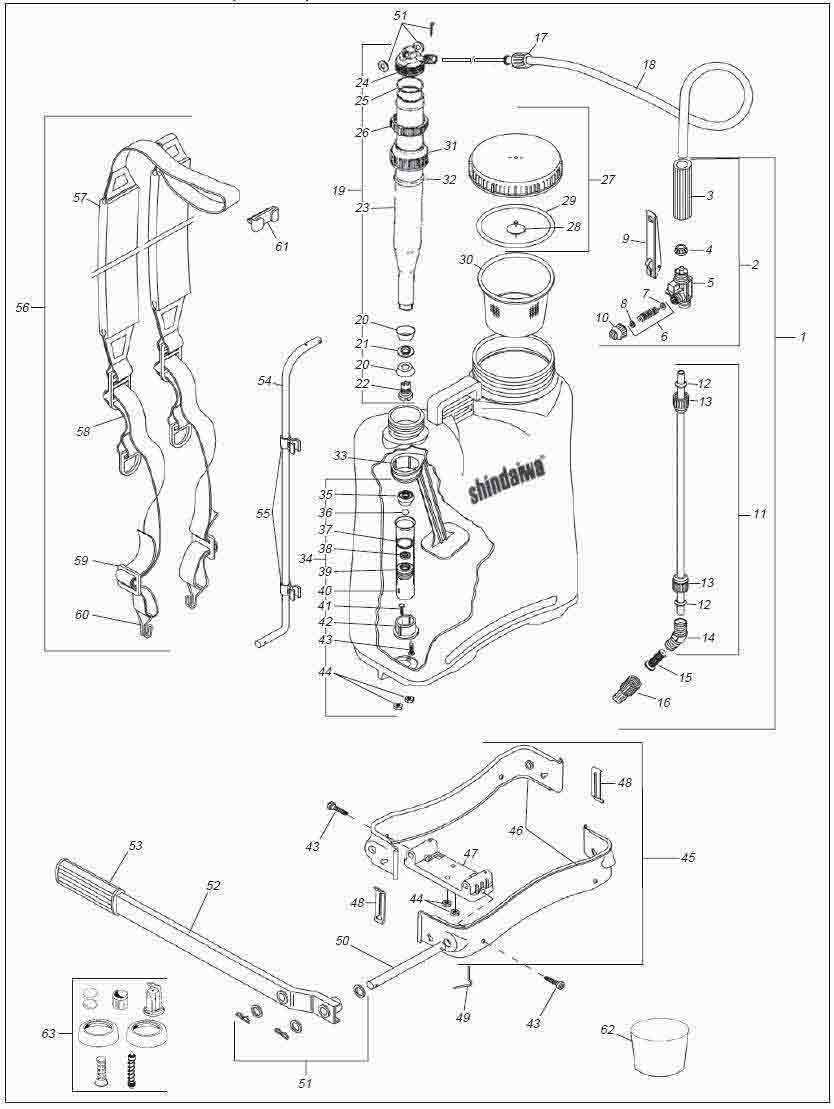

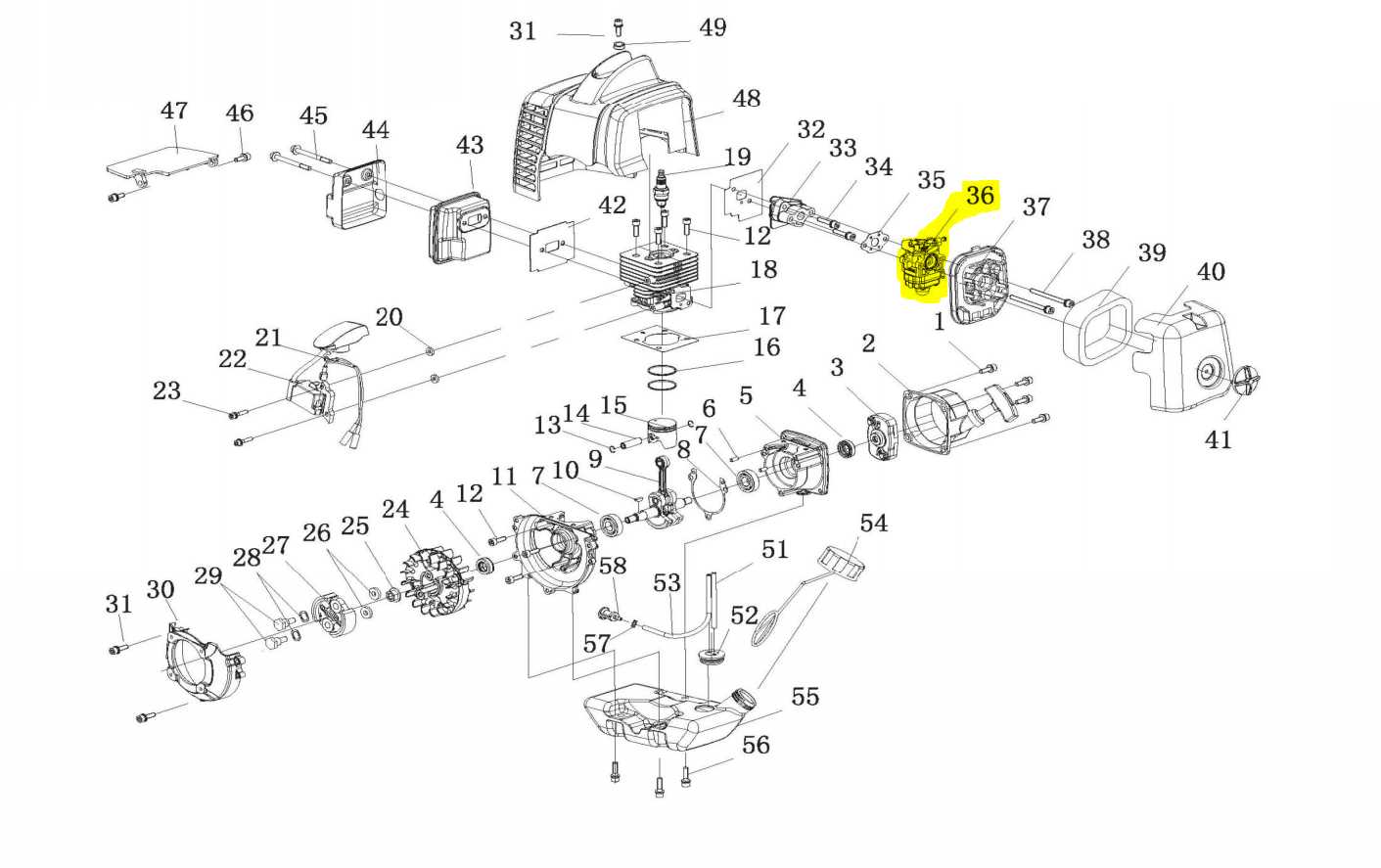

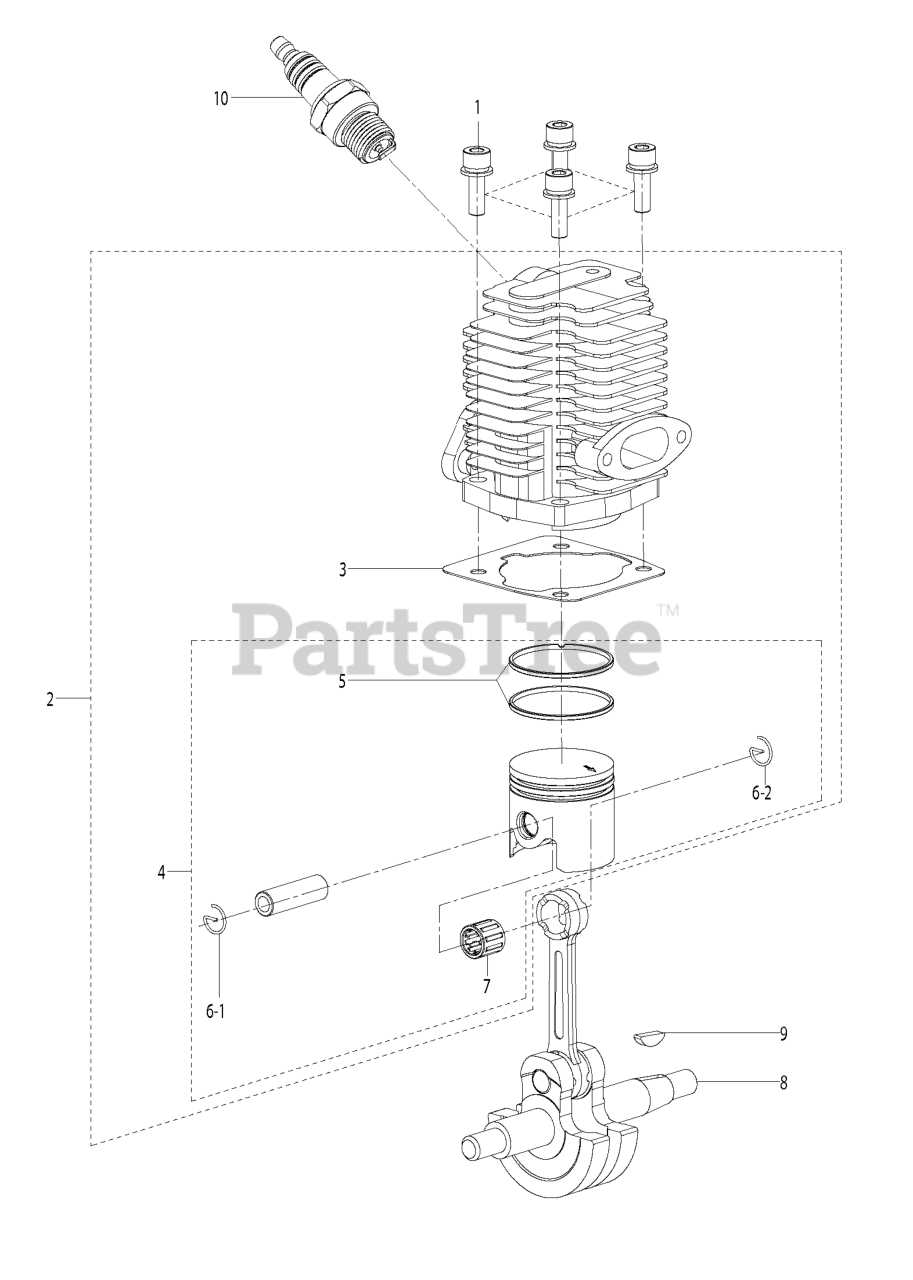

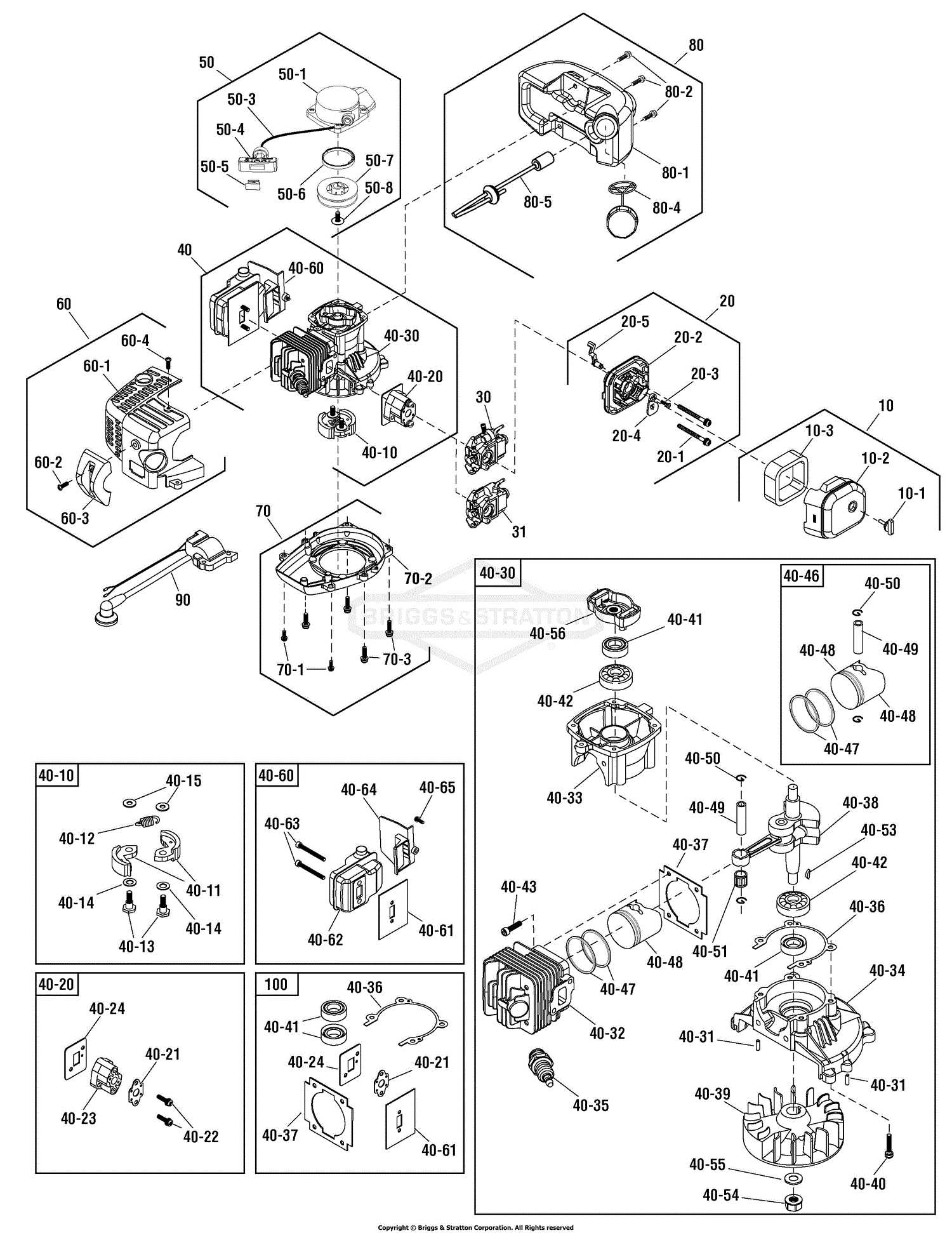

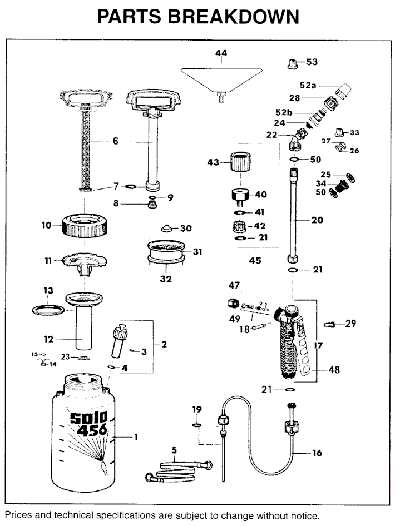

Visual aids can provide invaluable assistance in identifying and understanding these essential parts. By examining a detailed representation of the various elements, users can better appreciate their roles and interconnections, ensuring smoother operation and easier troubleshooting.

Whether you’re a seasoned professional or a novice enthusiast, knowing how to navigate these intricate structures will ultimately lead to improved performance. Delving into the specifics allows for more informed decisions when it comes to repairs and upgrades, fostering a deeper connection with your gear.

Understanding Husqvarna Backpack Sprayer Components

When it comes to effective gardening and agricultural tasks, comprehending the individual elements of a liquid application tool is crucial. Each component plays a specific role, contributing to the overall functionality and efficiency of the device. Familiarity with these features not only enhances performance but also aids in maintenance and troubleshooting.

Key Functional Elements

The core functional elements include the reservoir, which holds the liquid, and the delivery mechanism that ensures even application. Additionally, a pressure system is vital for maintaining consistent output, allowing for accurate and controlled dispersal of substances. Understanding how these components interact can greatly improve the user’s experience and results.

Maintenance and Replacement

Regular upkeep of the individual elements is essential for long-term reliability. Knowledge of how to identify wear and tear can lead to timely replacements, preventing costly repairs or inefficient performance. Engaging with the operational manual can provide insights into which components may require periodic attention, ensuring that the tool remains in optimal condition.

Importance of Quality Replacement Parts

Ensuring optimal performance and longevity of your equipment relies heavily on the quality of components used in maintenance and repair. High-grade replacements not only enhance functionality but also safeguard against potential breakdowns and inefficiencies. Investing in superior alternatives can make a significant difference in the overall reliability of your tools.

Using top-notch components offers numerous advantages:

- Enhanced Durability: Quality parts are engineered to withstand wear and tear, providing extended life for your equipment.

- Improved Efficiency: Premium replacements function more effectively, leading to better performance and reduced operational costs.

- Reduced Risk of Failure: Reliable components lower the chances of malfunction, minimizing downtime and costly repairs.

- Better Safety: High-quality items ensure safer operation, protecting users from potential hazards associated with inferior substitutes.

In the long run, the choice of replacements plays a crucial role in maintaining equipment functionality and achieving desired outcomes. Therefore, prioritizing quality over cost is essential for anyone looking to optimize their machinery’s performance.

Common Issues with Sprayer Parts

Understanding frequent challenges with various components can enhance the performance and longevity of equipment. Operators often encounter specific malfunctions that can hinder efficiency and effectiveness. Addressing these concerns promptly is essential for maintaining optimal functionality.

Clogs are a typical issue, often caused by debris or residues from previous use. Regular cleaning and maintenance can significantly reduce the occurrence of blockages.

Leaks can arise from worn seals or damaged connections, leading to inefficient operation. Checking for wear and replacing seals as needed is crucial to prevent fluid loss.

Poor pressure can result from faulty valves or air leaks in the system, impacting the distribution of the liquid. Regular inspection of the pressure regulator and hoses helps in identifying and rectifying such issues.

Corrosion can affect metal components, especially when exposed to harsh chemicals. Using appropriate protective coatings and rinsing after use can mitigate this problem.

Identifying Key Parts in Diagrams

Understanding the essential components represented in visual schematics is crucial for effective maintenance and troubleshooting. These illustrations serve as invaluable tools, providing clarity on the various elements involved in the equipment’s operation. By familiarizing oneself with the layout and labeling, users can enhance their ability to perform repairs or adjustments.

Familiarity with Terminology: Grasping the specific terminology associated with each component can greatly improve one’s comprehension of the visual representation. Terms like valve, nozzle, and tank are commonly used and knowing their functions aids in identifying their locations in the diagram.

Understanding Relationships: Recognizing how different components interact is essential. Many diagrams illustrate connections between parts, highlighting pathways for fluid movement or airflow. This interconnectedness is key for troubleshooting potential issues.

Utilizing Reference Guides: Many manufacturers provide detailed reference materials that accompany these visuals. Consulting such guides can clarify any uncertainties and enhance understanding of the schematic’s layout.

How to Read Parts Diagrams Effectively

Understanding visual schematics is essential for efficient maintenance and repairs. These illustrations provide a clear view of components and their relationships, making it easier to identify and troubleshoot issues. By following a systematic approach, users can enhance their comprehension and improve their repair skills.

Familiarize Yourself with Symbols: Different elements often use unique symbols or labels. Recognizing these can streamline the process of locating specific components.

Follow the Flow: Diagrams typically show the connection and arrangement of parts. Observing the flow helps in understanding how each piece interacts with others, which is crucial for effective repairs.

Use a Legend: Many schematics include a legend or key that explains the symbols used. Always refer to this guide to ensure accurate interpretation of the diagram.

Practice with Real Examples: The more you engage with actual schematics, the better you’ll become at reading them. Start with simpler layouts before tackling more complex ones to build your confidence.

Take Notes: Jot down any insights or unfamiliar terms as you study. This practice reinforces learning and provides a handy reference for future projects.

Maintenance Tips for Backpack Sprayers

Regular upkeep of your equipment is essential for optimal performance and longevity. Proper care not only enhances efficiency but also ensures safety during use. Here are some valuable tips to keep your gear in top shape.

Routine Cleaning

Cleaning your device after each use prevents residue buildup and potential clogs. Follow these steps:

- Rinse the tank thoroughly with water to remove any remaining liquid.

- Flush the hoses and nozzles with clean water.

- Wipe down all external surfaces to eliminate dirt and chemical residues.

Regular Inspections

Performing frequent checks can identify wear and tear before they become major issues. Consider the following:

- Examine seals and gaskets for signs of wear or damage.

- Inspect hoses for cracks or leaks.

- Check the nozzles for blockages or degradation.

Address any issues promptly to ensure seamless operation and prevent costly repairs.

Where to Find Original Parts

Ensuring optimal performance of your equipment requires access to authentic components. Identifying reliable sources is crucial for maintaining functionality and longevity. Here are some avenues to consider when searching for genuine replacements.

- Manufacturer’s Website: The official website often features a dedicated section for replacements. Here, you can find a comprehensive list of available items along with detailed specifications.

- Authorized Dealers: Visiting a certified retailer can provide access to original merchandise. These dealers typically maintain a stock of necessary components and can offer expert advice.

- Local Repair Shops: Many local service centers specialize in equipment maintenance. They may have direct connections with suppliers and access to genuine replacements.

- Online Marketplaces: Reputable e-commerce platforms often feature sections for authentic components. Look for sellers with positive reviews and verified ratings to ensure quality.

- Manufacturer Support: Reaching out to customer service can help in locating specific items. They can guide you to the best options for your needs.

lessCopy code

By exploring these resources, you can secure the authentic components necessary for effective maintenance and operation of your machinery.

Upgrading Your Sprayer’s Performance

Enhancing the efficiency and effectiveness of your application equipment can significantly impact your gardening or agricultural tasks. By focusing on various aspects of your device, you can achieve improved results, reduce downtime, and enhance user comfort. This section outlines key areas for optimization to ensure your equipment operates at its best.

Enhancing Pressure and Flow Rate

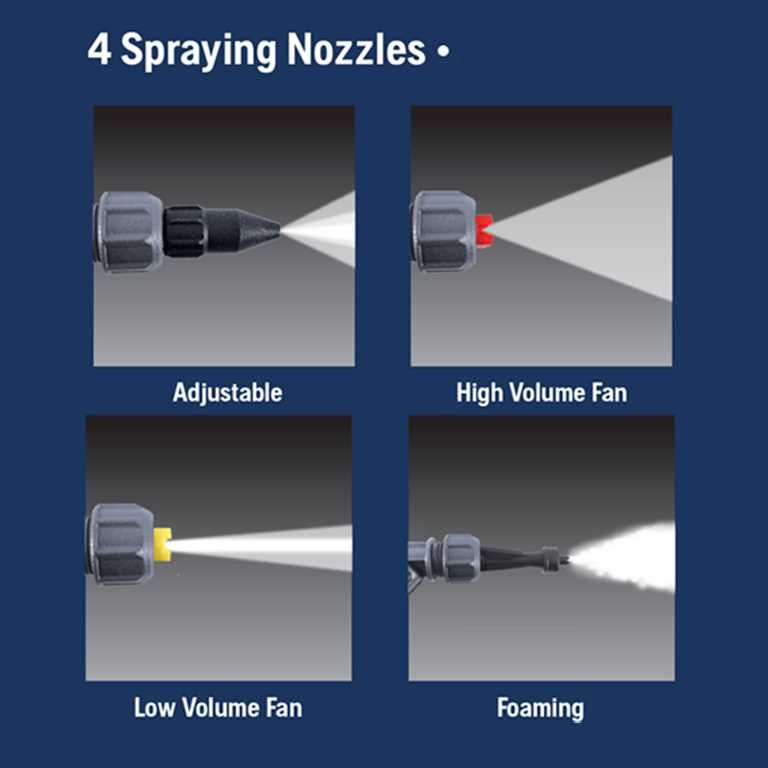

One of the primary factors influencing performance is the pressure and flow rate of the liquid being applied. Upgrading the nozzle to a more efficient design can help achieve finer droplets, ensuring better coverage and penetration. Additionally, checking and adjusting the pump mechanism for optimal pressure settings can lead to enhanced spraying efficiency, allowing you to cover larger areas with less effort.

Improving Comfort and Usability

Comfort plays a vital role in the overall experience of using your equipment. Investing in ergonomic straps and padding can reduce fatigue during extended use. Furthermore, ensuring that the tank is easy to fill and clean can save valuable time. Adding features such as a built-in gauge for liquid levels can help you monitor usage without interrupting your workflow, thus making your tasks smoother and more efficient.

Comparison of Various Models

This section aims to explore the differences and similarities among various models designed for efficient liquid application. By examining key features, functionality, and performance, users can make informed decisions tailored to their specific needs.

Model A is known for its lightweight design and ergonomic fit, making it ideal for extended use. Its adjustable nozzle allows for precision in application, catering to a variety of tasks.

Model B, on the other hand, boasts a larger capacity tank, enabling longer work sessions without frequent refills. Its robust construction ensures durability in demanding environments.

Model C emphasizes versatility, offering multiple spray patterns and an easy-to-clean filter system. This model is well-suited for both residential and commercial applications.

Ultimately, selecting the right option involves considering factors such as intended use, comfort, and efficiency, allowing for a tailored experience that meets individual preferences.

Assembly Instructions for New Parts

When integrating new components into your equipment, following a structured approach ensures optimal functionality and longevity. Proper assembly is crucial for achieving the desired performance and maintaining the integrity of the unit.

Here are the key steps to successfully put together your new components:

- Gather Necessary Tools:

- Wrenches

- Screwdrivers

- Sealing materials

- Safety goggles

- Review the Instruction Manual:

Ensure you have the latest manual on hand to familiarize yourself with the components and assembly guidelines specific to your model. - Prepare the Workspace:

Clear a clean, well-lit area where you can lay out all components and tools. This will help prevent misplacing items. - Inspect New Components:

Check for any visible damage or defects. Ensure that all necessary parts are included. - Start with Base Assembly:

Begin with the foundational parts, following the sequence outlined in the manual. Ensure each piece is securely fitted. - Attach Additional Components:

Progressively add remaining components, ensuring that you tighten screws and connections as you go to avoid leaks or instability. - Test the Assembly:

Once all components are assembled, conduct a thorough inspection and test run to confirm everything is functioning correctly.

By following these instructions, you can ensure that your new components are assembled correctly, contributing to the efficiency and effectiveness of your equipment.

Understanding Warranty and Parts Coverage

When investing in outdoor equipment, knowing the protection offered by the manufacturer is crucial. Warranty agreements provide peace of mind, ensuring that if issues arise, assistance is available. It’s essential to grasp the scope of these guarantees and how they relate to the components of your machinery, as this can significantly influence long-term satisfaction and maintenance costs.

Most warranties cover defects in materials and workmanship, but specifics can vary widely. Familiarizing yourself with the terms of coverage helps you understand what repairs or replacements are included, as well as the duration of protection.

| Coverage Aspect | Description |

|---|---|

| Duration | Typically, warranties last for a specific number of years or hours of use. |

| Labor Costs | Some agreements may include labor for repairs, while others might only cover parts. |

| Exclusions | Understanding what is not covered is equally important, as neglect or misuse often voids protection. |

| Transferability | Check if the warranty can be transferred to a new owner, which can enhance resale value. |

In summary, a clear understanding of warranty terms and component coverage can save you time and resources. It’s wise to review these details carefully before making a purchase, ensuring you choose a model that meets your needs while providing reliable support. Regular maintenance, as outlined in the user manual, can also help maintain your warranty eligibility.