Comprehensive Guide to Stihl 012 AV Chainsaw Parts Diagram

The intricacies of a powerful cutting instrument can often be overlooked. A comprehensive understanding of its individual elements not only enhances performance but also ensures longevity. Each component plays a vital role in the overall functionality, contributing to the ultimate efficiency of the device.

In this section, we will delve into the essential elements that make up this remarkable tool. By examining the relationships and interconnections among the various pieces, users can gain insight into maintenance and troubleshooting. Recognizing how these components interact is crucial for anyone looking to optimize their experience with such equipment.

With this knowledge, operators can better appreciate the engineering behind their cutting tools. A well-informed user is equipped to make sound decisions regarding repairs and upgrades, ultimately leading to improved performance and satisfaction in every task undertaken.

Overview of Stihl 012 AV Chainsaw

This section explores a renowned model in the world of cutting tools, highlighting its efficiency, design, and essential features. A reliable instrument for both professionals and enthusiasts, it embodies durability and ease of use, making it a popular choice for various tasks.

Key Features

One of the standout characteristics is its lightweight structure, which facilitates maneuverability without sacrificing power. Additionally, the advanced anti-vibration system enhances comfort during prolonged use, reducing fatigue significantly.

Performance and Reliability

With a robust engine, this tool delivers exceptional performance in diverse applications. Its construction ensures longevity, making it a worthwhile investment for those who seek ultimate reliability in their cutting endeavors.

Key Features of the 012 AV Model

This model is renowned for its exceptional performance and innovative design, making it a popular choice among professionals and enthusiasts alike. Its robust engineering ensures reliability and efficiency, enabling users to tackle various tasks with ease.

Powerful Engine

- High-output motor for effective cutting.

- Fuel-efficient technology reduces consumption.

- Easy start mechanism enhances user experience.

Durable Construction

- Quality materials ensure longevity.

- Lightweight design allows for improved maneuverability.

- Vibration dampening system provides comfort during use.

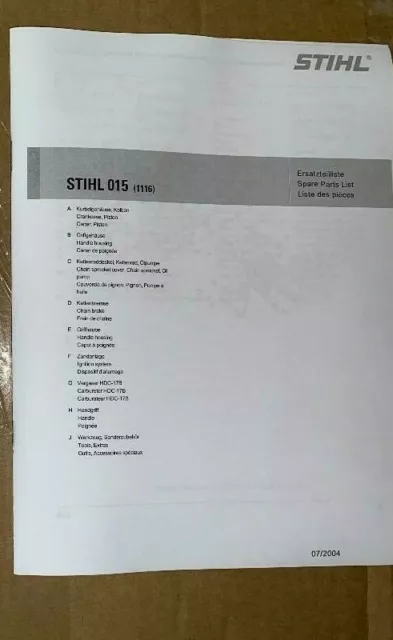

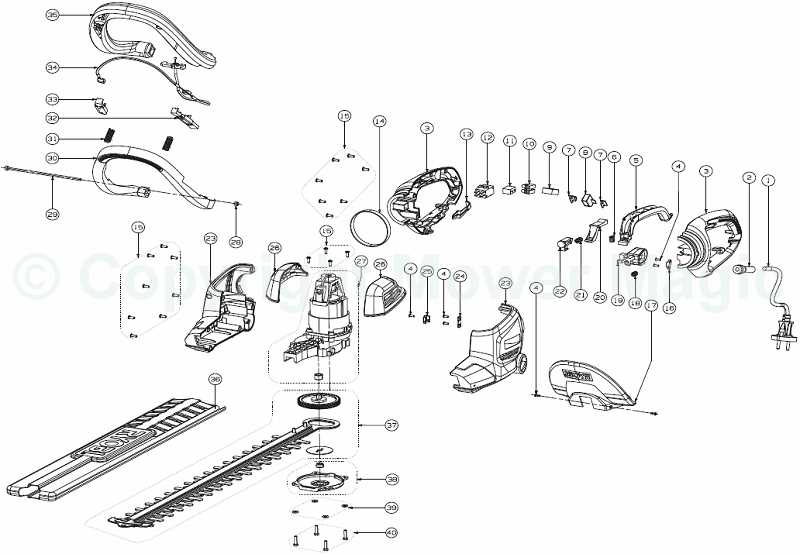

Importance of Chainsaw Diagrams

Understanding the layout and components of a cutting tool is essential for efficient operation and maintenance. Visual representations provide clarity on how various elements interact and help users troubleshoot issues effectively. Whether for professional use or personal projects, a comprehensive illustration aids in grasping the intricacies of the equipment.

Benefits of Visual References

Having access to a visual reference enhances the learning process, making it easier to identify components and their functions. It fosters better communication between users and technicians, ensuring that repairs and adjustments are performed correctly. Additionally, such resources can save time and reduce the risk of errors during maintenance.

Components Overview

Each visual guide typically includes a breakdown of essential elements, allowing users to familiarize themselves with the machinery. Below is a simplified overview of the most critical components often depicted in these resources:

| Component | Description |

|---|---|

| Engine | Power source that drives the cutting mechanism. |

| Guide Bar | The metal bar that supports the chain and determines the cutting length. |

| Chain | Teeth that cut through wood, moving around the guide bar. |

| Handle | Grip area for user control and maneuverability. |

| Brake | Safety feature that stops the chain in case of kickback. |

Ultimately, visual aids serve as a vital resource for anyone involved with this type of equipment, promoting safety and efficiency in operation.

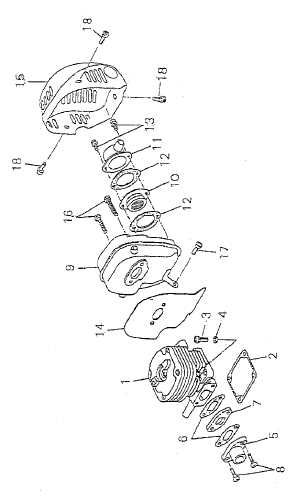

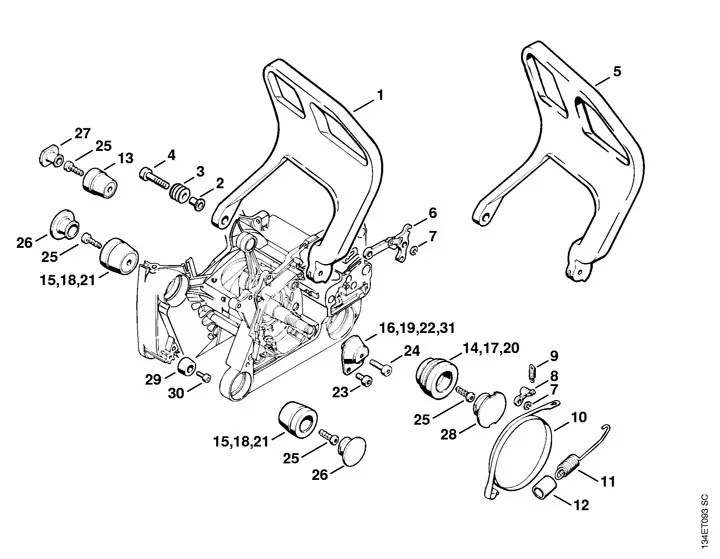

Identifying Parts in the Diagram

Understanding the layout of components is essential for effective maintenance and repair. A visual representation can significantly enhance one’s ability to locate and recognize individual elements. This knowledge is crucial for troubleshooting and ensuring the proper functioning of the equipment.

Familiarizing with the Layout

Before diving into specifics, it is important to become acquainted with the overall arrangement. Each section serves a unique purpose, contributing to the seamless operation of the machine. Identifying major categories, such as the engine assembly and the cutting mechanism, can provide a solid foundation for further exploration.

Locating Specific Elements

Once you have a grasp of the general layout, focus on pinpointing individual components. Pay attention to labels and numbering, which often accompany these illustrations. Understanding the function of each piece–whether it is a fastener, a housing, or a drive mechanism–will aid in both maintenance and potential upgrades. Moreover, having a clear reference will streamline the repair process, saving time and reducing frustration.

Common Components of the 012 AV

This section explores the essential elements that contribute to the functionality and efficiency of a particular cutting tool. Understanding these components helps users maintain and optimize performance for various tasks.

| Component | Description |

|---|---|

| Engine | The power source that drives the tool, providing the necessary energy for operation. |

| Guide Bar | A crucial element that directs the cutting process, ensuring precision and control. |

| Chain | The cutting element that engages with the material, designed for efficient cutting performance. |

| Clutch | A mechanism that allows for the engagement and disengagement of the cutting chain, enhancing safety. |

| Fuel Tank | The reservoir that holds the fuel required for the engine to operate. |

How to Read the Parts Diagram

Understanding the layout of components in a technical illustration is essential for maintenance and repair tasks. This guide will help you navigate these visuals effectively, ensuring you can identify and locate each element with ease.

Identifying Components

When examining a visual representation, pay attention to the following:

- Labels: Each part is usually marked with a unique identifier.

- Numbers: Look for corresponding numbers that reference a list or key, providing detailed descriptions.

- Connections: Observe how various elements are linked; this can indicate assembly order or dependencies.

Interpreting Symbols

Technical illustrations often employ symbols to convey additional information. Familiarize yourself with common representations:

- Solid Lines: Indicate physical connections or pathways.

- Dotted Lines: Often suggest optional parts or alternative configurations.

- Arrows: Show movement or the direction of flow.

By mastering these elements, you can effectively utilize the illustration to ensure accurate repairs and maintenance of your equipment.

Maintenance Tips for Stihl 012 AV

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular maintenance helps prevent issues and enhances efficiency, allowing you to tackle tasks with ease.

- Regularly check and clean the air filter to ensure proper airflow.

- Inspect and sharpen the cutting tool frequently to maintain cutting efficiency.

- Change the lubrication oil as recommended to reduce wear and tear.

- Keep all bolts and screws tight to avoid any loose parts during operation.

- Examine the fuel system for leaks and ensure clean fuel is used.

By adhering to these practices, you can delve into a maintenance routine that promotes the ultimate performance of your tool, ensuring it remains reliable for years to come.

Replacing Worn Parts Effectively

Maintaining the longevity and performance of your equipment requires timely replacement of deteriorated components. Identifying which elements need attention is crucial to ensure optimal functionality and prevent further damage. By systematically addressing these wear issues, you can enhance the overall efficiency and reliability of your machine.

Begin by assessing the condition of each component during routine inspections. Look for signs of wear such as cracks, excessive friction, or unusual noise during operation. Recognizing these indicators early can save time and reduce costs in the long run.

When it comes to replacing components, sourcing high-quality replacements is paramount. Opt for reputable suppliers to ensure that the new parts meet the necessary specifications and standards. This will not only improve performance but also contribute to the safety of your equipment.

Installation should be approached with care. Follow the manufacturer’s guidelines and take your time to ensure everything is fitted correctly. Improper installation can lead to further issues down the line, negating the benefits of the replacement.

Finally, consider keeping a maintenance log to track replacements and repairs. This can help in anticipating future needs and establishing a more proactive approach to maintenance.

Tools Needed for Disassembly

To successfully dismantle your equipment, having the right tools at hand is crucial. The appropriate instruments ensure a smooth process, minimizing the risk of damage and facilitating efficient reassembly.

Essential Tools

Begin with a reliable set of screwdrivers, including both flathead and Phillips options, to tackle various screws. Additionally, a good quality wrench set will be essential for loosening bolts and nuts.

Additional Equipment

Don’t forget to gather pliers for gripping and bending tasks, as well as a torque wrench to ensure proper fastening during reassembly. A workbench with adequate lighting can also enhance your efficiency throughout the disassembly process.

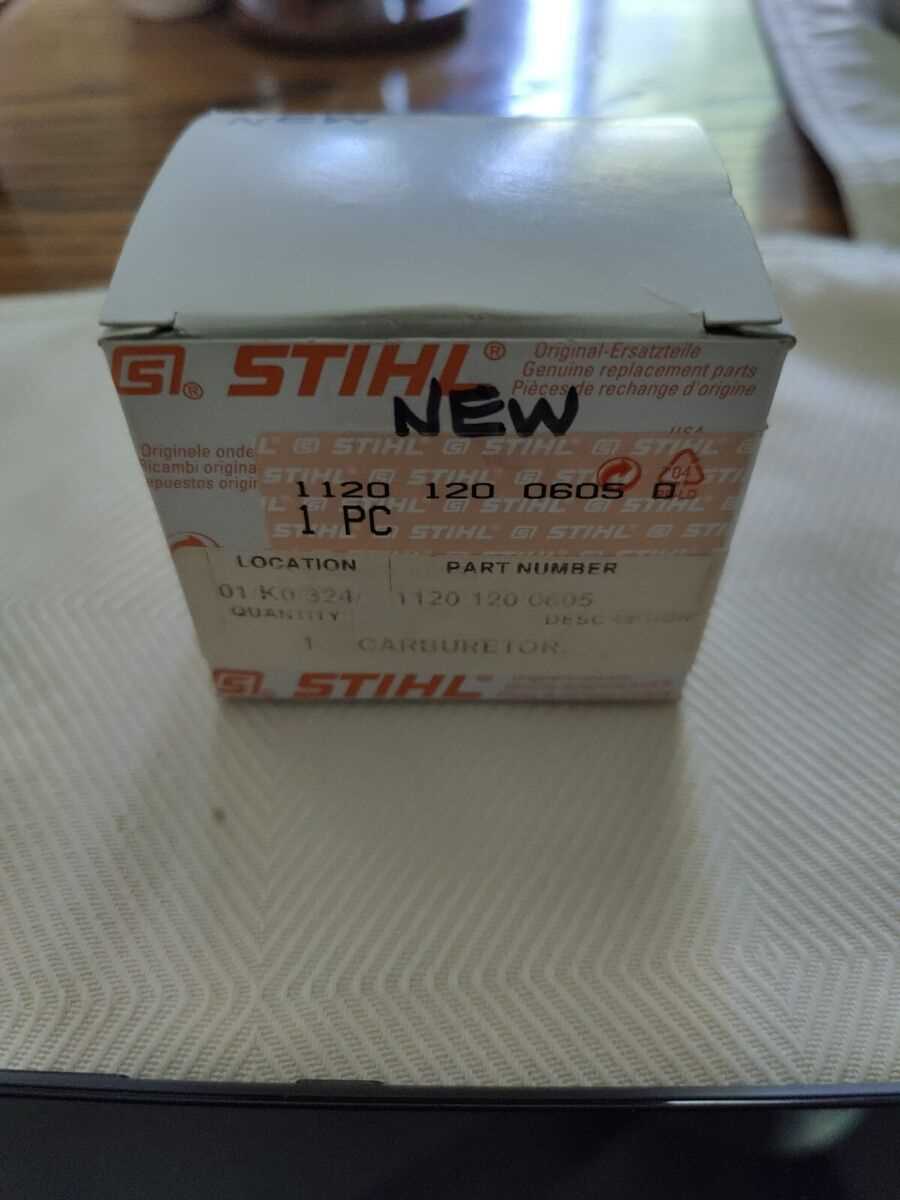

Where to Buy Replacement Parts

Finding the right components for your outdoor power equipment can significantly enhance its performance and longevity. Whether you are a professional or a hobbyist, having access to reliable sources for these essentials is crucial for efficient maintenance and repair.

Authorized Dealers

One of the best ways to ensure you are purchasing high-quality components is to visit authorized dealers. These locations typically offer:

- Genuine components that meet manufacturer specifications

- Expert advice from knowledgeable staff

- A warranty on the items purchased

Online Retailers

The internet provides a vast selection of options for acquiring necessary components. When shopping online, consider the following:

- Look for reputable websites with customer reviews.

- Check for return policies and shipping options.

- Compare prices across different platforms for the best deal.

By exploring these avenues, you can secure the components needed to keep your equipment in top condition.

Common Issues and Solutions

When operating power tools, users may encounter various challenges that can affect performance and safety. Understanding these common problems and their remedies is essential for effective maintenance and reliable operation.

Engine Difficulties

One prevalent issue involves engine performance. If the engine fails to start or runs inconsistently, it may be due to a clogged fuel filter or spark plug. Regular inspection and replacement of these components can prevent many issues. Additionally, ensuring the fuel mixture is correct is crucial; an improper ratio can lead to engine stalling.

Bar and Chain Problems

Another frequent concern arises with the cutting system. If the tool experiences reduced cutting efficiency, this might indicate that the chain is dull or improperly tensioned. Regular sharpening of the chain and checking the tension can enhance cutting performance. Furthermore, lubricating the bar and chain regularly helps reduce wear and prolongs the life of these components.

Understanding Warranty and Support Options

Having a clear grasp of the warranty and support alternatives available can significantly enhance your ownership experience. It ensures that you are informed about the protections offered and how to access assistance when necessary. This section delves into the essential aspects of these options, equipping you with the knowledge to make informed decisions.

Warranty Coverage

The warranty coverage typically outlines the manufacturer’s commitments regarding repairs and replacements. Understanding the specific terms can help you know what is included and how long the coverage lasts.

| Warranty Type | Duration | Coverage Details |

|---|---|---|

| Standard Warranty | 1 Year | Manufacturing defects and material issues |

| Extended Warranty | Up to 3 Years | Additional coverage for wear and tear |

Support Services

Access to customer support is crucial for troubleshooting and maintenance. Knowing how to reach out for assistance can save time and enhance your overall satisfaction.