Understanding the John Deere 635FD Parts Diagram

In the realm of modern farming, machinery plays a crucial role in enhancing productivity and efficiency. Every piece of equipment is made up of numerous elements, each contributing to the overall functionality and performance. Gaining insight into the structure and organization of these components is essential for operators and technicians alike.

Exploring the intricate layout of these mechanical parts allows for better maintenance and troubleshooting. A clear representation of these elements not only aids in understanding their relationships but also facilitates quicker repairs and replacements when necessary. Familiarity with this organized assembly ensures that users can maximize the lifespan of their equipment while minimizing downtime.

As technology advances, the complexity of these systems increases, making it vital for individuals involved in agricultural operations to stay informed. Recognizing the significance of each component empowers users to make informed decisions regarding their machinery, leading to enhanced agricultural practices and improved yield outcomes.

Understanding John Deere 635FD

This section explores the essential components and functions of a specific agricultural implement designed for harvesting, focusing on its efficiency and versatility in the field. Recognizing its features allows operators to maximize performance and maintenance.

Key Features

- Advanced cutting technology for optimal grain flow

- Adjustable header height for various crop types

- Durable construction for extended longevity

Maintenance Tips

- Regularly inspect blades for wear and tear.

- Keep the hydraulic system well-lubricated.

- Ensure proper alignment of all moving parts.

Key Features of 635FD Header

This advanced harvesting equipment is designed to optimize performance and efficiency in the field. Its construction and features are tailored to enhance crop gathering and minimize losses during operation.

Efficient Crop Flow: The header is engineered for smooth and consistent crop flow, ensuring that the harvested material moves seamlessly through the system.

Flexible Cutting Width: With adjustable cutting widths, this equipment accommodates various crop types and field conditions, allowing for greater versatility.

Robust Design: Built to withstand harsh conditions, the header features durable materials that enhance longevity and reduce maintenance needs.

Advanced Technology: Incorporating cutting-edge technology, the system offers precision control and monitoring, providing operators with valuable insights for optimal performance.

Easy Maintenance: The design prioritizes ease of maintenance, allowing for quick access to essential components and reducing downtime during operations.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for efficient maintenance and repair. Visual representations of these assemblies provide clarity, allowing users to identify each element and its function within the overall system. This knowledge is crucial for anyone involved in the upkeep of equipment, from technicians to operators.

Clarity in Maintenance: Utilizing graphical guides enhances the ability to perform repairs accurately. When individuals can see how components fit together, they can more easily diagnose issues and determine the correct procedures for replacement or adjustment.

Efficiency in Ordering: When a breakdown occurs, knowing the exact components needed speeds up the ordering process. Visual aids help ensure that the correct items are requested, minimizing downtime and reducing frustration.

Educational Value: These illustrations serve as valuable educational tools for new operators and technicians. They provide a clear understanding of how machinery operates, fostering a deeper comprehension of each part’s role and importance.

Streamlining Troubleshooting: In complex systems, troubleshooting can become challenging. Having a visual reference simplifies the process, enabling quicker identification of faults and reducing the time spent diagnosing problems.

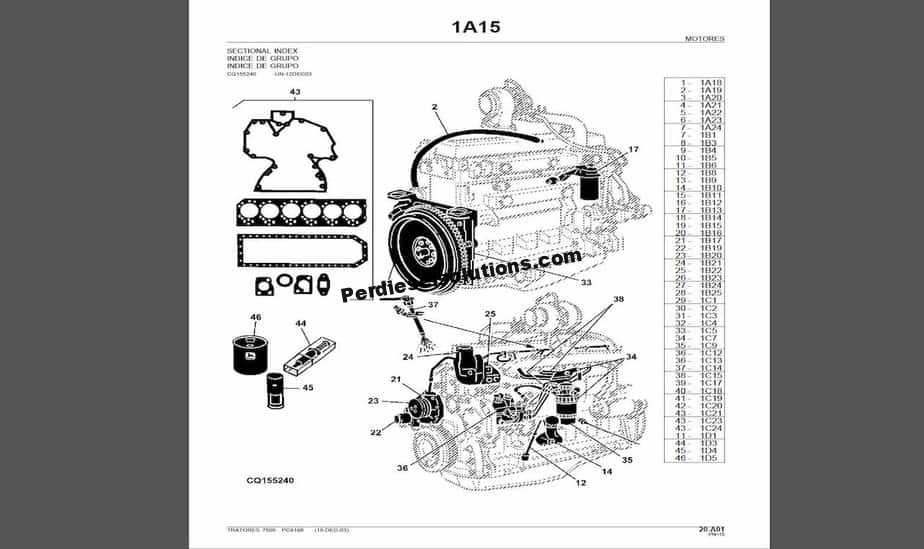

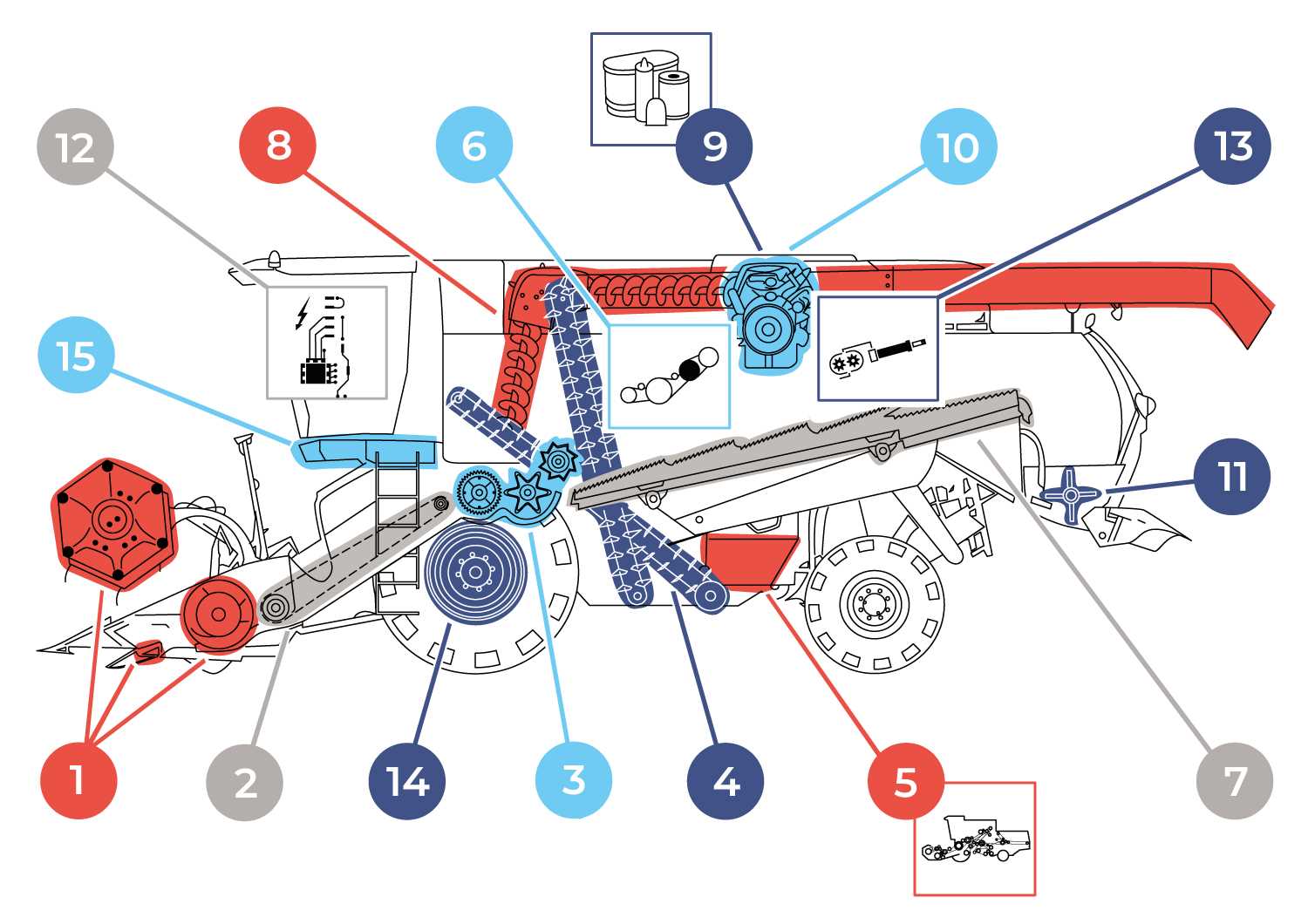

Common Components of 635FD

Understanding the essential elements of this harvesting tool is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance during harvesting. Below are the key parts that contribute to the functionality of this equipment.

Main Elements

- Header Assembly: Responsible for gathering and feeding the crop into the machine.

- Auger: A rotating component that helps to move the harvested material towards the center.

- Drive System: Powers various functions and ensures smooth operation.

- Cutting Mechanism: Includes blades and guards that efficiently cut the crop at the base.

Support Components

- Skid Shoes: Provide support and stability while operating on uneven terrain.

- Flexing System: Allows for adaptation to ground contours for better harvesting.

- Hydraulic System: Controls movement and adjustments of various parts during operation.

- Feed Plates: Guide the crop into the cutting area to enhance efficiency.

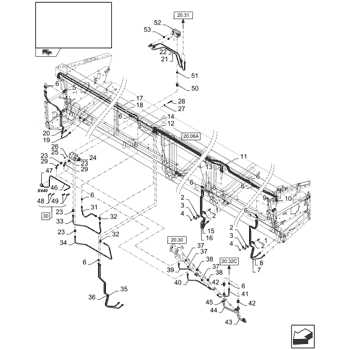

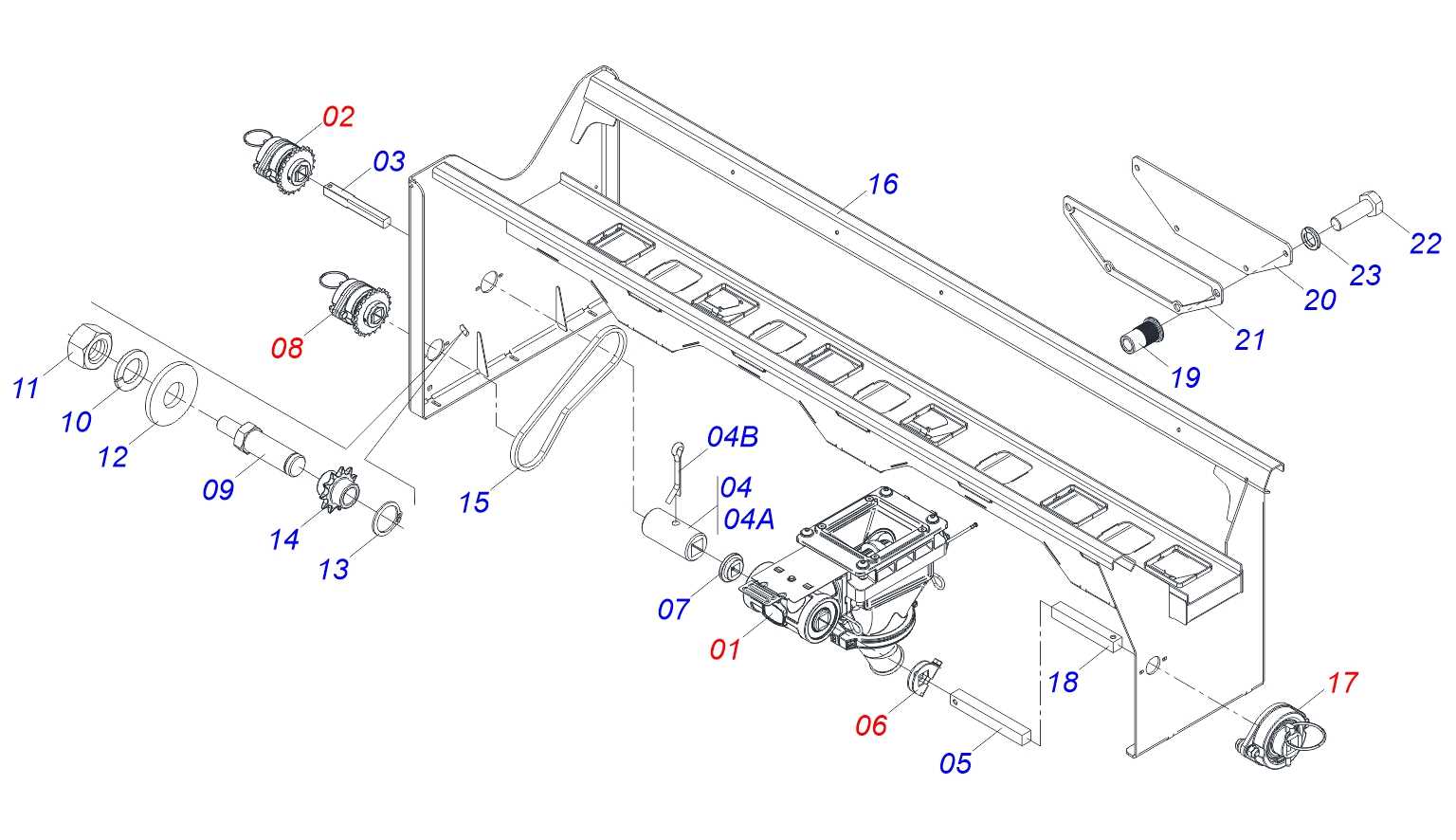

How to Read Parts Diagrams

Understanding assembly visuals is crucial for efficient maintenance and repair. These illustrations serve as a guide, providing a visual representation of components and their relationships within a system.

1. Familiarize Yourself with Symbols: Different icons represent various elements, from fasteners to main components. Recognizing these symbols helps streamline the interpretation process.

2. Follow the Flow: Components are often arranged in a logical sequence. Trace the connections and positioning to grasp how each part integrates into the whole.

3. Reference Numbers: Pay attention to numerical identifiers. They correlate with a list that specifies each element’s details, including specifications and compatibility.

By mastering these techniques, you can efficiently navigate assembly visuals, ensuring effective repairs and optimal performance.

Maintenance Tips for 635FD Parts

Ensuring the longevity and efficiency of your agricultural equipment requires regular upkeep and attention to detail. By focusing on specific components and understanding their maintenance needs, you can enhance performance and reduce the likelihood of unexpected failures.

Regular Inspections

Conducting frequent inspections is crucial. Check for wear and tear, and identify any loose connections or signs of damage. Addressing minor issues early can prevent larger problems down the line. Look for signs of corrosion and ensure that all moving parts are adequately lubricated.

Proper Storage and Cleaning

After each use, clean the machinery thoroughly to remove debris and residues. Proper storage is equally important; keep equipment in a dry, sheltered location to protect it from environmental factors. Regular cleaning not only maintains appearance but also helps in spotting potential issues before they escalate.

By following these maintenance tips, you can ensure that your equipment remains in optimal condition, enhancing productivity and extending its service life.

Replacing Worn-Out Components

Maintaining agricultural machinery is crucial for optimal performance and longevity. Regularly replacing outdated or damaged parts ensures efficient operation and minimizes downtime.

Identifying worn-out components can be achieved through:

- Visual inspections for cracks and wear

- Monitoring performance and listening for unusual noises

- Consulting maintenance logs for service history

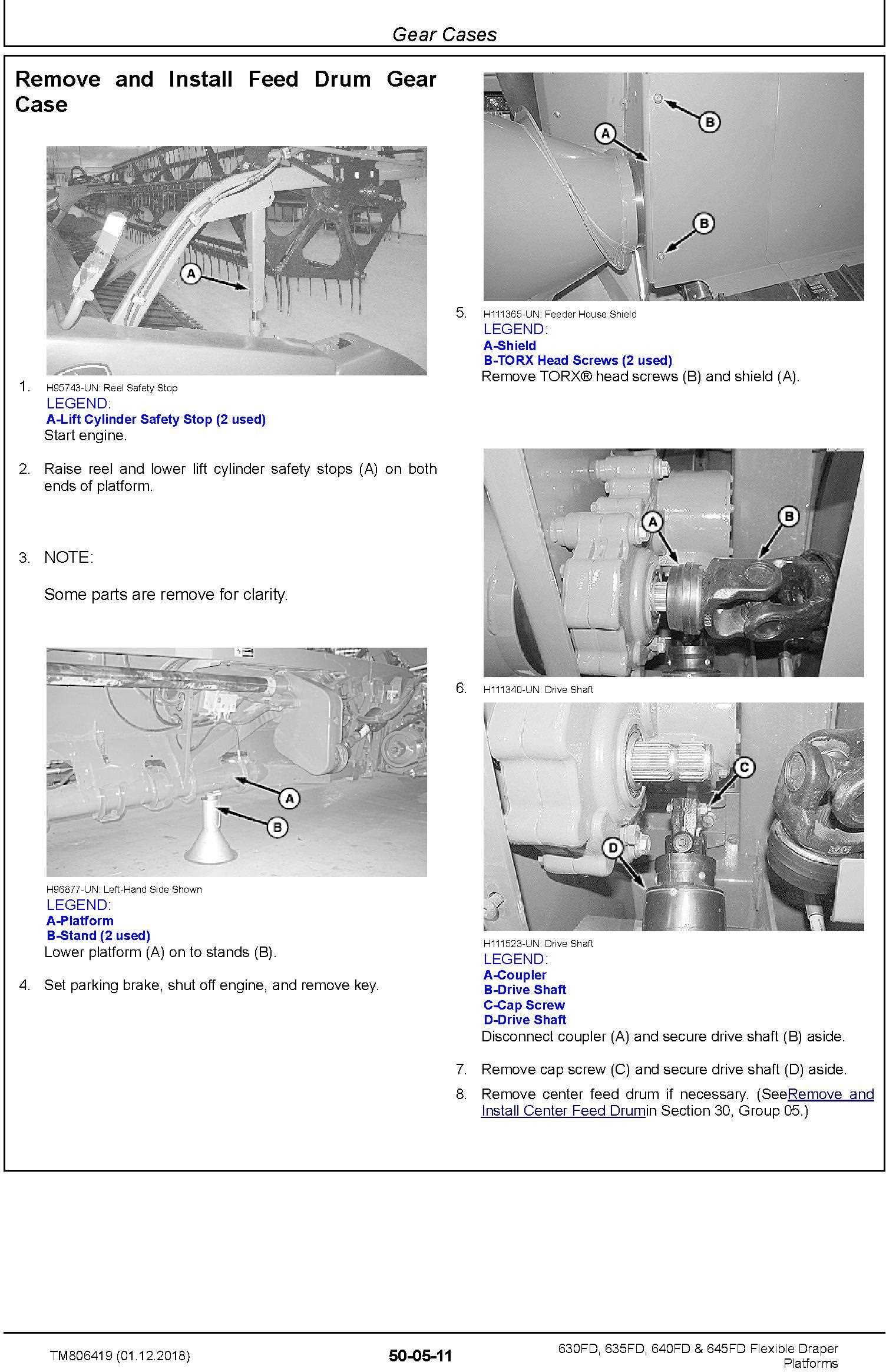

When it’s time to replace these components, follow these steps:

- Gather necessary tools and replacement items.

- Carefully remove the old parts, noting their arrangement.

- Install new components, ensuring proper alignment and fit.

- Test the machinery to confirm effective operation.

By staying proactive, operators can enhance the functionality of their equipment and achieve the ultimate efficiency in their agricultural practices.

Identifying Compatible Replacement Parts

When it comes to maintaining agricultural equipment, ensuring that you choose the right components is essential for optimal performance. Understanding how to identify suitable alternatives can save time and reduce costs while ensuring the machinery operates smoothly. This section focuses on strategies to find compatible components that meet the necessary specifications.

Research Specifications: Start by gathering detailed information about the original components, including measurements, material types, and functionality. Refer to the manufacturer’s documentation for precise data, as this will serve as a reliable reference point.

Cross-Reference with Trusted Sources: Utilize online databases and resources that specialize in equipment components. Many websites provide compatibility charts and lists that can help you identify suitable substitutes based on your machinery’s model and specifications.

Consult Industry Experts: Engaging with professionals in the field can offer valuable insights. Mechanics and suppliers often have extensive knowledge about which alternatives work effectively and can recommend reliable options based on their experience.

Evaluate Quality and Performance: When selecting replacement items, consider their quality and compatibility. Always opt for reputable brands or manufacturers known for producing durable and high-performing components to ensure longevity and reliability.

Test Fit and Function: If possible, perform a test fit of the chosen alternative before fully integrating it into your equipment. This step can help identify any potential issues with compatibility and allow for adjustments as needed.

By following these guidelines, you can confidently navigate the selection process for appropriate replacements, ensuring that your machinery continues to operate efficiently and effectively.

Common Issues and Solutions

In the realm of agricultural machinery, operational challenges can arise that may hinder efficiency and productivity. Understanding these common issues, along with their effective solutions, is essential for maintaining optimal performance and longevity of equipment. Below are some prevalent concerns and their corresponding remedies.

Frequent Mechanical Failures

Mechanical failures often stem from wear and tear or improper maintenance. Symptoms may include unusual noises, vibrations, or failure to operate at peak efficiency. Regular inspections and timely replacements of worn components can significantly mitigate these issues. Lubrication and adjustment of moving parts are crucial preventive measures to avoid unexpected breakdowns.

Hydraulic System Problems

Hydraulic system malfunctions are another common dilemma, often indicated by erratic movements or a complete lack of response. These problems can typically be traced back to leaks, air in the system, or insufficient fluid levels. To address this, operators should routinely check for leaks and maintain appropriate fluid levels. Bleeding the system can also help eliminate air pockets, restoring normal functionality.

Where to Find Parts Diagrams

Locating technical illustrations for machinery can significantly aid in understanding component layouts and assembly processes. These resources are essential for maintenance and repairs, allowing users to visualize how different elements fit together.

One effective approach is to explore the manufacturer’s official website, where you can often access detailed catalogs and technical resources. Additionally, specialized forums and online communities dedicated to machinery enthusiasts frequently share valuable links and documents.

For those seeking more interactive options, online retailers sometimes provide schematics alongside their product listings, making it easier to identify required components. Technical manuals are another reliable source, usually available through libraries or industry publications, offering comprehensive views and information.

Lastly, don’t overlook the power of social media groups and video platforms, where experienced users often demonstrate repairs and share visual aids. Networking with fellow owners can lead to discoveries of unique resources that may not be widely known.

Advantages of Genuine John Deere Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These items are specifically designed to fit seamlessly with the equipment, enhancing its overall efficiency and reducing the likelihood of malfunctions.

| Benefit | Description |

|---|---|

| Quality Assurance | Authentic components undergo rigorous testing to meet industry standards, ensuring reliability and durability. |

| Perfect Fit | Designed for specific models, these items guarantee compatibility, minimizing installation issues and enhancing performance. |

| Improved Resale Value | Maintaining equipment with genuine components can enhance its market value, appealing to potential buyers. |

| Warranty Protection | Using certified components often keeps warranties intact, safeguarding the investment in machinery. |

| Enhanced Performance | Original components work optimally with the machine, resulting in better fuel efficiency and operational effectiveness. |

Utilizing Online Resources Effectively

In today’s digital age, leveraging the wealth of information available online can significantly enhance your understanding and problem-solving capabilities. By navigating through various platforms, one can access valuable insights and resources that aid in maintenance and troubleshooting.

Key Strategies for Effective Use

- Identify Reliable Sources: Focus on reputable websites and forums that specialize in agricultural equipment.

- Utilize Visual Aids: Diagrams and videos can provide clearer understanding compared to text alone.

- Engage with Communities: Join online forums or social media groups to share knowledge and seek advice from experienced users.

Organizing Your Research

- Bookmark Useful Links: Create a dedicated folder for quick access to essential resources.

- Take Notes: Summarize key points to reinforce learning and facilitate easy reference.

- Stay Updated: Regularly check for new information to ensure you’re using the latest techniques and data.