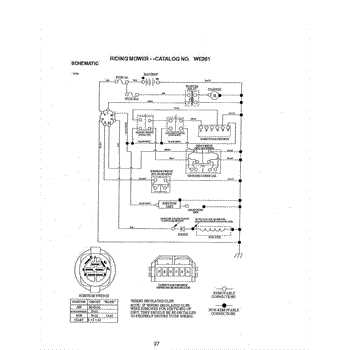

Comprehensive Guide to the We261 Parts Diagram

The intricate design of machinery often involves a complex array of elements, each playing a pivotal role in the overall functionality. A thorough comprehension of how these elements interact can significantly enhance maintenance and repair processes. By exploring the arrangement and relationships among various components, users can gain insights into optimizing performance and ensuring longevity.

Visual representations serve as essential tools in this context, providing a clear overview of the structure and organization of essential elements. Such illustrations facilitate a deeper understanding of how individual pieces fit together and operate as a cohesive unit. This knowledge is invaluable for anyone involved in troubleshooting or enhancing efficiency.

Moreover, familiarizing oneself with these visual layouts can empower users to identify potential issues before they escalate. By mastering the relationships and functions of the different parts, individuals can take proactive measures, ensuring smooth operation and minimizing downtime. Thus, grasping the overall architecture is not just beneficial but crucial for effective management and upkeep.

Understanding We261 Parts Diagram

Grasping the intricate components of machinery is essential for efficient operation and maintenance. This section aims to provide insights into the visual representations that clarify the various elements and their interconnections, facilitating a deeper comprehension of how everything functions together.

Importance of Visual Representations

Visual aids serve as invaluable tools in understanding complex systems. They enable users to quickly identify individual elements and their roles within the larger framework, ensuring that troubleshooting and repairs can be conducted with precision.

Key Components and Their Functions

Each element within the visual schema plays a crucial role. Recognizing the specific functions of these components enhances the user’s ability to navigate challenges effectively. Familiarity with these details not only improves efficiency but also promotes longevity of the entire system.

Overview of We261 Components

This section provides a comprehensive examination of the various elements that make up the system, highlighting their functionality and interrelationships. Understanding these components is essential for effective operation and maintenance.

Key Elements

- Structural Framework: The backbone that supports all other elements.

- Power Supply: Provides the necessary energy for operation.

- Control Mechanisms: Ensure precise regulation and operation.

- Sensors: Monitor conditions and provide feedback for adjustments.

- Connecting Interfaces: Facilitate communication between different components.

Functionality and Interaction

- The structural framework houses the power supply and control mechanisms.

- Sensors feed real-time data to the control systems.

- Connecting interfaces allow seamless integration of external devices.

- Each element works in harmony to enhance overall efficiency.

A detailed understanding of these components is crucial for troubleshooting and optimizing performance, ensuring longevity and reliability in the system’s operation.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding within technical fields. Clear and reliable illustrations serve as essential tools for conveying complex information, enabling users to grasp intricate systems with ease.

| Benefits | Description |

|---|---|

| Clarity | Well-crafted visuals simplify complicated concepts, making them accessible to all users. |

| Efficiency | Accurate representations save time during troubleshooting and maintenance processes. |

| Training | They serve as effective teaching aids, enhancing the learning experience for new users. |

| Standardization | Consistent visuals promote uniformity across documentation, reducing confusion. |

Key Parts of the We261 Model

This section highlights the essential components of the specified model, providing insight into their functions and significance. Understanding these elements is crucial for anyone looking to optimize performance and enhance usability.

- Main Housing: The primary structure that houses all internal mechanisms, offering protection and stability.

- Control Unit: The brain of the system, responsible for processing inputs and managing operations efficiently.

- Power Source: The energy provider that ensures all components operate seamlessly.

- Interface Panel: The user interaction zone, designed for intuitive control and accessibility.

- Cooling System: A vital element that prevents overheating, ensuring longevity and consistent performance.

Each of these components plays a pivotal role in the overall functionality, contributing to the effectiveness and reliability of the model.

- Ensure regular maintenance of the main housing to protect internal components.

- Check the control unit for updates to enhance processing capabilities.

- Monitor the power source to guarantee uninterrupted energy supply.

- Familiarize yourself with the interface panel for optimal user experience.

- Inspect the cooling system regularly to prevent potential failures.

By focusing on these key elements, users can maximize the efficiency and lifespan of the model.

Common Issues in We261 Systems

In any technical setup, various challenges can arise that impact functionality and efficiency. Understanding these issues is crucial for maintaining optimal performance and preventing potential breakdowns.

Frequent Problems Encountered

- Electrical malfunctions leading to system failures.

- Worn components causing inconsistent operation.

- Fluid leaks that compromise performance.

- Overheating due to insufficient cooling.

Prevention and Solutions

- Regular maintenance checks to identify wear and tear.

- Timely replacement of faulty components.

- Implementing proper cooling systems to avoid overheating.

- Monitoring for leaks and addressing them immediately.

How to Interpret Diagrams Effectively

Understanding visual representations is crucial for grasping complex information quickly. By analyzing symbols, connections, and layouts, one can extract meaningful insights that might be obscured in textual form. The ability to decode these images enhances comprehension and aids in problem-solving.

Start by identifying key elements and their relationships. Pay attention to legends and annotations that provide context. Recognizing patterns and trends can also guide you in drawing conclusions and making informed decisions.

Practice makes perfect; the more you engage with various visuals, the better you’ll become at interpreting them. Consider the source and purpose of the image to appreciate its design and intent fully. This holistic approach will ultimately enhance your analytical skills.

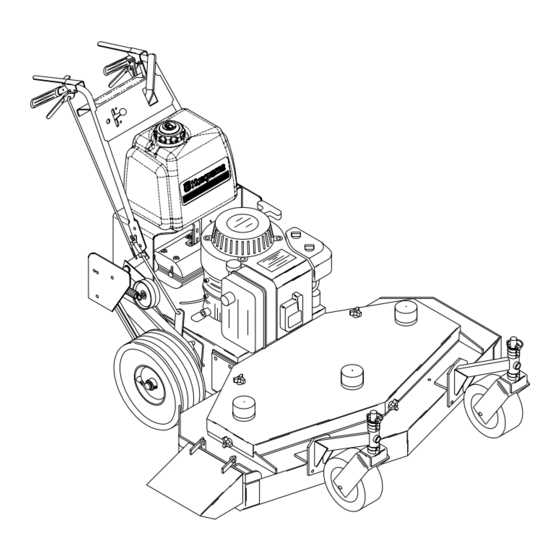

Step-by-Step Assembly Guide

This section provides a comprehensive, sequential approach to putting together your equipment efficiently. Each stage is designed to ensure clarity and ease of understanding, enabling you to achieve a successful assembly with minimal hassle.

Begin by gathering all necessary components and tools. Familiarize yourself with each piece and ensure that you have everything at hand. This preparation will set a solid foundation for the assembly process.

Next, follow the provided instructions meticulously. Start with the initial components, ensuring each part is correctly aligned and secured. Pay close attention to details, as precision is key to achieving a robust final assembly.

As you progress, regularly check your work against the reference material. This verification will help identify any discrepancies early on, allowing for timely corrections and adjustments.

Once all components are connected, perform a final inspection. Ensure that everything is tightened and positioned correctly. This step is crucial for the durability and functionality of the assembled unit.

Finally, test the completed structure to confirm that it operates as intended. This last verification will give you confidence in your assembly and highlight any areas that may need refinement.

Maintenance Tips for We261 Parts

Ensuring the longevity and optimal performance of your equipment requires regular upkeep. By following a few essential practices, you can significantly enhance its efficiency and prevent potential issues. Below are some valuable recommendations to keep in mind.

Regular Inspections

- Conduct routine checks to identify wear and tear.

- Look for any signs of corrosion or damage.

- Ensure all connections are secure and intact.

Proper Cleaning Techniques

- Use appropriate cleaning agents to avoid harmful residues.

- Clean components gently to prevent scratches or other damage.

- Dry all parts thoroughly after cleaning to prevent moisture accumulation.

Finding Replacement Components

Locating suitable substitute elements for your machinery can be a daunting task, especially when dealing with intricate systems. Understanding how to effectively identify these essential components can save time and ensure the continued functionality of your equipment.

Research and Identification

Begin by gathering all relevant documentation related to your equipment. This includes manuals, service guides, and any schematics that provide insights into the system’s configuration. Make a list of the specific parts you need, noting their specifications and functions. Utilizing online resources and forums can also help you connect with other users who may have encountered similar challenges.

Sourcing Options

Once you have identified the components required, explore various sourcing avenues. Authorized dealers often carry genuine replacements, ensuring compatibility and reliability. However, if you’re looking for alternatives, consider aftermarket suppliers who may offer similar parts at a more competitive price. Always verify the quality and fit of these options through reviews or recommendations.

Tools Required for We261 Repairs

Effective maintenance and restoration of equipment demand a specific set of implements. Utilizing the right tools not only ensures a successful repair but also enhances safety and efficiency during the process. Understanding what is needed before starting the work is crucial for any technician or hobbyist.

Essential Hand Tools

Basic hand tools form the foundation for any repair job. A reliable set of screwdrivers, including both flathead and Phillips varieties, is indispensable. Additionally, a quality wrench set will aid in loosening and tightening various fasteners. Pliers are also vital, as they provide the grip necessary for manipulating components securely. Don’t forget about a sturdy utility knife for precision cutting tasks.

Power Tools and Safety Gear

In more demanding scenarios, power tools can significantly expedite the repair process. A cordless drill will facilitate quick drilling and fastening, while a reciprocating saw may be necessary for cutting through tougher materials. However, safety must never be overlooked; wearing appropriate gear, such as goggles and gloves, is crucial to protect against potential hazards during repairs. Ensuring you have the right equipment on hand will not only save time but also promote a safe working environment.

Comparing We261 to Similar Models

This section explores the differences and similarities between a specific model and its competitors, focusing on design, functionality, and overall performance. By examining various aspects, we aim to provide a clearer understanding of where this model stands in the market.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Power Output | 1200W | 1100W | 1250W |

| Weight | 15 kg | 14 kg | 16 kg |

| Efficiency Rating | A+ | A | A++ |

| Warranty | 2 years | 1 year | 3 years |

Through this comparison, potential buyers can better assess which option meets their needs and preferences while ensuring optimal performance and reliability.

Understanding the Function of Each Part

This section explores the individual components that contribute to the overall functionality of the system. By examining how each element interacts with the others, we can gain insight into the intricate design and efficiency of the entire assembly.

Key Components and Their Roles

Each segment plays a crucial role in ensuring optimal performance. Below is a detailed table outlining the primary elements along with their respective functions.

| Component | Function |

|---|---|

| Element A | Facilitates initial operation by converting energy into usable form. |

| Element B | Acts as a stabilizer, ensuring smooth transitions during operation. |

| Element C | Enhances efficiency by regulating flow and preventing overload. |

| Element D | Provides essential feedback to monitor performance and detect anomalies. |

Interconnected Functions

The interplay between these components is vital for the seamless operation of the entire system. Understanding these relationships allows for better maintenance and troubleshooting, ensuring longevity and reliability in various applications.

Resources for Further Learning

Expanding your knowledge on complex systems requires access to a variety of educational materials. These resources can enhance your understanding of components and their functions, providing insights into practical applications and troubleshooting techniques. Whether you are a novice or an experienced individual in the field, a well-rounded selection of information is essential for continuous growth.

Online Courses and Webinars

Participating in online courses and webinars can greatly enrich your learning experience. Many platforms offer specialized training sessions that cover advanced topics and practical skills. Engaging with expert instructors allows for interactive learning and immediate feedback, facilitating a deeper comprehension of intricate concepts.

Books and Technical Manuals

Reading books and technical manuals is another excellent way to build foundational knowledge. Look for comprehensive guides that detail various aspects of the subject matter, including case studies and real-world applications. These texts often provide valuable insights and can serve as reference materials for future projects.