Graco Truecoat 360 DS Parts Diagram Overview

In the realm of home improvement and maintenance, understanding the various elements of your spraying tool is essential for effective operation and upkeep. Each segment plays a critical role in ensuring optimal performance, making it vital for users to familiarize themselves with these components. This knowledge empowers individuals to troubleshoot issues, perform necessary repairs, and enhance the lifespan of their equipment.

By examining the intricate layout of each section, one can better appreciate how these parts work together harmoniously. A comprehensive overview not only aids in identifying specific features but also provides insight into the assembly’s functionality. Moreover, being aware of each element’s position and purpose can facilitate more informed decisions when seeking replacements or upgrades.

Ultimately, equipping oneself with a solid understanding of the construction of your spraying apparatus will contribute to a smoother user experience. This foundational knowledge serves as a springboard for both novice users and seasoned professionals, encouraging confidence and competence in handling maintenance tasks.

Graco TrueCoat 360 DS Overview

This section provides an insight into a versatile and efficient painting tool designed for both professionals and DIY enthusiasts. The device is engineered to simplify the application of various coatings, making it suitable for a range of projects, from small touch-ups to larger surfaces.

Key Features

- Compact and lightweight design for easy handling.

- Adjustable settings to accommodate different materials and project sizes.

- Quick cleanup process, enhancing convenience after use.

- Innovative technology for smooth and even application.

Applications

- Ideal for interior and exterior surfaces.

- Suitable for furniture, fences, and walls.

- Perfect for both latex and oil-based paints.

Understanding the Components

Familiarity with the essential elements of a painting device is crucial for effective usage and maintenance. Each component plays a significant role in ensuring optimal performance and achieving desired results in various applications. Recognizing these parts enhances the overall experience, leading to better outcomes and longer equipment lifespan.

Key Elements

Among the most vital components are the motor, which drives the unit’s operation, and the nozzle, responsible for the even application of the material. The container holds the liquid, while the hose facilitates the transfer of material from the container to the nozzle. Understanding these elements helps users troubleshoot issues and perform necessary maintenance.

Importance of Maintenance

Regular inspection and care of each component not only prolong the life of the device but also improve its efficiency. Users should prioritize cleaning the nozzle and checking for wear in the hose to ensure smooth operation. Proper maintenance routines can prevent clogs and other common problems, ensuring that the equipment remains in peak condition.

Common Issues with TrueCoat 360 DS

Many users encounter various challenges when using this portable painting tool. Understanding these common problems can help enhance the painting experience and improve overall performance. From uneven application to technical malfunctions, recognizing these issues is essential for effective troubleshooting.

One frequent issue is the inconsistent flow of material, which can lead to streaks or missed spots on surfaces. This often occurs due to clogs in the nozzle or incorrect viscosity of the paint being used. Regular cleaning and ensuring proper paint consistency can mitigate this problem.

Another common challenge involves difficulty in achieving the desired spray pattern. Users may find that the tool sprays too wide or too narrow, affecting coverage. This can be adjusted by changing the settings or replacing the nozzle if it is worn out.

Additionally, some users report difficulties with the unit not turning on or losing power during use. This could be attributed to battery issues or poor connections within the device. Ensuring that the battery is fully charged and checking all connections can help resolve this issue.

Finally, the overall weight and design of the device may lead to fatigue during extended use. Ergonomic handling techniques and taking breaks can alleviate discomfort and improve efficiency during long painting sessions.

Replacement Parts Availability

Access to essential components is crucial for maintaining the functionality and efficiency of your equipment. Availability of these items ensures that users can easily restore their devices to optimal working condition without significant delays. Understanding where to find these components and how to acquire them can make a substantial difference in prolonging the lifespan of your machinery.

Several reliable sources offer a variety of components for your device. Here is a list of options to consider when looking for replacements:

| Source | Details |

|---|---|

| Online Retailers | Many websites specialize in tool components, providing a wide range of options and competitive pricing. |

| Local Hardware Stores | Visit nearby shops that carry various hardware items, which may include essential components for your equipment. |

| Manufacturer’s Website | Check the official site for direct purchasing options, ensuring you get genuine components. |

| Authorized Distributors | These distributors often have a comprehensive inventory of parts and can provide expert advice. |

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the durability and efficiency of your equipment. Regular maintenance not only enhances performance but also extends the lifespan of the device, allowing for consistent and reliable usage over time.

Regular Cleaning

- Always clean the exterior after each use to remove any dust or debris.

- Inspect and clean any filters or screens to prevent clogs.

- Use appropriate cleaning agents to avoid damage to surfaces.

Routine Checks

- Inspect hoses and connections for any signs of wear or leaks.

- Check all moving parts regularly to ensure they are functioning smoothly.

- Replace any worn or damaged components promptly to prevent further issues.

Implementing these simple yet effective practices will help maintain optimal performance and prolong the life of your device.

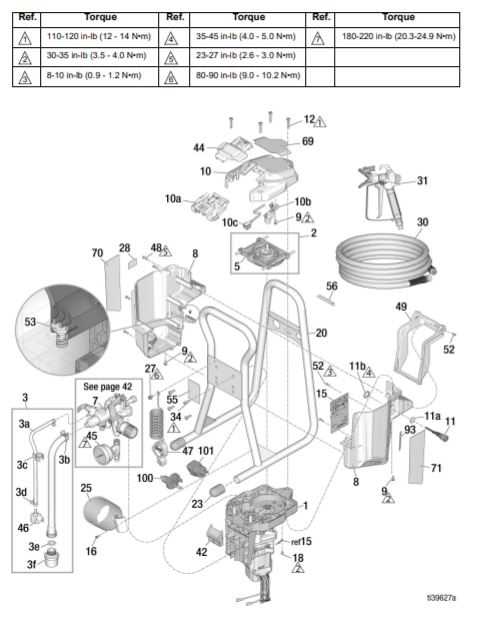

Exploring the Parts Diagram

This section aims to provide a comprehensive look at the components involved in the equipment’s operation. Understanding each piece’s function and interrelation is crucial for effective maintenance and troubleshooting.

Key Components Overview

Each element within the assembly plays a vital role in ensuring optimal performance. Here are some primary features:

- Motor Unit: Responsible for powering the device and ensuring smooth operation.

- Fluid Container: Holds the material used for application, designed for easy refills.

- Spray Tip: Regulates the material’s flow, impacting the finish quality.

- Trigger Mechanism: Controls the material output, allowing for precise application.

Assembly Relationships

Understanding how these elements connect is essential for anyone looking to maintain or repair the unit. The following aspects are important:

- Each component is designed to fit seamlessly with others, creating a cohesive system.

- Regular inspection of connections can prevent common issues.

- Replacement of worn or damaged parts should be done promptly to maintain functionality.

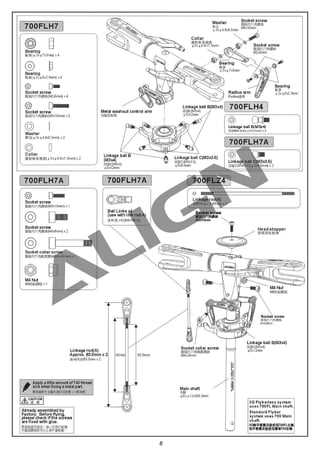

Assembly Instructions for Graco Model

This section provides a comprehensive guide for assembling the specified spray device model, ensuring efficient and effective use. Following these instructions will help users achieve optimal performance and longevity from their equipment.

Before starting the assembly process, ensure that you have all necessary components at hand. The following steps outline the assembly procedure:

- Begin by gathering all the items listed in the assembly checklist.

- Refer to the user manual for specific illustrations of each part.

- Identify the main unit and ensure it is positioned on a stable surface.

- Carefully attach the handle to the main unit using the provided screws.

- Connect the fluid supply tube to the designated inlet, ensuring a tight fit.

- Install the nozzle by aligning it with the connector and twisting it securely.

- Double-check all connections to confirm they are secure and leak-free.

- Finally, review the manual for any additional setup instructions specific to your model.

Following these steps will help ensure a successful assembly, allowing for smooth operation during use. Regular maintenance and checks will further enhance the functionality of your device.

Differences Between Models

The comparison of various models reveals a range of features and specifications that cater to different user needs. Understanding these distinctions is crucial for making an informed decision when selecting the right tool for your projects.

One significant difference often lies in the spraying technology employed by each variant. Some models may utilize advanced mechanisms that enhance efficiency and ensure a more even application, while others focus on simplicity and ease of use. Additionally, the capacity of the paint reservoir can vary, affecting the frequency of refills during operation.

Another aspect to consider is the accessories that come with each version. Certain models may include additional nozzles or specialized attachments, allowing for greater versatility in various applications. In contrast, more basic versions may offer fewer options, which could limit their functionality in specific tasks.

Furthermore, the overall design and ergonomics can differ significantly. Some tools are engineered for prolonged use, featuring comfortable grips and lighter weight, which reduce user fatigue. Others may prioritize compactness and portability, making them easier to transport but possibly less comfortable for extended sessions.

Recommended Accessories for Efficiency

To enhance the performance and convenience of your painting tasks, consider incorporating various tools and add-ons that can significantly improve efficiency. These accessories are designed to complement your primary equipment, ensuring a smoother workflow and better results.

- Extra Nozzles: Having a range of nozzles can allow you to adjust the spray pattern according to the surface you’re working on, providing versatility in your projects.

- Cleaning Kit: A dedicated cleaning set helps maintain your equipment in optimal condition, ensuring consistent performance and prolonging the lifespan of your tools.

- Protective Gear: Safety goggles, masks, and gloves are essential for personal protection while working, allowing you to focus on your task without distractions.

- Drop Cloths: These are useful for protecting floors and furniture from accidental splashes, maintaining a clean workspace and minimizing cleanup time.

- Extension Wands: Adding length to your tools allows for reaching high or awkward areas without the need for ladders, enhancing safety and accessibility.

Incorporating these accessories into your routine not only boosts your productivity but also improves the quality of your work. By being prepared with the right tools, you can tackle any project with confidence.

Safety Precautions During Use

Ensuring a safe working environment is crucial when operating any type of spraying equipment. Following appropriate safety measures can help prevent accidents and ensure effective performance. Here are key precautions to consider while using such devices.

- Always wear personal protective equipment (PPE), including gloves, goggles, and masks, to protect against harmful substances.

- Work in a well-ventilated area to minimize inhalation of fumes and ensure proper air circulation.

- Keep the workspace clean and free of any flammable materials to reduce fire hazards.

- Inspect the equipment regularly for any signs of wear or damage before use to ensure safe operation.

- Follow the manufacturer’s instructions carefully to ensure proper handling and usage.

- Keep children and pets away from the working area to prevent accidental exposure to hazardous materials.

By adhering to these safety guidelines, users can significantly reduce risks associated with the operation of spraying equipment and contribute to a safer working environment.

Customer Reviews and Feedback

This section highlights the experiences and opinions of users regarding the handheld spray equipment. Feedback from customers plays a crucial role in understanding the product’s performance, reliability, and overall satisfaction. Analyzing reviews can provide potential buyers with valuable insights, helping them make informed decisions.

Positive Experiences

Many users express satisfaction with the equipment’s ease of use and versatility. The compact design allows for comfortable handling, while the adjustable settings cater to various project needs. Customers often commend the smooth finish achieved, noting that it significantly reduces the time and effort required for painting tasks. Users appreciate the consistent spray pattern, which results in a professional look without the hassle of traditional methods.

Areas for Improvement

While feedback is predominantly positive, some users highlight areas where enhancements could be made. A few have mentioned challenges with maintenance and cleaning, suggesting that clearer instructions could be beneficial. Additionally, certain customers indicate a desire for improved durability, particularly for frequent users. Constructive criticism is essential for manufacturers, as it guides future developments and ensures customer satisfaction.