Comprehensive Guide to Hudson Sprayer Parts Diagram

In the world of gardening and agriculture, maintaining optimal performance of your machinery is essential. Knowing the intricate elements that contribute to the efficient operation of these devices can significantly enhance their longevity and functionality. Each component plays a vital role, and understanding how they interact is crucial for effective usage and maintenance.

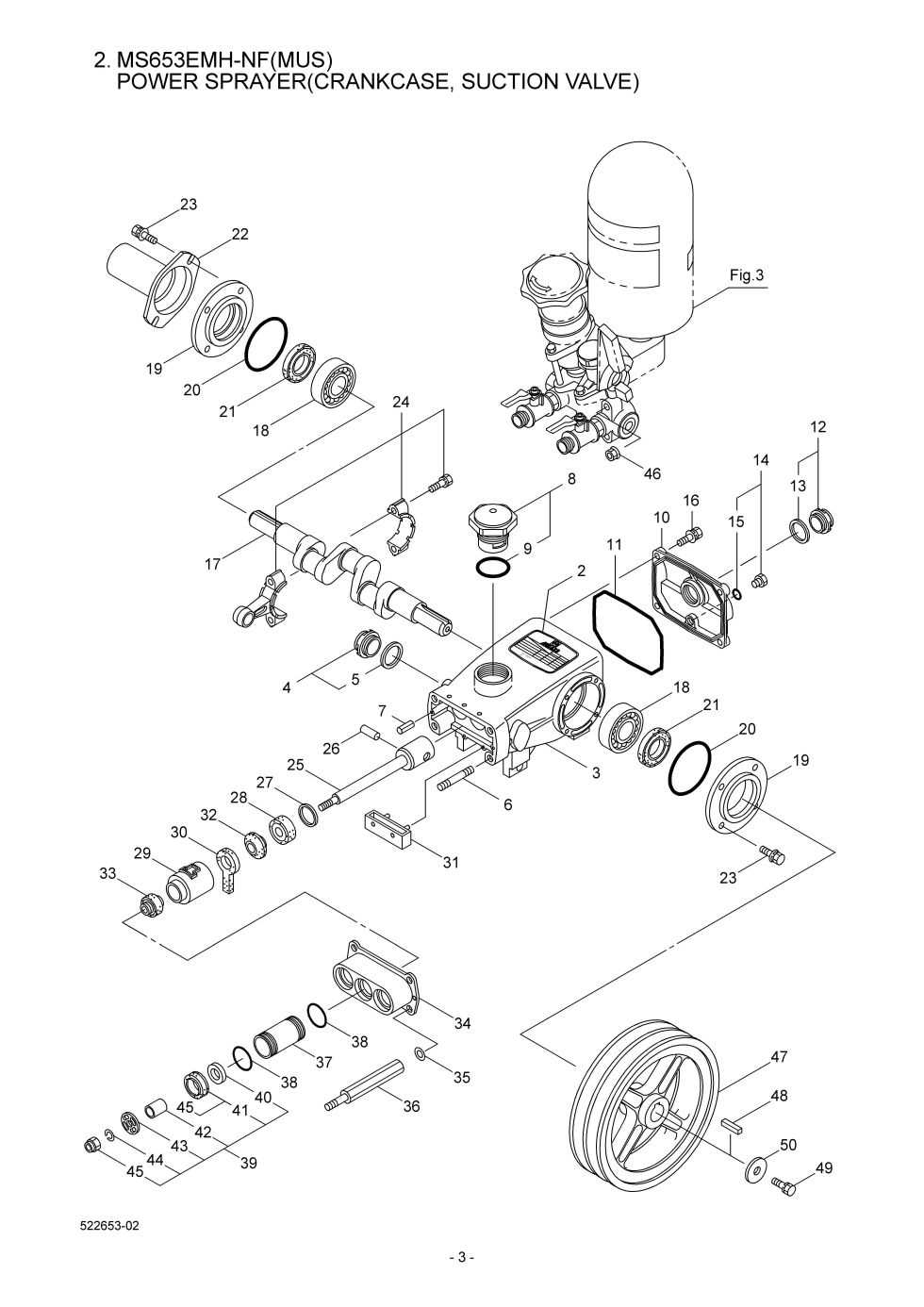

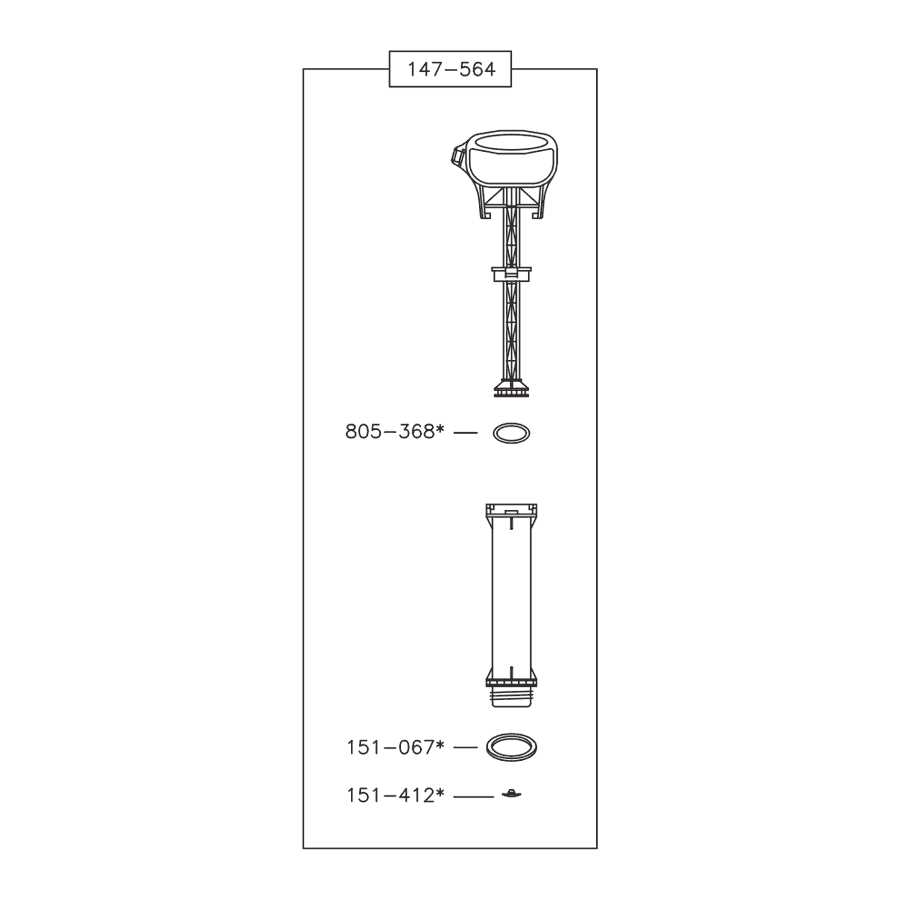

Visual aids can be invaluable tools for users seeking to grasp the configuration and layout of their tools. By examining the various elements, one can identify potential issues and make informed decisions regarding repairs and replacements. This knowledge empowers users to tackle challenges proactively, ensuring that their devices remain in peak condition.

Moreover, familiarity with these components not only aids in troubleshooting but also enriches the overall user experience. A well-informed operator can appreciate the engineering behind their equipment, leading to more efficient use and enhanced results in their gardening or agricultural endeavors. Embracing this understanding is a step towards achieving better outcomes and maximizing the benefits of one’s investment.

Understanding Hudson Sprayer Components

Grasping the various elements of a liquid application device is essential for effective usage and maintenance. Each component plays a critical role in ensuring optimal performance, enhancing efficiency, and prolonging the lifespan of the equipment. Familiarity with these parts empowers users to troubleshoot issues and make informed decisions regarding repairs and upgrades.

Reservoir: This is the primary container that holds the liquid solution, designed for easy filling and cleaning. Its size often dictates the duration of use between refills.

Pump: The heart of the system, this mechanism generates pressure to propel the liquid from the reservoir. Understanding how it operates is crucial for diagnosing performance issues.

Hose: Serving as the conduit, this flexible tubing delivers the solution from the pump to the nozzle. The length and diameter can affect flow rates and coverage.

Spray Nozzle: This component disperses the liquid in a controlled manner, allowing for various spray patterns and droplet sizes. Adjustability here can significantly influence application precision.

Trigger Mechanism: Often ergonomically designed, this part allows for easy activation and regulation of the flow. Familiarity with its function can enhance user comfort and efficiency.

Understanding these essential elements can significantly impact the effectiveness of your application tasks, ensuring that you achieve the desired results with confidence and ease.

Importance of Accurate Parts Diagrams

Precision in component illustrations plays a crucial role in maintaining equipment functionality and ensuring smooth operations. When users have access to clear and detailed visual representations of each element, they can easily identify, replace, or repair any faulty pieces, minimizing downtime and enhancing productivity.

Moreover, accurate visual guides significantly reduce the likelihood of errors during maintenance tasks. Technicians can refer to these illustrations to ensure they are using the correct components, which leads to improved efficiency and effectiveness in repairs. This not only saves time but also reduces the risk of damage caused by incorrect installations.

Additionally, these visual aids facilitate better communication among team members and between manufacturers and users. When everyone has a shared understanding of the equipment layout and specifications, collaboration becomes more effective, leading to quicker resolutions and improved overall performance.

In summary, having reliable visual representations of equipment components is vital for operational success. They empower users with the knowledge needed for effective maintenance, foster teamwork, and ultimately contribute to the longevity and reliability of the machinery in use.

Common Issues with Sprayer Parts

Understanding frequent challenges related to application equipment components is essential for maintaining optimal performance. These issues can affect efficiency and result in uneven distribution, leading to potential waste of resources.

- Clogs: Accumulation of debris can impede flow, requiring regular cleaning.

- Leaks: Deterioration of seals can cause unwanted spills, necessitating timely replacement.

- Pressure fluctuations: Inconsistent pressure may arise from malfunctioning regulators or blocked filters.

- Wear and tear: Continuous use can lead to degradation of components, affecting overall functionality.

- Connection issues: Loose fittings can result in inefficient operation and require frequent tightening.

Addressing these common problems proactively can enhance equipment longevity and effectiveness, ensuring successful application processes.

How to Identify Hudson Sprayer Parts

Understanding the components of a specific application is crucial for effective maintenance and operation. Familiarizing yourself with each element allows for quicker troubleshooting and enhanced performance. Knowing the function and appearance of each section can significantly improve your efficiency in the field.

Start by examining the exterior. Look for labels or markings that may indicate the model and type of device. These identifiers are often crucial for finding compatible accessories and replacements.

Next, take note of the key functions. Identify the major sections such as the tank, handle, and nozzle. Each has a distinct role, contributing to the overall effectiveness of the equipment.

Use resources such as manuals or online guides to gain insights into the design. These materials typically provide detailed visuals and descriptions, helping you pinpoint specific components with ease.

Finally, consider joining user forums or groups. Engaging with other enthusiasts can offer valuable tips and experiences, further enhancing your understanding of the device’s architecture.

Maintaining Your Hudson Sprayer Efficiently

Regular upkeep of your spraying equipment is essential for ensuring optimal performance and longevity. By adhering to a consistent maintenance routine, you can prevent common issues and enhance efficiency, ultimately leading to better results in your projects.

Key Maintenance Practices

- Clean Regularly: After each use, thoroughly clean the components to remove any residues. This helps prevent clogs and ensures smooth operation.

- Inspect for Wear: Periodically check all parts for signs of wear and tear. Replace any damaged components to maintain peak performance.

- Lubricate Moving Parts: Apply appropriate lubricants to moving parts to reduce friction and enhance durability.

- Check Fluid Levels: Regularly monitor the levels of fluids used in the system to ensure adequate supply during operation.

Seasonal Preparations

- Pre-Season Check: Before starting a new season, perform a comprehensive inspection of all equipment to identify any necessary repairs or replacements.

- Storage Tips: During off-seasons, store your equipment in a dry place. Drain any remaining fluids to prevent damage from freezing temperatures.

- Calibration: After maintenance, recalibrate the equipment to ensure accurate spraying and optimal results.

By implementing these practices, you can ensure that your spraying equipment remains in excellent condition, ready to deliver top performance whenever needed.

Step-by-Step Assembly Instructions

This section provides a detailed guide to assembling your equipment efficiently and accurately. Following these steps will ensure optimal functionality and longevity.

- Gather all necessary components and tools before starting.

- Begin with the base structure; connect the main sections securely.

- Attach the functional elements as indicated in your guide.

- Ensure all connections are tight and stable; check for any loose fittings.

- Incorporate any additional features, referring to the reference material for correct placement.

- Perform a final inspection to confirm everything is in order.

By following these clear instructions, you can achieve a well-assembled unit ready for use.

Tools Required for Repairs

Proper maintenance and restoration of equipment necessitate a specific set of instruments. Utilizing the right tools not only ensures efficiency but also enhances the overall quality of the repairs undertaken. Understanding the essential items can significantly streamline the process.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws. |

| Wrench | To grip and turn nuts and bolts. |

| Pliers | For gripping and bending materials. |

| Utility Knife | To cut through various materials. |

| Socket Set | For fastener assembly and disassembly. |

Replacement Parts: Where to Buy

Finding suitable components for your equipment can be essential for maintaining its functionality and efficiency. Numerous options exist for sourcing these essential elements, ensuring your machinery runs smoothly for years to come.

Online Retailers

- Major e-commerce platforms often have a vast selection.

- Specialized websites cater specifically to agricultural and gardening tools.

- Manufacturer websites typically offer direct purchases and guidance.

Local Suppliers

- Garden centers may stock necessary components for common models.

- Hardware stores often carry a range of compatible items.

- Local distributors may provide tailored options and advice.

Tips for Troubleshooting Sprayer Problems

Identifying and resolving issues with your application equipment can significantly enhance its performance and longevity. Common challenges often arise during operation, and understanding how to effectively address them can save time and resources. This guide provides useful strategies for diagnosing and fixing frequent malfunctions.

First, always ensure that the fluid supply is adequate and free from obstructions. Check hoses and filters for clogs, as blockages can lead to inconsistent performance. If pressure seems low, examine connections for leaks that may compromise efficiency.

Next, inspect the nozzle for wear or damage. A malfunctioning nozzle can lead to uneven distribution, affecting the overall effectiveness of your tasks. Regular maintenance and timely replacement of worn components are crucial for optimal results.

Additionally, assess the mechanical components for signs of wear. Pay close attention to moving parts, as friction and fatigue can cause performance issues. Lubrication and adjustments may be necessary to restore proper function.

Finally, keep a log of any problems encountered and the solutions implemented. This record can help in identifying patterns and anticipating future issues, making troubleshooting more efficient over time.

Safety Precautions When Repairing

Ensuring safety during maintenance and repair tasks is crucial for preventing accidents and injuries. Proper precautions not only protect the individual working on the equipment but also extend the life of the device itself. Adhering to safety guidelines creates a secure environment for effective troubleshooting and repairs.

Personal Protective Equipment

Wearing the appropriate personal protective equipment (PPE) is essential. This includes gloves to shield your hands from sharp objects and harmful substances, goggles to protect your eyes from debris, and masks if working with chemicals. Ensure that clothing is fitted and free from loose ends to avoid entanglement in moving parts.

Workspace Organization

Maintaining a tidy and organized workspace significantly reduces the risk of accidents. Clear away any unnecessary tools and materials to minimize hazards. Make sure that the area is well-lit and free from tripping obstacles. Familiarize yourself with the location of first aid kits and fire extinguishers for quick access in emergencies.

Understanding Sprayer Operation Principles

The effective functioning of a liquid application device relies on several key concepts that govern how substances are distributed in a controlled manner. At its core, the system is designed to ensure uniform coverage and precision, adapting to various terrains and target areas.

Pressure management plays a critical role in the operation. By adjusting the force exerted on the fluid, users can control the droplet size and distribution pattern. This is vital for achieving optimal results, particularly when working with different types of solutions.

Another essential aspect is nozzle design. Each type of nozzle serves a specific purpose, influencing the flow rate and spray pattern. Understanding how different nozzles interact with fluid dynamics allows for tailored applications that meet specific requirements.

Furthermore, flow control mechanisms ensure that the desired amount of liquid is dispensed at any given time. This contributes to efficient resource use and minimizes waste, making it a key consideration in operational planning.

Finally, regular maintenance of the system is crucial for longevity and consistent performance. By ensuring that all components function correctly, users can maintain the effectiveness of the device, achieving the best possible outcomes in their applications.

Innovations in Sprayer Design and Parts

Recent advancements in equipment design have significantly transformed the way liquid application is performed. These enhancements focus on increasing efficiency, improving user experience, and minimizing environmental impact. As technology evolves, the tools and components utilized in these systems have also adapted, leading to more precise and effective solutions.

Enhanced Efficiency and Precision

Modern systems are equipped with sophisticated technology that allows for better control and distribution of substances. Innovations such as variable rate application and automated monitoring systems have revolutionized how materials are delivered, ensuring that users achieve optimal results while reducing waste.

Sustainability and User-Centric Design

Incorporating eco-friendly materials and designs has become a priority. The latest models emphasize durability and ease of maintenance, enhancing usability for operators. These developments not only support sustainable practices but also enhance the overall experience, allowing users to focus on productivity.