Comprehensive Guide to VW Engine Parts Diagram

When delving into the intricate world of Volkswagen performance systems, one quickly realizes the significance of grasping the intricate arrangement and functionality of various mechanical elements. Each component plays a pivotal role in ensuring optimal operation and reliability, contributing to the overall performance of the vehicle.

By examining these individual segments, enthusiasts and mechanics alike can appreciate how they interact to create a seamless driving experience. Understanding the layout and relationship between these critical components not only aids in maintenance but also enhances the knowledge of those passionate about automotive engineering.

Whether you’re an experienced technician or a curious owner, familiarizing yourself with the specific configurations and roles of these elements can empower you to make informed decisions regarding repairs, upgrades, and modifications. The more you know, the better equipped you’ll be to tackle any challenge that arises in the realm of Volkswagen performance systems.

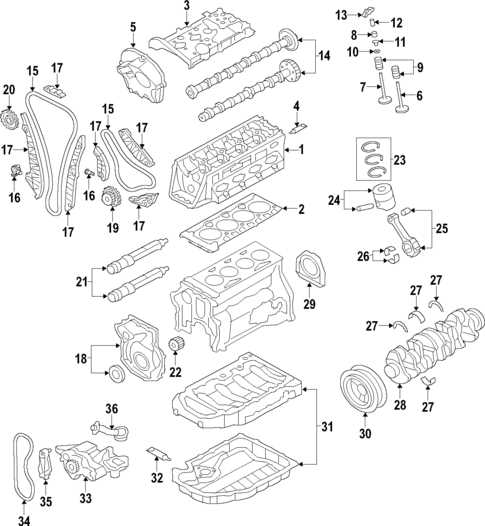

Understanding VW Engine Components

When exploring the intricacies of VW machinery, it’s essential to grasp the various elements that contribute to its functionality. Each component plays a vital role in ensuring optimal performance, reliability, and efficiency. By familiarizing oneself with these individual pieces, one can better appreciate how they work together harmoniously to achieve superior outcomes.

This section delves into the primary constituents, offering insights into their functions and interactions. Below is a concise overview of some key elements commonly found in VW models.

| Component | Function |

|---|---|

| Cylinders | House the combustion process, where fuel and air mix and ignite. |

| Pistons | Move up and down within the cylinders, converting energy from combustion into mechanical work. |

| Crankshaft | Transforms the linear motion of pistons into rotational movement to drive the vehicle. |

| Camshaft | Controls the opening and closing of valves, ensuring proper airflow and exhaust. |

| Valves | Regulate the intake of air-fuel mixture and the expulsion of exhaust gases. |

| Timing Belt | Synchronizes the movement of the crankshaft and camshaft for precise timing. |

Understanding these fundamental components provides a solid foundation for further exploration into maintenance and performance enhancements for VW vehicles.

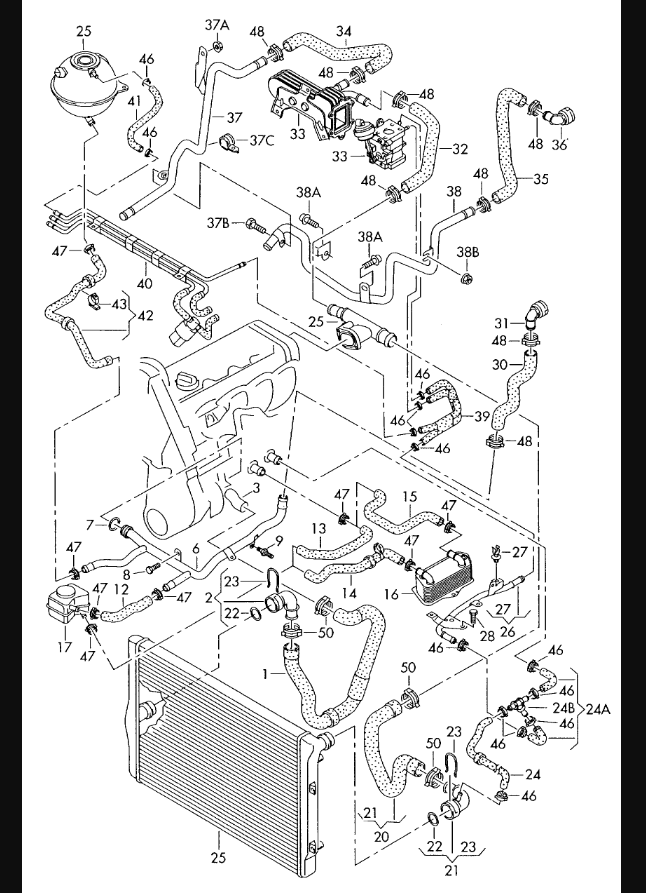

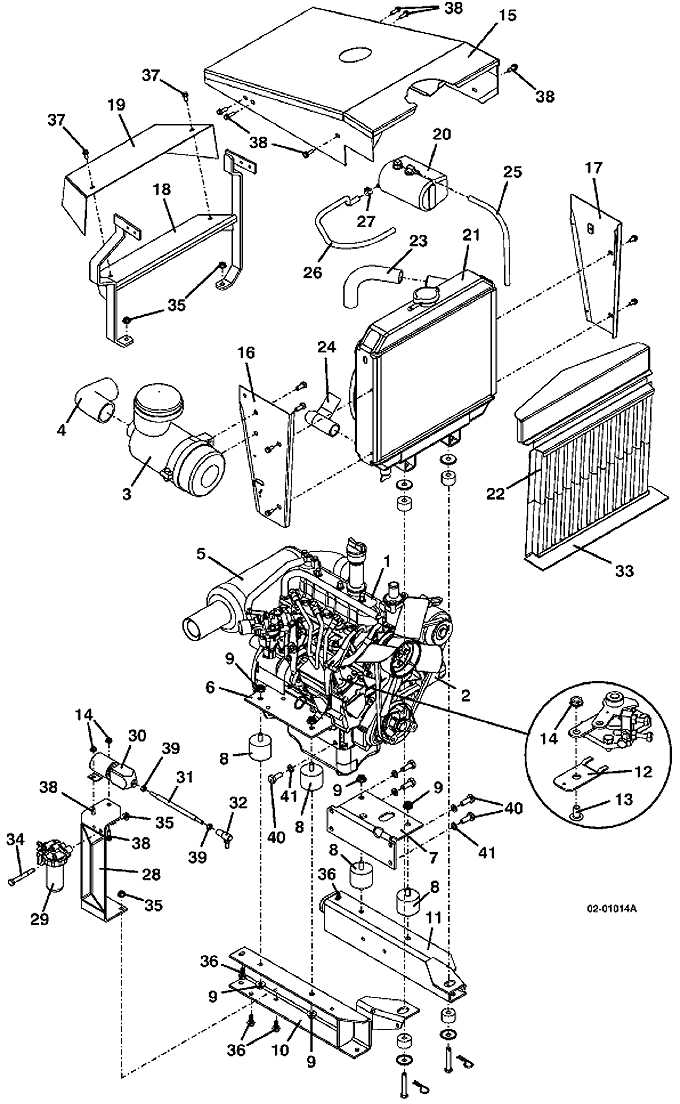

Overview of Engine Parts Layout

Understanding the configuration of key components within a vehicle’s power unit is essential for both enthusiasts and technicians. This layout not only influences performance but also dictates maintenance procedures and potential upgrades. Each section plays a crucial role, working harmoniously to ensure optimal functionality.

The arrangement of various elements is designed to maximize efficiency. From the intake system, which brings in air, to the exhaust framework that expels gases, every feature is strategically placed. This intentional setup aids in achieving smooth operation and effective energy conversion.

Moreover, accessibility to specific regions can greatly impact repair and service tasks. A thoughtful distribution of elements allows for easier inspection and replacement, minimizing downtime. Recognizing how these components interact and their respective locations enhances overall comprehension of the system’s operation.

Common Issues in VW Engines

Volkswagen vehicles, known for their distinctive design and engineering, can experience a variety of common challenges over time. Understanding these potential problems is essential for maintaining performance and reliability. This section will explore some frequent concerns that owners might encounter.

One prevalent issue is oil leaks, which can arise from worn seals or gaskets. These leaks not only affect lubrication but can also lead to overheating if not addressed promptly. Regular inspections are crucial to catch these signs early.

Another frequent challenge involves ignition difficulties, often linked to faulty spark plugs or ignition coils. Such problems can lead to misfiring and reduced efficiency, impacting overall driving experience. Regular maintenance can help mitigate these issues.

Overheating is also a significant concern, frequently caused by a malfunctioning cooling system or a blocked radiator. This issue requires immediate attention to prevent severe damage and costly repairs.

Lastly, wear and tear on components such as timing belts can lead to serious consequences if not replaced in a timely manner. Following the recommended maintenance schedule is vital to avoid unexpected failures.

Importance of Proper Engine Maintenance

Regular upkeep is essential for ensuring the longevity and reliability of any mechanical system. Neglecting routine care can lead to a range of issues, ultimately impacting performance and efficiency. Understanding the significance of maintaining these crucial components can save time and resources in the long run.

Benefits of Regular Upkeep

Consistent maintenance enhances performance, allowing for smoother operation and improved fuel efficiency. Addressing minor issues before they escalate helps avoid costly repairs and prolongs the lifespan of the machinery. Furthermore, a well-maintained unit operates more safely, reducing the risk of unexpected breakdowns.

Key Maintenance Practices

Regular checks and timely replacements of essential fluids and filters are vital practices that contribute to optimal functionality. Additionally, monitoring for wear and tear can help identify potential problems early on. Implementing a structured maintenance schedule fosters a proactive approach, ensuring that all elements operate harmoniously.

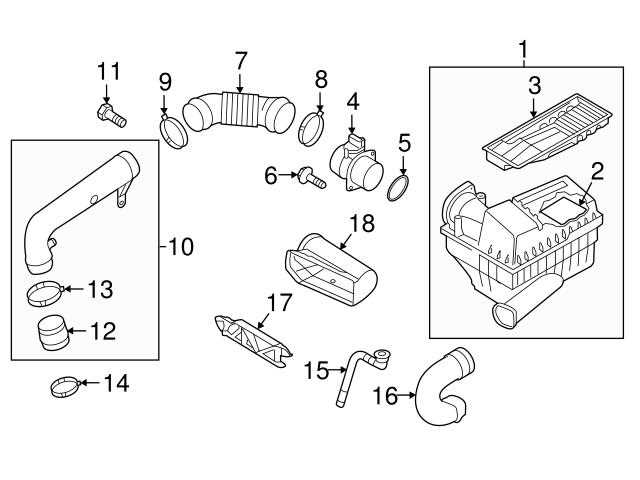

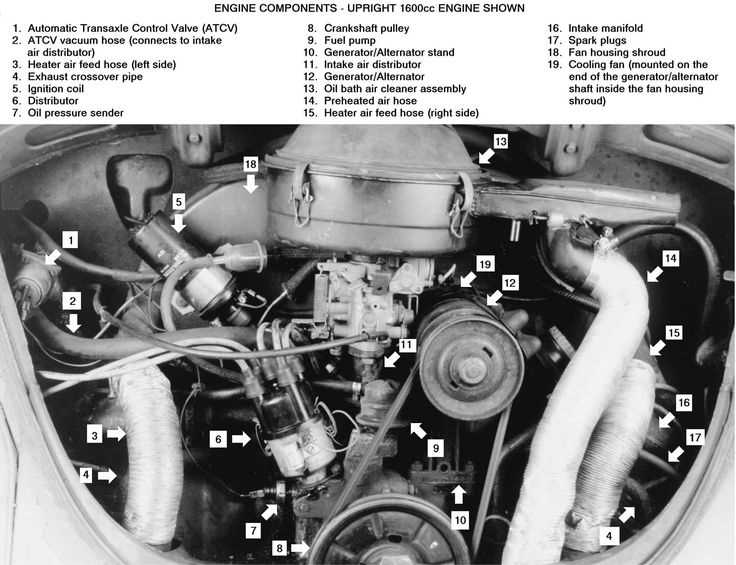

How to Identify Engine Parts

Recognizing the components of a motor can be a daunting task for many enthusiasts and professionals alike. Understanding the various elements that make up this complex system is essential for maintenance and repair. This section aims to provide insights into how to differentiate and recognize these vital components effectively.

Common Features to Look For

When attempting to identify specific components, pay close attention to the shape and size of each piece. Many elements have distinct profiles that can aid in their recognition. Additionally, the material used in construction often gives clues about the function and importance of the item. For example, metallic components are usually associated with strength and durability, while plastic parts may indicate lightweight or non-load bearing functions.

Utilizing Reference Materials

Consulting manuals or online resources can significantly enhance your ability to identify these elements. Visual aids, such as charts or photographs, can provide a clearer understanding of where each component is located and how it interacts with others. Taking notes or creating a checklist can also streamline the identification process, ensuring you cover all critical aspects systematically.

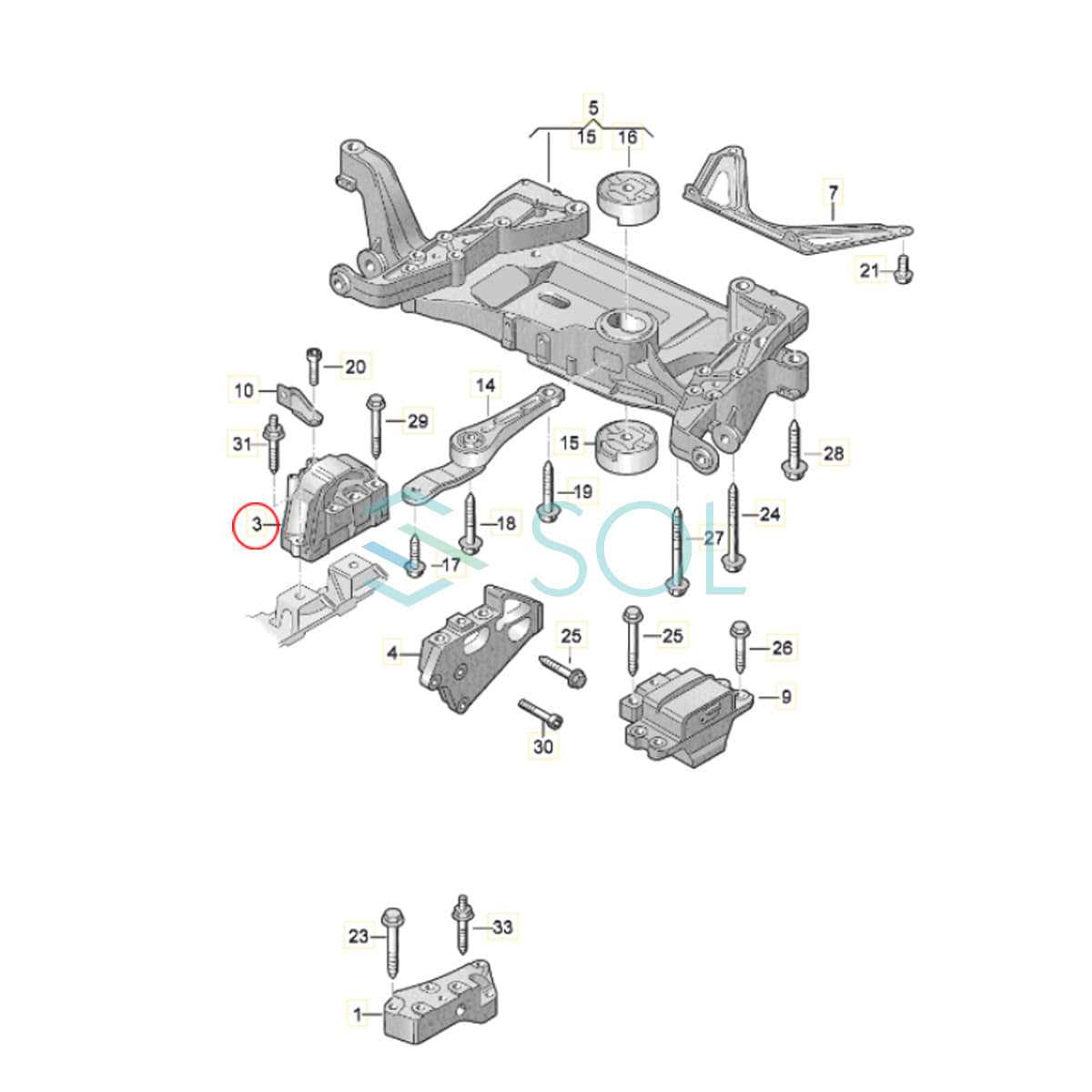

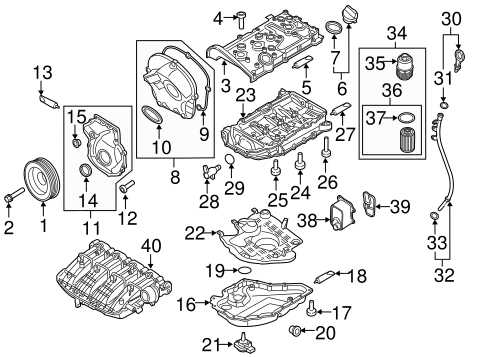

Parts Diagram for Different Models

Understanding the various components of vehicles from VW is crucial for maintenance and repair. Each model presents a unique layout, reflecting its specific design and functionality. This section explores the intricacies of different models, highlighting their distinctive arrangements.

Below are key models and their notable features:

-

Golf

- Compact size with efficient layout

- Includes modern technology for improved performance

-

Polo

- Designed for urban environments

- Focus on fuel efficiency and compact design

-

Passat

- Spacious and versatile interior

- Advanced safety features integrated into the framework

-

Tiguan

- SUV design with robust structure

- Enhanced off-road capabilities with strategic layout

Each of these models showcases a thoughtful arrangement of components tailored to meet different driving needs. Familiarity with their configurations aids in better understanding vehicle maintenance and repairs.

Benefits of Using OEM Parts

Choosing original components for vehicle repairs ensures compatibility and reliability. These products are specifically designed for your make and model, providing assurance in performance and longevity. By opting for manufacturer-certified items, you invest in quality that enhances your vehicle’s overall functionality.

Quality Assurance

Original components are subject to rigorous testing and quality control standards. This ensures that they meet the specifications set by the manufacturer, resulting in better performance and fewer issues in the long run. Using such items helps maintain the integrity of your vehicle and reduces the likelihood of unexpected breakdowns.

Warranty Protection

Utilizing original components often protects your warranty. Many manufacturers require the use of certified products for repairs to ensure coverage remains intact. This safeguards your investment and provides peace of mind, knowing that your vehicle is in good hands with genuine materials.

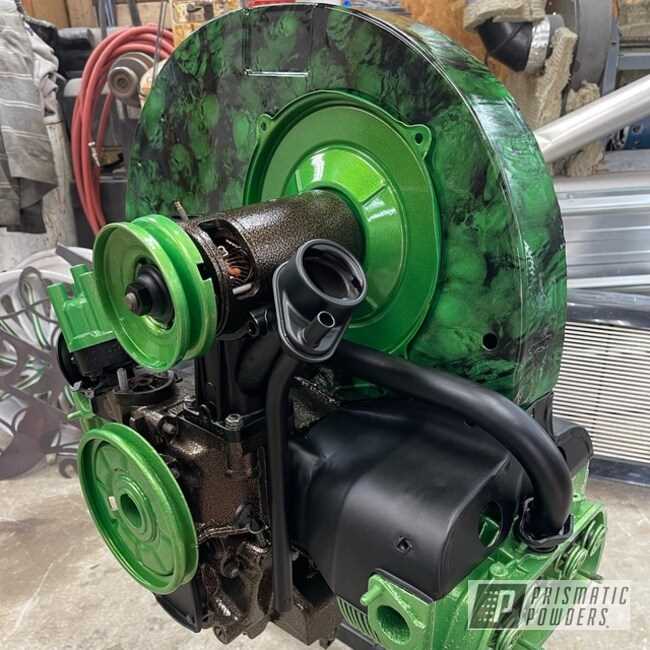

Aftermarket vs. Original Components

The choice between alternatives and factory-made components often sparks debate among enthusiasts and professionals alike. Each option carries its own set of advantages and drawbacks, influencing performance, reliability, and cost. Understanding these distinctions can guide consumers in making informed decisions that suit their specific needs.

Quality and Performance

Original components typically promise high quality and precise compatibility, crafted to meet the manufacturer’s exact specifications. This can lead to enhanced performance and durability. Conversely, aftermarket offerings vary widely; some may exceed factory standards, while others might fall short. It’s crucial to research brands and reviews to find reliable alternatives that align with performance goals.

Cost Considerations

Price is a significant factor in the decision-making process. Factory-made components generally come at a premium, reflecting their brand reputation and assurance of quality. Aftermarket options often present a more budget-friendly alternative, appealing to those looking to save money without sacrificing too much quality. However, it’s essential to weigh potential long-term costs, as lower initial expenses may lead to more frequent replacements or repairs.

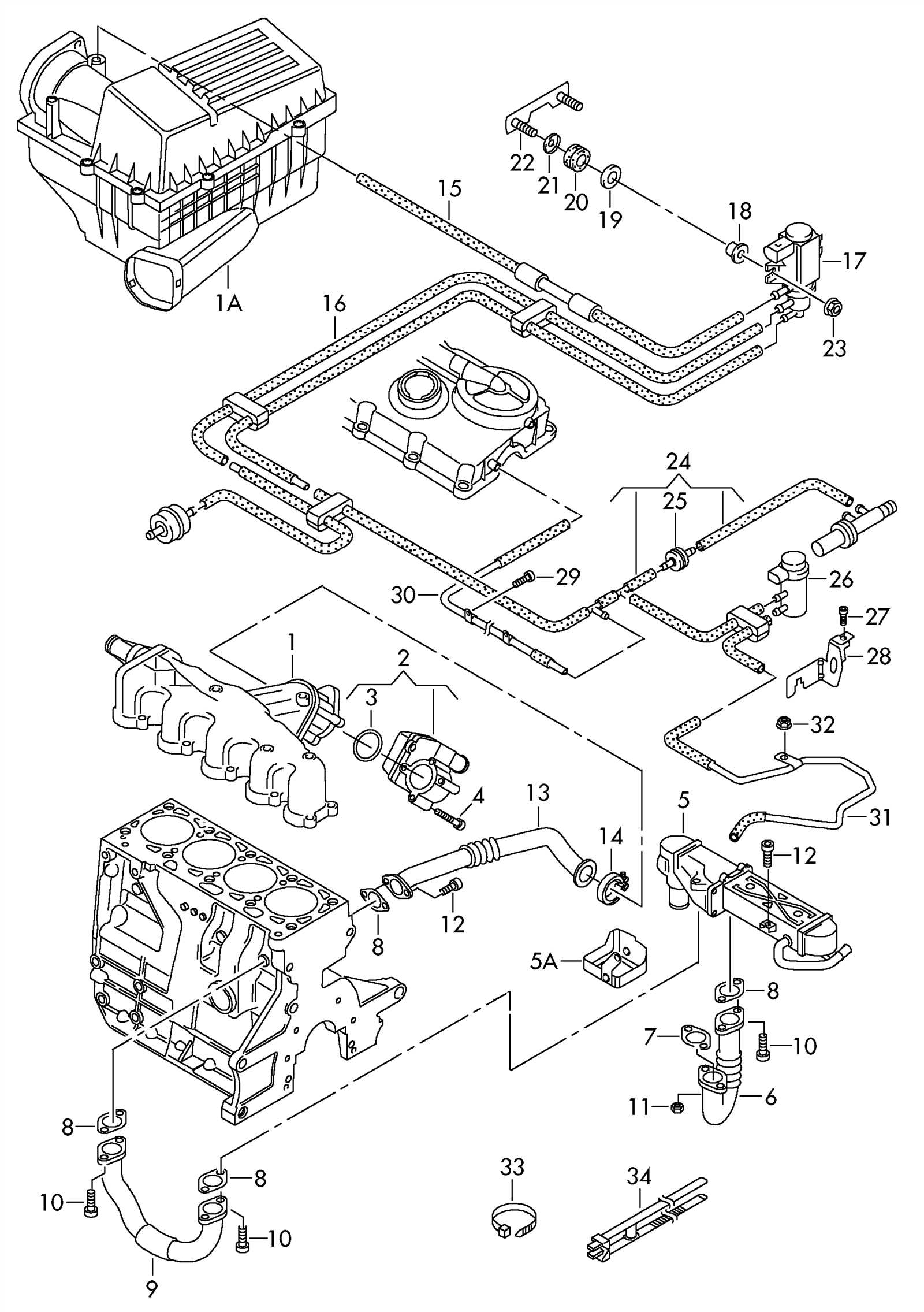

Step-by-Step Engine Assembly Guide

This guide provides a comprehensive approach to reassembling the vital components of your vehicle’s power source. Following each step carefully will ensure that everything fits perfectly and operates efficiently. Whether you’re a seasoned mechanic or a DIY enthusiast, this process can be rewarding and educational.

Preparation and Organization

Before starting, gather all necessary tools and components. Organizing your workspace will save time and minimize frustration. Lay out each item and refer to your manual for guidance on specifications and torque settings. Familiarizing yourself with the assembly sequence will also enhance your workflow.

Assembly Process

Begin with the foundation and progressively add elements, ensuring each piece is correctly aligned. Utilize lubrication where necessary to prevent wear. As you work through the installation, frequently check for any signs of misalignment or gaps. Following the prescribed tightening sequence is crucial to maintain structural integrity. Finally, once all components are in place, conduct a thorough inspection to ensure that everything is secure and ready for operation.

Tools Required for Engine Repairs

When it comes to performing maintenance or repairs on automotive machinery, having the right instruments is crucial for achieving optimal results. Each task may demand specific tools to ensure precision and efficiency, making it essential to be well-prepared before starting any work.

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening or tightening fasteners of various sizes. |

| Wrench Set | Provides leverage for turning bolts and nuts in tight spaces. |

| Screwdriver Set | Ideal for removing and installing screws of different types. |

| Pliers | Useful for gripping, twisting, and cutting wires or small components. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

| Oil Filter Wrench | Facilitates the removal of oil filters without damaging them. |

| Jack and Stands | Allows safe lifting of the vehicle for better access underneath. |

| Multimeter | Helps diagnose electrical issues by measuring voltage and current. |

Equipping yourself with these essential tools will significantly enhance your ability to perform repairs effectively and safely, ensuring that the machinery operates smoothly for years to come.

Tips for Troubleshooting Engine Problems

Identifying issues within your vehicle’s mechanical system can often feel overwhelming. However, with a systematic approach, you can effectively pinpoint and resolve many common concerns. Here are some valuable suggestions to guide you through the diagnostic process.

1. Start with Observations: Pay close attention to any unusual sounds, vibrations, or smells. These indicators can provide crucial clues about what may be going wrong.

2. Check the Basics: Ensure that fluid levels are adequate and that filters are clean. Sometimes, a simple top-up or replacement can alleviate many symptoms.

3. Utilize Diagnostic Tools: Investing in a good scanner can help read error codes, which serve as a starting point for identifying issues. This tool can save you time and effort in the long run.

4. Examine Electrical Components: Faulty wiring or connectors can lead to performance problems. Inspect these areas for signs of wear, corrosion, or loose connections.

5. Research Common Issues: Familiarize yourself with typical failures related to your vehicle model. Online forums and user groups can provide insights and shared experiences from other owners.

6. Seek Professional Help: If you find yourself stumped, don’t hesitate to consult a qualified technician. Their expertise can often lead to a quick resolution, saving you both time and frustration.

By following these tips, you can navigate the complexities of troubleshooting and restore your vehicle’s performance effectively.

Resources for VW Engine Enthusiasts

For those passionate about Volkswagen vehicles, a wealth of information and tools is essential for maintaining and upgrading their prized possessions. Whether you’re a seasoned mechanic or a curious novice, understanding the intricacies of these machines can greatly enhance your experience.

Online Forums and Communities: Engaging with fellow enthusiasts through online platforms offers invaluable insights. Websites dedicated to VW fans often feature discussions, troubleshooting tips, and shared experiences that can help you tackle any challenge.

Technical Manuals: Comprehensive guides provide detailed information about the inner workings of various models. These resources can help you familiarize yourself with specific components and their functions, ensuring that you approach your projects with confidence.

Video Tutorials: Visual learners will benefit from a plethora of instructional videos available on platforms like YouTube. These tutorials range from basic maintenance to complex modifications, making it easier to grasp new techniques.

Specialized Shops: Local and online retailers specializing in VW vehicles offer a variety of resources, including tools, upgrades, and knowledgeable staff. These establishments can be excellent places to find both products and advice tailored to your needs.

Events and Meetups: Participating in local or national gatherings allows enthusiasts to connect, share knowledge, and celebrate their love for VW. These events often include workshops, showcases, and the opportunity to meet experts in the field.

Utilizing these resources can elevate your understanding and enjoyment of your Volkswagen, transforming maintenance into a rewarding journey.