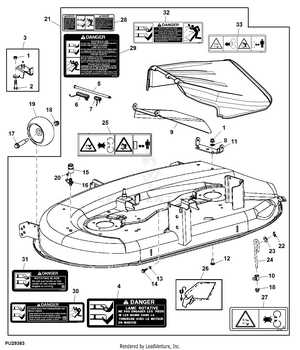

Craftsman 42 Inch Deck Parts Overview

Maintaining equipment used for lawn care often requires a deep understanding of its structural components. Without detailed insights into the specific elements that contribute to its operation, efficient upkeep becomes challenging. Whether it’s ensuring proper performance or troubleshooting potential issues, knowing how different mechanisms work together is essential for both professionals and hobbyists alike.

A thorough examination of each mechanical element is crucial when aiming for optimal functionality. Recognizing how individual pieces interact within the system can lead to better overall maintenance practices and fewer disruptions during usage. Regular checks and an informed approach can make a significant difference in the lifespan and efficiency of the tool.

For those dedicated to keeping their equipment in top condition, understanding the finer details of the tool’s build can make routine maintenance easier and more effective. By gaining knowledge of how each component works, repairs can be made swiftly, ensuring that the machinery remains in perfect working order season after season.

Mower Platform Components Overview

The platform beneath a riding lawn machine plays a crucial role in ensuring an even and efficient cut. Each component of this system works in harmony to optimize performance, from cutting blades to the support mechanisms. Understanding how these elements interact helps with both routine maintenance and troubleshooting issues.

Key Elements of the Cutting System

The cutting system includes a series of blades that rotate at high speeds to trim grass evenly. These blades are connected to spindles, which ensure smooth movement and minimal friction. Over time, wear and tear on these elements can impact the machine’s efficiency, making regular inspection essential.

Support Structures and Mounting

Supporting the cutting mechanism is a series of brackets and mounts, which stabilize the structure during operation. These components are designed to absorb shocks and ensure the cutting system remains level, contributing to an even trim across varying terrains. Maintaining these supports is key to long-term performance.

Blade Assembly for 42-Inch Deck

The blade assembly is a crucial element in ensuring smooth and efficient cutting performance. Designed to handle various terrains, this component plays a key role in delivering even, precise cuts while maintaining the overall health of the lawn. A well-maintained blade assembly ensures the cutting process remains consistent and effective over time.

Key Components of the Blade Assembly

The assembly consists of several interconnected elements that work together. Blades themselves are crafted from durable materials to withstand frequent use and potential obstacles. Supporting parts, such as washers and bolts, help secure everything in place, allowing the assembly to function smoothly.

Importance of Regular Maintenance

Maintaining the blade assembly is essential for prolonging the lifespan of the cutting system. Regular inspections, sharpening of the blades, and replacement of worn-out parts help prevent inefficiencies. Neglecting these

Belt and Pulley Mechanism Explained

The belt and pulley system is a key component in many machines, enabling efficient power transmission between different parts. It functions by transferring motion through a flexible loop that connects to rotating components, ensuring smooth operation. This system is widely used in various mechanical designs due to its simplicity and reliability.

Main Components

- Belt – A continuous loop, usually made of rubber or synthetic material, designed to move and transfer force.

- Pulley – A wheel with a groove around its edge, responsible for guiding the belt and maintaining tension.

How the System Works

When the pulley rotates, it drives the belt, which in turn moves other connected pulleys. This action transfers energy across the system, enabling the movement of different machine components. The tension and alignment of the belt are crucial for optimal performance, reducing wear and improving longevity.

- First, the be

Spindle and Bearing Maintenance Tips

Proper care of spindles and bearings ensures the longevity and smooth operation of your equipment. These components are critical in maintaining balance and efficient movement, reducing wear on surrounding parts. Regular inspection and timely maintenance can prevent costly repairs and extend the lifespan of your machine.

Inspect for Wear and Tear

Frequent inspections help identify early signs of wear. Check for unusual noise, excessive vibration, or any resistance during operation. These can indicate that bearings are wearing down or spindles are not aligned properly. Replacing damaged components early will prevent further issues.

Lubrication and Cleaning

Keeping spindles and bearings clean and well-lubricated is key to reducing friction and overheating. Use appropriate grease or lubricant, and ensure that dirt or debris is removed during regular cleanings. This simple step greatly reduces stress on moving parts, promoting longer performance.

Proper Care for Deck Shell

Maintaining the longevity and performance of your equipment’s shell is crucial for ensuring smooth operation and preventing premature wear. Regular cleaning and inspection are essential steps in keeping it in good condition, avoiding rust, and ensuring smooth operation over time.

- Clean regularly: After each use, remove any grass, dirt, or debris to prevent buildup that can lead to corrosion or performance issues.

- Inspect for damage: Regularly check for dents, cracks, or other signs of damage. Addressing small issues early can prevent more significant problems down the line.

- Apply protective coatings: Consider using rust-preventive coatings to help shield the surface from moisture and extend its lifespan.

- Adjusting Mower Deck Height Efficiently

Achieving the right cutting height is crucial for maintaining a healthy lawn. Proper adjustment ensures even trimming, prevents scalping, and promotes robust growth. Understanding how to modify the height of your mower effectively can enhance its performance and extend its lifespan.

Follow these steps to adjust the cutting height:

- Consult the user manual for specific guidelines related to your model.

- Locate the height adjustment lever or mechanism on your mower.

- Set the mower on a flat surface to ensure accurate adjustments.

- Raise or lower the cutting mechanism according to your desired height.

- Check the height on each side of the mower for uniformity.

For optimal results, consider the following tips:

- Adjust the height based on grass type and growth conditions.

- Perform adjustments when the mower is off and cool.

- Make incremental changes rather than large adjustments for better control.

- Regularly check the height setting to accommodate changing lawn conditions.

By following these guidelines, you can efficiently manage the height of your mower, ensuring a well-maintained and aesthetically pleasing yard.

Common Issues with Blade Engagement

When operating lawn maintenance equipment, users often encounter difficulties with the activation of cutting tools. These issues can arise from various factors, leading to inefficient operation and unsatisfactory results. Understanding these common problems is essential for effective troubleshooting and maintenance.

Mechanical Failures

One primary concern is mechanical failure within the engagement system. Components may wear down over time, resulting in improper activation. Regular inspection can help identify signs of wear, such as cracks or bending in levers and cables.

Electrical Malfunctions

Another factor that may hinder blade engagement is electrical issues. Problems with wiring or switches can disrupt the power supply, preventing the blades from functioning as intended. Ensuring that electrical connections are secure and free from corrosion is crucial for reliable operation.

Issue Possible Causes Solutions Blades not engaging Worn cables, faulty switch Inspect and replace damaged components Uneven cutting Misaligned blades, low power Realign blades and check power supply Noise during operation Loose parts, damaged belt Tighten parts and replace worn belts Craftsman Deck Tension Spring Guide

This section aims to provide essential information regarding the spring mechanism that is crucial for optimal operation of your lawn mower’s cutting apparatus. Understanding this component can enhance performance and prolong the lifespan of the machinery.

The tension spring plays a significant role in maintaining the appropriate pressure and alignment within the cutting assembly. Proper functioning of this element ensures that the blades operate effectively, leading to a clean and even cut. Below are some key aspects to consider:

- Functionality: The spring exerts force to keep the blades taut, preventing excessive slack that could lead to uneven cutting.

- Adjustment: Regular adjustments may be necessary to maintain optimal tension, which can be affected by wear and tear over time.

- Replacement: If the spring becomes damaged or worn, it is important to replace it promptly to avoid further complications.

To ensure proper maintenance, regularly inspect the spring for any signs of wear. A well-maintained tension spring not only enhances cutting performance but also contributes to the overall efficiency of your equipment.

Replacing the Deck Idler Pulley

Maintaining the functionality of your lawn equipment often requires the replacement of essential components. One such crucial part is the idler pulley, which plays a vital role in ensuring the smooth operation of the cutting system. This section will guide you through the process of replacing this component effectively.

Tools and Materials Needed

Before starting the replacement process, gather the following tools and materials:

Tool/Material Purpose Socket wrench To remove the old pulley Replacement idler pulley New component to install Safety gloves Protect your hands during the process Step-by-Step Replacement Guide

Follow these steps to successfully replace the idler pulley:

- Disconnect the power source to ensure safety during the replacement.

- Locate the old idler pulley and remove the mounting bolts using the socket wrench.

- Carefully detach the old pulley from the assembly.

- Position the new pulley in place and secure it with the previously removed bolts.

- Reconnect the power source and test the operation of the new pulley.

Importance of Washout Port

A washout port is a critical feature that enhances the performance and longevity of mowing equipment. This component serves a vital role in maintaining cleanliness and efficiency by allowing for easy removal of grass clippings and debris that accumulate during operation. Regular cleaning through this port can significantly improve the functionality of the machine.

Here are several reasons why having a washout port is essential:

- Prevents Build-Up: Regularly clearing away clippings prevents excessive accumulation that can lead to rust and corrosion.

- Enhances Performance: A clean cutting area ensures optimal blade performance, resulting in a cleaner cut.

- Reduces Maintenance Time: Utilizing the washout port makes cleaning quick and efficient, saving time during maintenance routines.

- Improves Airflow: A clean underside promotes better airflow, which is essential for effective grass cutting and preventing clumping.

In conclusion, a washout port is an invaluable feature that contributes to the overall efficiency and durability of mowing equipment. Regular maintenance using this component can lead to significant improvements in performance and longevity.

Safety Tips for Mower Deck Repairs

Ensuring safety during maintenance tasks is crucial for preventing accidents and injuries. Adhering to proper protocols and utilizing the right equipment can significantly enhance the repair experience and maintain a secure environment.

Here are some essential guidelines to follow:

- Read the Manual: Familiarize yourself with the manufacturer’s instructions and safety warnings before beginning any repair work.

- Wear Protective Gear: Always use safety glasses, gloves, and sturdy footwear to protect yourself from sharp objects and debris.

- Disconnect the Power: Before starting repairs, ensure that the power source is disconnected to avoid accidental starts.

- Work in a Well-Ventilated Area: Ensure proper ventilation to minimize exposure to fumes and avoid inhalation of harmful substances.

- Keep the Workspace Clean: Maintain a tidy work area to reduce the risk of tripping hazards and accidents.

- Use the Right Tools: Select appropriate tools for the task to ensure effective and safe repairs.

- Get Help When Needed: If you’re unsure about a procedure, don’t hesitate to ask for assistance or consult a professional.

By following these precautions, you can create a safer environment while performing maintenance tasks on your mower.

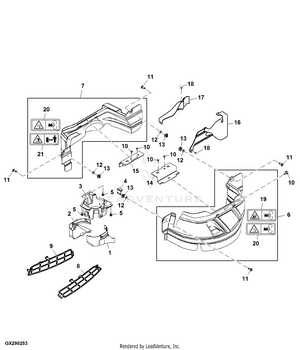

Choosing the Right Deck Accessories

When it comes to enhancing your outdoor equipment, selecting the appropriate supplementary components is crucial. These accessories can improve performance, increase versatility, and ensure a seamless operation throughout the seasons. Understanding your specific needs and the features available can significantly impact your overall satisfaction.

Consider Your Requirements

Before making a selection, it’s important to assess what you truly need. Consider the following:

- Type of terrain you frequently navigate.

- Size of the area you plan to cover.

- Frequency of use and maintenance requirements.

Popular Accessory Options

Here are some widely used supplementary components to consider:

- Mulching Kits: Ideal for those looking to recycle grass clippings, providing nutrients back to the soil.

- Bagging Systems: Perfect for easy collection of clippings and leaves, ensuring a tidy finish.

- Snow Blades: Essential for winter maintenance, allowing for efficient snow removal.

- Hitch Kits: Useful for towing additional equipment, increasing functionality.

By carefully evaluating your needs and exploring various options, you can effectively enhance your outdoor experience.