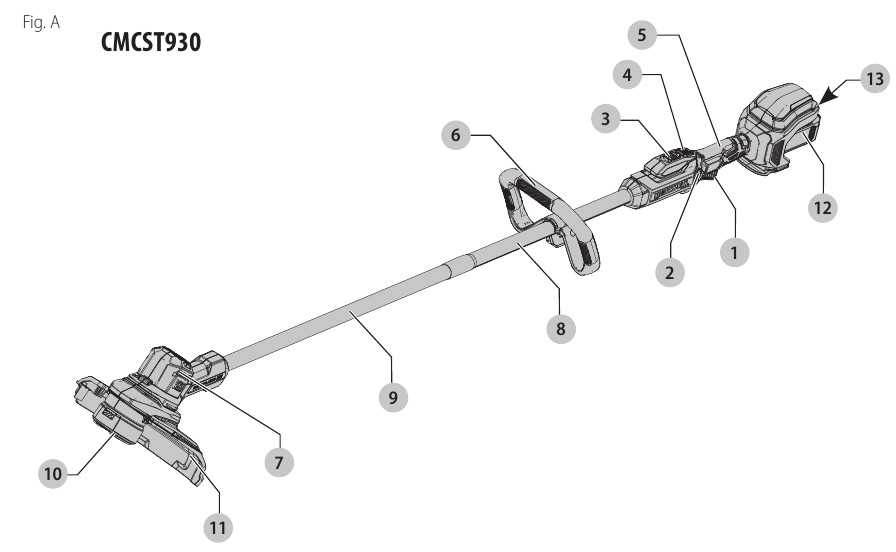

Exploring the Cmcst900 Parts Diagram for Optimal Understanding

In the realm of machinery and technical equipment, comprehending the various elements that contribute to functionality is crucial for both maintenance and operation. A detailed overview of these components enhances users’ ability to troubleshoot and optimize their devices. Each segment plays a vital role, and recognizing their interconnections can significantly improve performance and longevity.

Through an organized representation, users can easily identify each individual component, facilitating a clearer understanding of their specific functions and relationships. This systematic approach not only aids in assembling or disassembling units but also empowers users to address issues more effectively. Clarity in the layout fosters confidence in handling complex systems.

Moreover, having access to a well-structured outline of these essential elements allows for quicker repairs and replacements, ultimately minimizing downtime. Embracing this knowledge can lead to more informed decisions when it comes to upgrades or modifications. As technology continues to advance, staying informed about the inner workings of such systems becomes increasingly important for all users.

Understanding Cmcst900 Components

This section explores the various elements that constitute a complex system, focusing on their roles and interactions. By breaking down these components, we can gain insights into how they contribute to the overall functionality and performance of the unit.

Key Elements

The main components include mechanical parts, electrical elements, and software interfaces. Each plays a crucial role in ensuring smooth operation. Understanding their individual functions is essential for effective maintenance and troubleshooting.

Interactions and Functionality

Each element must work in harmony with others to achieve optimal results. For instance, a mechanical component might depend on an electrical one for power, while software ensures proper communication between them. This intricate relationship highlights the importance of each part within the larger framework.

Importance of Parts Diagrams

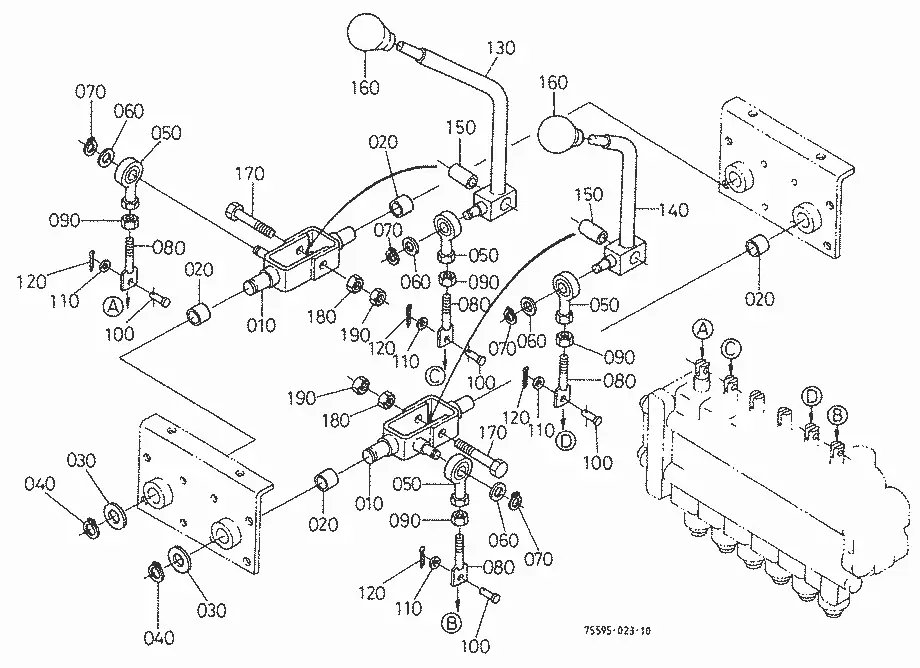

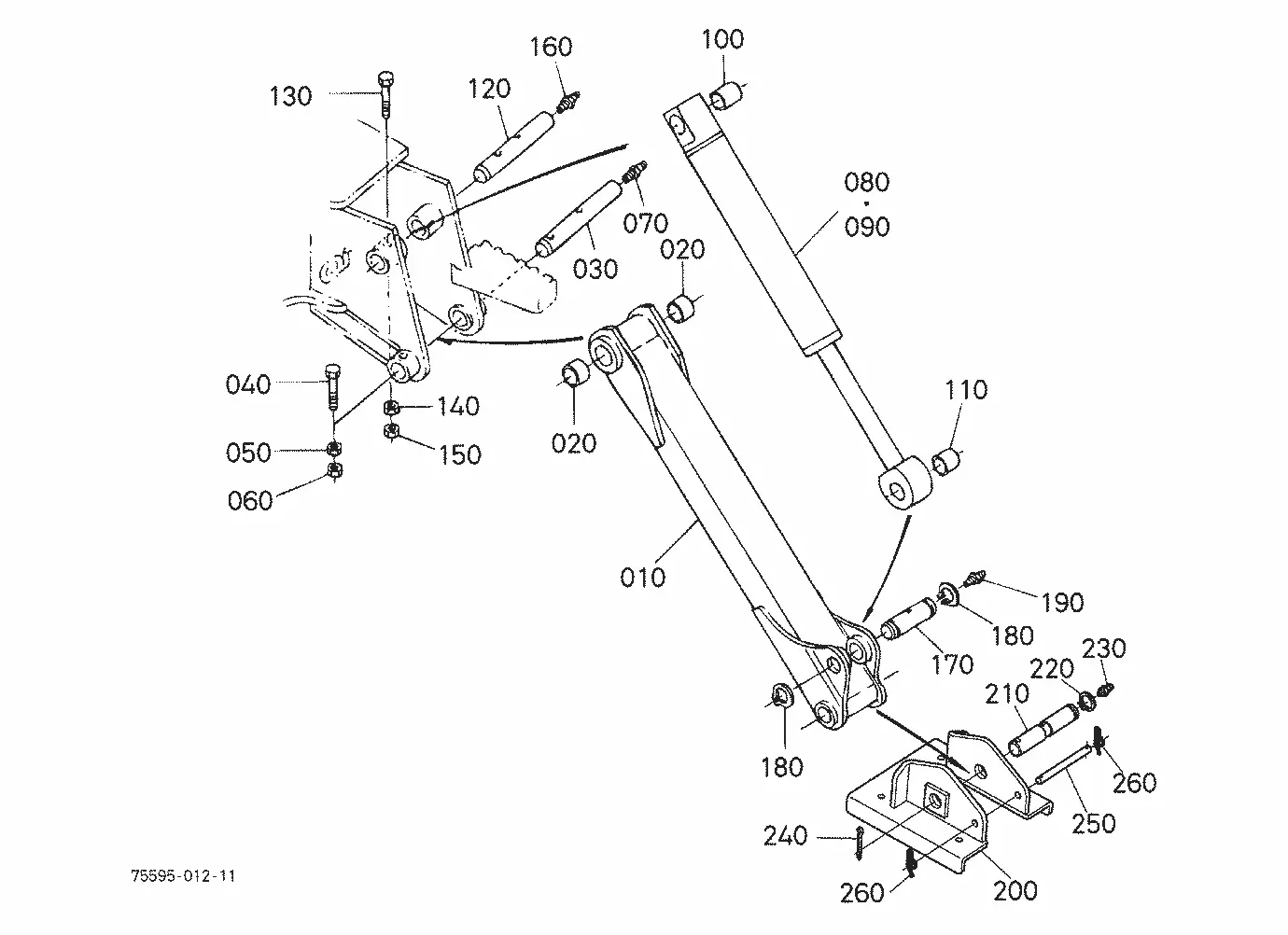

Visual representations of components play a crucial role in understanding complex machinery. They provide a clear overview of the various elements, allowing users to grasp the relationships and functions within the system. This clarity is essential for effective maintenance and troubleshooting.

Moreover, these illustrations serve as valuable references during assembly and disassembly processes. By highlighting the arrangement and interaction of different sections, they minimize errors and enhance efficiency. This ultimately leads to improved performance and longevity of the equipment.

Additionally, educational tools that utilize these visuals can significantly aid in training new technicians. By facilitating a deeper understanding of how each part contributes to overall functionality, learners can develop the skills needed for effective operation and repair.

In summary, comprehensive visual aids are indispensable for anyone involved in the management or operation of mechanical systems. They enhance clarity, streamline processes, and foster knowledge, making them essential resources in any technical field.

Key Features of Cmcst900 Model

This model stands out for its exceptional functionality and innovative design, catering to users seeking reliability and efficiency. Its robust construction ensures longevity, while a range of advanced features enhances user experience and performance across various applications.

Innovative Design

The thoughtful engineering behind this unit prioritizes ease of use and accessibility, making it suitable for both novices and experts. Its ergonomic layout allows for seamless interaction, ensuring that users can operate it intuitively.

Performance Specifications

| Feature | Specification |

|---|---|

| Power Output | 1000 Watts |

| Operating Range | 20-200°C |

| Weight | 5 kg |

| Dimensions | 30 x 25 x 15 cm |

Common Issues with Cmcst900 Parts

When dealing with mechanical components, several recurring problems can arise that may hinder performance or lead to malfunction. Understanding these issues is crucial for effective maintenance and troubleshooting, ensuring longevity and optimal function of the equipment.

One frequent concern is wear and tear, which can result from prolonged use and insufficient lubrication. This degradation may lead to reduced efficiency or complete failure of the system. Additionally, improper installation often causes misalignment, creating stress on surrounding elements and accelerating deterioration.

Another common issue is the accumulation of debris and contaminants, which can obstruct movement and compromise the integrity of connections. Regular cleaning and inspection are vital in preventing these blockages. Furthermore, temperature fluctuations can affect material properties, leading to expansion or contraction that impacts overall performance.

Lastly, compatibility between different components is essential. Using mismatched elements can result in operational inefficiencies and increased risk of damage. Regular assessment and proper selection of components are key to minimizing these risks.

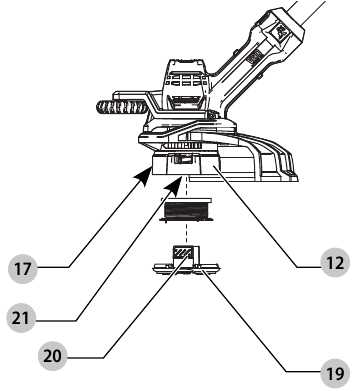

How to Read Parts Diagrams

Understanding visual representations of components is crucial for anyone working with machinery or complex systems. These illustrations serve as a guide to identifying various elements, their arrangement, and how they interact within the larger assembly. By familiarizing yourself with the conventions used in these visuals, you can enhance your ability to troubleshoot, maintain, or assemble devices effectively.

First, examine the overall layout to get a sense of the structure. Typically, these visuals are organized in a way that highlights the relationship between different pieces. Pay attention to labels and numbers, as they often correspond to a list or key that provides detailed descriptions of each element.

Next, look for any color coding or symbols that might indicate specific functions or categories. This information can provide insights into how each component operates within the system. Additionally, note any arrows or lines that illustrate connections or flow, which can be crucial for understanding the operational dynamics.

Lastly, practice interpreting these visuals by comparing them with actual components or assembly instructions. This hands-on approach will deepen your comprehension and enable you to apply your knowledge effectively in real-world scenarios.

Maintenance Tips for Cmcst900

Regular upkeep is essential for ensuring the longevity and efficiency of any equipment. By following some straightforward practices, users can maximize performance and minimize the risk of unexpected issues.

- Always consult the manufacturer’s guidelines for recommended maintenance intervals.

- Perform routine inspections to identify any wear and tear that may require attention.

- Keep the unit clean and free of debris to prevent operational hindrances.

- Check and replace any worn components to maintain optimal functionality.

Additionally, it’s beneficial to maintain a log of all maintenance activities. This not only helps in tracking the history of care but also aids in scheduling future maintenance tasks effectively.

- Begin with a visual inspection before each use.

- Ensure that all moving parts are adequately lubricated.

- Test functionality regularly to catch potential problems early.

- Store the equipment in a dry, protected environment to prevent damage.

By adhering to these simple yet effective strategies, users can ensure their equipment remains in peak condition, providing reliable performance for years to come.

Replacing Worn-Out Components

Over time, certain elements of machinery can deteriorate, leading to decreased performance and potential malfunctions. Timely replacement of these components is crucial to maintain operational efficiency and extend the lifespan of the equipment. Understanding the signs of wear and knowing when to intervene can prevent more significant issues down the line.

Identifying which parts need attention is essential. Common indicators include unusual noises, decreased output, or visible signs of damage. Regular inspections and maintenance routines can help pinpoint these worn areas before they cause failures.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Seals and Gaskets | Leaks, cracks | Replace immediately |

| Bearings | Grinding noises, heat | Inspect and replace if necessary |

| Filters | Clogs, reduced flow | Change regularly |

| Belts and Hoses | Fraying, swelling | Monitor and replace when worn |

By proactively managing the condition of these essential components, operators can ensure the smooth operation of their machinery, minimize downtime, and enhance overall productivity. Regular training and awareness can further empower teams to recognize issues early, facilitating timely replacements and repairs.

Tools Required for Repairs

Effective maintenance and troubleshooting of equipment necessitate a selection of essential instruments. Having the right tools on hand ensures that tasks can be completed efficiently and safely. Below is a comprehensive list of items that are commonly required for successful repairs.

- Wrenches: Various sizes, including adjustable and socket types, are crucial for loosening and tightening components.

- Screwdrivers: A set of flathead and Phillips screwdrivers will allow you to tackle different types of screws.

- Pliers: Needle-nose and regular pliers are helpful for gripping, twisting, and cutting wires.

- Multimeter: This tool is essential for checking electrical connections and diagnosing issues.

- Torque wrench: Ensures that fasteners are tightened to the correct specifications to prevent damage.

- Hammer: Useful for gentle persuasion of components without causing harm.

- Safety gear: Always include gloves, goggles, and masks to protect yourself during repairs.

Equipped with these tools, you will be well-prepared to handle a variety of maintenance challenges effectively. Proper organization and care of your tools will further enhance your repair capabilities.

Where to Find Parts Diagrams

Locating detailed schematics for various components can significantly enhance your understanding and maintenance of equipment. These resources are invaluable for anyone looking to identify specific elements or perform repairs efficiently.

Online Resources

The internet offers a wealth of platforms dedicated to providing comprehensive schematics. Manufacturer websites often host detailed catalogs, while forums and specialized websites can also serve as excellent repositories for these valuable illustrations.

Local Dealers and Repair Shops

Visiting local dealerships or repair centers can yield physical copies of schematics. These professionals often have access to proprietary resources and can assist in obtaining the exact visual guides needed for any maintenance task.

Upgrading Cmcst900 Performance

Enhancing the efficiency and capability of your equipment can lead to significant improvements in overall functionality. By focusing on key areas such as component optimization and system tuning, you can achieve remarkable results that elevate the user experience. The goal is to unlock the full potential of the system, making it more responsive and effective in its tasks.

One effective approach involves evaluating the existing setup and identifying bottlenecks. Upgrading internal elements can provide a substantial boost, allowing for smoother operation and increased reliability. Consider integrating advanced technology that complements the core functionalities, ensuring that each upgrade synergizes with the others.

Regular maintenance and calibration also play a crucial role in performance enhancement. By keeping the system in optimal condition, you can prevent issues that might hinder its capabilities. Consistent monitoring and adjustments ensure that you maintain the highest level of efficiency, adapting to any evolving demands.

Ultimately, investing in quality enhancements and staying informed about the latest advancements will pave the way for a superior operational experience. By taking a comprehensive approach to upgrading, you can achieve a system that not only meets but exceeds your expectations.

Expert Recommendations for Users

Understanding the intricacies of any machinery is essential for optimal performance and longevity. Whether you are a seasoned professional or a novice, following expert advice can significantly enhance your experience and efficiency.

Prioritize Regular Maintenance

Routine upkeep is crucial. Regular checks not only prevent unexpected breakdowns but also extend the lifespan of your equipment. Ensure that all components are clean and functioning properly, and replace any worn parts promptly.

Utilize Quality Resources

Always refer to reliable manuals and guides tailored to your machinery. Quality documentation provides valuable insights that can help you navigate challenges and improve your understanding of the system as a whole.

Frequently Asked Questions

This section addresses common inquiries that users may have regarding the assembly and components of their equipment. It aims to provide clear answers to enhance understanding and facilitate troubleshooting.

General Queries

- What should I do if I notice missing elements?

- How can I identify compatible accessories?

- Are there any recommended maintenance practices?

Troubleshooting

- If a part is not functioning properly, what steps should I take?

- How do I determine if a component needs replacement?

- Where can I find reliable support for issues not covered here?