Understanding the Onan 5500 Parts Diagram for Efficient Maintenance

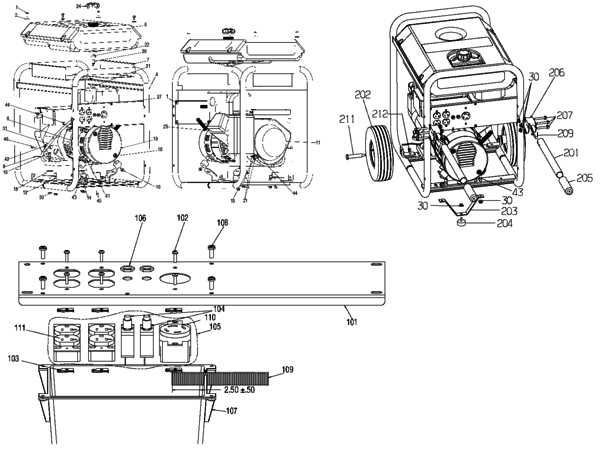

When it comes to maintaining the efficiency and longevity of your generator, having a comprehensive understanding of its various elements is essential. Each component plays a crucial role in the overall functionality, and familiarity with these parts can aid in troubleshooting and repairs. This section will explore the intricate relationships between these elements, providing insight into how they work together to ensure optimal performance.

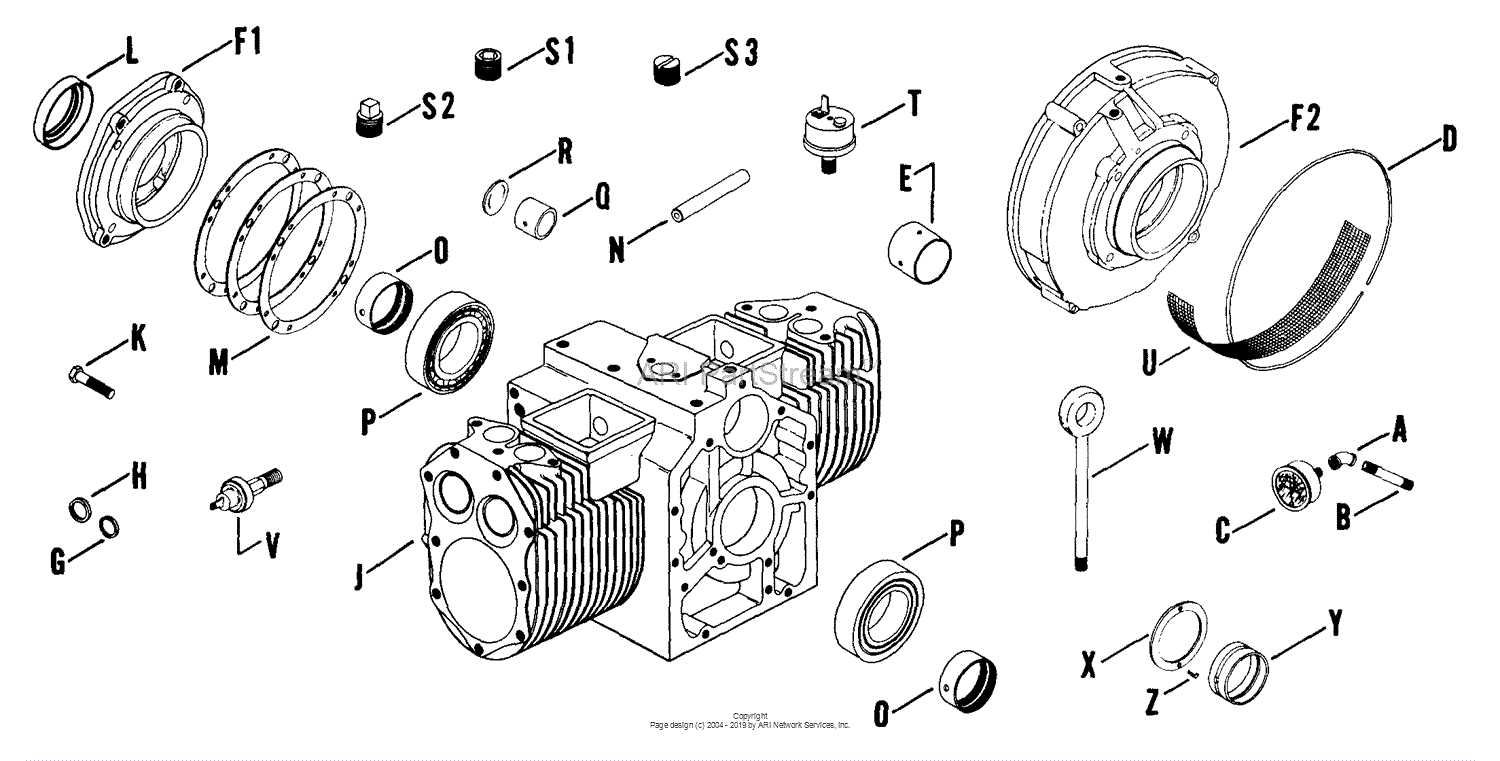

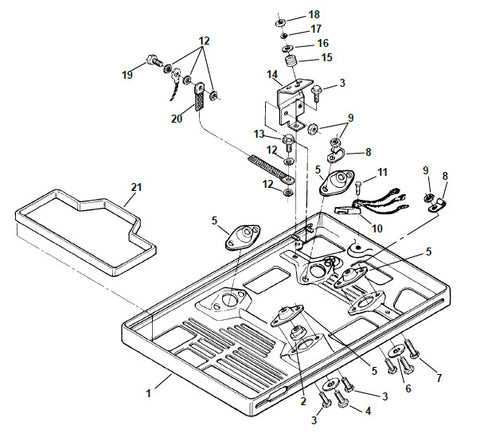

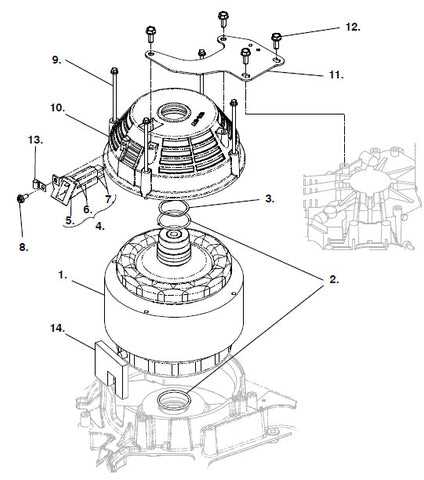

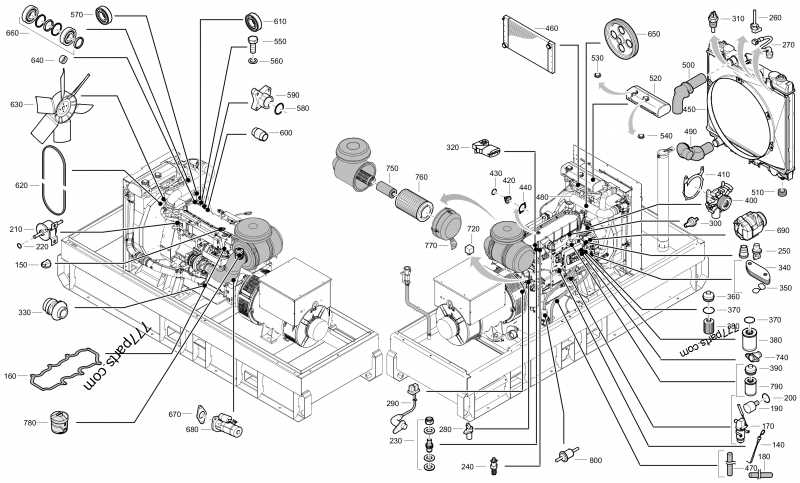

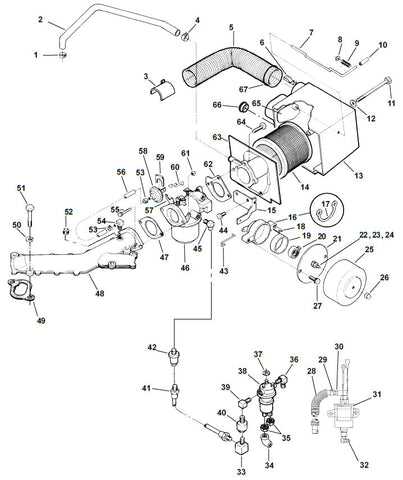

Visual representations serve as invaluable tools for grasping the layout and connection of different components within the machine. By examining detailed illustrations, users can easily identify where specific parts are located and how they interact with one another. This knowledge not only enhances one’s ability to carry out maintenance tasks but also empowers individuals to make informed decisions regarding replacements and upgrades.

Whether you’re a seasoned technician or a novice user, understanding the intricacies of your generator’s structure will ultimately lead to improved efficiency and reliability. This guide will help you navigate through the essential components, ensuring you are well-equipped to manage your equipment effectively.

Understanding the Onan 5500 Diagram

Grasping the intricacies of a technical schematic can greatly enhance your ability to maintain and troubleshoot complex machinery. These visual representations serve as blueprints, highlighting the relationships between various components and illustrating how they interact within the system. By familiarizing yourself with these layouts, you empower yourself to make informed decisions regarding repairs and enhancements.

Key Components and Their Functions

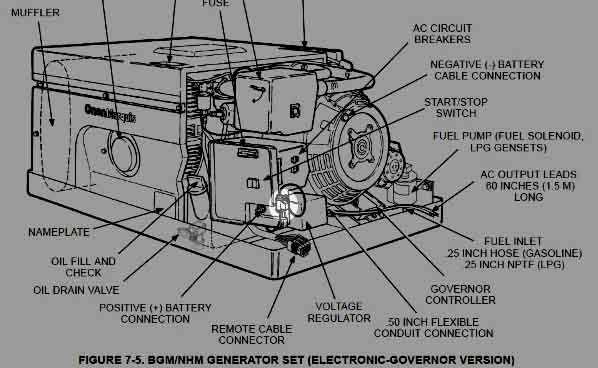

In any mechanical assembly, each element plays a crucial role in ensuring optimal performance. Recognizing the purpose of individual parts can provide clarity when diagnosing issues. For example, the electrical connections are vital for proper power distribution, while the mechanical segments are essential for operation. Understanding these functions allows for more efficient repairs and can minimize downtime.

Interpreting the Visual Layout

Reading a schematic requires attention to detail and a systematic approach. Start by identifying the main units and their respective connections. Look for symbols that represent different functionalities, and pay attention to the orientation of each component. Emphasis on how parts are interconnected will facilitate a deeper understanding of the overall structure. Moreover, recognizing patterns can help in anticipating potential points of failure, enabling proactive maintenance strategies.

Key Components of Onan 5500

Understanding the essential elements of a power generator is crucial for effective maintenance and optimal performance. Each component plays a significant role in the overall functionality, contributing to reliability and efficiency. Below is an overview of the primary constituents that ensure smooth operation.

Essential Elements

- Engine: The heart of the generator, responsible for converting fuel into mechanical energy.

- Alternator: This part transforms mechanical energy into electrical energy, ensuring a steady power supply.

- Fuel System: Comprising the fuel tank, lines, and pump, this system stores and delivers fuel to the engine.

- Cooling System: A vital component that prevents overheating by circulating coolant around the engine.

- Control Panel: The interface for monitoring and managing the generator’s functions, including start/stop operations and output levels.

Supporting Mechanisms

- Exhaust System: Directs exhaust gases away from the engine, reducing emissions and noise.

- Lubrication System: Ensures all moving parts operate smoothly by reducing friction and wear.

- Starting System: Facilitates the ignition of the engine, typically utilizing a battery and starter motor.

- Frame: Provides structural support and houses all components, ensuring durability and stability.

Each of these components works in harmony to provide reliable energy solutions. Regular inspection and maintenance of these elements can greatly enhance the longevity and performance of the generator.

How to Interpret the Parts Diagram

Understanding the layout of components is essential for effective maintenance and troubleshooting. A well-structured illustration serves as a visual guide, allowing users to identify various elements and their relationships. By familiarizing oneself with the arrangement and symbols used, individuals can navigate the complexities of the machinery more efficiently.

To begin, pay attention to the legend or key that accompanies the visual representation. This section provides crucial information about the symbols and numbers that correspond to different pieces. Knowing what each symbol signifies helps in pinpointing the exact parts needed for repairs or replacements.

Next, examine the overall organization of the image. Components are typically grouped based on their function or location within the system. Recognizing these clusters can aid in understanding how each part interacts with others, enhancing comprehension of the overall operation.

Additionally, take note of any directional arrows or flow indicators present. These elements often depict the movement of fluids or electrical signals, which are vital for grasping how the system works as a whole. Understanding the flow can reveal potential bottlenecks or areas that may require attention.

Lastly, it’s beneficial to cross-reference the visual guide with the accompanying documentation. Specifications and detailed descriptions can provide deeper insights into the components’ roles and importance, ensuring a thorough understanding for maintenance or repairs.

Common Issues with Onan 5500 Parts

In the realm of portable generators, various components can encounter issues that affect overall performance and reliability. Understanding these common problems can help users troubleshoot effectively and maintain optimal functionality.

Frequent Mechanical Failures

Mechanical breakdowns often stem from wear and tear, particularly in high-stress components. Regular inspection can identify signs of fatigue, which may lead to unexpected outages.

| Component | Common Issues | Symptoms |

|---|---|---|

| Fuel Pump | Clogging or Leaks | Inconsistent fuel delivery, stalling |

| Starter Motor | Electrical Faults | Failure to start, clicking noise |

| Air Filter | Blockage | Reduced power output, overheating |

Electrical System Complications

Electrical malfunctions can disrupt the flow of power and may originate from faulty wiring or worn-out connections. Addressing these issues promptly is crucial for ensuring reliable operation.

| Component | Common Issues | Symptoms |

|---|---|---|

| Battery | Corrosion or Discharge | Difficulty starting, dim lights |

| Control Panel | Display Failures | Erratic readings, unresponsive controls |

| Voltage Regulator | Overvoltage or Undervoltage | Flickering lights, equipment damage |

Maintenance Tips for Onan Generators

Regular upkeep is crucial for ensuring optimal performance and longevity of your power generation unit. Following a structured maintenance routine can help prevent breakdowns and enhance efficiency, allowing the equipment to operate smoothly when you need it most.

Routine Maintenance Tasks

- Check and replace the oil regularly to keep the engine lubricated.

- Inspect and clean the air filter to maintain proper airflow.

- Examine the spark plugs for wear and replace them if necessary.

- Inspect fuel lines and connections for leaks or damage.

- Ensure that the battery is charged and terminals are clean.

Seasonal Preparations

- Before winter, run the unit to ensure it operates smoothly and is ready for cold weather.

- During summer, check for overheating issues and ensure adequate ventilation around the unit.

- Store fuel in a cool, dry place and consider using fuel stabilizers for long-term storage.

- Test the unit under load periodically to confirm it can handle power demands.

By adhering to these guidelines, you can maximize the reliability and efficiency of your generator, ensuring it meets your energy needs effectively.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining its performance and longevity. Various sources can provide high-quality alternatives, whether you are seeking original items or reliable substitutes. Understanding where to search is crucial in ensuring you find the right fit for your machinery.

Here are some common avenues to explore when looking for necessary components:

| Source Type | Description |

|---|---|

| Authorized Dealers | These vendors often offer genuine components and can provide expert guidance for your specific needs. |

| Online Retailers | Websites specializing in machinery parts may have extensive inventories and competitive pricing. |

| Local Repair Shops | Local technicians may have access to quality alternatives or be able to order what you need directly. |

| Manufacturer Websites | Checking the official site of the manufacturer can yield authentic replacements and useful documentation. |

| Second-Hand Marketplaces | Online platforms for used items can offer cost-effective options, although condition and reliability should be verified. |

By considering these sources, you can enhance your chances of finding the right components to keep your equipment running smoothly.

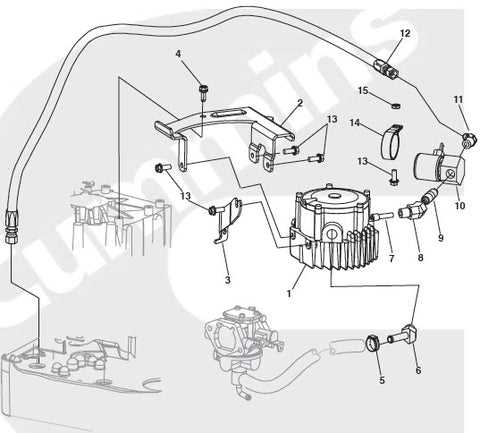

Wiring Schematic Overview

This section provides a comprehensive look at the electrical layout of the generator system. Understanding the wiring connections is crucial for maintenance and troubleshooting, ensuring optimal performance and safety.

The wiring schematic serves as a visual representation of the various components and their interconnections. It highlights key elements such as power supply routes, control circuits, and grounding systems. Familiarity with this schematic can assist technicians and users in diagnosing issues and implementing effective repairs.

- Power Connections:

- Main power lines

- Generator output connections

- Voltage regulation points

- Control Circuits:

- Start and stop mechanisms

- Safety interlocks

- Monitoring indicators

- Grounding System:

- Grounding points

- Return paths for electrical currents

- Protection against overloads

To effectively utilize the wiring schematic, it’s important to follow the layout closely and reference each component’s specifications. This careful approach ensures reliable operation and enhances the longevity of the equipment.

- Identify key components based on the schematic.

- Trace power routes to understand energy flow.

- Check connections for integrity and safety.

- Perform regular maintenance based on findings from the schematic.

By adhering to these guidelines, users can maintain a well-functioning electrical system, preventing potential issues and ensuring safety during operation.

Tools Needed for Onan Repairs

Effective maintenance and troubleshooting of your generator require a specific set of instruments and equipment. Having the right tools on hand not only streamlines the repair process but also ensures that tasks are performed safely and efficiently. Familiarizing yourself with the necessary implements can significantly enhance your ability to address various mechanical issues that may arise.

First and foremost, a comprehensive tool kit is essential. This should include screwdrivers of various sizes, wrenches, and pliers to tackle different types of fasteners. Additionally, a socket set will be invaluable for loosening and tightening bolts in confined spaces. Multimeters and voltage testers are crucial for diagnosing electrical problems, allowing you to check for continuity and measure voltage levels accurately.

Furthermore, having a good supply of replacement components such as filters, gaskets, and hoses is vital for quick fixes. For more extensive repairs, you may need specialty tools like torque wrenches or compression testers, which ensure that all components are tightened to the manufacturer’s specifications. Lastly, safety gear such as gloves and goggles should always be worn to protect yourself while performing any repair work.

Identifying Faulty Components Easily

Recognizing defective elements within a system can significantly enhance performance and longevity. Implementing a systematic approach to troubleshooting allows for efficient identification of problematic parts. By understanding common signs of failure and utilizing available resources, users can maintain optimal functionality and avoid unnecessary downtime.

To assist in the diagnosis process, here is a table outlining typical symptoms, potential causes, and suggested remedies for various components:

| Symptom | Potential Cause | Suggested Remedy |

|---|---|---|

| Unusual noises | Worn bearings or loose fittings | Inspect and replace bearings; tighten fittings |

| Poor performance | Clogged filters or fuel supply issues | Replace filters; check fuel lines |

| Frequent shutdowns | Overheating or electrical faults | Examine cooling system; check wiring and connections |

| Inconsistent operation | Faulty sensors or control modules | Test and replace defective sensors; reprogram control modules |

| Excessive vibration | Unbalanced components or mounting issues | Rebalance components; secure mounting points |

By utilizing this guide, users can streamline the process of identifying and rectifying issues, ultimately leading to improved reliability and efficiency of the machinery.

Comparing Onan 5500 with Other Models

This section aims to explore the differences and similarities between a particular generator model and its competitors. Understanding these aspects can help consumers make informed decisions based on their specific needs and requirements. By analyzing performance, features, and reliability, we can gain a clearer picture of how this model stands in the crowded market of power generation equipment.

Performance Analysis

When evaluating power units, performance is a critical factor. The model in question offers distinct advantages and some limitations when compared to other options:

- Power Output: It provides a robust output suitable for various applications, but some competitors may offer higher wattage for larger power needs.

- Fuel Efficiency: This unit is known for its economical fuel consumption, although certain alternatives might offer even greater efficiency.

- Noise Levels: This generator operates relatively quietly, making it a good choice for residential areas; however, some newer models are designed to be even quieter.

Features and Usability

Features play a significant role in user experience. Here’s how this unit compares with others:

- Control Panel: The interface is user-friendly, yet some brands provide more advanced digital displays and connectivity options.

- Portability: This generator is compact, but a few competitors come equipped with better wheels and handles for easier transport.

- Maintenance: Regular upkeep is straightforward; however, some models have features that simplify maintenance even further.

In conclusion, while this particular generator has its strengths, it’s essential to consider other models’ offerings to ensure the best fit for individual needs. By weighing the performance and features against other options, consumers can make choices that maximize value and satisfaction.

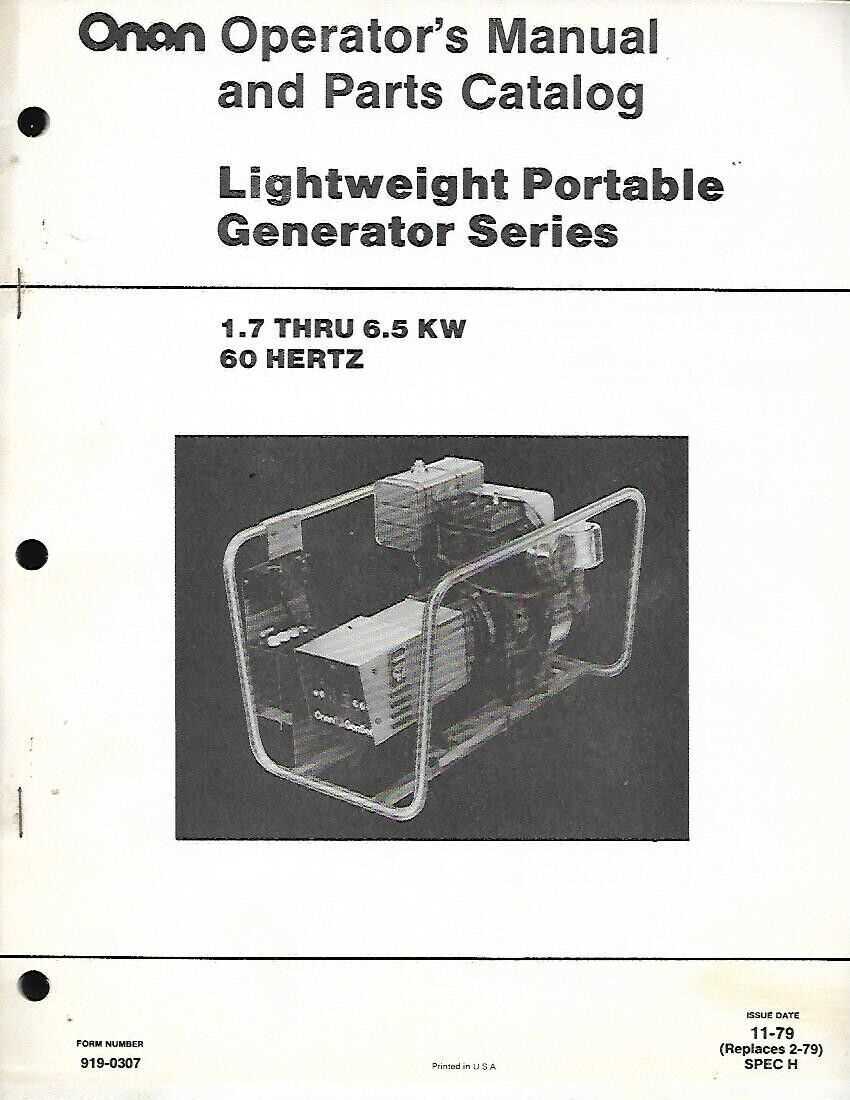

Resources for Onan Generator Owners

For individuals who rely on portable power units, having access to reliable information and tools is essential for effective maintenance and repair. A variety of resources can assist owners in maximizing the efficiency and longevity of their generators, ensuring they perform optimally when needed most.

- Official Manuals: User guides and maintenance manuals provide comprehensive details about operation, troubleshooting, and maintenance schedules.

- Online Forums: Community-driven platforms allow owners to share experiences, ask questions, and find solutions from fellow users.

- Video Tutorials: Many creators offer step-by-step instructions for repairs and maintenance on popular video-sharing platforms, making it easy to follow along.

- Parts Suppliers: Reputable suppliers provide access to replacement components and accessories specifically designed for various models, ensuring compatibility and quality.

In addition to these resources, joining local clubs or groups focused on power equipment can enhance your knowledge and offer support from experienced users. Regular engagement with these communities will keep you informed about the latest updates, tips, and best practices for maintaining your unit.

- Stay proactive with regular inspections and servicing.

- Utilize available resources to troubleshoot issues effectively.

- Network with other users to exchange knowledge and experiences.

With the right resources at hand, owners can ensure their generators remain reliable and efficient, providing peace of mind during power outages or outdoor adventures.