Understanding the Beretta 92S Parts Diagram for Maintenance and Repairs

In the world of firearms, grasping the intricate makeup of a classic handgun is essential for enthusiasts and professionals alike. This exploration unveils the various elements that contribute to its functionality and reliability, allowing for a deeper appreciation of the craftsmanship involved.

Every piece plays a critical role in ensuring optimal performance, from the trigger mechanism to the safety features. As we delve into the specifics, we will uncover how each component interconnects, forming a harmonious unit that stands the test of time.

Understanding these intricacies not only enhances knowledge but also aids in maintenance and customization. Whether for personal use or professional applications, familiarity with the internal structure paves the way for informed decision-making and responsible ownership.

Understanding Beretta 92S Components

In order to appreciate the functionality and design of this particular firearm, it is essential to explore its individual elements. Each component plays a vital role in ensuring reliable performance, contributing to the overall operation and efficiency of the weapon. Understanding how these pieces work together allows for a deeper insight into the mechanics and engineering involved.

Key Components

Among the various elements, the frame serves as the foundation, providing stability and housing critical mechanisms. The slide, which moves during firing, houses the firing pin and facilitates ejection of spent cartridges. Additionally, the barrel is integral to accuracy, guiding the projectile toward its target. Each of these parts interacts seamlessly, illustrating the ultimate goal of precision and reliability.

Maintenance and Care

Regular maintenance of these components is crucial for optimal performance. Cleaning and lubrication can prevent wear and tear, ensuring longevity and dependability. Understanding each element’s function helps enthusiasts and users make informed decisions regarding upkeep and modifications.

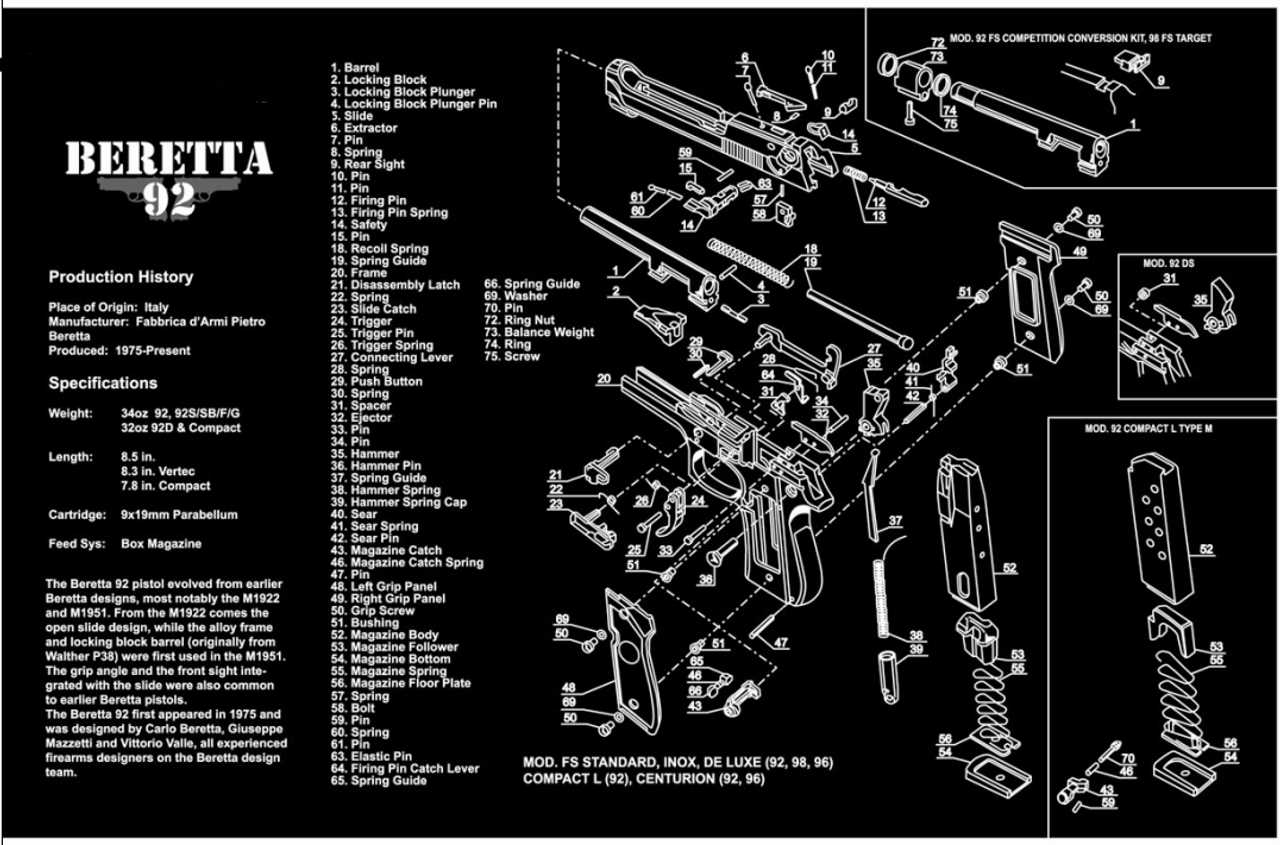

History of the Beretta 92 Series

This series of firearms has a rich legacy that spans several decades, known for its reliability and innovative design. Developed in the late 20th century, it quickly gained popularity among military and law enforcement agencies worldwide.

The evolution of this model can be outlined as follows:

- Initial development in the 1970s aimed at enhancing usability and performance.

- Adoption by various military forces, leading to modifications for operational requirements.

- Integration of advanced materials and manufacturing techniques in subsequent versions.

Key milestones in its history include:

- Introduction of the double-action system for improved safety.

- Wide acceptance in various competitive shooting events.

- Continuous upgrades to accommodate modern tactical needs.

This firearm series represents a significant achievement in design and engineering, establishing itself as an iconic choice in the realm of handguns.

Importance of Parts Diagrams

Understanding the layout and components of mechanical systems is crucial for effective maintenance and repair. Visual representations serve as invaluable tools for both professionals and enthusiasts, enabling clearer insights into the assembly and functionality of various elements.

Key benefits include:

- Enhanced comprehension of intricate designs.

- Streamlined troubleshooting processes.

- Improved efficiency in sourcing replacements.

These illustrations empower users to delve deeper into their equipment, ultimately fostering greater confidence in handling repairs and modifications.

Key Features of the Beretta 92S

This section highlights the distinctive attributes of a renowned semi-automatic pistol, focusing on its design, functionality, and overall performance. Understanding these features is essential for enthusiasts and users alike, as they contribute to the weapon’s reputation and usability in various situations.

| Feature | Description |

|---|---|

| Ergonomic Design | The grip and frame are crafted to ensure comfort and control during use, allowing for a more natural handling experience. |

| Double/Single Action | This mechanism provides versatility, enabling the user to choose between double-action for the first shot and single-action for subsequent shots. |

| Durable Construction | Made from high-quality materials, the firearm is designed to withstand rigorous use while maintaining reliability and accuracy. |

| High Magazine Capacity | The magazine allows for a substantial number of rounds, reducing the frequency of reloads during critical situations. |

| Accessory Rail | Equipped with a rail system, it allows for the attachment of various accessories, enhancing customization and functionality. |

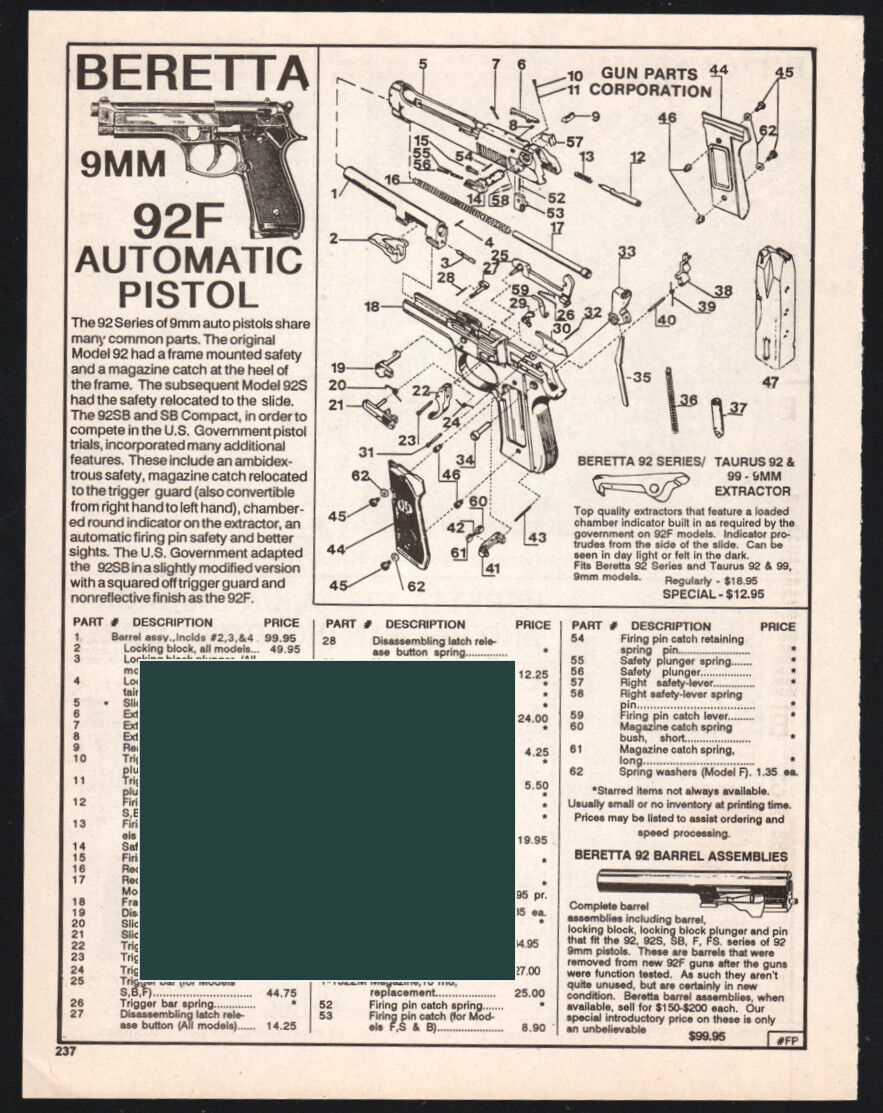

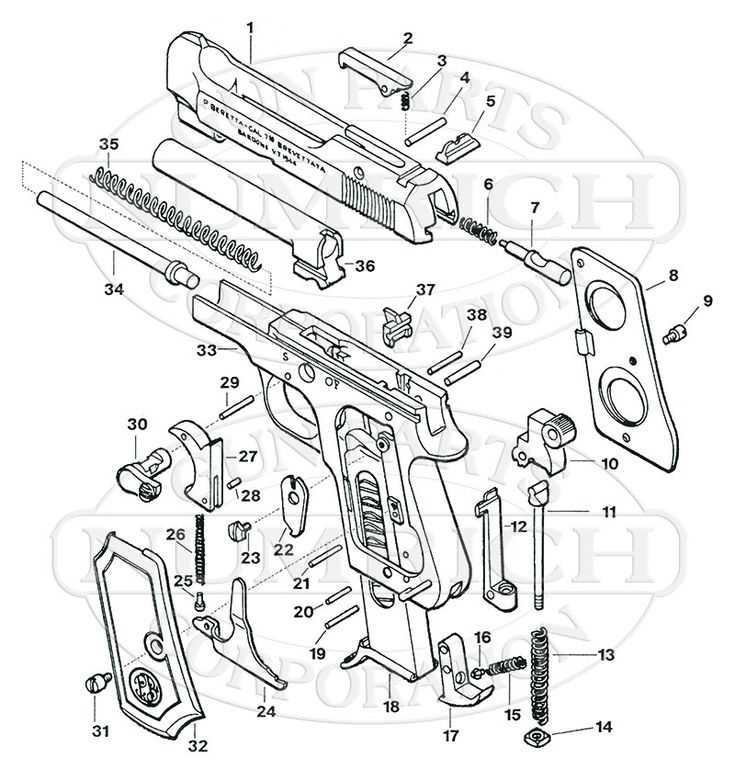

Common Parts in the 92S Model

This section explores the essential components that define the functionality and reliability of this firearm. Understanding these elements is crucial for enthusiasts and those involved in maintenance or upgrades.

Key Components

The major elements include the trigger mechanism, the slide assembly, and the recoil spring. Each of these components plays a vital role in ensuring optimal performance and user safety. The trigger mechanism is responsible for initiating the firing sequence, while the slide assembly houses the firing pin and facilitates the ejection of spent cartridges.

Replacement Considerations

When considering replacements or upgrades, it’s important to focus on quality and compatibility. Aftermarket options can enhance performance, but users should ensure they match the specifications of the original parts. Proper installation and regular maintenance will prolong the lifespan of these crucial components, ensuring consistent operation.

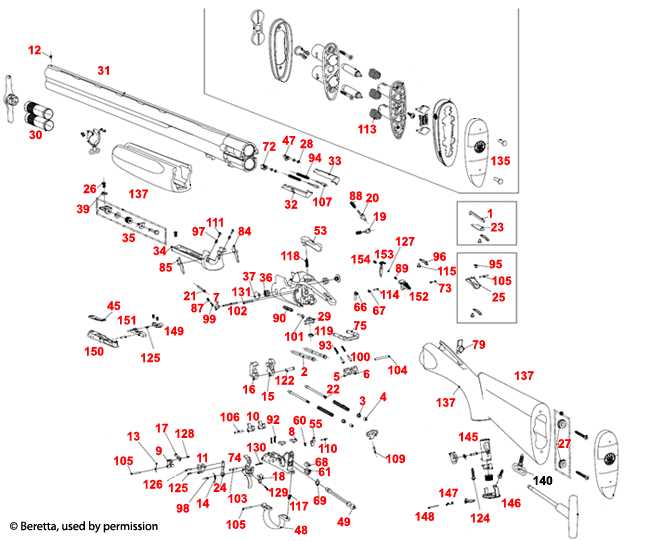

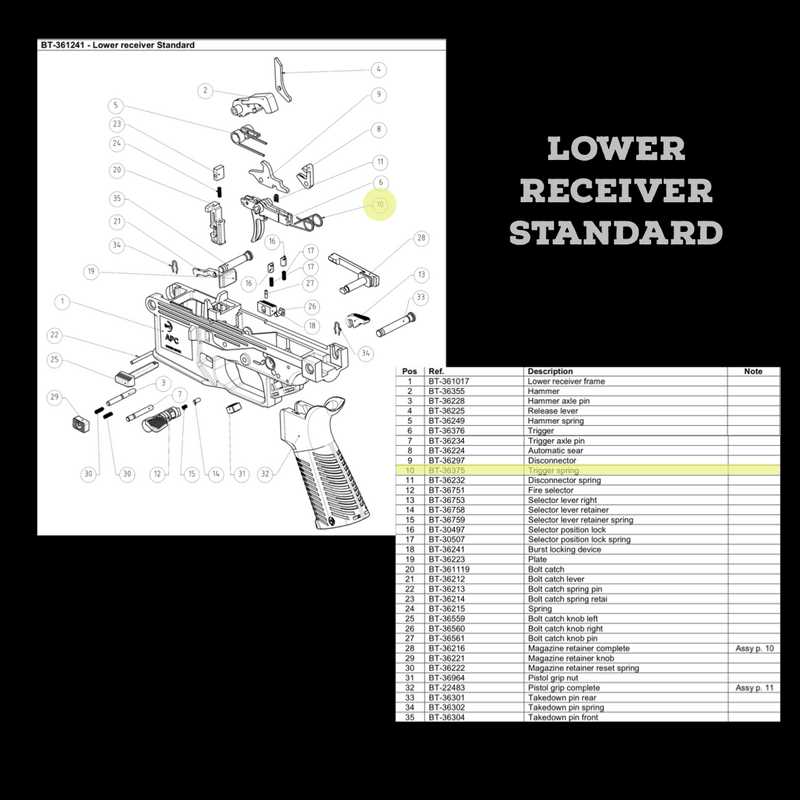

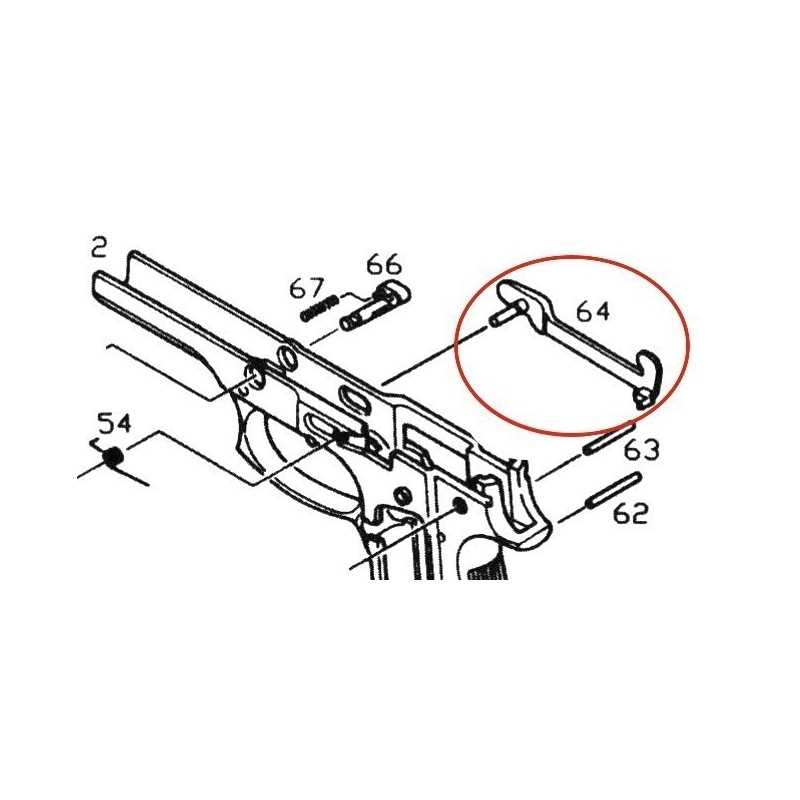

Exploring the Internal Mechanisms

The intricate design of a firearm reveals a sophisticated interplay of components that work in harmony to ensure reliable performance. Understanding these internal mechanisms provides insights into the functionality and engineering prowess behind modern weaponry.

At the heart of this system lies the firing mechanism, a crucial element responsible for igniting the cartridge. This assembly typically includes a hammer or striker, which, upon being released, strikes the primer to initiate the firing sequence. The precision with which these parts interact is vital for achieving accurate shots.

The slide serves as another essential component, facilitating the ejection of spent casings and chambering of fresh rounds. Its smooth movement is achieved through a series of rails and grooves, engineered to minimize friction and enhance reliability during operation.

Additionally, the recoil spring plays a critical role in returning the slide to its original position after a shot is fired. This mechanism not only ensures the seamless cycling of ammunition but also contributes to the overall balance and handling of the firearm.

Furthermore, the trigger assembly is integral to user interaction with the weapon. Variations in design can significantly influence the feel and responsiveness of the trigger pull, impacting both accuracy and control during use.

Overall, delving into these internal systems not only enriches the appreciation of firearm engineering but also highlights the meticulous craftsmanship that goes into creating a dependable and effective tool.

Replacement Parts and Upgrades

When it comes to enhancing the performance and longevity of your firearm, selecting the right components is essential. This section delves into the various options available for replacement and enhancement, ensuring your equipment operates at its best.

Essential Components for Replacement

- Barrels: Upgrading to a match-grade barrel can significantly improve accuracy.

- Triggers: A lighter trigger pull enhances shooting comfort and precision.

- Sights: Opt for night sights or adjustable options for better target acquisition.

- Recoil Springs: Replacing springs can improve cycling and reduce felt recoil.

Popular Upgrades for Enhanced Performance

- Grip Enhancements: Custom grips can improve handling and comfort.

- Extended Magazines: Increasing magazine capacity can enhance shooting experience.

- Accessory Rails: Adding rails allows for mounting lights or lasers for tactical use.

- Finishing Touches: A cerakote finish can provide added durability and aesthetic appeal.

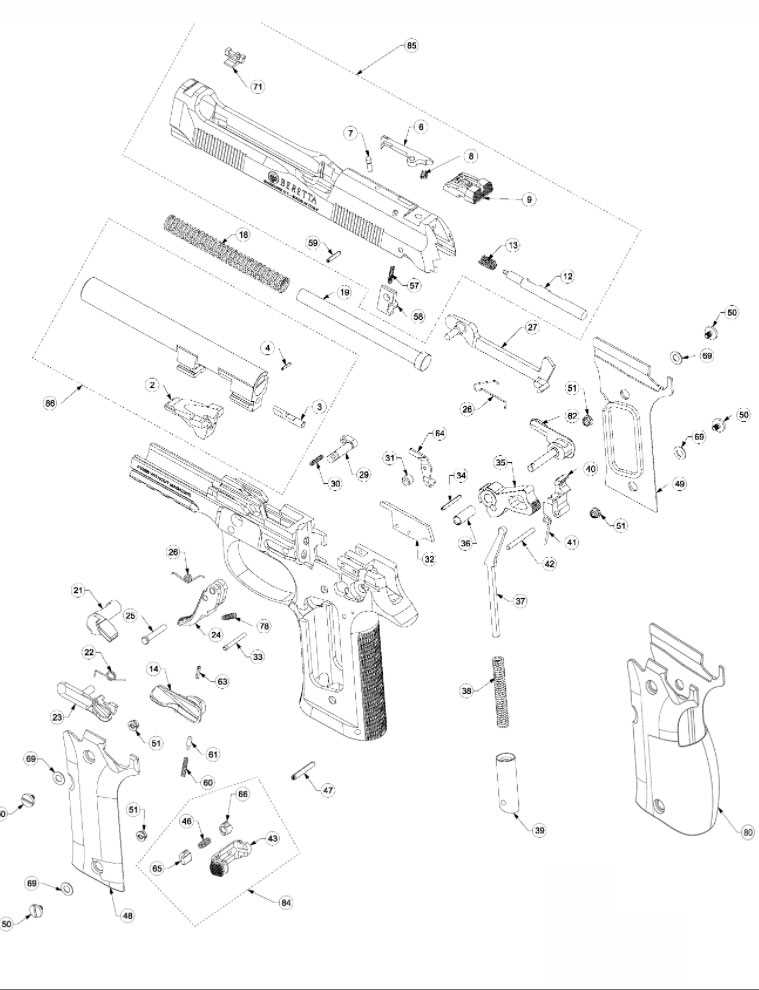

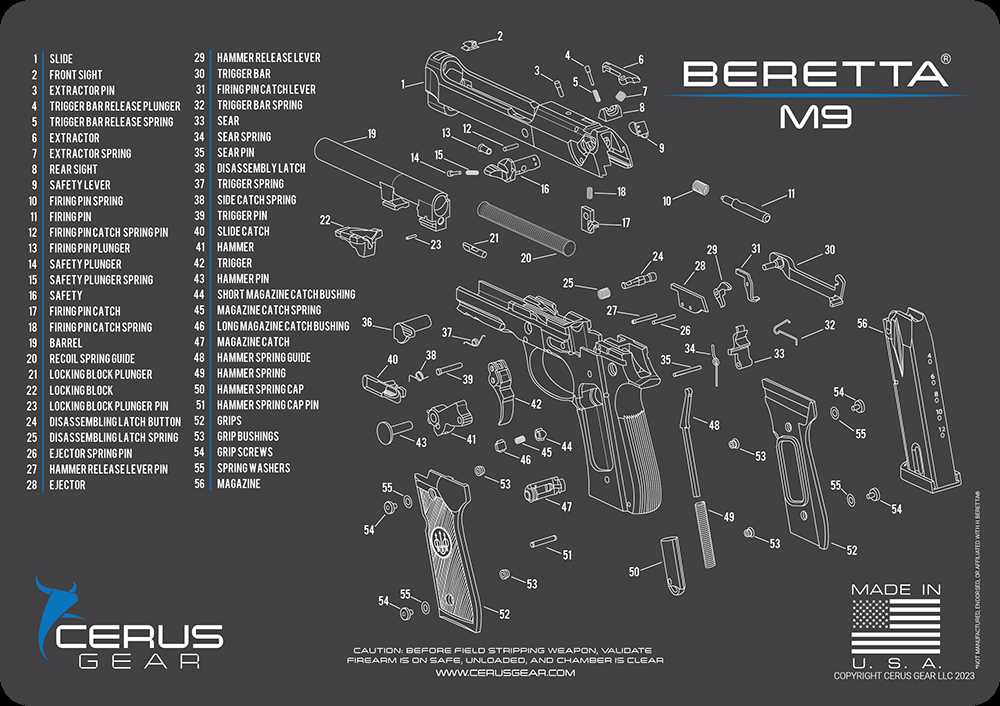

How to Read a Parts Diagram

Understanding the components of a mechanical system is essential for effective maintenance and repair. A visual representation of these elements provides a comprehensive overview, allowing one to identify each section and its function. Mastering the interpretation of these visuals can greatly enhance one’s technical skills.

Identifying Key Elements

When examining a visual representation, start by familiarizing yourself with the labeling. Each part is usually marked with a reference number or letter. Pay attention to the legend, as it often correlates with a list that provides detailed descriptions of each element. This aids in recognizing the specific function and importance of individual pieces within the assembly.

Understanding Connections and Relationships

Look closely at how the components interact with one another. Lines or arrows may indicate connections, illustrating how various elements work together to achieve the desired operation. This relationship is crucial for diagnosing issues and determining which parts may need replacement or adjustment. By comprehensively analyzing these interactions, you can develop a deeper understanding of the entire system’s functionality.

Maintenance Tips for Your Beretta

Proper care is essential for ensuring the longevity and reliability of your firearm. Regular maintenance not only enhances performance but also promotes safety during use. This section offers practical guidance to help you keep your weapon in optimal condition.

Cleaning and Lubrication

Routine cleaning is crucial. After each use, disassemble the firearm according to the manufacturer’s instructions. Use a cleaning rod, patches, and appropriate solvent to remove residue from the barrel and chamber. Pay attention to the action and frame, wiping away any dirt or grime. Once clean, apply a light coat of lubricant to moving parts to ensure smooth operation. Avoid over-lubrication, as excess oil can attract dirt and debris.

Regular Inspections

Conduct regular inspections to identify wear and tear. Check for any cracks, rust, or signs of damage on the exterior and internal components. Ensure that all screws and pins are secure. If you notice any abnormalities, consult a qualified gunsmith for further assessment. Keeping your firearm in top shape not only enhances its performance but also ensures your safety during operation.

Identifying Parts in the Diagram

Understanding the components within a visual representation is essential for effective maintenance and repair. Each element plays a vital role, contributing to the overall functionality and performance. By familiarizing oneself with these elements, users can enhance their proficiency and ensure optimal operation.

To aid in recognizing various components, consider the following categories:

- Structural Elements: These are the foundational pieces that provide stability and form.

- Mechanical Components: These parts are responsible for the movement and interaction between different sections.

- Functional Accessories: Items that enhance the usability and features of the entire system.

When analyzing a visual guide, it’s helpful to follow a systematic approach:

- Start by identifying the major sections to get an overview.

- Focus on each individual piece, noting its shape and function.

- Compare similar elements to understand their unique characteristics.

- Utilize a reference to clarify any unfamiliar terms or functions.

By applying these strategies, one can become adept at recognizing and understanding the intricacies of the components represented, leading to more informed decision-making in handling and maintenance tasks.

Tools Needed for Disassembly

When preparing for the disassembly of a firearm, having the right tools at your disposal is essential for ensuring safety and efficiency. A well-organized toolkit not only facilitates a smooth process but also minimizes the risk of damaging any components during the procedure.

Essential Tools

Begin with a basic set of hand tools. A set of screwdrivers, particularly those with varying sizes and heads, is crucial for removing screws without stripping them. Additionally, a wrench or pliers may be necessary for loosening any tightly secured parts.

Specialized Equipment

For those who wish to ensure the utmost precision, consider investing in punch sets to safely drive out pins without marring the finish. A cleaning brush and a lubrication kit can also be beneficial for maintenance after disassembly. Keeping these tools organized will make the entire process more manageable and enjoyable.

Aftermarket vs. OEM Parts

The choice between replacement components from the original manufacturer and those produced by third-party companies is a common consideration for enthusiasts and users alike. Each option presents unique advantages and potential drawbacks, influencing both performance and cost. Understanding these distinctions can help users make informed decisions that align with their needs and preferences.

Original components are designed specifically for a particular model, ensuring compatibility and adherence to manufacturer standards. Here are some key points to consider:

- Quality Assurance: Typically subjected to rigorous testing, these items are made to meet specific safety and performance criteria.

- Warranty Coverage: Often, using these components helps maintain warranty coverage on the product.

- Consistent Performance: Designed to work seamlessly with the original system, ensuring reliability.

In contrast, third-party alternatives can offer various benefits that might appeal to a different set of users:

- Cost Efficiency: Often more affordable, these options can save money without sacrificing too much on quality.

- Diverse Options: A wider range of choices may provide enhancements or modifications that are not available from the original source.

- Community Support: Many aftermarket products are backed by user reviews and community feedback, which can guide decisions.

Ultimately, the decision between these two categories hinges on individual priorities, whether they lean towards reliability and warranty protections or cost savings and customization potential. Each option has its place, and understanding the implications of each can lead to a more satisfying ownership experience.

Safety Considerations During Maintenance

When performing maintenance on firearms, it is essential to prioritize safety to prevent accidents and ensure a secure working environment. Proper precautions not only protect the individual conducting the work but also safeguard others in the vicinity. Awareness and adherence to safety protocols are fundamental during every stage of the maintenance process.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial. This may include safety glasses to shield the eyes from debris and gloves to protect the hands from sharp components or harmful substances. It is advisable to wear clothing that minimizes exposure to potential hazards, ensuring that no loose fabric can become entangled during the maintenance procedure.

Work Environment

The workspace should be organized and free of distractions. Adequate lighting is vital for clear visibility, allowing for careful inspection of components. Additionally, it is important to work in a secure area where unauthorized individuals cannot access the tools or items being handled. Always verify that the firearm is unloaded before beginning any maintenance tasks, and follow established safety protocols to minimize risk.