Understanding the Neato D7 Parts Diagram

Exploring the intricate elements of robotic cleaners can enhance your experience and ensure optimal performance. Each unit is equipped with various sections, each playing a crucial role in the functionality of the device. Familiarizing yourself with these components can lead to better maintenance and troubleshooting.

In this guide, we will delve into the essential elements that make up your robotic cleaner. By grasping the layout and purpose of each part, you can gain valuable insights into how they interact and contribute to the overall efficiency. This knowledge can empower you to make informed decisions when it comes to care and upkeep.

Recognizing the individual sections not only aids in identifying issues but also assists in the replacement of worn or malfunctioning pieces. Understanding these aspects ultimately leads to a longer lifespan for your device, ensuring it remains a reliable companion in maintaining your home.

Neato D7 Parts Overview

The D7 vacuum is designed with a range of components that work together to ensure efficient cleaning. These elements are strategically placed to cover the entire space, from navigation systems to collection containers, providing an integrated experience for users. Each section is built to enhance functionality and maximize coverage, making maintenance and repair straightforward when needed.

- Core Structure: The outer shell and frame provide durability and protect internal mechanisms, while also housing key features like the power source and dust collection unit.

- Movement System: Equipped with reliable wheels and drive motors, the device is capable of moving smoothly across various floor types, adapting to changes in terrain.

- Navigation Mechanism: Advanced sensors and mapping technologies allow for precise movement, avoiding obstacles and covering the most efficient path during operation.

- Cleaning Units: Brushes and suction modules are optimized for capturing dirt and debris, with easy access for cleaning or replacing parts as needed.

These components are engineered to work in harmony, ensuring effective cleaning and ease of use over time.

Main Components of Neato D7

The latest robotic cleaning device comprises several essential elements that enhance its functionality and efficiency. Understanding these critical components can help users maximize the device’s performance and maintenance.

- Chassis: The primary frame that houses all internal components, providing structural integrity.

- Motor: Powers the movement and suction capabilities, crucial for effective cleaning.

- Sensors: Allow the unit to navigate and avoid obstacles, ensuring thorough coverage.

- Battery: Supplies energy for operation, impacting the device’s runtime and charging time.

- Brushes: Essential for agitating dirt and debris from various surfaces, enhancing cleaning efficiency.

- Dustbin: Collects debris, making it easy to empty and maintain.

Each of these components plays a vital role in ensuring optimal performance and user satisfaction.

Understanding the Dustbin Assembly

The dustbin assembly is a crucial component of robotic cleaning devices, responsible for collecting debris and maintaining optimal performance. Understanding its structure and function can enhance the cleaning efficiency and longevity of the machine. This section provides insights into the various elements of the dustbin and how they work together to ensure effective operation.

Components of the Dustbin Assembly

The dustbin consists of several key elements that contribute to its functionality. Each part plays a specific role, making it essential for users to be familiar with these components.

| Component | Description |

|---|---|

| Container | The main body that holds collected dirt and debris. |

| Filter | A crucial part that captures fine particles and allergens. |

| Latch | Mechanism that secures the dustbin in place. |

| Handle | Facilitates easy removal and emptying of the dustbin. |

Maintenance Tips for the Dustbin Assembly

Proper maintenance of the dustbin assembly is vital for ensuring optimal performance. Regular cleaning of the container and filter can prevent clogs and maintain suction power. Additionally, checking the latch and handle for wear can help avoid any issues during operation.

Battery Specifications and Details

This section provides an overview of the energy source used in robotic devices, focusing on its performance characteristics and essential features. Understanding these specifications is crucial for ensuring optimal functionality and longevity of the unit.

The battery typically features a specific voltage and capacity, which directly impact the operational time and efficiency of the equipment. Users should pay attention to the recharge cycle and expected lifespan, as these factors determine how frequently the power source needs to be replaced. Additionally, various safety mechanisms are integrated to prevent overheating and short circuits, enhancing user safety and device reliability.

It’s important to consider the compatibility of the power unit with different models, as well as any maintenance requirements. Regular inspections can help identify signs of wear or decline in performance, ensuring that the device operates at its best for an extended period.

Brush System and Maintenance Tips

The brush mechanism plays a crucial role in enhancing the efficiency of cleaning appliances. Proper upkeep of this component not only extends its lifespan but also ensures optimal performance. Regular attention to the brushes helps maintain effective dirt and debris removal, contributing to a cleaner environment.

Importance of Regular Cleaning

Maintaining the cleanliness of the brush system is essential for peak performance. Dust and hair can accumulate, hindering the brushes’ ability to rotate freely and pick up debris. Routine inspections and cleaning can significantly improve functionality.

Maintenance Guidelines

Here are some best practices for keeping the brush system in excellent condition:

| Action | Frequency | Description |

|---|---|---|

| Inspect Brushes | Weekly | Check for wear and tear, ensuring they are not damaged or excessively worn. |

| Clean Debris | Weekly | Remove hair, dirt, and other particles that may obstruct movement. |

| Replace Brushes | Every 6-12 months | Substitute worn brushes with new ones to maintain cleaning efficiency. |

Navigation Sensors Explained

Understanding how robotic devices navigate their surroundings is essential for grasping their functionality. These advanced mechanisms utilize various sensing technologies to perceive obstacles, determine their position, and create a map of the environment. This section delves into the principles behind these essential components, shedding light on their significance in ensuring efficient movement.

Types of Navigation Sensors

Different sensing technologies serve unique roles in navigation. Below are some common types:

- Infrared Sensors: Utilize infrared light to detect obstacles and measure distances.

- Ultrasonic Sensors: Emit sound waves to determine the distance to nearby objects.

- Lidar: Employs laser beams to create a detailed map of the environment.

- Gyroscopes: Measure the rotation and orientation of the device for precise movement control.

Functionality and Importance

Each sensor type plays a crucial role in facilitating navigation. Their functionalities include:

- Obstacle Detection: Sensors identify and help avoid obstacles, ensuring smooth travel.

- Path Planning: Information gathered by sensors allows the device to chart the most efficient route.

- Position Tracking: Continuous monitoring of surroundings aids in maintaining an accurate position within a space.

In conclusion, navigation sensors are vital for the effective operation of robotic systems, enabling them to navigate complex environments safely and efficiently.

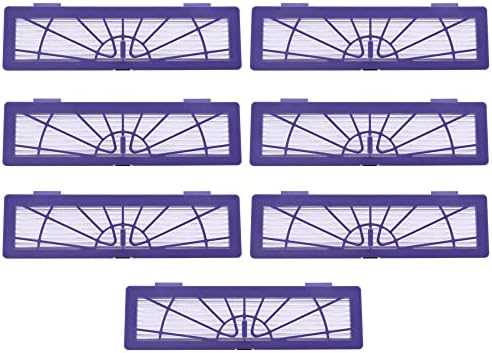

Filters: Types and Replacement

Filters play a crucial role in maintaining the efficiency of cleaning devices. They capture dust, allergens, and debris, ensuring that the air released is clean and free of contaminants. Understanding the various types of filters available and knowing when to replace them is essential for optimal performance.

Types of Filters

- HEPA Filters: These high-efficiency filters trap tiny particles, making them ideal for allergy sufferers.

- Foam Filters: Often washable, foam filters help capture larger debris and can be reused multiple times.

- Carbon Filters: Designed to absorb odors, these filters enhance the overall air quality in the environment.

Replacement Guidelines

Regular replacement of filters is vital to ensure the effectiveness of the device. Here are some general recommendations:

- Check the manufacturer’s guidelines for specific replacement intervals.

- Inspect filters monthly for signs of wear or clogging.

- Replace HEPA filters every 6 to 12 months, depending on usage.

- Wash foam filters as needed, typically every few weeks.

- Consider changing carbon filters every 3 to 6 months for optimal odor control.

By keeping filters clean and replacing them on schedule, users can maintain the efficiency of their cleaning equipment and ensure a healthier environment.

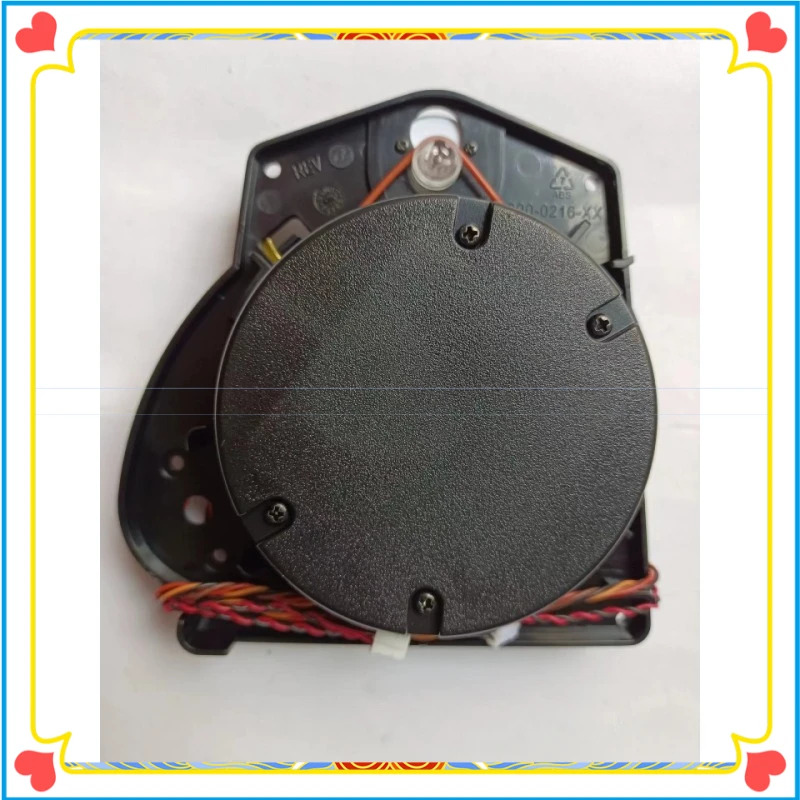

Motor Functions and Importance

The effectiveness of a robotic cleaner heavily relies on its driving components, which are essential for its operation. These elements facilitate movement, ensuring the device navigates various surfaces while maintaining optimal cleaning performance. Understanding the significance of these components provides insight into the overall efficiency and reliability of the appliance.

Key Roles of the Motor

The primary role of the driving unit is to power the wheels, enabling seamless mobility across different floor types. Additionally, this component assists in various cleaning patterns, enhancing coverage and reducing the chances of missed spots. A well-functioning motor contributes to the longevity of the device by minimizing wear and tear during operation.

Impact on Performance

Robust motor functionality directly influences the cleaning effectiveness of the device. A high-quality motor ensures consistent speed and stability, allowing the cleaner to tackle debris and dust effectively. Furthermore, the motor’s reliability is crucial for maintaining the unit’s overall performance, as any malfunction can lead to diminished cleaning capabilities.

Chassis and Structural Elements

The framework and supporting components of a robotic cleaner play a crucial role in its overall functionality and performance. These foundational elements are designed to provide stability, durability, and efficient movement across various surfaces. Understanding the arrangement and characteristics of these structures is essential for maintenance and upgrades.

Key Components and Their Functions

At the core of the device is a robust chassis that houses the motor and various electronic systems. This structural base is designed to absorb vibrations and reduce noise during operation. Additionally, elements like the wheels and axles are integral for mobility, allowing the unit to navigate seamlessly through different environments.

Maintenance Tips for Longevity

Regular inspection and cleaning of the chassis and structural components are vital for optimal performance. Ensuring that the wheels are free of debris and the chassis is free from dust can significantly enhance the unit’s efficiency. Periodic checks for wear and tear can also prevent potential issues and extend the lifespan of the robotic cleaner.

Wheel Mechanism and Troubleshooting

The wheel system of robotic vacuums plays a crucial role in mobility and navigation. Understanding its components and functionality is essential for effective maintenance and resolution of common issues. This section explores the mechanism that drives the wheels and offers guidance on addressing typical problems that may arise.

Understanding the Wheel System

The wheel assembly consists of various elements, including motors, gears, and sensors, all working together to facilitate movement. These components allow the device to traverse different surfaces while avoiding obstacles. Regular inspection of the wheel mechanism ensures optimal performance and longevity.

Troubleshooting Common Issues

When encountering mobility problems, such as unresponsiveness or erratic movement, it is vital to check for potential obstructions in the wheel area. Additionally, ensuring that the motors are functioning correctly and that the sensors are clean can significantly enhance performance. Regular maintenance can prevent these issues and keep the device operating smoothly.

Electronic Components Overview

This section provides a broad understanding of the various electronic elements utilized within robotic devices. These components are integral to the functionality and efficiency of the system, contributing to both operational performance and durability.

Each element serves a specific purpose, often working in harmony with others to ensure seamless operation. Below is a summary of some essential electronic components commonly found in such systems.

| Component | Function |

|---|---|

| Microcontroller | Acts as the brain of the device, managing tasks and processing information. |

| Capacitor | Stores electrical energy and smoothens voltage fluctuations. |

| Resistor | Controls the flow of electric current within the circuit. |

| Sensor | Detects environmental changes and sends data to the microcontroller. |

| Motor | Converts electrical energy into mechanical motion to drive various functions. |

Software and Firmware Components

The functionality of modern robotic cleaners relies heavily on their software and firmware systems. These components play a crucial role in enabling efficient operation, ensuring seamless interaction between hardware and user commands.

Key elements of the software and firmware include:

- Control Algorithms: These are the logical processes that guide the device’s movements and navigation.

- Sensor Integration: This component manages data from various sensors, allowing the cleaner to detect obstacles and navigate effectively.

- User Interface: The software provides an intuitive interface for users to schedule cleaning sessions, adjust settings, and monitor performance.

- Firmware Updates: Regular updates enhance functionality and security, ensuring the device operates optimally over time.

Understanding these components is essential for troubleshooting and improving the performance of robotic cleaning devices.

Accessories for Enhanced Performance

Improving the efficiency and functionality of cleaning devices can be achieved through a variety of supplementary components. These enhancements not only optimize performance but also extend the lifespan of the equipment. Utilizing specific accessories can lead to a more thorough and effective cleaning experience.

Key additions that can significantly boost performance include:

- High-Efficiency Filters: These components trap smaller particles, ensuring cleaner air and reducing allergens in the environment.

- Replacement Brushes: Various brush types are available, designed for different surfaces and debris types, enhancing the cleaning capability.

- Extended Battery Packs: Additional or higher-capacity batteries allow for longer operation times, making cleaning sessions more efficient.

- Advanced Charging Docks: Improved docking stations can speed up the recharging process and provide better storage options.

- Virtual Barriers: Accessories that create invisible boundaries help keep cleaning devices focused on specific areas, preventing them from entering undesired spaces.

Investing in these enhancements can lead to superior results and a more satisfying user experience, allowing users to maximize the effectiveness of their cleaning routines.