Sno-way Plow Parts Diagram for Easy Maintenance

The efficiency of any snow removal machinery heavily relies on the intricate components that work together to ensure optimal performance. Familiarizing oneself with these essential elements can greatly enhance maintenance practices and improve overall functionality. A comprehensive overview of these crucial features not only aids in troubleshooting but also promotes better understanding of the equipment’s capabilities.

In this section, we will explore the specific arrangements and relationships between various components involved in winter maintenance operations. This knowledge is invaluable for operators and technicians alike, empowering them to make informed decisions regarding repairs and upgrades. By delving into the structural makeup of your snow management system, you can ensure it operates at peak efficiency throughout the winter season.

Moreover, having a clear grasp of the machinery’s assembly can significantly reduce downtime during critical snow events. Understanding how each segment contributes to the overall function allows users to quickly identify issues and implement effective solutions. This proactive approach not only saves time but also enhances the longevity of the equipment, ensuring it remains a reliable ally against harsh winter conditions.

Understanding Sno-way Plow Components

Gaining insight into the various elements of a snow removal system is essential for efficient operation and maintenance. Each component plays a vital role in ensuring the functionality and effectiveness of the entire setup. Familiarity with these elements can enhance performance and extend the lifespan of the equipment.

Key components to consider include:

- Frame: The structural backbone that supports the entire system.

- Hydraulic system: Responsible for controlling movement and positioning of the blade.

- Blade: The primary tool for clearing snow, available in various shapes and sizes.

- Mounting brackets: Essential for secure attachment to the vehicle.

- Electrical system: Powers controls and indicators for operation.

Each of these components works together to deliver efficient snow management. Understanding their functions and interactions can aid in troubleshooting and improving overall effectiveness.

- Regular inspections are crucial for identifying wear and tear.

- Proper maintenance practices can significantly enhance durability.

- Familiarity with specific components enables quick repairs when necessary.

By comprehensively understanding these crucial elements, operators can ensure reliable performance during winter conditions and maximize productivity.

Importance of Accurate Parts Diagrams

Precise schematics play a crucial role in ensuring the efficiency and longevity of machinery. They serve as essential references for identifying components and understanding how they fit together, ultimately facilitating maintenance and repairs. A well-crafted visual representation helps users avoid errors, reducing downtime and enhancing overall performance.

In addition, detailed illustrations can significantly improve communication among technicians and engineers. When everyone has access to the same accurate visuals, it fosters collaboration and minimizes misunderstandings. This clarity is particularly beneficial in complex systems where even minor discrepancies can lead to substantial issues.

| Benefit | Description |

|---|---|

| Efficiency | Streamlines maintenance processes and reduces time spent troubleshooting. |

| Collaboration | Enhances communication among team members and promotes teamwork. |

| Accuracy | Minimizes errors during repairs by providing clear identification of components. |

| Longevity | Supports proper maintenance, leading to extended lifespan of equipment. |

Overall, having accurate representations is vital for optimal operation, ensuring that users can effectively manage and service their machinery. This investment in clarity ultimately translates to better performance and reliability in the long run.

Common Issues with Plow Systems

Understanding the frequent challenges encountered with snow removal equipment is essential for maintaining efficiency and ensuring safety. This section outlines typical problems that users may face, along with possible solutions to keep operations running smoothly.

- Hydraulic Failures:

- Leaks in hoses or fittings can lead to a loss of pressure.

- Poor maintenance of hydraulic fluid levels may result in overheating.

- Electrical Malfunctions:

- Wiring issues can disrupt power to critical components.

- Corroded connections may cause intermittent failures.

- Wear and Tear:

- Frequent usage can lead to fatigue in moving parts.

- Accumulation of debris can hinder the functionality of essential components.

- Control System Problems:

- Faulty switches may prevent proper operation.

- Calibration issues can affect responsiveness.

Proactive maintenance and timely repairs can mitigate many of these issues, ensuring optimal performance during winter operations.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular attention and care. Implementing a consistent maintenance routine not only enhances performance but also minimizes the risk of unexpected failures. A proactive approach can lead to greater efficiency and reduced costs over time.

First, always inspect your machinery before and after use. Look for signs of wear or damage, and address any issues immediately. Regular cleaning is also essential; removing debris and dirt can prevent corrosion and other damage. Utilize appropriate cleaning agents to avoid harmful residues.

Lubrication is another critical aspect. Ensure that all moving components are well-lubricated to reduce friction and wear. Check the manufacturer’s guidelines for recommended oils and greases, as using the wrong type can lead to complications.

Storing your equipment properly is equally important. When not in use, keep it in a dry, sheltered location to protect it from the elements. If possible, elevate it off the ground to prevent rusting and degradation from moisture.

Lastly, keep an eye on fluid levels, including hydraulic fluids and antifreeze. Regularly replacing these fluids according to the schedule provided by the manufacturer will help maintain optimal functionality and prevent damage.

How to Identify Plow Parts

Recognizing various components of snow removal equipment is crucial for effective maintenance and repair. Understanding the function and characteristics of each element can enhance performance and extend the lifespan of the machinery.

Here are some key strategies for identifying these components:

- Consult the Manual: Start with the manufacturer’s manual. It usually contains detailed descriptions and diagrams of each element.

- Look for Labels: Many components have labels or tags that provide information about the model and specifications.

- Examine Shape and Size: Different elements often have unique shapes and dimensions. Compare them with reference images.

- Check the Material: Understanding the materials used can help identify the purpose and durability of each component.

By following these steps, you can gain a clearer understanding of the equipment’s structure and ensure proper functioning.

Tools Required for Repairs

Proper maintenance and repairs of machinery necessitate a variety of tools to ensure efficient and effective work. Having the right equipment on hand not only streamlines the repair process but also enhances safety and precision. Below, we outline the essential tools that are commonly needed for successful servicing.

Basic Hand Tools

To begin with, a set of basic hand tools is crucial. These typically include wrenches, screwdrivers, and pliers. Each of these tools serves a specific purpose, from tightening bolts to manipulating small components. A well-stocked toolbox will also include ratchet sets for quicker adjustments and hex keys for hexagonal fasteners.

Specialized Equipment

In addition to hand tools, specialized equipment may be required for more intricate tasks. Torque wrenches are vital for ensuring that fasteners are tightened to the manufacturer’s specifications. Diagnostic tools can help identify issues and monitor performance, while lubrication devices ensure all moving parts operate smoothly. Investing in high-quality tools can significantly reduce repair time and improve outcomes.

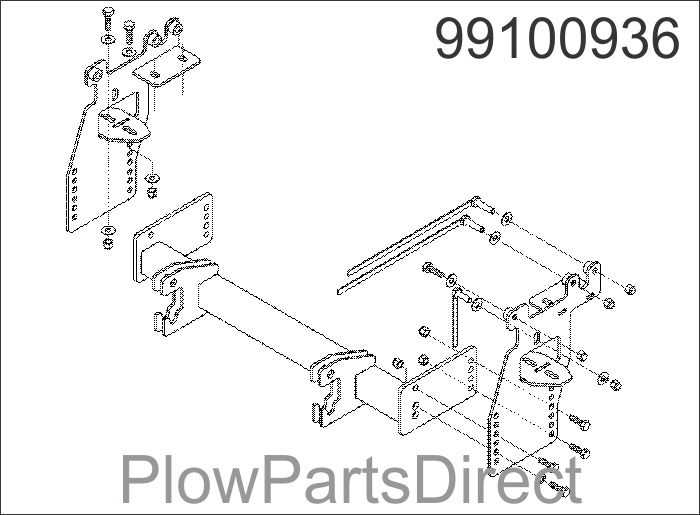

Step-by-Step Assembly Guide

This guide will walk you through the process of assembling essential components for your winter equipment. Following these steps will ensure a smooth and efficient setup, enabling optimal performance during harsh weather conditions.

Preparation Phase

Before you begin, gather all necessary tools and components. It is crucial to have everything on hand to streamline the assembly process. Ensure your workspace is clean and organized to avoid misplacing any items.

Assembly Steps

1. Align the Framework: Start by positioning the main framework on a flat surface. Ensure all mounting points are accessible for the next steps.

2. Secure the Components: Attach the individual elements according to the manufacturer’s specifications. Use the appropriate fasteners and ensure a snug fit to maintain stability.

3. Connect the Mechanisms: Link the operational components carefully, following the provided guidelines. Double-check connections to prevent operational failures during use.

4. Test the Assembly: Once assembled, conduct a preliminary test to verify that all parts function correctly. Look for any irregularities and make adjustments as necessary.

By adhering to this structured approach, you can ensure that your winter equipment is assembled effectively, ready to tackle any challenge that comes your way.

Upgrading Your Sno-way Plow

Enhancing your snow-clearing equipment can significantly improve its efficiency and performance during the harsh winter months. Whether you’re a professional or a dedicated enthusiast, considering various upgrades can lead to a more effective and enjoyable experience. This section explores potential modifications that can elevate your setup to new heights.

One effective approach is to evaluate the blade design and material. Upgrading to a more durable or specialized blade can help tackle different snow conditions more effectively. For instance, a reinforced edge can provide better cutting performance, while a wider blade may cover more ground in less time.

Additionally, examining the mounting system for improved stability and ease of use can make a noticeable difference. A quick-release feature allows for faster transitions between tasks, while enhanced brackets can ensure a secure fit during operation.

Another area for consideration is the incorporation of advanced control systems. Upgrading to a wireless or remote-controlled mechanism can streamline operations, allowing for greater maneuverability and convenience, especially in challenging environments.

Finally, investing in lighting solutions can extend your working hours and enhance safety during low-visibility conditions. LED lights can provide bright, energy-efficient illumination, making night operations safer and more efficient.

Where to Find Replacement Parts

Locating suitable components for your equipment can be crucial for maintaining its efficiency and longevity. Numerous avenues exist for sourcing the necessary items, ensuring that your machinery operates optimally throughout the season.

Online Retailers: Many websites specialize in aftermarket components, offering a wide selection for various models. These platforms often provide detailed specifications and customer reviews, helping you make informed decisions.

Manufacturer Websites: The official sites of manufacturers typically feature a dedicated section for ordering replacements. This option ensures compatibility and often comes with warranty assurances.

Local Distributors: Establishments in your area may carry a range of components, allowing you to inspect items before purchase. Building relationships with local suppliers can also lead to valuable advice and support.

Forums and Community Groups: Engaging with fellow users in online forums or local clubs can provide insights into where to find specific items. Members often share experiences and recommend trusted sources.

Salvage Yards: Visiting salvage yards can yield surprising finds at a fraction of the cost. While this route requires more effort and patience, it can be rewarding for those who enjoy a bit of treasure hunting.

By exploring these options, you can efficiently procure the necessary components to keep your equipment in peak condition, ensuring reliable performance whenever you need it.

Safety Precautions While Working

Ensuring a safe working environment is paramount when handling machinery and tools. Awareness of potential hazards and adherence to safety guidelines can significantly reduce the risk of accidents and injuries. Implementing proper safety measures not only protects the individual but also promotes a culture of responsibility within the team.

Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and helmets, to safeguard against flying debris and sharp edges. This gear serves as the first line of defense against injuries.

Before starting any task, inspect all equipment thoroughly. Check for any signs of wear or damage that could compromise safety during operation. Regular maintenance is essential to ensure everything functions correctly.

Maintain a clean and organized workspace to prevent accidents. Clutter can lead to trips and falls, so it’s crucial to keep tools and materials neatly arranged and within reach.

Be mindful of your surroundings and communicate effectively with colleagues. Ensure that everyone is aware of the task at hand and any potential hazards that may arise during operation.

Finally, never rush the process. Taking the time to work methodically reduces the likelihood of mistakes that can lead to dangerous situations. Prioritize safety over speed to ensure a productive and secure working experience.