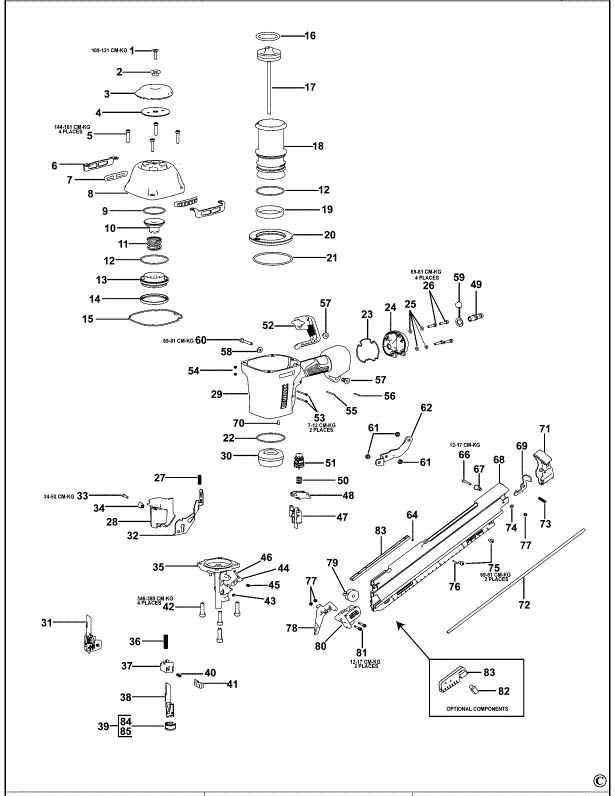

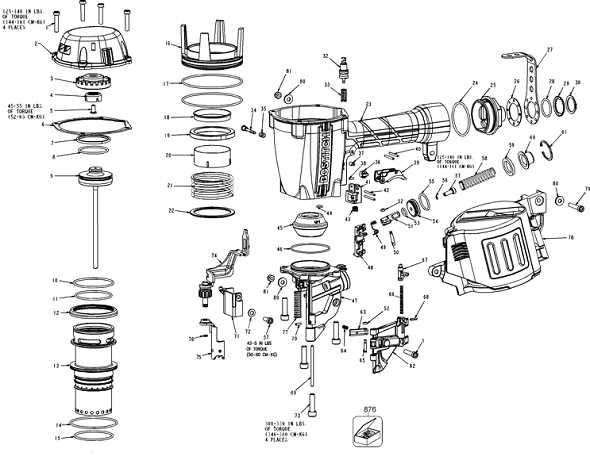

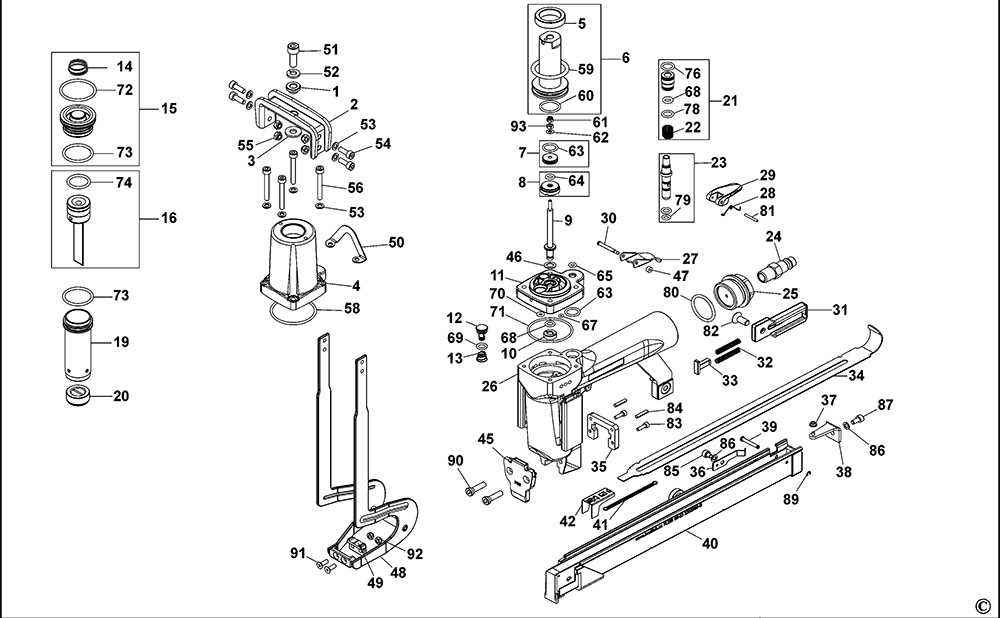

Bostitch F28WW Parts Diagram Overview

The inner workings of a pneumatic fastening tool can often seem complex and intricate. For those looking to grasp the functionality and maintenance of such devices, a detailed visual representation of their elements is invaluable. Recognizing how each component interacts with one another can lead to more effective usage and troubleshooting.

In the realm of fastening technology, knowledge about the specific roles of various elements not only enhances performance but also extends the lifespan of the equipment. Having a clear picture of the assembly aids users in identifying wear and tear, thus facilitating timely repairs or replacements.

This exploration will guide you through the essential features of these tools, offering insights into their organization and function. By familiarizing yourself with the layout of components, you empower yourself to optimize your tool’s efficiency and ensure it operates smoothly for years to come.

Bostitch F28WW Overview

This section provides a comprehensive look at a popular model in the pneumatic fastening category, designed to meet the demands of both professionals and DIY enthusiasts. Renowned for its durability and efficiency, this tool plays a crucial role in a variety of construction and woodworking tasks, ensuring precision and reliability.

With a lightweight design and ergonomic features, it allows for extended use without compromising comfort. The mechanism is engineered for consistent performance, making it suitable for various applications, from framing to siding. Understanding the key components and functionalities enhances the user experience and maintenance.

| Feature | Description |

|---|---|

| Weight | Lightweight design for ease of handling |

| Operating Pressure | Optimized for high performance with various pressure settings |

| Fastener Capacity | Accommodates a range of fasteners for versatility |

| Durability | Constructed with high-quality materials for longevity |

| Ergonomics | Designed for comfort to reduce fatigue during prolonged use |

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations of individual elements not only enhance comprehension but also streamline the troubleshooting process. By offering a clear view of how each part interacts, these illustrations serve as essential tools for both professionals and DIY enthusiasts.

Facilitating Maintenance

Detailed visuals enable users to quickly identify and locate specific components that may require attention. This efficiency is especially beneficial during routine inspections or unexpected breakdowns, allowing for faster resolutions and reduced downtime.

Enhancing Communication

Clear depictions foster better communication among team members and with suppliers. When discussing repairs or ordering replacements, having a visual reference minimizes misunderstandings and ensures everyone is on the same page.

| Component | Function |

|---|---|

| Trigger | Activates the tool |

| Magazine | Holds fasteners |

| Motor | Drives the mechanism |

| Casing | Protects internal parts |

Key Components of the F28WW

The efficient functioning of any pneumatic tool relies heavily on its essential elements. Understanding these components not only aids in proper maintenance but also enhances the user experience. Each part plays a significant role in the overall performance, contributing to durability and reliability.

Housing serves as the framework that protects internal mechanisms. A robust exterior is crucial for ensuring longevity under rigorous conditions.

Trigger Mechanism allows for precise control over the tool’s operation. This feature is vital for achieving optimal results, particularly in tasks requiring accuracy.

Drive Blade is responsible for propelling fasteners into the material. The design and material of this component can significantly impact driving efficiency and effectiveness.

Air Filter plays a crucial role in maintaining the cleanliness of the internal system. A clean air supply ensures that the tool operates smoothly and reduces the likelihood of malfunctions.

Depth Adjustment feature allows users to customize the penetration of fasteners, providing flexibility for various applications. This adaptability enhances the versatility of the tool.

Magazine is designed to hold fasteners securely and deliver them efficiently to the drive blade. An efficient magazine design minimizes downtime during projects, facilitating a smoother workflow.

By familiarizing oneself with these critical elements, users can optimize their experience and ensure the longevity of their tool, making each task more manageable and effective.

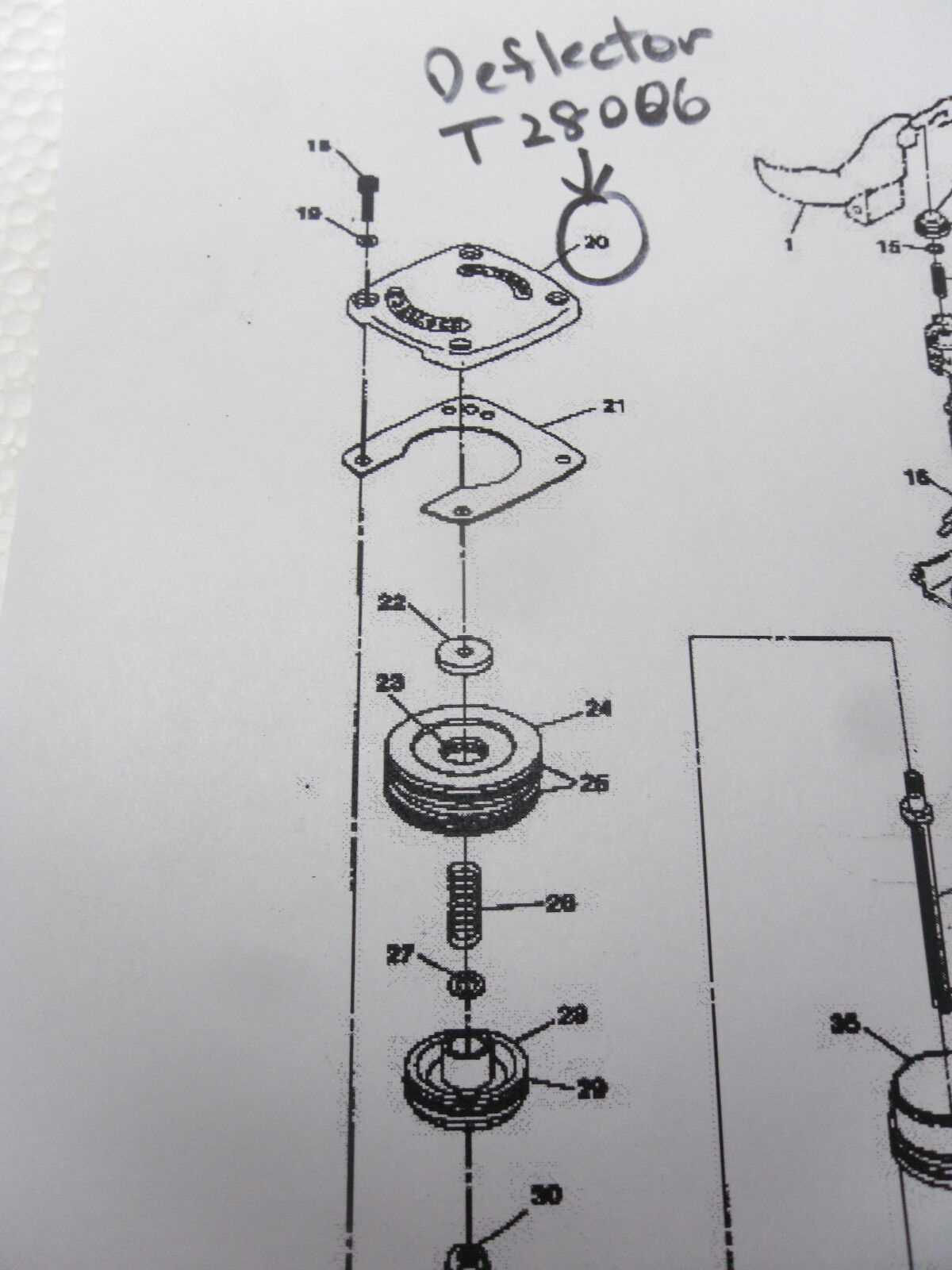

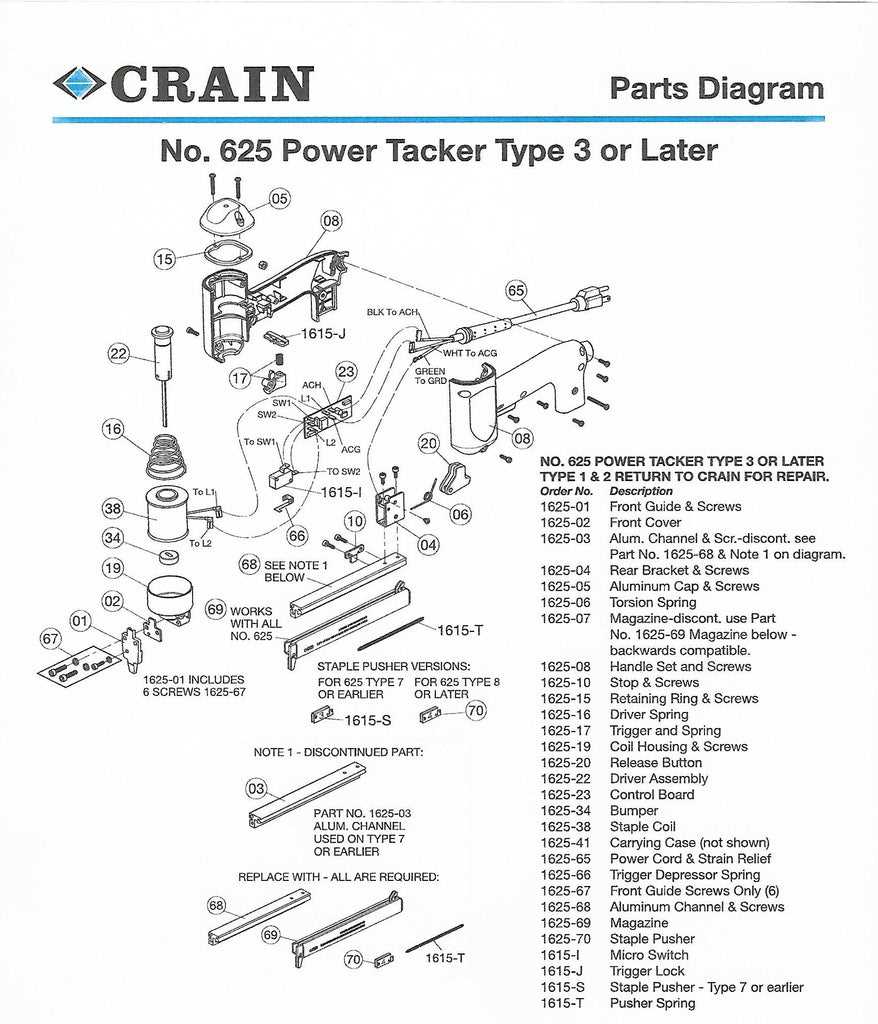

Understanding the Diagram’s Symbols

Interpreting visual representations of machinery can be challenging, yet it is essential for effective maintenance and repairs. Each symbol within these illustrations serves a specific purpose, conveying critical information about the components and their functions. Familiarizing oneself with these icons enhances comprehension and aids in troubleshooting and assembly processes.

Typically, symbols are categorized into various groups, including electrical, mechanical, and operational. Recognizing these categories helps in identifying the nature of each part. For example, mechanical symbols often depict movement or connections, while electrical symbols signify power sources or circuitry. Understanding the meaning behind each icon streamlines the repair process and minimizes the risk of errors.

Moreover, many symbols include annotations or numerical designations, providing additional context about the components’ specifications. These notations are invaluable for sourcing replacements or determining compatibility with other systems. A clear grasp of these elements not only fosters confidence but also promotes efficiency during maintenance tasks.

In conclusion, becoming proficient in reading and interpreting these symbols is a fundamental skill for anyone working with machinery. By investing time in understanding these visual cues, one can significantly improve their technical abilities and ensure optimal performance of the equipment.

Common Replacement Parts

In any tool, certain components are prone to wear and may require occasional replacement to ensure optimal performance. Understanding which elements commonly need replacing can help users maintain their equipment effectively. This section highlights some of the most frequently exchanged components in pneumatic tools.

Nails and Fasteners: These are essential for the operation of the device and can become damaged or depleted over time. Regularly checking and replenishing the supply is crucial for seamless functionality.

O-rings: These small yet vital components play a significant role in maintaining air pressure within the tool. Over time, they can deteriorate, leading to air leaks and reduced efficiency. Replacing them promptly can restore performance.

Drive Blade: This part is responsible for driving fasteners into materials. It can wear down or become misaligned with use, necessitating replacement to maintain accuracy and effectiveness.

Trigger Mechanism: A malfunctioning trigger can disrupt operation. This component may require replacement if it becomes unresponsive or jammed, ensuring that the tool remains safe and user-friendly.

Filter Screen: This element prevents debris from entering the tool, protecting internal mechanisms. A clogged or damaged filter can impair performance, making it essential to inspect and replace it regularly.

By staying aware of these commonly replaced components, users can prolong the life of their tools and maintain optimal operational standards.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your tools requires regular care and attention. Implementing a few essential maintenance practices can significantly enhance performance and reliability, ultimately saving you time and money in the long run.

Regular Cleaning

Keeping your equipment clean is crucial. Dust, debris, and residue can accumulate and interfere with functionality. Regularly inspect and clean all surfaces to prevent any buildup that may cause wear or malfunction.

Lubrication and Inspection

Proper lubrication is vital for smooth operation. Periodically apply appropriate lubricants to moving parts. Additionally, conduct inspections to identify any signs of wear or damage that may need addressing before they lead to more significant issues.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Cleaning | After each use | Focus on critical areas |

| Lubrication | Every month | Use recommended products |

| Inspection | Every three months | Check for wear and tear |

How to Read Parts Diagrams

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as valuable guides, allowing users to identify each element, its function, and how it interacts with others. Mastering this skill can lead to more efficient troubleshooting and assembly processes.

Interpreting the Visual Elements

Begin by familiarizing yourself with the layout of the image. Each section typically corresponds to specific functions or areas within the device. Numbers or letters may denote individual components, making it easier to locate them in accompanying documentation. Pay attention to the scale as well; understanding the size relationships between parts can be crucial for accurate identification.

Utilizing the Key or Legend

Most illustrations include a key or legend that provides definitions for the symbols and labels used. This section is critical for clarifying any abbreviations or icons that may not be immediately obvious. Take the time to consult this reference thoroughly; it enhances comprehension and prevents misinterpretation of the depicted elements.

Where to Find Original Parts

When seeking components for your equipment, it’s crucial to ensure you are acquiring authentic replacements. Genuine pieces not only enhance performance but also extend the lifespan of your tools. This section explores the best sources for obtaining original items, ensuring you maintain the quality and efficiency of your devices.

Authorized Retailers: One of the most reliable options is to purchase from authorized dealers. These outlets are typically well-versed in the specific requirements of your tools and offer a wide range of authentic items. You can often find their locations through the manufacturer’s website.

Official Websites: Visiting the official site of the manufacturer is another effective approach. Many brands provide an online catalog of available components, making it easy to identify and order the exact items you need.

Specialty Shops: Consider looking into specialty shops that focus on tools and accessories. These establishments often carry a selection of genuine components and can provide valuable advice on installation and maintenance.

Online Marketplaces: Trusted online platforms can also be a good resource. Always ensure that the seller has a good reputation and offers guarantees on the authenticity of their products.

By utilizing these sources, you can confidently procure the necessary components to keep your equipment operating smoothly and efficiently.

Comparing F28WW with Other Models

When evaluating a specific model in the realm of pneumatic fastening tools, it is essential to consider how it stacks up against its competitors. Different devices may offer varying features, functionalities, and performance levels, which can greatly influence their suitability for particular tasks. This comparison highlights key distinctions and similarities, helping users make informed choices.

Power and Performance: One of the primary factors to examine is the power output. Some models are designed to handle heavier materials, providing greater driving force, while others focus on efficiency and precision. Users should assess their typical applications to determine which tool aligns best with their needs.

Weight and Ergonomics: Another important aspect is the weight and design of the tool. Heavier models might offer more durability but can lead to fatigue during prolonged use. Conversely, lighter options tend to enhance maneuverability, making them ideal for extended projects. Ergonomic features such as grip and balance also play a crucial role in user comfort.

Fastening Capacity: The capacity for different fasteners is a significant consideration as well. While some tools may accommodate a wider range of fasteners, others might be specialized for specific types. Understanding the fastening needs for various projects can guide users in selecting the right device.

Price and Value: Lastly, evaluating the price relative to features and durability is vital. A more affordable option may seem attractive, but it is important to ensure that it meets performance expectations over time. Investing in a high-quality tool can lead to long-term savings and increased productivity.

DIY Repair vs. Professional Service

When it comes to fixing tools, many users face the decision between tackling the job themselves or hiring an expert. Both approaches have their own set of advantages and drawbacks, making the choice highly dependent on individual circumstances and preferences.

Choosing the DIY route can be appealing for those who enjoy hands-on projects and have a basic understanding of how their equipment operates. This approach often leads to cost savings, as it eliminates labor fees and can foster a sense of accomplishment. However, it requires a certain level of skill, access to appropriate resources, and the time to dedicate to the repair process.

On the other hand, seeking professional assistance can provide peace of mind, especially for those who may not feel confident in their abilities. Experts typically have the experience and tools necessary to diagnose and fix issues quickly and efficiently. While this option can be more expensive, it often ensures that repairs are done correctly, reducing the risk of future complications.

Ultimately, the decision between a do-it-yourself fix and professional help should be based on one’s comfort level, the complexity of the issue, and the potential costs involved. Evaluating these factors will lead to a more informed choice that aligns with individual needs and situations.

Frequently Asked Questions

This section addresses common inquiries regarding the assembly and maintenance of specific fastening tools. Whether you are seeking troubleshooting advice or guidance on replacement components, you’ll find valuable insights here.

What should I do if my tool is not functioning properly?

If you experience issues with your fastening device, first ensure that it is clean and free from debris. Check the air supply and connections, as these can often cause malfunctions. If problems persist, consult the user manual for detailed troubleshooting steps.

How can I find replacement components for my tool?

To locate suitable replacement items, consider visiting authorized retailers or online marketplaces. It’s crucial to verify compatibility with your specific model. Additionally, consult the manufacturer’s website for diagrams and lists of available parts to ensure you select the correct components.

Resources for Further Learning

Expanding your knowledge about tools and their components can significantly enhance your understanding and ability to troubleshoot various equipment. There are numerous resources available that provide valuable insights, whether you’re a novice or an experienced user seeking to refine your skills.

Online Tutorials and Videos

Numerous platforms offer instructional content, including video tutorials that demonstrate assembly, maintenance, and repair techniques. Websites like YouTube host channels dedicated to tool usage, where experts share practical tips and walkthroughs. Engaging with these visual resources can help solidify your comprehension and provide hands-on learning experiences.

Technical Manuals and Guides

Consulting official manuals is crucial for anyone looking to gain a deeper understanding of specific models. These documents typically include detailed illustrations, parts listings, and maintenance advice. Online forums and community websites often host digital copies of such manuals, making them accessible for anyone in need of guidance. Always consider reputable sources to ensure the information is accurate and up-to-date.